Professional Documents

Culture Documents

Design and Development

Uploaded by

SalmanShahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Development

Uploaded by

SalmanShahCopyright:

Available Formats

Design and development[edit]

Pratt & Whitney designed the engine with minimum complexity to significantly reduce

maintenance cost and achieve weight and fuel consumption savings. However, tests revealed

that the initial five-stage high compressor based design did not meet promised fuel burn

performance. As a result, many of the original customers switched their orders to the rival CFM

International CFM56-5. To address the problem, Pratt & Whitney re-certified an updated design

utilizing a six-stage high compressor designed by MTU Aero Engines in order to achieve

promised performance. The German company manufactures the high-pressure compressor and

the low-pressure turbine. The HP compressor is driven by a single-stage turbine. On the LP

spool a three-stage turbine drives a single-stage fan and a four-stage LP compressor.

The engine made its first flight August 21, 2000 on a test aircraft flown from Plattsburgh

International Airport (KPBG), successfully completing a 1-hour-20-minute flight.[1]The engine final

assembly line is located at MTU Aero Engines at their location in Hanover, Germany.

LAN Airlines confirmed an order for 15 Airbus A318 aircraft, for a total of 34 engines (30 installed

and 4 spares) powered by PW-6000 engines on 15 August 2005. In addition, LAN signed with

Pratt and Whitney to power up to 25 option aircraft. If LAN exercises all options it would mean an

additional 56 (50 installed and six spare) engines.

Prior to the LAN order, 84 CFM56-5 powered Airbus A318 aircraft had been ordered, with 28

currently in service as of December 2005.

You might also like

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- 2013 BCA Purchase Planning HandbookDocument25 pages2013 BCA Purchase Planning Handbooktomay777100% (1)

- APU HoneywellDocument2 pagesAPU HoneywellJJ100% (1)

- Analysis of Argument QuestionsDocument64 pagesAnalysis of Argument QuestionsSalmanShahNo ratings yet

- 777 Groundwork Apu Transcript PDFDocument12 pages777 Groundwork Apu Transcript PDFberjarry5938No ratings yet

- The Design and Construction of Flying Model AircraftFrom EverandThe Design and Construction of Flying Model AircraftRating: 5 out of 5 stars5/5 (2)

- Pratt Whitney Finds A Fix For Engine FailuresDocument1 pagePratt Whitney Finds A Fix For Engine FailuresJacinto Gomez EmbolettiNo ratings yet

- CFM 3-D Aero Providing Better Fuel Burn, Longer On-Wing LifeDocument4 pagesCFM 3-D Aero Providing Better Fuel Burn, Longer On-Wing LifeHari Krishnan CNo ratings yet

- 002 PDFDocument6 pages002 PDFrsahu_36No ratings yet

- Powerplant (II) CFM56 SystemsDocument24 pagesPowerplant (II) CFM56 Systemsa0968973521No ratings yet

- Nozzle Selection and Design CriteriaDocument11 pagesNozzle Selection and Design CriteriajbmccavalcantiNo ratings yet

- Auxiliary Power UnitDocument40 pagesAuxiliary Power UnitAnupNo ratings yet

- CF680EDocument5 pagesCF680Ecf34No ratings yet

- Advanced Trends in Turbomachinery DesignsDocument22 pagesAdvanced Trends in Turbomachinery DesignsKarandeep SinghNo ratings yet

- Grob SPNDocument2 pagesGrob SPNsztoggyNo ratings yet

- GEnx Development Emphasizes Composites, Combustor TechnologyDocument3 pagesGEnx Development Emphasizes Composites, Combustor TechnologySiva KumarNo ratings yet

- Fleet Strategy: Investor Day 2007 Frankfurt, January 25, 2007Document29 pagesFleet Strategy: Investor Day 2007 Frankfurt, January 25, 2007cengiz072428951No ratings yet

- CF6-80C2 Engine History and Evolution: Paolo Lironi, Senior TechnicalDocument5 pagesCF6-80C2 Engine History and Evolution: Paolo Lironi, Senior TechnicalAnonymous kluQX93vNo ratings yet

- Napier Nomad - Flight (1954) - 1Document1 pageNapier Nomad - Flight (1954) - 1migss1074No ratings yet

- Bharath University: Department of Mechanical EngineeringDocument14 pagesBharath University: Department of Mechanical EngineeringVarun Mishra100% (2)

- Fiat Diesel-Type Engine: FLIGHT JANUARY 16, 1931Document1 pageFiat Diesel-Type Engine: FLIGHT JANUARY 16, 1931Roberto Carlos Subauste PérezNo ratings yet

- IAE International Aero Engines AG Is A Zürich-RegisteredDocument5 pagesIAE International Aero Engines AG Is A Zürich-RegisteredĐoàn Hồng NgọcNo ratings yet

- Commercial Engines: Special ReportDocument48 pagesCommercial Engines: Special ReportDarwis IdrusNo ratings yet

- Commercial Engines: Special ReportDocument48 pagesCommercial Engines: Special ReportDarwis IdrusNo ratings yet

- Aero Engine PP DoneDocument30 pagesAero Engine PP DoneHAMMAD AliNo ratings yet

- Pratt Whitney PurePower Engine For Airbus A320neo Soars On Wing Begins First Flight Test ProgramDocument2 pagesPratt Whitney PurePower Engine For Airbus A320neo Soars On Wing Begins First Flight Test Programaurel_dantis8197100% (1)

- Pratt & Whitney Canada PT6: DevelopmentDocument1 pagePratt & Whitney Canada PT6: DevelopmentWisuit SookthaweeNo ratings yet

- Aerospace SystemsDocument13 pagesAerospace Systemsanon-358417100% (8)

- TurbojetDocument6 pagesTurbojetShivamPanchariyaNo ratings yet

- Hyper EngineDocument3 pagesHyper EnginetorrefacaomerendaNo ratings yet

- Aero Vodochody L-39ZO AlbatrosDocument8 pagesAero Vodochody L-39ZO AlbatrosratherbeglidingNo ratings yet

- The BMW 003 Jet Engine PDFDocument6 pagesThe BMW 003 Jet Engine PDFWin Min Oo100% (1)

- Intelligent Air Technology: Compressed Air Solutions For Every ApplicationDocument8 pagesIntelligent Air Technology: Compressed Air Solutions For Every ApplicationLorenzo RossiNo ratings yet

- Pratt& Whitney Jt8D-1: B O E I N G 7 2 7 - .Document1 pagePratt& Whitney Jt8D-1: B O E I N G 7 2 7 - .StrawichDanielNo ratings yet

- CFM International CFM56: Type National Origin Manufacturer First Run Major ApplicationsDocument13 pagesCFM International CFM56: Type National Origin Manufacturer First Run Major ApplicationsBeing AirWindNo ratings yet

- The CF6-80E1: Maurick Groeneveld, Director Aircraft Management at DoricDocument4 pagesThe CF6-80E1: Maurick Groeneveld, Director Aircraft Management at DoricMuhammad Faizan KhanNo ratings yet

- Spey PowerplantyDocument3 pagesSpey PowerplantyvcNo ratings yet

- ASME UAV Engine CompetitionDocument35 pagesASME UAV Engine CompetitionbfehrmNo ratings yet

- TurbojetDocument12 pagesTurbojetnileshko10100% (1)

- Cost-Effective, Off-the-Shelf Commercial Re-Engining: Turbofan EngineDocument2 pagesCost-Effective, Off-the-Shelf Commercial Re-Engining: Turbofan EngineStrawichDanielNo ratings yet

- MTU Helps To Fill A New Think Tank: Automatically-Generated Code Flying at Mach 9.8Document9 pagesMTU Helps To Fill A New Think Tank: Automatically-Generated Code Flying at Mach 9.8Gute_FeeNo ratings yet

- LEAP Brochure 2015Document15 pagesLEAP Brochure 2015KITTU75% (4)

- Commercial Engines 2013Document48 pagesCommercial Engines 2013Carlo Farlocchiano100% (1)

- Extended Range Operation With Two-Engine Airplanes (ETOPS) : HistoryDocument80 pagesExtended Range Operation With Two-Engine Airplanes (ETOPS) : HistoryGautam KashyapNo ratings yet

- Foil Airgas Bearing Technology - An OverviewDocument11 pagesFoil Airgas Bearing Technology - An OverviewOye OdemadighiNo ratings yet

- Jet Engine Research PaperDocument5 pagesJet Engine Research Papergw08nnfr100% (1)

- Propfans, Turbofans y TurbopropDocument8 pagesPropfans, Turbofans y TurbopropMario VolpattiNo ratings yet

- A Technique To Determine Lift and Drag Polars in FlightDocument7 pagesA Technique To Determine Lift and Drag Polars in Flightmykingboody2156No ratings yet

- Research Paper On TurbojetDocument6 pagesResearch Paper On Turbojetqptwukrif100% (1)

- Gearing Up For The GTF: Regional PerspectiveDocument7 pagesGearing Up For The GTF: Regional PerspectiveJohn CarellaNo ratings yet

- Multi Point Fuel Injection SystemDocument23 pagesMulti Point Fuel Injection SystemGoutham Reddy100% (2)

- A Transport Aft-Turbofan 59-GTP-20: B. E. Sells - W. R. DodgeDocument9 pagesA Transport Aft-Turbofan 59-GTP-20: B. E. Sells - W. R. Dodge128mansouriNo ratings yet

- Multi Point Fuel Injection SystemDocument23 pagesMulti Point Fuel Injection SystemVenkatesan SwamyNo ratings yet

- TSBC BAC 050615 A05p0137Document8 pagesTSBC BAC 050615 A05p0137bombardierwatchNo ratings yet

- General Electric F110 Turbofan MotorDocument11 pagesGeneral Electric F110 Turbofan MotorlizfireupNo ratings yet

- Aircraft Gas Turbine Engines Assignment 2Document13 pagesAircraft Gas Turbine Engines Assignment 2Abdul MuizzNo ratings yet

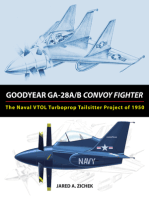

- Goodyear GA-28A/B Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950From EverandGoodyear GA-28A/B Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Rating: 4 out of 5 stars4/5 (2)

- The First Airplane Diesel Engine: Packard Model DR-980 of 1928From EverandThe First Airplane Diesel Engine: Packard Model DR-980 of 1928No ratings yet

- Al-Baqarah 1-4Document9 pagesAl-Baqarah 1-4Muhammad Indra Arifin100% (1)

- Sda 3Document2 pagesSda 3SalmanShahNo ratings yet

- Verification PDFDocument1 pageVerification PDFSalmanShahNo ratings yet

- Al-Baqarah 75-78Document3 pagesAl-Baqarah 75-78SalmanShahNo ratings yet

- Galaxy DemoDocument4 pagesGalaxy DemoSalmanShahNo ratings yet

- Site-to-Site VPN TemplateDocument2 pagesSite-to-Site VPN TemplateSalmanShahNo ratings yet

- Chat 2Document7 pagesChat 2SalmanShahNo ratings yet

- Parallelaisma: - Ing or Must Be in The Form of A Who-Clause - If There Is ADocument1 pageParallelaisma: - Ing or Must Be in The Form of A Who-Clause - If There Is ASalmanShahNo ratings yet

- 2Gbps FAQ CustomerDocument5 pages2Gbps FAQ CustomerSalmanShahNo ratings yet

- Arabic Vocabulary Bank: (Madinah Book 1 Chapter 1-23)Document29 pagesArabic Vocabulary Bank: (Madinah Book 1 Chapter 1-23)mazad1985No ratings yet

- 4.1 02 To BE Negative EXC PDFDocument11 pages4.1 02 To BE Negative EXC PDFSalmanShahNo ratings yet

- 19 SC New Questions and Answer KeyDocument8 pages19 SC New Questions and Answer KeySalmanShahNo ratings yet

- The New Yorker - September 23 2019 UserUpload Net PDFDocument78 pagesThe New Yorker - September 23 2019 UserUpload Net PDFSalmanShahNo ratings yet

- 4.1 02 - TO-BE-negative-EXC PDFDocument3 pages4.1 02 - TO-BE-negative-EXC PDFSalmanShahNo ratings yet

- Davechild - Linux Command Line - BW PDFDocument2 pagesDavechild - Linux Command Line - BW PDFFrank CampbellNo ratings yet

- Chat 6 Part 2Document6 pagesChat 6 Part 2SalmanShahNo ratings yet

- Chat 3 Part 1Document6 pagesChat 3 Part 1SalmanShahNo ratings yet

- DescriptionDocument29 pagesDescriptionAna Bogdanovic GagiNo ratings yet

- Requirement AnalysisDocument3 pagesRequirement AnalysisSalmanShahNo ratings yet

- ChatDocument9 pagesChatSalmanShahNo ratings yet

- Anna University ChennaiDocument121 pagesAnna University ChennaivicterpaulNo ratings yet

- Char II Unit 002 Lesson 04 LNDocument3 pagesChar II Unit 002 Lesson 04 LNSalmanShahNo ratings yet

- Davechild Linux Command LineDocument2 pagesDavechild Linux Command LineSalmanShahNo ratings yet

- Chat 6 Part 1Document1 pageChat 6 Part 1SalmanShahNo ratings yet

- Brian JonesDocument3 pagesBrian Jonesgnikiv85No ratings yet

- OutputDocument1 pageOutputSalmanShahNo ratings yet

- CV SamplesDocument8 pagesCV SamplesJohn Carl ValdezNo ratings yet

- GmatDocument35 pagesGmatarjun130788100% (1)