Professional Documents

Culture Documents

Moisture Susceptibility of Superpave Mixtures With Varying Binder Contents

Uploaded by

alberto1234567Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Moisture Susceptibility of Superpave Mixtures With Varying Binder Contents

Uploaded by

alberto1234567Copyright:

Available Formats

1

Airfield and Highway Pavements 2015 © ASCE 2015 86

Moisture Susceptibility of Superpave Mixtures with Varying Binder Contents

Kiran Kumar Uppu1; M. Hossain, Ph.D., P.E.1; Lon S. Ingram, P.E.2; and Rick

Kreider, P.E.3

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

1

Department of Civil Engineering, Kansas State University, 2118 Fielder Hall,

Manhattan, KS 66506. E-mail: mustak@ksu.edu

2

Consultant. E-mail: lon.i@cox.net

3

Bureau of Research, Kansas Department of Transportation, 2300 Van Buren,

Topeka, KS 66611. E-mail: RickK@ksdot.org

Abstract

The process control for the hot-mix asphalt mixtures (HMA) by the Kansas

Department of Transportation (KDOT) requires each lot of HMA be produced within

±0.6% of the design binder content. Recent reviews indicate that HMA lots are being

produced consistently with lower binder contents. This situation has been exacerbated

by the use of higher proportion of Reclaimed Asphalt Pavement (RAP) materials in

the HMA mixtures. This project evaluated two moisture susceptibility test methods to

assess the effect of asphalt content on the moisture resistance of HMA. Two different

commonly used mixtures for overlaying and four varying asphalt contents, optimum

and lower, were selected. The Hamburg Wheel Tracking Device (HWTD) test was

used to predict moisture damage potential of these mixes. All specimens tested were

prepared with the Superpave gyratory compacter. Results indicate that within the

tested range, deformation decreases as the binder content decreases. This trend was

verified by studying the correlation of the number of wheel passes with the asphalt

binder film thickness.

© ASCE

Airfield and Highway Pavements 2015

2

Airfield and Highway Pavements 2015 © ASCE 2015 87

INTRODUCTION

Binder content is an important mix design parameter for Superpave pavements.

The role of proper asphalt amount in determining long-term performance of hot-mix

asphalt (HMA) mixtures is well known. It affects mixture stiffness, strength, durability,

fatigue life, raveling, rutting, and moisture damage. Insufficient binder in the HMA mix

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

can lead to high permeability, high air voids, and thin asphalt coatings around the

aggregates which will cause durability problems (Kandhal et al. 1998). On the other

hand, excessive asphalt though durable and flexible, but may cause flushing and low mix

stability. A mixture is said to be durable when it offers long-term resistance to weathering

and aging, and provides good performance without abnormal raveling and cracking of the

paved surface (Kumar and Goetz 1977). The process control for the hot-mix asphalt

mixtures (HMA) by the Kansas Department of Transportation (KDOT) requires that each

lot of HMA be produced within ±0.6% of the design binder content in the job-mix

formula. Recent reviews indicate that HMA lots in Kansas are being produced

consistently with lower asphalt contents than that in the job-mix formula (Gedafa et al.

2011). This situation has been exacerbated by the use of higher proportion of Reclaimed

Asphalt Pavement (RAP) materials in the HMA mixtures. These drier mixtures are

thought to be moisture susceptible to moisture due to thinner asphalt films. KDOT is

considering use of the Hamburg Wheel Tracking Device (HWTD) test for evaluating

moisture susceptibility of Superpave mixtures with reclaimed asphalt pavement (RAP). It

is to be noted that HWTD test is not necessary a moisture susceptibility test. It is actually

a torture test that subjects the sample to extreme conditions not encountered in the field.

However, it is accepted that a mixture that passes the established test criterion (in terms

of number of passes and/or maximum depression or rut depth), it will be resist rutting

and/or stripping in the field.

OBJECTIVE

The main objective of this study was to investigate the moisture resistance of two

Superpave mixtures with reclaimed asphalt pavement (RAP) and varying asphalt contents

using the Hamburg Wheel Tracking Device (HWTD) test. The mixtures were sampled

from two different projects in Kansas.

HAMBURG WHEEL TRACKING DEVICE TEST

Hamburg wheel tracking device (HWTD) evaluates combined effects of rutting

and moisture susceptibility of HMA mixtures (Brown et al. 2009). The Hamburg wheel

tracking device, manufactured by PMW, Inc. of Salina, Kansas, was used in this study.

This device can test two specimens simultaneously. The device is operated by rolling a

pair of steel wheels across surface of specimens submerged in a water bath held at 50oC.

The wheels have a diameter of 204 mm (8 inches) and width of 47 mm (1.85 inches). The

device operates at approximately 50 wheel passes/min and the load applied by each

wheel is approximately 705±22 N (158±5 lbs). Specimens used in this test were

compacted to 7±1 percent air voids using a Superpave gyratory compactor. The

specimens were 150 mm (6 inches) in diameter and 62 mm (2.4 inches) in height. Rut

© ASCE

Airfield and Highway Pavements 2015

3

Airfield and Highway Pavements 2015 © ASCE 2015 88

depth was measured automatically and continuously at 11 different points along the

wheel path of each sample with a linear variable differential transformer (LVDT) with an

accuracy of 0.01 mm (0.0004 inch). HWTD automatically ends the test if the preset

number of cycles is reached or if the rut depth measured by the LVDTs reaches a value of

20 mm (0.8 inch) for an individual specimen. The maximum rut depth versus number of

cycles is plotted to obtain a typical curve which is shown in Figure 1. The maximum rut

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

depth value anywhere in the specimen was taken following the Texas Department of

Transportation (TxDOT) practices (TxDOT 2009).

The main parameters obtained from the plot are rut depth, average number of

wheel passes, creep slope, stripping slope, stripping inflection point, and post-compaction

consolidation. Post-compaction consolidation is the deformation (mm) at 1,000 wheel

passes. Creep slope is the inverse rate of deformation (wheel passes per 1-mm rut depth)

in the linear region of the plot between the post-compaction consolidation and the

stripping inflection point. Creep slope is used to measure rutting susceptibility due to

mechanisms other than moisture damage. The stripping inflection point and stripping

slope are used to measure moisture damage. The stripping inflection point is the number

of wheel passes at the intersection of the creep slope and stripping slope. The stripping

slope is the inverse rate of deformation (wheel passes per 1-mm rut depth) after the

stripping inflection point (Brown et al. 2009).

Figure 1. Typical HWTD test plot showing test output parameters (after

Brown et al. 2009).

PROJECT SELECTION

Two different Superpave mixture types were selected for this study. The mixtures

represent typical 9.5 mm (SR-9.5A) and 12.5 mm (SR-12.5A) Nominal Maximum Aggregate

Size (NMAS) Superpave mixes with Reclaimed Asphalt Pavement (RAP). These mixtures had

been used in past construction seasons in Kansas.

© ASCE

Airfield and Highway Pavements 2015

4

Airfield and Highway Pavements 2015 © ASCE 2015 89

Aggregates and Binder Sources

SR-12.5A and SR-9.5A mixtures were collected from two different projects in Kansas.

The binder used was PG 58-28 for all mix types. Liquid antistripping additive (Arr Maz HP+)

was also used in all mixtures.

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

Gradations and Blending

Figures 2(a) and 2(b) show the combined aggregate gradations of the mixtures, SR-9.5A

and SR-12.5A, respectively. The combined gradations pass over the maximum density line in the

sand sizes. Thus these gradations are finer. Both mixes have 25% RAP materials. SR-12.5A also

has 15% 12.5-mm crushed limestone, 20% sand, 5% limestone screening, and 35% crushed

gravel. SR-9.5A has 17% 9.5-mm crushed limestone, 12% limestone screening, 11% finer

limestone screening, and 35% sand in addition to RAP.

Experimental Design Matrix

The only variable that changed was the mixture asphalt content. The HWTD tests were

conducted on specimens prepared at four different asphalt contents, starting from the design

asphalt content and decrements of two tenths (0.2%) of a percent each time. In order to expedite

the statistical analysis of data, three sets of HWTD specimens (four plugs per set) were prepared

at each asphalt content. The design matrix is presented in Table 1.

© ASCE

Airfield and Highway Pavements 2015

5

Airfield and Highway Pavements 2015 © ASCE 2015 90

( SR-9.5A

(a) A

100

90

80

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

70

Percent Retained

60

50

40

30

20

10

0

0.075 0.3 0.6 1.18 2..36 4.755 9.5 12.5 19

S

Sieve Size in mm

m

Maax Density Line Co

ombined Gradaation

b) SR-12.5A

(b A

10

00

9

90

8

80

7

70

Percent Retained

6

60

5

50

4

40

3

30

2

20

1

10

0

0.075

5 0.3 0.6 1.18 2.36 4.75 9.5

5 12.5

Sieve

e size in mm

M Density

Max Combined…

Fig

gure 2. 0.45--power charrt of Superp

pave mixturres studied.

© ASCE

Airfield and Highway Pavements 2015

6

Airfield and Highway Pavements 2015 © ASCE 2015 91

Table 1 Experimental design matrix

SR-9.5A SR-12.5A

Design binder content=5.54% Design binder content=5.3%

Additive: Arr Maz HP+ (0.6%) Additive: Arr MazHP+ (0.45%)

5.54% 5.34% 5.14% 4.94% 5.3% 5.1% 4.9% 4.7%

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

3 sets for each binder content 3 sets for each binder content

(3×4=12 plugs) (3×4=12 plugs)

Air voids=7±1% Air voids=7±1%

RESULTS AND ANALYSIS

All specimens were compacted to 7±1 air voids and tested in wet condition. In general,

the HWTD specimens are subjected to 20,000 wheel passes or a maximum rut depth of 12.5 mm

(TxDOT) or 20 mm (Colorado DOT), whichever comes first. However, in this study, specimens

were subjected to unlimited wheel passes or 20-mm rut depth, whichever came first. The only

variable in the study was binder content (%). For each binder content, three replicate sets (each

set with four plugs) were fabricated and tested. Average number of wheel passes and

corresponding rut depths are tabulated in Table 2 for the SR-9.5A mixture.

Table 2 shows the average number of wheel passes is lower for the design binder content

when compared to the number of wheel passes for the drier mixes. The highest average number

of wheel passes recorded was 11,861 when 4.94% of asphalt (0.6 % below design binder

content) was used. The lowest number of wheel passes recorded was 5,087 when 5.54% of

asphalt (design binder content) was used. For specimens SB-2,3 and SB-4,5, the average number

of wheel passes was too high when compared to the other specimens in the same subset (samples

with 5.34 % AC), thus they were discarded and not taken into consideration while calculating the

average number of wheel passes since these were proven to be outliers by conducting influence

statistics such as Cook’s Distance, Dffits and Rstudent were calculated (SAS 9.3 User Guide,

2011). Details can be found in somewhere else (Uppu, 2012).

From Table 3, we can see that performance of SR-12.5A was better at lower binder

content i.e., below the design binder content. As the binder content decreased, the average

number of wheel passes increased. The average number of wheel passes increased from 5,380 to

40,244 when the binder content was decreased from 5.3% to 4.7%.

The trends in the results of decreasing wheel passes in the HWDT test with higher asphalt

content were also studied using the asphalt film thickness of both mixtures (Uppu, 2012). The

results of linear regressions show that the number of wheel passes decreases as the asphalt film

thickness increases. Trend line showing the relationship between these two parameterd has a

coefficient of determination (R2) value of 0.74 and 0.81 for SR-9.5A and SR-12A, respectively.

© ASCE

Airfield and Highway Pavements 2015

7

Airfield and Highway Pavements 2015 © ASCE 2015 92

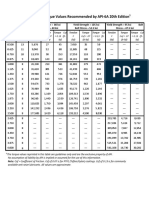

Table 2 Summary of Hamburg Wheel Tracking Device test results for SR-9.5A mixture

Asphalt Virgin asphalt No of Rut depth

Sample ID

content (%) added (%) passes in mm

SA-1,SA-4 5,759 20

SA-2,SA-3 4,789 20

5.54 4.11

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

SA-6,SA-7 2,250 20

(Design Asphalt

SA-9,SA-10 3,700 20

Content)

SA-11,SA-12 7,433 20

SA-13,SA-15 6,589 20

Average 5.54 4.11 5,087 20

SB-2,SB-3 20,855* 20

SB-4,SB-5 24,187* 20

SB-6,SB-7 3.91 8,367 20

5.34

SB-8,SB-11 9,091 20

SB-12,SB-13 9,450 20

SB-14,SB-15 3.91 11,621 20

Average 5.34 3.91 9,632 20

SC-3,SC-4 8,867 20

SC-5,SC-6 11,689 20

SC-7,SC-8 3.71 12,679 20

5.14

SC-9,SC-10 13,033 20

SC-11,SC-14 9,217 20

SC-13,SC-15 9,649 20

Average 5.14 3.71 10,856 20

SD-2,SD-4 11,547 20

SD-3,SD-5 11,049 20

SD-6,SD-14 3.51 9,550 20

4.94

SD-7,SD-12 10,903 20

SD-8,SD-15 12,091 20

SD-9,SD-10 16,023 20

Average 4.94 3.51 11,861 20

* statistically identified outliers

© ASCE

Airfield and Highway Pavements 2015

8

Airfield and Highway Pavements 2015 © ASCE 2015 93

Table 3 Summary of Hamburg Wheel Tracking Device test results for SR-12.5A mixture

Asphalt % Virgin No of Rut depth

Sample ID

content (%) Asphalt added passes in mm

RA-2,RA-3 15,723* 20

RA-4,RA-5 5.3 26,211* 20

RA-7,RA-6 (Design 4,113 20

4.14

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

RA-9,RA-10 asphalt 4,583 20

RA-12,RA-13 content) 5,291 20

RA-14,RA-15 7,533 20

Average 5.3 4.14 5,380 20

RB-1,RB-3 7,127 20

RB-4,RB-5 11,347 20

RB-6,RB-9 14,653 20

5.1 3.94

RB-8,RB-10 12,621 20

RB-11,RB-13 11,967 20

RB-14,RB-15 25,563* 20

Average 5.1 3.94 11,543 20

RC-1,RC-4 8,373* 20

RC-2,RC-3 15,401 20

RC-6,RC-10 29,541* 20

4.9 3.74

RC-8,RC-9 26,893* 20

RC-11,RC-13 16,637 20

RC-12,RC-14 18,519 20

Average 4.9 3.74 16,852 20

RD-1,RD-4 19,125* 20

RD-2,RD-3 18,355* 20

RD-6,RD-9 42,335 20

4.7 3.54

RD-7,RD-8 38,153 20

RD-11,RD-13 25,650* 13.3*

RD-14,RD-15 25,650* 6.1*

Average 4.7 3.54 40,244 20

*statistically identified outliers

When testing specimens RD-11, 13 and RD-14 and 15, the test stopped due to technical

error in the HWTD machine. Thus the final number of wheel passes could not be determined but

the test still yielded valuable information in the form of creep slope, stripping slope, and

stripping inflection points, if any.

From Figure 3, we can clearly see that for both mixtures the lowest number of wheel

passes was recorded when design asphalt content (Pb) was used, and the highest number of wheel

passes was recorded when the lowest binder content was used in the mixture (Pb-0.6%), where

Pb is the design asphalt content. There was a large variation in the average number of wheel

passes for the SR-12.5A mixture when compared to the SR-9.5A mixture. The SR-12.5A

mixture seems to be affected by variation in asphalt content more than the SR-9.5A mixture.

© ASCE

Airfield and Highway Pavements 2015

9

Airfield and Highway Pavements 2015 © ASCE 2015 94

SR-9.5A NMAS SR-12.5A NMAS

50000

No of Wheel Passes

40000

30000

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

20000

10000

0

Pb Pb-0.2 Pb-0.4 Pb-0.6

Asphalt content (%)

Figure 3. Effect of asphalt content on average number of wheel passes.

Hamburg Wheel Tracking Device Test Output Parameters (Creep slope, Stripping Slope

and Stripping Inflection Point)

The performance of the mixtures can be better studied with the HWTD output

parameters. Figures 4(a) and 4(b) show creep slopes, stripping slopes, and stripping inflection

points for the SR-9.5A and SR-12.5A mixture, respectively.

From the number of wheel passes data, we concluded that mixtures performed better in

HWTD tests at asphalt contents lower than the design asphalt contents. This also can be affirmed

from the HWTD parameters for Figures 4(a) and 4(b). The creep slope and stripping inflection

points also increased with a decrease in asphalt content indicating the performance of the mixture

was better for mixes with lower asphalt content. HWTD tests are known to be affected by the

binder grade. The increase may have happened because of the aged RAP binders in the mixtures

and use of a liquid anti-stripping agent. The anti-stripping agent degrades the aged binder less.

CONCLUSIONS

The main objective of this research study was to investigate the moisture resistance of Superpave

HMA mixtures with varying asphalt content especially with RAP in it with the Hamburg Wheel

Tracking Device (HWTD) tests. Based on the results obtained from the two mixtures, the

following conclusions can be drawn:

• Binder content significantly affects the response of HMA mixtures in the HWTD

tests.

• For two mixtures tested, the number of wheel passes, creep slope, and stripping

inflection point was higher on the dry side of the design asphalt content.

• For both mixtures, the number of wheel passes, creep slope, and stripping inflection

point increased as the asphalt content decreased.

© ASCE

Airfield and Highway Pavements 2015

10

Airfield and Highway Pavements 2015 © ASCE 2015 95

• These trends in results were verified by studying the correlation of the number of

wheel passes with the asphalt binder film thickness.

(a) SR-9.5A

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

14000

12000

No of Wheel Passes

10000

8000

6000

4000

2000

0

5.54 5.34 5.14 4.94

Asphalt Content (%)

Average No of wheel passes Average Stripping Inflection Point

Average Creep Slope Average Stripping Slope

(b) SR-12.5 A

40000

35000

No of Wheel Passes

30000

25000

20000

15000

10000

5000

0

5.3 5.1 4.9 4.7

Asphalt Content (%)

Average No of wheel passes Average Stripping Inflection Point

Average Creep Slope Average Stripping Slope

Figure 4. Effect of varying asphalt content on HWTD test parameters.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the Kansas Department of Transportation for sponsoring

this study under its Kansas Transportation and New Developments (K-TRAN) program.

© ASCE

Airfield and Highway Pavements 2015

11

Airfield and Highway Pavements 2015 © ASCE 2015 96

REFERENCES

Brown, E., P. S. Kandhal, F.L. Roberts, Y.R. Kim, D. Lee, and T.W. Kennedy (2009). Hot Mix

Asphalt Materials, Mixture Design, and Construction. Third Edition, NAPA Research

and Education Foundation, Lanham, Maryland.

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 08/08/16. Copyright ASCE. For personal use only; all rights reserved.

Gedafa, D.S., M. Hossain, L.S. Ingram, and R. Kreider (2011) Performance-Related

Specification for Superpave Pavements. In Transportation Research Record: Journal of

Transportation Research Board, No. 2228, Washington, D.C., pp. 78-86.

Kandhal, P. S., and S. Cross (1993). Effect of Aggregate Gradation on Measured Asphalt

Content. In Transportation Research Record: Journal of the Transportation Research

Board, No. 1417, Washington, D.C., 1993, pp. 21-28.

Kandhal, P. S., K. Y. Foo, and R. B. Mallick (1998). A Critical Review of VMA Requirements

in Superpave. In Transportation Research Record: Journal of the Transportation Research

Board, No. 1609, Washington, D.C.

Kumar, A., and W. H. Goetz (1977). Asphalt Hardening as Affected by Film Thickness, Voids

and Permeability in Asphaltic Mixtures. Proceedings of Association of Asphalt Paving

Technologists, San Antonio, Texas, pp. 571-605.

SAS Institute Inc. (2011). SAS user guide for Windows, Release 9.3. Cary, North Carolina.

TxDOT (2009). TEX-242-F: Test Procedure for Hamburg Wheel-Tracking Test. Texas

Department of Transportation, Austin. Retrieved from ftp://ftp.dot.state.tx.us/pub/txdot-

info/cst/TMS/200-F_series/pdfs/bit242.pdf.

Uppu, Kiran (2012). Durable Superpave Hot-Mix Asphalt Mixes in Kansas. Master’s Thesis.

Dept. of Civil Engineering, Kansas State University, Manhattan, July.

© ASCE

Airfield and Highway Pavements 2015

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Evaluation of Natural Zeolite As Warm Mix Asphalt Additive and Its Comparison With Other Warm Mix AdditivesDocument11 pagesEvaluation of Natural Zeolite As Warm Mix Asphalt Additive and Its Comparison With Other Warm Mix Additivesalberto1234567No ratings yet

- Chemistry The Central ScienceDocument13 pagesChemistry The Central Sciencealberto12345670% (1)

- Resilient Modulus SoilDocument1 pageResilient Modulus Soilalberto1234567No ratings yet

- Texcoco WayDocument1 pageTexcoco Wayalberto1234567No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Besser Materials Innovations SST TalkDocument22 pagesBesser Materials Innovations SST Talkgvm0072002No ratings yet

- Reviewer Dec ExamDocument3 pagesReviewer Dec ExamCamille Dela PazNo ratings yet

- Ammonia ProductionDocument5 pagesAmmonia ProductionHarsh WaliaNo ratings yet

- SLMR 1912 09 15Document24 pagesSLMR 1912 09 15Russell HartillNo ratings yet

- Af 163-2Document10 pagesAf 163-2lacsmm982No ratings yet

- Assignment 154Document18 pagesAssignment 154NUREEN HUMAIRANo ratings yet

- Ch3a ManualDocument16 pagesCh3a ManualAllen YuNo ratings yet

- Carbon & It's Compounds (X)Document27 pagesCarbon & It's Compounds (X)Pakhi MauryaNo ratings yet

- 9th Lines and Angle Test Paper-3Document7 pages9th Lines and Angle Test Paper-3DeepakNo ratings yet

- Cooling System Specifications: General Coolant InformationDocument1 pageCooling System Specifications: General Coolant InformationKamal PakdamanNo ratings yet

- Tagupa, Mara Erna-ResearchworkDocument14 pagesTagupa, Mara Erna-ResearchworkMara Erna TagupaNo ratings yet

- Basic Specifications: Product SheetDocument2 pagesBasic Specifications: Product SheetZSOLT PULAINo ratings yet

- Chapter 2Document9 pagesChapter 2Behar AbdurahemanNo ratings yet

- Thermodynamics HandoutsDocument5 pagesThermodynamics HandoutsEnigma YTNo ratings yet

- Difference Between Biodegradable and Non Biodegradable WasteDocument3 pagesDifference Between Biodegradable and Non Biodegradable WasteArjun ParmarNo ratings yet

- Metal Organic Frameworks Vs Buffers Case Study of Ui o 66 StabilityDocument19 pagesMetal Organic Frameworks Vs Buffers Case Study of Ui o 66 StabilitymahahajNo ratings yet

- Industrial Chemistry PDFDocument168 pagesIndustrial Chemistry PDFHafiz Hamza100% (1)

- T02 11 Simonovic - Medic - Medic - Selimotic - GNP2020Document8 pagesT02 11 Simonovic - Medic - Medic - Selimotic - GNP2020Kenan KajosevicNo ratings yet

- Prediction of Void Growth and Fiber Volume Fraction Based On Filament Winding Process MechanicsDocument10 pagesPrediction of Void Growth and Fiber Volume Fraction Based On Filament Winding Process MechanicsHassan HabibNo ratings yet

- Flange Bolting Torque Values API 6ADocument1 pageFlange Bolting Torque Values API 6Aparthameister100% (1)

- Hand Book of Mark Pottery & Porcelain 1901Document279 pagesHand Book of Mark Pottery & Porcelain 1901blacky_2950% (2)

- Penetration and Softening PointDocument34 pagesPenetration and Softening PointLaxmikantNo ratings yet

- Hong2016 Gél DégelDocument7 pagesHong2016 Gél DégelHichem BoukhetachNo ratings yet

- Lab Report - Part A: Kanvasree Vuyyuru (C2084903)Document8 pagesLab Report - Part A: Kanvasree Vuyyuru (C2084903)suryaNo ratings yet

- Lecture 4-9: Bonding in Ceramics and Structure of Ceramics: MM 362 Ceramics and Glasses Spring Semester 2020, FMCE, GIKIDocument70 pagesLecture 4-9: Bonding in Ceramics and Structure of Ceramics: MM 362 Ceramics and Glasses Spring Semester 2020, FMCE, GIKIUsamaNo ratings yet

- UOP-Mercury-Removal-From-Natural-Gas-and-Liquid-Streams-Tech-Paper 2 PDFDocument9 pagesUOP-Mercury-Removal-From-Natural-Gas-and-Liquid-Streams-Tech-Paper 2 PDFPedraza Velandia JhonNo ratings yet

- Aggregate Sub-Base Course and Base Course: Engr. Juniffen I. Tacadena, Meng-Ce, Pe-1, Me-1Document24 pagesAggregate Sub-Base Course and Base Course: Engr. Juniffen I. Tacadena, Meng-Ce, Pe-1, Me-1T JNo ratings yet

- Verification of Johnson-Cook Parameters of Ferritic Stainless Steel by Drilling ProcesDocument9 pagesVerification of Johnson-Cook Parameters of Ferritic Stainless Steel by Drilling ProcesDuslerinalargaNo ratings yet

- Double Acting Spring Hinges Specification 453Document10 pagesDouble Acting Spring Hinges Specification 453Satish KumarNo ratings yet

- TDS - Pidicryl 126MDocument2 pagesTDS - Pidicryl 126MLaura Isabel RodriguezNo ratings yet