Professional Documents

Culture Documents

Process Change Note

Uploaded by

SUBODHHOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Change Note

Uploaded by

SUBODHHCopyright:

Available Formats

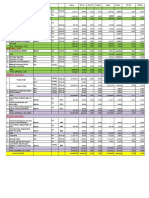

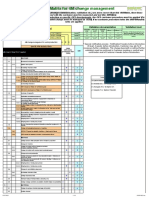

PROCESS CHANGE NOTE

Change Details

Change Item

(Incase of Change) Type

Verification /validation of Date of change Sign and

(Permanent/Tempo Details of change Control measures

change implementation remarks, if any

rary)

Extended shift working

Extra shift working

Contract manpower

Skill level change (Regular)

Organisation structure change

Man New joinee

Provison of process/

product related

Operator change- Operator replaced by

information such as

Maru-A operator change P Mr--- in place of trained competent

control plan, work

14.01.2018

Mr. ----- operator

instruction, machine

paramter chart,drawing

Different spec / grade

Raw material size/thickness/weight

Material

Different raw material approved supplier

Different raw material unapproved supplier

Process change

Process sequence change

New Technology

Sub-process supplier change

Additional process

Bin/Trolley (WIP/Storage/Despatch)

Packaging change

Transportation mode change

Method

Number of material handling

Any change in WIP

Traceability (Batch code) marking change

Inspection method

Inspection frequency

Inspection marking change

Limit sample change

Inspection equipment

Tool change

Die change

Machine change

Welding fixtures change

Machine Removal / Addition of Pokayoke

M/c parameter change

Power source change (non-routine)

Machine internal change

Power source change (non-routine)

Manufacturing

Machine internal change

Location

You might also like

- 4M SheetDocument1 page4M Sheetmani317No ratings yet

- Process Flow Chart (PFC) : Write Down The Opposite of Product Characteristics As in PFCDocument4 pagesProcess Flow Chart (PFC) : Write Down The Opposite of Product Characteristics As in PFCakav123No ratings yet

- Change Management C Pillar Stacking Reduced From 1+4 To 1+2Document18 pagesChange Management C Pillar Stacking Reduced From 1+4 To 1+2shobha shelarNo ratings yet

- Suppliers Quality Assurance Manual (PDFDrive)Document135 pagesSuppliers Quality Assurance Manual (PDFDrive)umtNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Turtle Diagrams - Stores + ShippingDocument1 pageTurtle Diagrams - Stores + Shippingcem electromechNo ratings yet

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- 6000 Series PFMEA (English For Reference)Document8 pages6000 Series PFMEA (English For Reference)RonNo ratings yet

- MKT Procedure - Evaluating Customer Satisfaction P1Document1 pageMKT Procedure - Evaluating Customer Satisfaction P1sumanNo ratings yet

- DWM FormatDocument4 pagesDWM Formatdharmendra ChaurasiaNo ratings yet

- HRD Procedure - Employee Motivation & Empowerment P2Document1 pageHRD Procedure - Employee Motivation & Empowerment P2sumanNo ratings yet

- Ref Flow Charts Layout InspectionDocument1 pageRef Flow Charts Layout Inspectionrajesh.bNo ratings yet

- APQP TrackerDocument10 pagesAPQP TrackerBharathNo ratings yet

- F-PD-11 Tool Development Plan (Micro Plan)Document3 pagesF-PD-11 Tool Development Plan (Micro Plan)Trivesh SharmaNo ratings yet

- Procedure For Set Up Approval, in Process & Final InspectionDocument7 pagesProcedure For Set Up Approval, in Process & Final InspectionRavi javaliNo ratings yet

- % Cont. Per AH % Sales % Cont. Per AH % Sales: A) Preventive CostDocument10 pages% Cont. Per AH % Sales % Cont. Per AH % Sales: A) Preventive CostmuthuselvanNo ratings yet

- Toaz - Info Red Bin Analysis Procedure PRDocument4 pagesToaz - Info Red Bin Analysis Procedure PRRohit QualityNo ratings yet

- Development Time LineDocument1 pageDevelopment Time LineMohitrajranikashyapNo ratings yet

- Q411 - 8D ReportDocument13 pagesQ411 - 8D ReportAnandha VasanNo ratings yet

- Capa - 2Document1 pageCapa - 2Quality DWINo ratings yet

- Apqp Time Plan: Risk AnalysisDocument4 pagesApqp Time Plan: Risk AnalysisRakesh PandeyNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- 43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueDocument4 pages43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueVasanth KumarNo ratings yet

- FINETURN Feasibility FormatDocument1 pageFINETURN Feasibility FormatAyush NarangNo ratings yet

- NCR VDA 6.3 Process Audit 02.04.2020Document11 pagesNCR VDA 6.3 Process Audit 02.04.2020r arumugamNo ratings yet

- APS-WP-15 Process Validation ProcedureDocument24 pagesAPS-WP-15 Process Validation Procedureshobha shelarNo ratings yet

- Sr. No. Metric Goal Data Source Base Line: TallbrosDocument3 pagesSr. No. Metric Goal Data Source Base Line: TallbrosVikas KashyapNo ratings yet

- LSAI SQA Manual FileDocument39 pagesLSAI SQA Manual FileSivakumar L100% (1)

- CSR - Audit ChecklistDocument2 pagesCSR - Audit Checklistmahesk_dmNo ratings yet

- PFMEA - 4th Edition PFMEA RankingDocument2 pagesPFMEA - 4th Edition PFMEA RankingDjurdjina PetkovicNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- Roles & Responsibilities Job Position: HOD-Quality AssuranceDocument12 pagesRoles & Responsibilities Job Position: HOD-Quality AssurancemuthuselvanNo ratings yet

- QMS Formats PDFDocument11 pagesQMS Formats PDFBhavin SukhadiyaNo ratings yet

- COMP-OPP-03 Procedure For Product Identification, Traceability and Inspection MarkingDocument4 pagesCOMP-OPP-03 Procedure For Product Identification, Traceability and Inspection MarkingISODCC DSPINo ratings yet

- Gauge Repeatability & Reproduceability Report (MSA Study)Document2 pagesGauge Repeatability & Reproduceability Report (MSA Study)Karan MalhiNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- Weekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 MarimuthuDocument10 pagesWeekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 Marimuthuom cncNo ratings yet

- FMEA & Cost of Quality (COQ) Analysis Tool: EXAMPLE: Current StateDocument51 pagesFMEA & Cost of Quality (COQ) Analysis Tool: EXAMPLE: Current StateDerecichei SergiuNo ratings yet

- Jipl CL Pur 10 Testing Lab AuditDocument8 pagesJipl CL Pur 10 Testing Lab AuditMeghna SharmaNo ratings yet

- P-PRD-04 Initial Flow ControlDocument4 pagesP-PRD-04 Initial Flow ControlPk NimiwalNo ratings yet

- 4 M Change LatestDocument8 pages4 M Change LatestVikas KashyapNo ratings yet

- What Are APQP and PPAPDocument3 pagesWhat Are APQP and PPAPignaunaqNo ratings yet

- Manufacturing Process Audit Excel FormDocument2 pagesManufacturing Process Audit Excel FormTri Hdyvtdt100% (1)

- QAD Procedure - Lab Management P1Document1 pageQAD Procedure - Lab Management P1sumanNo ratings yet

- Quality Evaluation, Problem and Follow Up Results Pdca FormatDocument1 pageQuality Evaluation, Problem and Follow Up Results Pdca FormatPk Nimiwal100% (1)

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Tool Life Monitoring RecordDocument4 pagesTool Life Monitoring RecordMani ManishNo ratings yet

- Process Validation Record: Format No.: - DateDocument2 pagesProcess Validation Record: Format No.: - DateRaja DuraiNo ratings yet

- Shutter Mag WiDocument1 pageShutter Mag Wikiran vkNo ratings yet

- Procedure For ApqpDocument19 pagesProcedure For ApqpRaja RehaNo ratings yet

- Top 3 Rejections: Rejected Qty Rej %Document1 pageTop 3 Rejections: Rejected Qty Rej %om cncNo ratings yet

- Production Validation TemplateDocument1 pageProduction Validation Templatesathyabalaraman100% (1)

- Kaga Components (M) SDN BHD: Operator Training ProceduresDocument2 pagesKaga Components (M) SDN BHD: Operator Training Proceduresrajesh sharmaNo ratings yet

- SOP-QA-7.3.6.3-001 Production Part Approval Process (PPAP)Document7 pagesSOP-QA-7.3.6.3-001 Production Part Approval Process (PPAP)XionNo ratings yet

- TMT Procedure - Management Review P2Document1 pageTMT Procedure - Management Review P2sumanNo ratings yet

- 4M Change ManagementDocument2 pages4M Change ManagementDamodaran RajanayagamNo ratings yet

- Error Proofing QSP-37 REV 00Document3 pagesError Proofing QSP-37 REV 00BRPLNo ratings yet

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHH100% (1)

- SOP Sales Prodn Planning DespatchDocument2 pagesSOP Sales Prodn Planning DespatchSUBODHHNo ratings yet

- Electric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderDocument7 pagesElectric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderSUBODHHNo ratings yet

- LABELS SmallDocument6 pagesLABELS SmallSUBODHHNo ratings yet

- LABELS SmallDocument6 pagesLABELS SmallSUBODHHNo ratings yet

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHH0% (1)

- Process Validation ReportDocument4 pagesProcess Validation ReportSUBODHHNo ratings yet

- LABELS BigDocument10 pagesLABELS BigSUBODHHNo ratings yet

- Electric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderDocument7 pagesElectric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderSUBODHHNo ratings yet

- LABELS BigDocument10 pagesLABELS BigSUBODHHNo ratings yet

- Mould Trial ReportDocument5 pagesMould Trial ReportSUBODHH0% (1)

- Kaizen ReportDocument1 pageKaizen ReportSUBODHHNo ratings yet

- Mould Trial ReportDocument5 pagesMould Trial ReportSUBODHH0% (1)

- LABELS SmallDocument6 pagesLABELS SmallSUBODHHNo ratings yet

- Labour Licence Renewal FormatDocument1 pageLabour Licence Renewal FormatSUBODHHNo ratings yet

- Performance Assessment and Review Admin and Accounts ManagersDocument3 pagesPerformance Assessment and Review Admin and Accounts ManagersSUBODHHNo ratings yet

- Electric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderDocument7 pagesElectric Material Electric Material Fin Machine Parts Fin Machine Parts Expander ExpanderSUBODHHNo ratings yet

- Manpower Requisition FormDocument1 pageManpower Requisition FormSUBODHHNo ratings yet

- Mobile Policy: When Sim + Mobile Allotted To EmployeeDocument5 pagesMobile Policy: When Sim + Mobile Allotted To EmployeeSUBODHHNo ratings yet

- Performance Appraisal ManagersDocument1 pagePerformance Appraisal ManagersSUBODHHNo ratings yet

- Leave Application Form: SL CL Half Day LeaveDocument1 pageLeave Application Form: SL CL Half Day LeaveSUBODHHNo ratings yet

- Leave PolicyDocument2 pagesLeave PolicyManas Ranjan PattanaikNo ratings yet

- Leave Travel Allowance Claim LTADocument1 pageLeave Travel Allowance Claim LTASUBODHHNo ratings yet

- Performance Appraisal Managers-Performance LinkedDocument1 pagePerformance Appraisal Managers-Performance LinkedSUBODHHNo ratings yet

- Name of Company: Sub: Application For LeaveDocument2 pagesName of Company: Sub: Application For LeaveSUBODHHNo ratings yet

- Fire Response PlanDocument1 pageFire Response PlanSUBODHHNo ratings yet

- Training Record 1Document1 pageTraining Record 1SUBODHHNo ratings yet

- Compliance RcordDocument1 pageCompliance RcordSUBODHHNo ratings yet

- Kaizen ReportDocument1 pageKaizen ReportSUBODHHNo ratings yet

- Kaizen ReportDocument1 pageKaizen ReportSUBODHHNo ratings yet

- Basic Principles and Application Handbook: Project Scheduling Technique: MethodDocument32 pagesBasic Principles and Application Handbook: Project Scheduling Technique: MethodLouie Macni100% (1)

- Principles of Mechatronics PresentationDocument68 pagesPrinciples of Mechatronics PresentationJosué CuevasNo ratings yet

- 5 ProductionLogisticsDocument62 pages5 ProductionLogisticsSebastian OrdoñezNo ratings yet

- CH 16, 17, 18, 20, 21 Business Studies UnitsDocument4 pagesCH 16, 17, 18, 20, 21 Business Studies UnitsaskjdNo ratings yet

- Completed (James P) Phouvanai Inthavongsa - Year 10 Accounting IGCSE Opt 3 Week 7 HomeworkDocument4 pagesCompleted (James P) Phouvanai Inthavongsa - Year 10 Accounting IGCSE Opt 3 Week 7 HomeworkYolo LeetNo ratings yet

- Oee TemplateDocument4 pagesOee TemplateGiancarlos LópezNo ratings yet

- Best Metal Casting DesignDocument71 pagesBest Metal Casting DesignVijay Pawar100% (2)

- 11 Quality Management - FDocument15 pages11 Quality Management - FdumNo ratings yet

- Demand Flow Technology 2Document9 pagesDemand Flow Technology 2Franz Allan RodriguezNo ratings yet

- Managing Production and Service OperationsDocument10 pagesManaging Production and Service OperationsJuana Abetria100% (1)

- 11.process Turtile DiagramDocument20 pages11.process Turtile DiagrammuthuselvanNo ratings yet

- Sample FMEADocument20 pagesSample FMEATaufikRasyadiNo ratings yet

- Chapter12 Solutions Hansen6eDocument27 pagesChapter12 Solutions Hansen6eRimon DomiyandraNo ratings yet

- CMMSDocument1 pageCMMSVanessa Elizabeth BeshaiesNo ratings yet

- Project Management AssignmentDocument2 pagesProject Management Assignmentwhatisthis11No ratings yet

- Grp8 - Performance Measurement in Supply ChainDocument8 pagesGrp8 - Performance Measurement in Supply ChainHarsh KherNo ratings yet

- APQPWorkbookDocument39 pagesAPQPWorkbookAnjani kumarNo ratings yet

- Brewer 8e PPT Ch01 TDocument54 pagesBrewer 8e PPT Ch01 TJuan Camilo IdarragaNo ratings yet

- Tutorial Set 5 - Microeconomics UGBS 201-2Document7 pagesTutorial Set 5 - Microeconomics UGBS 201-2FrizzleNo ratings yet

- Job, Batch and Mass ProductionDocument37 pagesJob, Batch and Mass ProductionNeha Ashani100% (24)

- Yo WearDocument13 pagesYo Weararslan0989No ratings yet

- Schedule LevelsDocument4 pagesSchedule LevelsNalini TiwariNo ratings yet

- Operations Management Is The Process in Which Resources/inputs Are Converted IntoDocument2 pagesOperations Management Is The Process in Which Resources/inputs Are Converted IntoSuraj KumarNo ratings yet

- An Introduction To 3D Scanning E-BookDocument30 pagesAn Introduction To 3D Scanning E-BookInaamNo ratings yet

- This Study Resource Was: Inventory Shrinkage Perpetual InventoryDocument1 pageThis Study Resource Was: Inventory Shrinkage Perpetual InventoryHassan Sardar KhattakNo ratings yet

- Toyota: Green Supply Chain ManagementDocument18 pagesToyota: Green Supply Chain ManagementZaima LizaNo ratings yet

- Oral Que For CIMDocument10 pagesOral Que For CIMUnimportant WorkNo ratings yet

- Wilson Tool Wheel Tool WebinarDocument51 pagesWilson Tool Wheel Tool WebinarAndres Byke SepulvedaNo ratings yet

- Material Requirements Planning (MRP) and ERPDocument79 pagesMaterial Requirements Planning (MRP) and ERPandresetyawan11111No ratings yet