Professional Documents

Culture Documents

(SNC-AA) - 3767 - W-Beam Barrier - 09.08.2014 PDF

Uploaded by

Pratik Gupta0 ratings0% found this document useful (0 votes)

19 views18 pagesOriginal Title

(SNC-AA)_3767_W-Beam Barrier_09.08.2014.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views18 pages(SNC-AA) - 3767 - W-Beam Barrier - 09.08.2014 PDF

Uploaded by

Pratik GuptaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 18

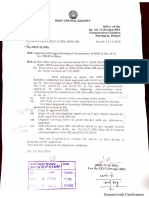

) SNCLAVALIN _ Ropaarvee associates jy

International architects engineers & consultants pvt. itd

Independent Engineer for Chennai - Tada section of NH 5

Ref; SNC-AA/CT/W-Beam Barrier/2014/3767 09-08-2014

To: Mr. Elangovan

Project Manager

L & T Chennai — Tada Tollway Limited

(A Subsidiary of L&T IDPL)

2° Floor, Main Control Building,

Toll Plaza, GNT Road, NH-5, Nallur Village,

Sholavaram Post, Chennai ~ 600 067 Tamil Nadu

Tel: 044- 2633 0891 / 93/94

Sub: Installation of W-Beam Barrier - Reg

Six ~ Laning of Chennai ~ Tada Section of NH ~ 5 from Km 11.000 to Km 84.400 in the state

of Tamil Nadu to be executed as BOT on DBFO Pattern under NHDP Phase V.

Ref: Site Inspection on 04" August, 2014.

Dear Mr. Elangovan,

During our site inspection on 4” August, 2014, along with your representative, we noticed

the execution of excavation work with 0.50 m depth of foundation from ground level, for

installation of W-Beam Barrier at Ch.52+050 on LHS without raising RFI for our inspection.

We have informed the said work is not compliance with the Specifications and Standards.

The acceptable Standards shall be followed as per Clause 1.4 under SECTION-1

(GENERAL) of Manual of Specifications and Standards for Six laning of National Highways

of Concession Agreement.

The Guidelines for installation of traffic safety barriers shall be followed as per Ministry's,

Circular no.RWINH-33022/1/94-DO Ill dated 24” June 1994, and the same is enclosed for

your ready reference as Annexure-1.

The details of locations as well as drawings for the installation of W-Beam Barriers shall be

‘submitted as per the provisions of Concession Agreement.

The executed / ongoing work of W-Beam Barrier is not meeting the requirements of

Specifications & Standards. It shall be rectified as per above mentioned Ministry's Circular.

Sincerely yours,

UR IMT RB _

Ch.Murali Krishna

Acting Team Leader / Bridge Engineer

SNC-Lavalin International - Aarvee Associates, JV

Encl: As above

———66+PB-PIU; Chennai - ——

Project Office : _ H.No: 17, Harbour Colony, Kolathur, Chennai - 600 099, Temi Nadu, India.

Tel: +91-44-96519607; Fax: +91-44-26512608; emall: sncsarvee.chennal@gmail.com

Head Office Ravula Resiclency, Srinagar Colony Main Rd., Hyderabad - 500 089, India.

Tel: +91-40-23737633; Fox: +91-40-23736977; email: aarvee@aarvee.net; web: www.aarvee.com

604/11

mio’ bighway syst is in an inwodueiory sage, it ie

therefore, be eased thatthe manufacturers

‘Perience gained, In the meantime, suggestions

Buidelines will be appreciated, A

Enclosure to Ministry's Circular No.RWINH:

Dated 24th June, 1994

poles, tees, bridge supports, simply rolling dow,

curves. Additionally. «

vit it cia, LO sah ait punfase af shes guidlines Is 5 bing out we ‘design apc OF sly taniers and

> Buble the Warranis for teic provision 0 desert information cn various types of safely batriets available

-_ Alongwith their sength and Safety chavactersis, dimensional aspects and Jayout deta forte baie,

: Revulimist ty vaniee be

ya

5 2.1. The basic even For deértinin

energy and teduce the SEVERITY of sect

) in sella nasa 16 trafic it should be ae

{hielding the hazard, is lower ten whee ing

2 ica be sale) equremenedy on

So) 2)

ete PM Ong sod ser he impact nd her shuld ne be nylon

Petetratetevehiee,

lemens which ean

2

mt vbicle should otade only milly iio the ajucent wate

‘oul provide «gous visual pude forthe ced vir

>

‘9 Mahou no dees mre than he pace smal or deco,

)

. nS

2.5, “The mayor facvar vo te considered for the solection of a particular bamrer system isthe maiching

siynamie laeral deflection characteristics ef the system lo the space available at site (including space for end treaument)

0 2810 mligate the severity of impact, Cuber factors needing consideration ave inital cos, future maintenance costs nd

esthetics. However, enhianceinen’of wehicular safely and ceashworthiness ofthe system should be given more weightage

as compared to aesthetics

‘ ‘Types of safety barriers i

3a, The safety barriers can be classified as flexible, semi-rigid, or rigid. The major difference between

the various types isthe amount of bares deflection that takes place when the batieris struck. The flexible system isthe

‘ost yielding type and is more for containment than redirogtion of the vehicle and requires more lateral clearence fiom

Jixed objects due to deMection during imc, ’Semi-rigid barriers offer requisite resistance 19 control the deflection of

Jongitudinal member to an acceptable limit shal We errant vohicle is redirected along the, tavel paui,."The rigid sysiem

‘does not deflect on'impaci but causes the maximum severity of impact, amongst the thee types. AS the angle of impact

increases this barrier becomes less forgiving. Installation ofa rigid system should be considered where shallow impact.

‘angles are expected such as along narrow medians or shoulders which could be expected in urban situations. AS te rigid

system suffers Title or no darmage on inypact, i requires the least maintenance effors,

32, ‘Safety barriers dealtin these guidelineS ave longitudinal roadside safety barriers, and median safety

barriers. Steel barriers of scmirigid type and rigid concrete barriers are described. » ete

(TiornosisaoMETATES ne ae

4a“ Warronts 3

4.1.1, The longitudinal roadside barriers are basically ineant to shield wo types of roadside hazards ie,

‘embankments and roadside obstacles and slso for preventing the vehicles veering olf the sharp curves. ‘The warrans for

2 Gill section, in terms of its height and slope, needing protection with roadside barriers are shown in Fig, 1. Itmay be

‘noted that n0 barrier is warranted for enviankment having a fill slope of 3:1 or later. ‘The warrants for roudside objects

ace mainly dependent upon the type of obstacle and the probability oftheir being hit.-A barrier should be installed only

‘ifthe resulrof vehicle striking the barriers likely to be less severe than the severity of accident resulting from the vehicle

impacting the unshielded obstacte, Judgement of the Enginecr-in-Charge should be applied to arrive atthe necessity of

providing a barrier to shield obstacles which cannot be removed. Some of the commonly encountered roadside obstacles

‘ve bridge piers, abutments and railing ends, roadside rock mass, culverts, pipes and bzad walls, cut slopes, reining walls,

lighting suppors, traffic sign and sigusl suppor, wees, and utility poles.

42, Types of Rondside Safety lNurrlers

4.2.1.° Types of longitudinal roadside safety barriers which could be used are :=

i) Pade beam ype ses hier

(i) Cone

Bouh he sicel barriers are of sng post type und usually remain functional afier moderate collisions thereby +

eliminating the need For immediate repair. e

43, Roadside Steel Barriers

43.L Design Aspects

bs ‘The "W" beam type safety barier Cosisis ofa steel post and a 3 mm thick "W" beam rail element

‘wiih is spaced away from the posts, The spacer minimises vehicular snagging and reduces the ikeUhood ofa vehicle

‘auling over the barter. ‘The steljosuu! dhe blocking out spacer shall both be channel section of 75 x 150 mm size

5 mm thick, “The el shall be 70cm above the ground level un poss shal be spaced 2m center to center, Typical Geils

ie shown in Fig 2

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Piling Works Tender For NrepDocument10 pagesPiling Works Tender For NrepPratik GuptaNo ratings yet

- UC - British Universal ColumsDocument2 pagesUC - British Universal ColumsPratik GuptaNo ratings yet

- Corrigendum V 61027 Fab-Strl BarmerDocument3 pagesCorrigendum V 61027 Fab-Strl BarmerPratik GuptaNo ratings yet

- Tendernotice - 1 - 2021-03-06T123119.604Document2 pagesTendernotice - 1 - 2021-03-06T123119.604Pratik GuptaNo ratings yet

- Tendernotice - 1 - 2021-03-06T122948.098Document2 pagesTendernotice - 1 - 2021-03-06T122948.098Pratik GuptaNo ratings yet

- Tender Document 2346Document127 pagesTender Document 2346Pratik GuptaNo ratings yet

- Container Corporation of India LTDDocument163 pagesContainer Corporation of India LTDPratik GuptaNo ratings yet

- Tendernotice - 1 - 2021-03-06T123253.960Document1 pageTendernotice - 1 - 2021-03-06T123253.960Pratik GuptaNo ratings yet

- CAO/C/NR Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No 74-W-1-1-512-WA-UMB ClosingDocument28 pagesCAO/C/NR Acting For and On Behalf of The President of India Invites E-Tenders Against Tender No 74-W-1-1-512-WA-UMB ClosingPratik GuptaNo ratings yet

- New Detailed NoticeDocument10 pagesNew Detailed NoticePratik GuptaNo ratings yet

- New Doc 2020-12-16 11.59.35Document1 pageNew Doc 2020-12-16 11.59.35Pratik GuptaNo ratings yet

- viewNitPdf 3094372 PDFDocument7 pagesviewNitPdf 3094372 PDFPratik GuptaNo ratings yet

- 8320 46 057 0082 - 000 - 00 - PDFDocument1 page8320 46 057 0082 - 000 - 00 - PDFPratik GuptaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)