Professional Documents

Culture Documents

Saic L 2115

Uploaded by

khuram shahzadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saic L 2115

Uploaded by

khuram shahzadCopyright:

Available Formats

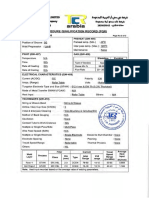

SAUDI ARAMCO ID/PIEU - 29-Jun-2017 - REV. 2017.02.00 (Standards Cutoff - February 28, 2017) Rev. 2017.02.

00 28-Feb-17

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pipeline Inspection Prior to Welding of Temperature Tie-

SAIC-L-2115 29-Jun-17 PIPING-

In Weld Joint

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A REMARKS

No.

A temperature tie-in weld is a weld that connects

one of the following:

1) Two pipeline strings together.

SAES-L-450

Def: 2) An existing pipeline to a pipeline under construction.

Para. 15.1

3) A pipeline to an anchor.

4) Pipeline sections to an intermediate mainline valve

that is being inserted.

A General Requirements

One of the following provisions must be in place prior to welding of

temperature tie-in joint:

1) Anchor is installed on the end of pipeline upstream of the welding

progression, along with friction forces on the tail.

SAES-L-450

A1 2) At least 450 m of buried

Para. 15.1

pipeline downstream of the tie-in weld. 3) 900 m to 1200 m of

pipeline string resting on wooden skids or sand.

4) 1800 m to 2400 m of pipeline string resting on steel supports.

The first string of a buried pipeline is placed in the trench and spot SAES-L-450

A2

backfilled (or tied into an anchor), during the hottest part of the day. Para. 15.5.1

SAES-L-450

A3 Subsequent strings are connected by temperature tie-in welds.

Para. 15.5.1

All welding requirements and preparations conform with SATIP-W-

A4 Quality Plan

012, and inspection conforms with SAIC-W-2057.

Welding shall not be done when surfaces are wet or damp or

SAES-W-012

A5 exposed to rain or when the welders are exposed to inclement

Para. 10.2.2

conditions.

Wind shields or tents are in place if the wind is strong enough to

SAES-W-012

A6 affect arc stability or shielding gas coverage, or when deemed

Para. 10.2.1

necessary by Saudi Aramco Inspection.

Welding surface is clean and free from oil, moisture, rust, scale,

sand, paint, metallic coatings or other foreign matter, at least 25 mm SAES-W-012

A7

of adjacent base metal prior to welding, including any such coatings Para. 10.3.1

on temporary attachments or supports

Protective sleeves made from welding blankets or similar

nonflammable material at least 0.5 m wide shall be wrapped snugly

SAES-H-200

A8 around the coated ends of the pipes adjacent to the girth weld area

Para 6.2.1

while field welding is taking place in order to prevent weld spatter

from burning through the coating.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 29-Jun-2017 - REV. 2017.02.00 (Standards Cutoff - February 28, 2017) Rev. 2017.02.00 28-Feb-17

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pipeline Inspection Prior to Welding of Temperature Tie-

SAIC-L-2115 29-Jun-17 PIPING-

In Weld Joint

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A REMARKS

No.

External line-up clamp may be used for pipe diameter 16 inches or

SAES-W-012

larger if approved by CSD Welding Engineer with a condition that

A9 Para. 10.4.1

100% radiography is performed to the production welds. the root

& 10.4.2

bead is 50% complete prior to removal of the external clamp.

At least two welders are used for pipelines greater than 16 inch SAES-W-012

A10

diameter, operating simultaneously and in opposite quadrants. Para. 10.7.1

Working clearance for welding is not less than 900 mm all around the SAES-W-012

A11

pipe. Para. 10.8

The Construction Engineer has determine the highest practical tie-in

temperature for each tie-in weld.

*NOTE: The tie-in temperature shall be within the range stated in the

SAES-L-450

A12 Project Specifications.

Para. 15.2

**NOTE: Indicate the following:

a. Project specified Tie-In Temperature Range: __________

b. Highest practical Tie-In Temp: __________

The measured tie-in temperature is within the project specified tie-in

temperature range. ( Tie-In Temp=____________)

*NOTES:a) Contact measuring device shall be shielded from direct SAES-L-450

A13

sunlight to prevent an inaccurate reading. Para. 15.3

b) Actual tie-in temperature is the average of two readings, one at

the top and one at the bottom of the pipe.

The actual tie-in temperature and the pipeline stations of the tie-ins SAES-L-450

A14

are recorded in the inspection record books. Para. 15.4

The hot pass is made while the pipe is still fully supported by the SAES-W-012

A15

sideboom tractor or supports. Para. 10.7.3

Each new string must be kept free of movement to prevent cracks in SAES-L-450

A16

the temperature tie-in welds. Para. 15.5.1

During the night and the cool periods of the day, there should be at

SAES-L-450

A17 least 900 m to 1200 m of pipe outside the trench to keep the S-curve

Para. 15.5.1

in sufficient tension to restrain the pipe already in the trench.

B Aboveground Non-restrained Pipelines:

A string is always connected to each side of the anchor stub when SAES-L-450

B1

the work is stopped at the end of the day. Para. 15.8

C Buried Pipelines:

When a sufficient number of strings have been completed, the first

SAES-L-450

C1 string of a buried pipeline shall be placed in the trench and spot REMARKS

Para. 15.5.1

backfilled (or tied into an anchor) during the hottest part of the day.

The subsequent strings shall be connected by temperature tie-in SAES-L-450

C2

welds. Para. 15.5.1

Each new string must be kept free of movement to prevent cracks in SAES-L-450

C3

the tie-in weld. Para. 15.5.1

The portion of the pipeline outside the trench shall be supported by SAES-L-450

C4

side booms holding the line in a gentle S-curve. Para. 15.5.2

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 29-Jun-2017 - REV. 2017.02.00 (Standards Cutoff - February 28, 2017) Rev. 2017.02.00 28-Feb-17

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pipeline Inspection Prior to Welding of Temperature Tie-

SAIC-L-2115 29-Jun-17 PIPING-

In Weld Joint

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A REMARKS

No.

Spot backfilling (used to anchor to the line) may be completed at any SAES-L-450

C5

temperature but no closer than 1200 m from the free end of the tail. Para. 15.5.4

If spot backfilling closer to the free end is required, it shall be done SAES-L-450

C6

during the hottest part of the day. Para. 15.5.4

If the tie-in weld is made with the pipe in the trench (at tie-in

temperature) the string being tied in and the tail must be spot

SAES-L-450

C7 backfilled on the same day of the tie-in.

Para. 15.5.5

* NOTE: The spot backfilling shall not be closer than 24 meters from

the free end.

D Aboveground Restrained Lines:

When a sufficient number of strings have been completed, the

SAES-L-450

D1 starting end of the pipeline is tied-in to a full thrust anchor or to a

Para. 15.6.1

minimum of 600 meters of buried pipeline using a temperature tie-in.

The strings which have been tied-in while resting on the skids or on

SAES-L-450

D2 the sand, are placed onto the supports by side booms, holding the

Para. 15.6.2

line in a gentle S-curve between supports and skids.

The pipeline that has been placed onto the supports has the top

SAES-L-450

D3 halves of ring girder supports or support straps, bolted in place on

Para. 15.6.2

the same day it is placed.

There shall always be at least 900 m to 1200 m of pipe attached to

SAES-L-450

D4 the line on skids or on the ground, to restrain it during the night and

Para. 15.6.3

cool periods of the day.

The pipeline strings may also be welded while resting on permanent

SAES-L-450

D5 supports, but only if the supports are designed to resist the friction

Para. 15.6.4

forces of the line developed under full temperature differential.

Two strings on supports may be tied together with a temperature tie-

in weld. This 1800 m to 2400 m double string may then be tied in to

SAES-L-450

D6 the pipeline at normal daily temperatures. However, the pipeline

Para. 15.6.5

being tied into must have an end anchor or be buried in order to

obtain the highest possible effective tie-in temperature.

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-L-450, Construction of On-Land and Near Shore Pipelines, (12 October 2015)

2. SAES-W-012, Welding Requirements for Pipelines, (10 August 2016)

3. SAES-H-200, Storage, Handling and Installation of Externally Coated Pipe, ( 7 February 2017)

REMARKS:

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 29-Jun-2017 - REV. 2017.02.00 (Standards Cutoff - February 28, 2017) Rev. 2017.02.00 28-Feb-17

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pipeline Inspection Prior to Welding of Temperature Tie-

SAIC-L-2115 29-Jun-17 PIPING-

In Weld Joint

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A REMARKS

No.

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Welder Aramco CardDocument68 pagesWelder Aramco Cardkhuram shahzad100% (1)

- Impact Load FactorsDocument13 pagesImpact Load FactorsMuralidharan ShanmugamNo ratings yet

- Api 5l Grade x65 Pipe Specification PDFDocument1 pageApi 5l Grade x65 Pipe Specification PDFkhuram shahzadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- SAIC-W-2086 In-Process Welding Inspection PDFDocument5 pagesSAIC-W-2086 In-Process Welding Inspection PDFkarioke mohaNo ratings yet

- Saic S 4058Document6 pagesSaic S 4058Engr IrfanNo ratings yet

- Saic W 2006Document1 pageSaic W 2006Abdelaziz MohamedNo ratings yet

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldDocument1 pageSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- SAIC-W-2006 Rev 8Document4 pagesSAIC-W-2006 Rev 8saravananmenmathiNo ratings yet

- SAIC-L-2106 Rev 7Document8 pagesSAIC-L-2106 Rev 7Jaseel KanhirathingalNo ratings yet

- Saic S 4057Document5 pagesSaic S 4057Engr IrfanNo ratings yet

- SAIC-W-2031 In-Process Welding Inspection of Hot TapDocument2 pagesSAIC-W-2031 In-Process Welding Inspection of Hot TapAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldjahaanNo ratings yet

- SAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld InspectionDocument5 pagesSAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld Inspectionاحمد حسنNo ratings yet

- Saic D 2025Document12 pagesSaic D 2025Md ShariqueNo ratings yet

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- Saudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 PipeDocument10 pagesSaudi Aramco Inspection Checklist: Valve Installation Inspection & Valve Stroking SAIC-L-2043 30-Apr-17 Pipesuresh100% (1)

- Saudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Buttering And/or Weld Build-Up - Pipelines SAIC-W-2047 31-Dec-14 WeldpravinNo ratings yet

- SAIC-W-2005 Rev 8Document5 pagesSAIC-W-2005 Rev 8saravananmenmathiNo ratings yet

- SAIC-L-2015 Rev 7Document7 pagesSAIC-L-2015 Rev 7Jaseel KanhirathingalNo ratings yet

- SAIC-W-2081 Receiving Inspection of Welding Consumables (EE)Document2 pagesSAIC-W-2081 Receiving Inspection of Welding Consumables (EE)karioke mohaNo ratings yet

- Saic L 2015Document8 pagesSaic L 2015Engr IrfanNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Welding Insp - Weld Overlay & Cladding Restoration SAIC-W-2021 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables - API Tanks SAIC-W-2081 17-Mar-16 WeldjeswinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saic e 2005Document13 pagesSaic e 2005jerinNo ratings yet

- SAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresDocument4 pagesSAIC-W-C013-Inprocess Welding Inspection - Offshore StructuresVinu MadhavanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- SAIC-W-2015 Select Welds For NDE (On-Plot)Document3 pagesSAIC-W-2015 Select Welds For NDE (On-Plot)KirubhakarPooranamNo ratings yet

- SAIC-W-C014-Post Weld Visual Inspection - Offshore StructuresDocument4 pagesSAIC-W-C014-Post Weld Visual Inspection - Offshore StructuresVinu MadhavanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Welding Consumables SAIC-W-2010 15-Jul-18 Weldm4metz100% (1)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- SAIC-W-2085 Pre-Welding Inspection PDFDocument4 pagesSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaNo ratings yet

- SAIC-D-2020 Tank Trim Installation MAS-rlcDocument3 pagesSAIC-D-2020 Tank Trim Installation MAS-rlcAnonymous S9qBDVkyNo ratings yet

- SAIC-W-2007 Rev 8Document6 pagesSAIC-W-2007 Rev 8saravananmenmathiNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- SAIC-K-4012 Rev 08 - Metal Duct Hangers and Support InstallationDocument3 pagesSAIC-K-4012 Rev 08 - Metal Duct Hangers and Support Installationranausman1987No ratings yet

- SAIC-K-4020 Rev 08 - Chilled Water Piping Lay-OutDocument4 pagesSAIC-K-4020 Rev 08 - Chilled Water Piping Lay-Outranausman1987No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- Saudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldDocument6 pagesSaudi Aramco Inspection Checklist: Post-Welding Visual Inspection (Plant Piping) SAIC-W-2007 30-Apr-13 WeldManoj KumarNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Jul-18 Weldm4metzNo ratings yet

- Saic W 2005Document1 pageSaic W 2005Abdelaziz MohamedNo ratings yet

- SAIC-W-2078 Review PWHT Proc For TankDocument5 pagesSAIC-W-2078 Review PWHT Proc For Tankkarioke mohaNo ratings yet

- Saudi Aramco Inspection Checklist: Final Inspection For Types I - V Fences SAIC-M-1005 1-Nov-09 CivilDocument4 pagesSaudi Aramco Inspection Checklist: Final Inspection For Types I - V Fences SAIC-M-1005 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Document3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Grade & Site Preparation SAIC-Q-1011 15-Nov-17 MAH-SA-RFI-C2626Abdul HannanNo ratings yet

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- SAIC-S-4002 Rev 7Document6 pagesSAIC-S-4002 Rev 7Muhammad TariqNo ratings yet

- Saudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 WeldDocument1 pageSaudi Aramco Inspection Checklist: Pre Welding Inspection - Offshore Structures SAIC-W-1312 Weldkartik_harwani4387No ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19Document3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of APCS-113 Coating Systems Application SAIC-H-2049 31-Mar-19harisNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Interview Notes by Vishal DhameliyaDocument60 pagesInterview Notes by Vishal DhameliyaghanicwiNo ratings yet

- CPP Jps1 1 QC Pro 0056 - 0 CPP Wsteel Pipe Welding (Gtaw) .PDF - 17Document1 pageCPP Jps1 1 QC Pro 0056 - 0 CPP Wsteel Pipe Welding (Gtaw) .PDF - 17khuram shahzadNo ratings yet

- All Combine Merged Questions CBT Welding and PipingDocument57 pagesAll Combine Merged Questions CBT Welding and Pipingdada shaik100% (11)

- Api 510 Exam 2021Document14 pagesApi 510 Exam 2021eng_far100% (2)

- 2 10uDocument7 pages2 10uPaulNo ratings yet

- Root Cause & Corrective Action Corrective Action (RCCA) (RCCA)Document37 pagesRoot Cause & Corrective Action Corrective Action (RCCA) (RCCA)Bisma Masood100% (1)

- Causes of Internal Concavity in Fcaw WeldingDocument234 pagesCauses of Internal Concavity in Fcaw Weldingkhuram shahzadNo ratings yet

- ASNT-L3 Qualifications PDFDocument3 pagesASNT-L3 Qualifications PDFElankumaran PeriakaruppanNo ratings yet

- Eye BoltsDocument1 pageEye Boltskhuram shahzad100% (1)

- ASNT-L3 Fees PDFDocument4 pagesASNT-L3 Fees PDFElankumaran PeriakaruppanNo ratings yet

- Analysis Regarding HazDocument6 pagesAnalysis Regarding Hazkhuram shahzadNo ratings yet

- Annual ReportDocument106 pagesAnnual ReportMuhammad IshaqNo ratings yet

- Appendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Document14 pagesAppendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Jobaer ShaonNo ratings yet

- List of Branches Authorized For Overnight ClearingDocument17 pagesList of Branches Authorized For Overnight Clearingkhuram shahzadNo ratings yet

- 02whole PDFDocument467 pages02whole PDFkhuram shahzadNo ratings yet

- 02whole PDFDocument467 pages02whole PDFkhuram shahzadNo ratings yet

- SNT TC 1a 2011Document38 pagesSNT TC 1a 2011khuram shahzad0% (1)

- Saes X 800 PDFDocument12 pagesSaes X 800 PDFkhuram shahzadNo ratings yet

- Appendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Document14 pagesAppendix B3-03 Welding Procedure Specification ENB-MA-WPS-3 Rev. 0 - A4A2E2Jobaer ShaonNo ratings yet

- Saes Z 004Document39 pagesSaes Z 004khuram shahzad100% (1)

- Saes A 010Document32 pagesSaes A 010hyderabadNo ratings yet

- Saes y 501Document16 pagesSaes y 501khuram shahzadNo ratings yet

- Saes Z 010Document17 pagesSaes Z 010khuram shahzadNo ratings yet

- Saes A 005 PDFDocument32 pagesSaes A 005 PDFAdnanAtifNo ratings yet

- Saes A 004Document22 pagesSaes A 004Branko_62100% (1)

- Nas 1351Document6 pagesNas 1351Kadir YavuzNo ratings yet

- Standard Detail Wall Anchor Clips Saudi ArabiaDocument1 pageStandard Detail Wall Anchor Clips Saudi ArabiaJohn Paul ApostolNo ratings yet

- PSOW2 - MS For Waterproofing Dated 04.11.2023Document5 pagesPSOW2 - MS For Waterproofing Dated 04.11.2023projectsNo ratings yet

- Renewal of Product Approval MS Sika India PVT LTDDocument4 pagesRenewal of Product Approval MS Sika India PVT LTDsandeepNo ratings yet

- Pickling Handbook PDFDocument16 pagesPickling Handbook PDFJunMamauagDelaCruzNo ratings yet

- Aquamine 50.01Document17 pagesAquamine 50.01Armando RelajoNo ratings yet

- Survey of Precast Concrete Method and Cast-in-Situ Concrete MethodDocument4 pagesSurvey of Precast Concrete Method and Cast-in-Situ Concrete MethoderpublicationNo ratings yet

- Mechanical Engineering Drawing: SR KaleDocument22 pagesMechanical Engineering Drawing: SR KaleAdnan RanaNo ratings yet

- Steel Mesh System For Reinforced FillDocument25 pagesSteel Mesh System For Reinforced FillThameem SharaafNo ratings yet

- Improvement & 5 Year Maintenance of Construction of Bridge On Nehuli Karle Road at Chainege 1+440 Tal. Alibag, Dist. RaigadDocument23 pagesImprovement & 5 Year Maintenance of Construction of Bridge On Nehuli Karle Road at Chainege 1+440 Tal. Alibag, Dist. RaigadPravin MasalgeNo ratings yet

- 23 - Pressure ConduitsDocument9 pages23 - Pressure ConduitsYahya KhanNo ratings yet

- Additive Manufacturing 2Document12 pagesAdditive Manufacturing 2Gourav SamaNo ratings yet

- Eucalyptus CLTDocument13 pagesEucalyptus CLTmiguelcambiumNo ratings yet

- UK Smoothbore 16.12.21 Rev 46Document13 pagesUK Smoothbore 16.12.21 Rev 46stevensilvasaNo ratings yet

- Advanced Concrete Technology Assignment-1 High Performance ConcreteDocument12 pagesAdvanced Concrete Technology Assignment-1 High Performance Concreteyedida v r aviswanadhNo ratings yet

- Abstract of 05Th Final Bill SR - No. Particulars Amount (RS.) Previous Present TotalDocument11 pagesAbstract of 05Th Final Bill SR - No. Particulars Amount (RS.) Previous Present TotalJay Rupchandani100% (1)

- Jurnal FiberglassDocument10 pagesJurnal FiberglassChristian Jovie YudhanantaNo ratings yet

- Pipe Support StandardDocument32 pagesPipe Support StandardHema Nandh100% (1)

- Extrusion ProcessesDocument6 pagesExtrusion ProcessesSreejith VaneryNo ratings yet

- API 526 - Spring Loaded Material TableDocument1 pageAPI 526 - Spring Loaded Material TableGanda SamosirNo ratings yet

- AOT 4-1/2" & 5-1/2" "TS-100" MANUAL SPIDER: Aot# Description # REQ. WTDocument1 pageAOT 4-1/2" & 5-1/2" "TS-100" MANUAL SPIDER: Aot# Description # REQ. WTRICHARDNo ratings yet

- Guideline For Quality Management of Concrete BDocument62 pagesGuideline For Quality Management of Concrete BRam KrishnaNo ratings yet

- Bills of QuantityDocument36 pagesBills of QuantityManish MiglaniNo ratings yet

- 2009破碎机备件及耗材重量Document184 pages2009破碎机备件及耗材重量Lina JiaNo ratings yet

- PVC Schedule 80 Catalogue NEWDocument32 pagesPVC Schedule 80 Catalogue NEWMohammed sabatinNo ratings yet

- D4. SBS Iran PDFDocument10 pagesD4. SBS Iran PDFMohammed QaderNo ratings yet

- MATERIALSDocument25 pagesMATERIALSNaisha JadwaniNo ratings yet

- Sheet Metal ProccessesDocument43 pagesSheet Metal ProccessesisharaNo ratings yet

- MS - Sika Waterbars - Placing in Construction & Movement Joints (v.02.2018)Document6 pagesMS - Sika Waterbars - Placing in Construction & Movement Joints (v.02.2018)Proyek Headquarter SurabayaNo ratings yet

- Price List For Reinforcing Steel Bars: Search..Document2 pagesPrice List For Reinforcing Steel Bars: Search..Leomark RespondeNo ratings yet