Professional Documents

Culture Documents

ISO 5817-2003 Quality Levels 4 Imperfections - Fusion Welds

Uploaded by

ngtchung0 ratings0% found this document useful (0 votes)

29 views27 pagesiso

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentiso

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views27 pagesISO 5817-2003 Quality Levels 4 Imperfections - Fusion Welds

Uploaded by

ngtchungiso

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 27

ISO 5817:2003(E)

Introduction

This International Standard should be used as a reference in the drafting of application codes and/or other

application standards. It contains a simplified selection of fusion weld imperfections based on the designations

given in ISO 6520-1

Some of the imperfections described in ISO 6520-1 have been used directly and some have been grouped

together. The basic numerical referencing system from ISO 6520-1 has been used

The purpose of this International Standard is to define dimensions of typical imperfections which might be

expected in normal fabrication. It may be used within a quality system for the production of factory-welded

joints. It provides three sets of dimensional values from which a selection can be made for a particular

application, The quality level necessary in each case should be defined by the application standard or the

responsible designer in conjunction with the manufacturer, user and/or other parties concemed. The level

shall be prescribed before the start of production, preferably at the enquiry or order stage. For special

Purposes, additional details may be prescribed

The quality levels given in this International Standard provide basic reference data and are not specifically

related to any particular application. They refer to the types of welded joint in a fabricated structure and not to

the complete product or component itself. It is possible, therefore, that different quality levels be applied to

vidual welded joints in the same product or component.

would normally be expected that for a particular welded joint the dimensional limits for imperfections could

all be covered by specifying one quality level. In some cases, it may be necessary to specify different quality

levels for diferent imperfections in the same welded joint

The choice of quality level for any application should take account of design considerations, subsequent

processing (e.g. surfacing), mode of stressing (eg. static, dynamic), service conditions (e.g. temperature,

environment) and consequences of failure. Economic factors are also important and should include not only

the cost of welding but also of inspection, test and repair.

Although this International Standard includes types of imperfection relevant to the fusion welding processes

ted in Clause 1, only those which are applicable to the process and application n question need to be

considered

Imperfections are quoted in terms of their actual dimensions, and their detection and evaluation may require

the use of one or more methods of non-destructive testing. The detection and sizing of imperfections is

dependent on the inspection methods and the extent of testing specified in the application standard or

contract,

The need for detecting imperfections is not subject of this International Standard However, ISO 17635

contains a correlation between the quality level and acceptance level for different NDT methods.

This Intemational Standard is directly applicable to visual testing of welds and does not include details of

fecommended methods of detection or sizing by non-destructive means, It should be considered that there

are difficulties in using these limits to establish appropriate criteria applicable to non-destructive testing

methods such as ultrasonic, radiographic, eddy current, penetrate, magnetic particle testing and may need to

be supplemented by requirements for inspection, examining and testing

The values for imperfections take into consideration normal welding pra:

additional manufacturing processes, @ 9. gh

welding processes

ice. Higher specifications require

ng or welding under stringent laboratory conditions or speci

Requests for official interpretations of any aspect of

Secretariat of ISO/TC 44/SC 10 via your ni

International Standard should be directed to the

nal standards body. For a complete listing consult www iso.org

2180 2003 — ai

INTERNATIONAL STANDARD ISO 5817:2003(E)

Welding — Fusion-welded joints in steel, nickel, titanium and their

alloys (beam welding excluded) — Quality levels for imperfections

4 Scope

This International Standard provides quality levels of imperfections in fusion-welded joints (except for beam

welding) in all types of steel, nickel, titanium and their alloys. It applies to material thickness above 0,5 mm.

Quality levels for beam welded joints in steel are presented in ISO 13919-1.

Three quality levels are given in order to permit application to a wide range of welded fabrication. They are

designated by symbols 8. C and D. Quality level B corresponds to the highest requirement on the finished wel.

The qualily levels refer to production quality and not to the fitness-for-purpose (see 3.2) of the product

manufactured

This International Standard applies to

——_unalloyed and alloy steels

— nickel and nickel alloys,

wanium and titanium alloys,

— manual, mechanized and automatic welding,

— all welding positions,

— all types of welds, eg. butt welds, filet welds and branch connections,

— the following welding processes and their defined sub-processes in accordance with ISO 4083

— 11 metal-arc welding without gas protection;

— 12 submerged-are welding;

~~ 13 gas-shielded metal-are welding

14 gas-shielded welding with non-consumable electrodes,

— 18 plasma arc welding

31 oxy-fuel gas welding (for steel only)

Metallurgical aspects, e.g. grain size, hardness, are not covered by this International Standard,

eserves 1

ISO 5817:2003(E)

2 Normative references

The following referenced documents are indispensable for the applic

only the edition cited applies. For undated references,

amendments) applies.

ion of this decument. For dated references.

ie latest edition of the referenced document (including any

ISO 2553:1992, Welded, brazed and soldered joints — Symbolic representation on drawings

ISO 4063:1998, Welding and allied processes — Nomenclature of processes and

rence numbers

ISO 6520-1:1998, Welding and allied processes — Classification of geometric imperfections in metallic materials —

Part 1: Fusion welding

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply

description of the quality of a weld on the basis of type and size of selected imperfections,

32

iness-for-purpose

ability of a product. process or service fo serve a defined purpose under specific conditions

33

short imperfections

‘one or more imperfections of total length not greater than 25 mm in any 100 mm leagth of the weld or a maximum

of 25 % of the weld length for a weld shorter than 100 mm, the range with most imperfections being applicable

34

‘systematic imperfection

imperfections that are distributed at regular distances in the weld over the weld lenglhs to be examined, the sizes of

the single imperfections being within the limits of the imperfections given in Table 1

35

projected area

Brea where imperfections distributed along the volume of the weld under consideration are imaged two-

dimensional

In contrast to the surface crack area the occurrence of imperfections is dependent on the weld thickness when

exposed radiographically (see Figure 1).

36

cross-section area

area to be considered after fracture or sectioning

2 "180

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Repaired defects still an issueDocument4 pagesRepaired defects still an issuengtchungNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 3 Overall ConsiderationsDocument65 pages3 Overall ConsiderationsngtchungNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Packing ProcedureDocument67 pagesPacking ProcedurengtchungNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- API Rp-571 - GuideDocument33 pagesAPI Rp-571 - Guidengtchung100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Course Facilities Layout Training IntroductionDocument45 pagesCourse Facilities Layout Training IntroductionngtchungNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 7 Safety SystemsDocument61 pages7 Safety SystemsngtchungNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Giao An Thi Giao Vien Gioi Cap Huyen PTGTDocument7 pagesGiao An Thi Giao Vien Gioi Cap Huyen PTGTngtchungNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 04welding EngineerengDocument3 pages04welding EngineerengngtchungNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- E&I Inspector Job DescriptionDocument2 pagesE&I Inspector Job DescriptionngtchungNo ratings yet

- 6 Specific AreasDocument98 pages6 Specific AreasngtchungNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Uvex Ambient OTG English USDocument3 pagesUvex Ambient OTG English USngtchungNo ratings yet

- 15 AbbreviationsDocument4 pages15 AbbreviationsngtchungNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 13A ExercisesDocument3 pages13A ExercisesngtchungNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 8 EquipmentDocument148 pages8 Equipmentngtchung100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- 5 Offshore Work OperationsDocument6 pages5 Offshore Work OperationsngtchungNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 4 Layout Facility Segregation ZoningDocument50 pages4 Layout Facility Segregation ZoningngtchungNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Shipbuilding Process 1Document53 pagesShipbuilding Process 1tiwaripur100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Tofd PCNDocument22 pagesTofd PCNmarforall5205No ratings yet

- CV Surveyor Tran Van QuyDocument7 pagesCV Surveyor Tran Van QuyngtchungNo ratings yet

- DK Essential Managers - Managing BudgetsDocument71 pagesDK Essential Managers - Managing BudgetsSeeyian Simon Metoyu86% (7)

- 2 Regulations StandardsDocument16 pages2 Regulations StandardsngtchungNo ratings yet

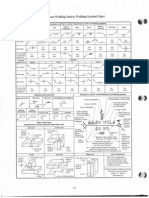

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanNo ratings yet

- Vocabulary in Context - Lesson 1Document6 pagesVocabulary in Context - Lesson 1ngtchungNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- MEPCOM - Management Philosophy - Vision Rev 0Document1 pageMEPCOM - Management Philosophy - Vision Rev 0ngtchungNo ratings yet

- VISA APPLICATION FORMDocument1 pageVISA APPLICATION FORMngtchungNo ratings yet

- Love TestDocument4 pagesLove TestngtchungNo ratings yet

- 3-List of Main EquipmentDocument2 pages3-List of Main EquipmentngtchungNo ratings yet

- Stative VerbsDocument3 pagesStative Verbsngtchung0% (1)

- Mind You, Even So, You Know, Believe It or Not, Just As WellDocument4 pagesMind You, Even So, You Know, Believe It or Not, Just As WellngtchungNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)