Professional Documents

Culture Documents

OSHPD Approved Sway Brace Attachment

Uploaded by

makmak90 ratings0% found this document useful (0 votes)

43 views1 pageThe Fig. 1001 is a sway brace attachment used to brace pipes from 21⁄2" to 8" against sway and seismic disturbances. It is made of carbon steel and connects a pipe to a TOLCO 900 series fitting with bracing pipe to form a complete sway brace assembly. It can brace schedule 7 through 40 pipes and is field adjustable for easy installation without measuring bracing pipe length. It has a built-in visual indicator and maximum design loads of up to 2765 lbs depending on pipe size.

Original Description:

ffg d 34 tger er eq

Original Title

dfyy4 4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Fig. 1001 is a sway brace attachment used to brace pipes from 21⁄2" to 8" against sway and seismic disturbances. It is made of carbon steel and connects a pipe to a TOLCO 900 series fitting with bracing pipe to form a complete sway brace assembly. It can brace schedule 7 through 40 pipes and is field adjustable for easy installation without measuring bracing pipe length. It has a built-in visual indicator and maximum design loads of up to 2765 lbs depending on pipe size.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

43 views1 pageOSHPD Approved Sway Brace Attachment

Uploaded by

makmak9The Fig. 1001 is a sway brace attachment used to brace pipes from 21⁄2" to 8" against sway and seismic disturbances. It is made of carbon steel and connects a pipe to a TOLCO 900 series fitting with bracing pipe to form a complete sway brace assembly. It can brace schedule 7 through 40 pipes and is field adjustable for easy installation without measuring bracing pipe length. It has a built-in visual indicator and maximum design loads of up to 2765 lbs depending on pipe size.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

www.tolco.

com

Revision 12/3/2008

Fig. 1001 - Sway Brace Attachment Component of State of

California OSHPD Approved

Seismic Restraints System

Size Range — Pipe size to be braced: 21⁄2" thru 8" IPS.* Pipe size

used for bracing: 1" and 11⁄4" Schedule 40 IPS.

Material — Carbon Steel

Function — For bracing pipe against sway and seismic distur-

bance. The pipe attachment component of a sway brace system:

The Fig. 1001 is used in conjunction with a TOLCO 900 Series fitting

and joined together with bracing pipe per NFPA 13, forming a com-

plete sway brace assembly.

Features — Can be used to brace schedules 7 through 40 IPS.

Field adjustable, making critical pre-engineering of bracing pipe

length unnecessary. Unique design requires no threading of brac-

ing pipe. Can be used as a component of a four-way riser brace.

Comes assembled and ready for installation. Fig. 1001 has built-in

visual verification of correct installation. See installation note below.

Installation Note — Position Fig. 1001 over the pipe to be braced

and tighten two hex head cone point set bolts until heads bottom

out. A minimum of 1" pipe extension is recommended. Brace pipe

can be installed on top or bottom of pipe to be braced.

Maximum Design Load

Approvals — Underwriters Laboratories Listed in the USA (UL)

Sch. 7 - 1600 lbs.

and Canada (cUL). Approved by Factory Mutual Engineering (FM).

Sch. 10 & 40 w/1" Brace Pipe - 2015 lbs.

Included in our Seismic Restraints Catalog approved by the State

Sch. 10 & 40 w/11⁄4" Brace Pipe - 2765 lbs.

of California Office of Statewide Health Planning and Development

(OSHPD). For additional load, spacing and placement information

relating to OSHPD projects, please refer to the TOLCO Seismic FM Approved Design Loads*

Restraint Systems Guidelines. 2½" - 2400 lbs.

3" - 4" - 2500 lbs.

Finish — Plain

5" - 8" - 1500 lbs.

Note — Available in Electro-Galvanized and HDG finish.

Order By — Indicate pipe size to be braced followed by pipe size

used for bracing, figure number and finish.

Important Note — The Fig. 1001 is precision manufactured to

perform its function as a critical component of a complete brac-

ing assembly. To ensure performance, the UL Listing requires

that the Fig. 1001 must be used only with other TOLCO bracing

products. The Fig 1001 is not intended for use with the Fig. 907

4-Way Longitudinal Brace Attachment.

OFFICE/MANUFACTURING FACILITY • 1375 SAMPSON AVE. • CORONA, CA 92879 • PH: 951.737.5599 • FAX: 951.737.0330

156 CUSTOMER SERVICE • 800.786.5266

www.tolco.com

You might also like

- Soporte Antisísmico Fig1001Document1 pageSoporte Antisísmico Fig1001Michael IturraNo ratings yet

- Soporte Antisísmico Fig910Document1 pageSoporte Antisísmico Fig910Michael IturraNo ratings yet

- Fig. 1000 - "Fast Clamp" Sway Brace Attachment: Maximum Design Load 1" Thru 4" Pipe Size - 2015 Lbs. 6" Size - 1265 LbsDocument2 pagesFig. 1000 - "Fast Clamp" Sway Brace Attachment: Maximum Design Load 1" Thru 4" Pipe Size - 2015 Lbs. 6" Size - 1265 LbsrutyNo ratings yet

- Soporte Antisísmico Fig980Document1 pageSoporte Antisísmico Fig980Michael IturraNo ratings yet

- Soporte Antisísmico Fig825Document1 pageSoporte Antisísmico Fig825Michael IturraNo ratings yet

- Soporte Antisísmico Fig800Document1 pageSoporte Antisísmico Fig800Michael IturraNo ratings yet

- Soporte Antisísmico Fig981Document1 pageSoporte Antisísmico Fig981Michael IturraNo ratings yet

- Fig 980Document1 pageFig 980Steve CamposNo ratings yet

- Fig. 910 - Swivel Sway Brace FittingDocument1 pageFig. 910 - Swivel Sway Brace FittingANTONIO GUTIERREZ MIRANDANo ratings yet

- Fig. 906 - Sway Brace Multi-Fastener Adapter: Dimensions - WeightsDocument1 pageFig. 906 - Sway Brace Multi-Fastener Adapter: Dimensions - WeightsMichael IturraNo ratings yet

- Pipe Hangers Supports Seismic BracingDocument5 pagesPipe Hangers Supports Seismic BracingBryan S. AlejandroNo ratings yet

- Soporte Antisísmico Figura 909Document1 pageSoporte Antisísmico Figura 909Carlitos Way Golden BrainNo ratings yet

- SB Sway Brace AttachmentDocument2 pagesSB Sway Brace Attachmentrvalentino2012No ratings yet

- TOLCO Fig. 907 - Multi-Angle AttachmentDocument1 pageTOLCO Fig. 907 - Multi-Angle AttachmentAndrés HLNo ratings yet

- Figura 980Document1 pageFigura 980YoniNo ratings yet

- 825A TolcoDocument1 page825A TolcoANTONIO GUTIERREZ MIRANDANo ratings yet

- Fig. 909 - No-Thread Swivel Sway Brace Attachment: A Brand ofDocument1 pageFig. 909 - No-Thread Swivel Sway Brace Attachment: A Brand ofZaira LorenaNo ratings yet

- Clevis HangerDocument60 pagesClevis HangerFernando RuizNo ratings yet

- Fig. 4A - Pipe Clamp For Sway BracingDocument1 pageFig. 4A - Pipe Clamp For Sway BracingZaira LorenaNo ratings yet

- Tolco CatalogDocument77 pagesTolco CataloghasanmnhNo ratings yet

- Polymer Suspension Insulators 69kV To 765kV: CatalogDocument20 pagesPolymer Suspension Insulators 69kV To 765kV: CataloggitaNo ratings yet

- 1000 SB Fast Clamp Sway Brace AttachmentDocument1 page1000 SB Fast Clamp Sway Brace AttachmentANTONIO GUTIERREZ MIRANDANo ratings yet

- Catálogo Tolco PDFDocument80 pagesCatálogo Tolco PDFAgustin RosasNo ratings yet

- Tolco - Pipe Hangers Supports Seismic Bracing PDFDocument77 pagesTolco - Pipe Hangers Supports Seismic Bracing PDFMichael IturraNo ratings yet

- Tolco Pipe Hangers PDFDocument80 pagesTolco Pipe Hangers PDFHeather C BarretoNo ratings yet

- Fig. 69 - Beam Clamp Retaining Strap: DimensionsDocument1 pageFig. 69 - Beam Clamp Retaining Strap: DimensionsUcok DedyNo ratings yet

- Rehabilitation of Street Light Along All The Road NetworksDocument278 pagesRehabilitation of Street Light Along All The Road NetworksAbdulyekini AhmaduNo ratings yet

- Catalog TOLCODocument80 pagesCatalog TOLCOCostel BalasoiuNo ratings yet

- Maxxsonics Car Amplifier P1-2000Document13 pagesMaxxsonics Car Amplifier P1-2000Ivan Felipe ChamorroNo ratings yet

- Otc 21209Document11 pagesOtc 21209Rasheed YusufNo ratings yet

- Special Specification 1625 Pedestrian LightingDocument3 pagesSpecial Specification 1625 Pedestrian Lighting476500No ratings yet

- Lambda 2019.CdrDocument5 pagesLambda 2019.CdrNarpet VashunNo ratings yet

- CPM1500 CP of Onshore Well CasingsDocument22 pagesCPM1500 CP of Onshore Well Casingskirubha_karan2000No ratings yet

- InsulatorDocument6 pagesInsulatorMuhammad AftabuzzamanNo ratings yet

- 12-054 AmphenolDocument104 pages12-054 AmphenolPrejit RadhakrishnaNo ratings yet

- Laflksad DasDocument28 pagesLaflksad Dasrkpatel40No ratings yet

- Our Mission: The Coax LeaderDocument3 pagesOur Mission: The Coax LeaderArindam BanerjeeNo ratings yet

- EL01 - FS-Oil Filled Transformer Power and DistributionDocument9 pagesEL01 - FS-Oil Filled Transformer Power and DistributionBinu ManiNo ratings yet

- Kidde HPCO2 75 and 100 LB Cylinder and Valve Assemblies K-81-1010Document2 pagesKidde HPCO2 75 and 100 LB Cylinder and Valve Assemblies K-81-1010Alejandro BlancoNo ratings yet

- External Electrical Boq R2Document15 pagesExternal Electrical Boq R2mudassir mNo ratings yet

- Seismic TolcoDocument24 pagesSeismic TolcoJaider CamachoNo ratings yet

- Special Specification 6315 Self Supporting Radio TowerDocument10 pagesSpecial Specification 6315 Self Supporting Radio TowerECiiNo ratings yet

- Series 850 Specification SheetDocument2 pagesSeries 850 Specification SheetFEBCONo ratings yet

- Accesorios de Fibra de Vidrio (Conley)Document43 pagesAccesorios de Fibra de Vidrio (Conley)Juan Carlos Vazquez RosasNo ratings yet

- Pole Line Hardware JoslynDocument140 pagesPole Line Hardware Joslynsalvandy100% (1)

- Job Procedure 04 For CABLE TRAYDocument5 pagesJob Procedure 04 For CABLE TRAYSoumik KarNo ratings yet

- LAPP Insulator Post CatalogDocument34 pagesLAPP Insulator Post Catalogjorge.morales926750% (2)

- Ductile Iron CastingsDocument6 pagesDuctile Iron CastingsSusan Sue Berrospi MerinoNo ratings yet

- ASTM F1387 Approval Letter PDFDocument4 pagesASTM F1387 Approval Letter PDFRafael AndradeNo ratings yet

- Reversible Beam Clamps for RodsDocument1 pageReversible Beam Clamps for RodsmikesazNo ratings yet

- Trench BushingDocument0 pagesTrench BushingdkymqNo ratings yet

- Anchoring The WorldDocument8 pagesAnchoring The WorldjdfnortonNo ratings yet

- Corrosion: Paper NoDocument15 pagesCorrosion: Paper NoReza AbadiNo ratings yet

- Page 52Document1 pagePage 52Abhishek ShatagopachariNo ratings yet

- Opwes Overfill Protection Rack Parts Amp Accessories Brochure v2 PDF 1Document8 pagesOpwes Overfill Protection Rack Parts Amp Accessories Brochure v2 PDF 1JESUS SANCHEZ GOMEZNo ratings yet

- Soporte Antisísmico Fig1CBSDocument1 pageSoporte Antisísmico Fig1CBSmiturraNo ratings yet

- 03.datasheet Radiating Clamp PA v03Document4 pages03.datasheet Radiating Clamp PA v03Roberto OlveraNo ratings yet

- Catalog 1.0Document24 pagesCatalog 1.0Dax Xenos ArenasNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 5 MBR Branch Piping-5 MBR Left Branch PipingDocument1 page5 MBR Branch Piping-5 MBR Left Branch Pipingmakmak9No ratings yet

- Filmtec™ Reverse Osmosis / Nanofiltration Element (S) Three-Year Limited Prorated Element WarrantyDocument10 pagesFilmtec™ Reverse Osmosis / Nanofiltration Element (S) Three-Year Limited Prorated Element Warrantymakmak9No ratings yet

- Sprinkler System Specification PrimaryDocument1 pageSprinkler System Specification Primarymakmak9No ratings yet

- Column Setting Plan PDFDocument1 pageColumn Setting Plan PDFmakmak9No ratings yet

- Acident/Incident Analysis: By: Eng'r. Edwin D. VillanuevaDocument8 pagesAcident/Incident Analysis: By: Eng'r. Edwin D. Villanuevamakmak9No ratings yet

- Full Sprinkler SpecificationDocument22 pagesFull Sprinkler Specificationmakmak9100% (1)

- fddfdf23 E34 RFDocument3 pagesfddfdf23 E34 RFmakmak9No ratings yet

- Hvac Accessory CatalogDocument19 pagesHvac Accessory Catalogmakmak9No ratings yet

- Wade, Floor DrainDocument12 pagesWade, Floor DrainzfrlNo ratings yet

- Rectangular Duct & FittingsDocument26 pagesRectangular Duct & Fittingsmakmak90% (1)

- Engineering and Purchasing Controls for Workplace SafetyDocument13 pagesEngineering and Purchasing Controls for Workplace Safetymakmak9No ratings yet

- Employee TrainingDocument10 pagesEmployee Trainingmakmak9No ratings yet

- Spec - Sheet Clarke Engine - Ju4h-24 3000rpmDocument2 pagesSpec - Sheet Clarke Engine - Ju4h-24 3000rpmmakmak9100% (1)

- Construction Safety ManualDocument51 pagesConstruction Safety Manualmakmak9No ratings yet

- Quick Study For Computer Keyboard Short CutsDocument2 pagesQuick Study For Computer Keyboard Short Cutsmahazari100% (3)

- Virtual Area HsDocument1 pageVirtual Area Hsoverdrive0No ratings yet

- Procedural Guideline Do 13-ConstructionDocument41 pagesProcedural Guideline Do 13-ConstructionKim Limuel Tabago Gomez86% (14)

- Safety Manual ConstructionDocument56 pagesSafety Manual Constructionrafaelcardena73No ratings yet

- 3”-6” vertical recirculator chopper pump specificationsDocument2 pages3”-6” vertical recirculator chopper pump specificationsmakmak9No ratings yet

- Cabinet Selection GuideDocument4 pagesCabinet Selection Guidemakmak9No ratings yet

- Vasco 2 PDFDocument8 pagesVasco 2 PDFalexmuchmure2158No ratings yet

- 1000 Series Hose Cabinets Accommodate 11/2” Fire Hose RacksDocument1 page1000 Series Hose Cabinets Accommodate 11/2” Fire Hose Racksmakmak9No ratings yet

- Wade, Floor DrainDocument12 pagesWade, Floor DrainzfrlNo ratings yet

- 3"-6" Vertical Wet Well Screw Centrifugal Pumps: Materials of ConstructionDocument2 pages3"-6" Vertical Wet Well Screw Centrifugal Pumps: Materials of Constructionmakmak9No ratings yet

- Orbital welding equipment for pulled-tee jointsDocument2 pagesOrbital welding equipment for pulled-tee jointsmakmak9No ratings yet

- fddfdf23 E34 RFDocument3 pagesfddfdf23 E34 RFmakmak9No ratings yet

- End Suction Centrifugal: TH SeriesDocument2 pagesEnd Suction Centrifugal: TH Seriesmakmak9No ratings yet

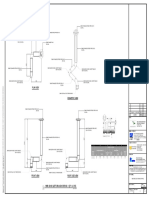

- Ground Floor Sewer & Vent/Drainage Layout: Scale: P-4 1:100 MTSDocument1 pageGround Floor Sewer & Vent/Drainage Layout: Scale: P-4 1:100 MTSmakmak9No ratings yet

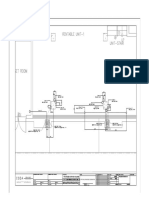

- Stub-Out Plan Ground Floor - ADocument1 pageStub-Out Plan Ground Floor - Amakmak9No ratings yet

- Exp. 5 Test For Fats and ProteinsDocument6 pagesExp. 5 Test For Fats and ProteinsEMELIE GRACE E CACHERONo ratings yet

- Calcul BADocument15 pagesCalcul BAHanane BenGamraNo ratings yet

- CKD EsrdDocument83 pagesCKD EsrdRita Lakhani100% (1)

- TST-13 Aircraft Manual With 503 Engine LSA Rev.1Document52 pagesTST-13 Aircraft Manual With 503 Engine LSA Rev.1smeassick100% (1)

- YUMMY TUMMY - Beef Biryani Recipe - Beef Dum Biryani RecipeDocument48 pagesYUMMY TUMMY - Beef Biryani Recipe - Beef Dum Biryani RecipeWilliam Cj LyngdohNo ratings yet

- Soap Making: Borax (NaDocument15 pagesSoap Making: Borax (Naa aNo ratings yet

- Screening Criteria For Application of EOR Processes in Offshore FieldsDocument7 pagesScreening Criteria For Application of EOR Processes in Offshore FieldsSajad FalahNo ratings yet

- ABS and Air Conditioner Wiring DiagramDocument207 pagesABS and Air Conditioner Wiring Diagramservice_00783% (30)

- AZIZ Ur RehmanDocument3 pagesAZIZ Ur Rehmantop writerNo ratings yet

- Chad Yakobson ThesisDocument5 pagesChad Yakobson Thesiscrystaltorresworcester100% (2)

- DSI-DYWIDAG Geotechnics Rock Bolts enDocument6 pagesDSI-DYWIDAG Geotechnics Rock Bolts enTomás Nunes da SilvaNo ratings yet

- Desensitization ProtocolsDocument28 pagesDesensitization ProtocolsAnonymous 9dVZCnTXSNo ratings yet

- English Based On Latest PatternDocument13 pagesEnglish Based On Latest PatternAtish ToppoNo ratings yet

- New Accreditation ToolsDocument52 pagesNew Accreditation ToolsLyle Guion Paguio100% (1)

- Reliance Tabletop SonicDocument20 pagesReliance Tabletop SonicbrisaNo ratings yet

- Ventilation SystemDocument13 pagesVentilation SystemSaru BashaNo ratings yet

- 16-Bit UUID Numbers DocumentDocument28 pages16-Bit UUID Numbers DocumentJuan M Iñiguez RNo ratings yet

- Data SheetDocument15 pagesData SheetLucian Sorin BortosuNo ratings yet

- Multiple Choice RadioactivityDocument4 pagesMultiple Choice RadioactivityGodhrawala AliasgerNo ratings yet

- Inu 2216 Idt - Question PaperDocument5 pagesInu 2216 Idt - Question PaperVinil JainNo ratings yet

- PERDEV Module 3 (Week 5 and 6)Document8 pagesPERDEV Module 3 (Week 5 and 6)Christy ParinasanNo ratings yet

- Ravi ProjectDocument92 pagesRavi ProjectAvinash Avii100% (1)

- EPG Health Report The Future of HCP Engagement Impact 2023Document73 pagesEPG Health Report The Future of HCP Engagement Impact 2023paulilongereNo ratings yet

- O-Rings & SealsDocument10 pagesO-Rings & SealsPartsGopher.comNo ratings yet

- Corrosion and Its Objective QuestionsDocument2 pagesCorrosion and Its Objective QuestionsSrinivasan Alagappan100% (4)

- Distance Protection SchemesDocument10 pagesDistance Protection SchemesdebasishNo ratings yet

- 7220 Instrucciones de Intalacion PDFDocument2 pages7220 Instrucciones de Intalacion PDFAttackDenied123No ratings yet

- Star T: Flowchart "Physical Fitness Test"Document1 pageStar T: Flowchart "Physical Fitness Test"Eller-Jed Manalac MendozaNo ratings yet

- CX-5 BX-10 No. 1 & 1.5 Fluid Cylinder PartsDocument5 pagesCX-5 BX-10 No. 1 & 1.5 Fluid Cylinder PartsPierreNo ratings yet

- Official Game GuideDocument30 pagesOfficial Game GuideHhfugNo ratings yet