Professional Documents

Culture Documents

IRC-58-2015 Design - Pg-1

Uploaded by

KRISHNA YELDI0 ratings0% found this document useful (0 votes)

74 views1 pageIRC-58-2015 design - Pg-1

Original Title

IRC-58-2015 design - Pg-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIRC-58-2015 design - Pg-1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views1 pageIRC-58-2015 Design - Pg-1

Uploaded by

KRISHNA YELDIIRC-58-2015 design - Pg-1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

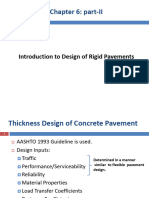

IRC:58-2015 Guidelines for Design of

Plain Jointed Rigid Pavements for Highways

Example of Design of Slab Thickness for Pavement

(with and without doweled transverse joints. Beta value will be 0.66 for doweled joint and 0.90 for without dowels case)

Type of pavement considered Pavement Structural Details

Carriageway 2-lane divided Modulus of subgrade reaction of subgrade, MPa/m 50.33

Thickness of Granular Subbase, mm 150

Shoulders :- Tied concrete shoulders ? (yes/no) no Thickness of Dry Lean Concrete subbase, mm 100

Effective modulus of subgrade reaction of foundation,

Transverse joint spacing (m) 4.5 231

MPa/m

3

Lane width (m) 4.5 Unit weight of Concrete, kN/m 24

Transverse Joints have dowel bars? (yes/no) yes 28-day Flexural strength of cement concrete, MPa 4.7

Max. day-time Temperature Differential in slab, 0C (for

Design Traffic Estimation 12.5

bottom-up cracking)

0

Night-time Temperature Differential in slab, C (for top-

Design Period (years) 30 11.25

down cracking) = day-time diff/2 + 5

Total Two-way Commercial Traffic (cvpd) in the year of

50 Trial Thickness of Concrete Slab, m 0.2

completion of construction

Av. Annual rate of growth of commercial traffic Load Transfer Efficiency Factor for TDC analysis, Beta =

0.05 0.66

(expressed as decimal) 0.66 for dowel Joints, 0.90 for joints without dowels

Cumulative No of Commercial vehicles during design

1212509 Elastic Modulus of Concrete, Ec (MPa) 30000

period (two-way), A

Average No of axles per commercial vehicle, B 2 Poisson's Ratio of Concrete, Mu 0.15

Cumulative No of Commercial Axles during design

2425018 Radius of relative stiffness, m 0.54554

period (two-way), C = A*B

Proportion of traffic in predominant direction (For 2-

1.00 Design Axle Load Repetitions for Fatigue Analysis

lane 2-way highways use a value of 1.0), D

Lateral Placement factor (0.25 for 2-lane 2-way. For

0.250 For Bottom-up Cracking Analysis

multilane highways the value is 0.25 X C), E

Factor for selection of traffic for BUC analysis (for six-

0.2 Front single (steering) Axles = H * K1 42438

hour period during day), F

Factor for selection of traffic for TDC analysis (for six-

0.3 Rear single Axles = H * K2 66688

hour period during day), G

Design axle repetitions for BUC analysis (for 6 hour day

121251 Tandem Axles = H * K3 12125

time traffic), H = C*E*F

Proportion of vehicles with spacing between front and

the first rear axle less than the spacing of transverse 0.70 Tridem Axles = H * K4 0

joints, I

Design axle repetitions for TDC analysis (for 6-hour night

127313 For Top-Down Cracking Analysis

time traffic), J = C*E*G*I

Proportion of Front single (steering) Axles, K1 0.350 Front single (steering) Axles = J * K1 44560

Proportion of Rear single Axles,K2 0.550 Rear single Axles = J * K2 70022

Proportion of tandem Axles, K3 0.100 Tandem Axles = J * K3 12731

Proportion of Tridem Axles, K4 = (1-K1-K2-K3) 0.000 Tridem Axles = J * K4 0

As per IRC:58-2015, Table 5 & Table 6

Use Dowel Bars of 25mm Dia, 360mm Length & 300mm Spacing

Use Deformed Tie Bars of 12mm Dia, 800mm Length & 600mm Spacing

You might also like

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Irc 58 2015 Excel Sheet PDFDocument3 pagesIrc 58 2015 Excel Sheet PDFtally3tallyNo ratings yet

- CC Design forDLC 100 MMDocument14 pagesCC Design forDLC 100 MMamit singhNo ratings yet

- Interface / Interphase in Polymer NanocompositesFrom EverandInterface / Interphase in Polymer NanocompositesAnil N. NetravaliNo ratings yet

- Detailed Project Report Development of Industrial Area,: at Piparsewa, Dist - MorenaDocument44 pagesDetailed Project Report Development of Industrial Area,: at Piparsewa, Dist - MorenaVIKASNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- (PDF) IRC-58 2015 Excel SheetDocument3 pages(PDF) IRC-58 2015 Excel SheetMadhavpokale0% (1)

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- (PDF) IRC-58 2015 Excel SheetDocument3 pages(PDF) IRC-58 2015 Excel SheetPratik JoshiNo ratings yet

- IRC 58-2011 (Guidelines For The Design of Plain Jointed Rigid Pavements For Highways)Document8 pagesIRC 58-2011 (Guidelines For The Design of Plain Jointed Rigid Pavements For Highways)rekha kn0% (1)

- Design of Concrete Pavement Name of The WorkDocument10 pagesDesign of Concrete Pavement Name of The WorkDurga Rama Swamy KalvakolanuNo ratings yet

- Report On Design of CC PavmentDocument11 pagesReport On Design of CC PavmentAnand RaghuwanshiNo ratings yet

- Pavment DesignDocument2 pagesPavment Designshivshankar kushwahaNo ratings yet

- IRC-58 2015 Excel SheetDocument3 pagesIRC-58 2015 Excel SheetBilal Ahmed Barbhuiya72% (18)

- Pavement Design ReportDocument11 pagesPavement Design ReportIrfanNo ratings yet

- IRC-58-2015-for Pakhdeva Kokha MargDocument9 pagesIRC-58-2015-for Pakhdeva Kokha MargRam Samujh SharmaNo ratings yet

- Rigid Pavement Design 200mm Alipingal-KhairaDocument15 pagesRigid Pavement Design 200mm Alipingal-KhairaPradeepta PatraNo ratings yet

- Module 05 Amador Part 1 AASHTO RigidDocument52 pagesModule 05 Amador Part 1 AASHTO RigidPaul Anderson-TrocmeNo ratings yet

- Structural Testing - Project2022Document27 pagesStructural Testing - Project2022Đặng Nhật HàoNo ratings yet

- Rigid Pavement Joint Design - 2020 - QRDC (Less Than 450CVPD)Document9 pagesRigid Pavement Joint Design - 2020 - QRDC (Less Than 450CVPD)geoprabhatNo ratings yet

- 36-Article Text-169-1-10-20220605Document20 pages36-Article Text-169-1-10-20220605S A KaleNo ratings yet

- Rigid Pavement DesignDocument4 pagesRigid Pavement Designankesh0108No ratings yet

- Eng Nazih PDFDocument1 pageEng Nazih PDFJackie ChanNo ratings yet

- Rigid Pavement Design1Document21 pagesRigid Pavement Design1s100% (1)

- Restoration Design For Capacity Performance Assessment of RC Slab BridgesDocument8 pagesRestoration Design For Capacity Performance Assessment of RC Slab BridgesbadmaNo ratings yet

- Beam - To-Column Connection PDFDocument5 pagesBeam - To-Column Connection PDFValentinoNo ratings yet

- Jagtap-2015-Simulation of Quarter Car Model Using MatlabDocument8 pagesJagtap-2015-Simulation of Quarter Car Model Using MatlabKyle N SamarooNo ratings yet

- 7 - Serviceability Requirements: Clar Don Evangelio, MeqengDocument37 pages7 - Serviceability Requirements: Clar Don Evangelio, MeqengBlack Fist ZepHyRNo ratings yet

- Design SheetDocument10 pagesDesign SheetPadma Shahi100% (1)

- 2020 2.1 Midas Gen Release PDFDocument38 pages2020 2.1 Midas Gen Release PDFmarkespinoNo ratings yet

- Latest Midas Gen Release Note 2020 (v2.1)Document38 pagesLatest Midas Gen Release Note 2020 (v2.1)markespinoNo ratings yet

- Format Pavement DesignDocument10 pagesFormat Pavement DesignsinghconstNo ratings yet

- 18 Appendix ADocument23 pages18 Appendix AHardik PrajapatiNo ratings yet

- Sstruc Ctur Flyo Ral de Ver A Esign AT 0+ N Rep + Port 950 (LHS)Document70 pagesSstruc Ctur Flyo Ral de Ver A Esign AT 0+ N Rep + Port 950 (LHS)Chandra prakash AndhwanNo ratings yet

- Reinforced Concrete (RC) Beam Design Application For Android Based On SNI 2847:2013 (CEMA)Document7 pagesReinforced Concrete (RC) Beam Design Application For Android Based On SNI 2847:2013 (CEMA)Ronald De GuzmanNo ratings yet

- Chapter 6-Part-II Introduction To Design of Rigid PavementsDocument22 pagesChapter 6-Part-II Introduction To Design of Rigid Pavementsznabu asefaNo ratings yet

- Concrete Industrial Ground Floor Design To Tr34 Third EditionDocument3 pagesConcrete Industrial Ground Floor Design To Tr34 Third EditionRuemu Godwin InikoriNo ratings yet

- 4design ReviewDocument22 pages4design ReviewAnonymous fS6Znc9No ratings yet

- 295 PDFDocument3 pages295 PDFعبد القادر جمالNo ratings yet

- Wind Load SheetDocument32 pagesWind Load SheetNishan GajurelNo ratings yet

- A Comparative Study On RC Flat Slab & Post-Tensioning SlabDocument21 pagesA Comparative Study On RC Flat Slab & Post-Tensioning SlabChandra ShekarNo ratings yet

- Rigid Pavement DesignDocument4 pagesRigid Pavement Designankesh0108No ratings yet

- CC Road Design PalasaDocument18 pagesCC Road Design PalasaManikantaNo ratings yet

- Design of RCC Bedding, Joint Boxing, and Manhole: of A Sewer Line From Rajpur Khadar To ShyamkutiDocument22 pagesDesign of RCC Bedding, Joint Boxing, and Manhole: of A Sewer Line From Rajpur Khadar To ShyamkutizohaNo ratings yet

- Rigid Pavement Joint Design - 2020 - QRDCDocument11 pagesRigid Pavement Joint Design - 2020 - QRDCgeoprabhatNo ratings yet

- The University of Dar Es SalaamDocument6 pagesThe University of Dar Es SalaamChris AdaminovicNo ratings yet

- Boxdrain 1.2x1.5 Final PDFDocument24 pagesBoxdrain 1.2x1.5 Final PDFRaghums GOWDANo ratings yet

- Preliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesDocument4 pagesPreliminary Design Report: Arcelormittal Composite Bridge Predesign Preliminary Design Software For Composite BridgesIoana Codrea OrtelecanNo ratings yet

- Template 2021Document4 pagesTemplate 2021irma nurcahyani gunturNo ratings yet

- Uncracked Concrete DesignDocument15 pagesUncracked Concrete Designmohamad jbaraNo ratings yet

- Mat Foundation Y Dir Rebar DesignDocument4 pagesMat Foundation Y Dir Rebar DesignGaneshalingam Ramprasanna2No ratings yet

- Chapter 07-Unit 03 - Flanged Beam Design PDFDocument15 pagesChapter 07-Unit 03 - Flanged Beam Design PDFabdullahNo ratings yet

- CVPDDocument4 pagesCVPDmiestyNo ratings yet

- ETABS 2016 16.2.0 AISC 360-10 Composite Beam Details License # 1PJPHBGNRCE4GAWDocument1 pageETABS 2016 16.2.0 AISC 360-10 Composite Beam Details License # 1PJPHBGNRCE4GAWIvan PorrasNo ratings yet

- 4.d Crust DesignDocument4 pages4.d Crust DesignAATVIK SHRIVASTAVANo ratings yet

- Lecture 5 Worked Example-Shear-Torsion (Part 2) PDFDocument15 pagesLecture 5 Worked Example-Shear-Torsion (Part 2) PDFAnonymous apmOvzVzmjNo ratings yet

- Chapter-7 Cost Estimates 7.1. GeneralDocument4 pagesChapter-7 Cost Estimates 7.1. GeneralSANDEEP GAWANDENo ratings yet

- Simply Supported Beam ExampleDocument4 pagesSimply Supported Beam ExampleTruong Phuoc TriNo ratings yet

- STUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and ThrustDocument9 pagesSTUP Consultants P. LTD.: 2.6.1 Analysis of Pile Section Under Bending and Thrustraja mistryNo ratings yet

- Project Report SynopsisDocument26 pagesProject Report SynopsisKRISHNA YELDINo ratings yet

- QueuingDocument32 pagesQueuingSasana SanNo ratings yet

- Shaikh AfrazDocument1 pageShaikh AfrazKRISHNA YELDINo ratings yet

- Sathe Aniket VasantDocument1 pageSathe Aniket VasantKRISHNA YELDINo ratings yet

- RESUME FdsDocument1 pageRESUME FdsKRISHNA YELDINo ratings yet

- Santosh Suresh PawarDocument1 pageSantosh Suresh PawarKRISHNA YELDINo ratings yet

- Santosh Kumar YadhavDocument1 pageSantosh Kumar YadhavKRISHNA YELDINo ratings yet

- Christmas Time Template 16x9Document5 pagesChristmas Time Template 16x9sopiaNo ratings yet

- Changing CAT Exam PatternDocument4 pagesChanging CAT Exam PatternKRISHNA YELDINo ratings yet

- Christmas Time Template 16x9Document5 pagesChristmas Time Template 16x9sopiaNo ratings yet

- Characteristics of Urban Transportation Systems: Revised Edition September 1992Document147 pagesCharacteristics of Urban Transportation Systems: Revised Edition September 1992Jay PatelNo ratings yet

- Vehicle Delay AnalysisDocument12 pagesVehicle Delay AnalysisKRISHNA YELDINo ratings yet

- Equivalent Axle LoadsDocument6 pagesEquivalent Axle LoadsKRISHNA YELDINo ratings yet

- Changing CAT Exam PatternDocument4 pagesChanging CAT Exam PatternKRISHNA YELDINo ratings yet

- Traffic Impact Assessment: O'Callaghan Moran & Associates Mchale Facility, Ballinrobe, Co. MayoDocument24 pagesTraffic Impact Assessment: O'Callaghan Moran & Associates Mchale Facility, Ballinrobe, Co. MayoKRISHNA YELDINo ratings yet

- Irc Gov in SP 019 2001 PDFDocument124 pagesIrc Gov in SP 019 2001 PDFCharlene ChuaNo ratings yet

- TRAFFIC IMPACT STUDY REPORT - TTMC - Jayanagar PDFDocument74 pagesTRAFFIC IMPACT STUDY REPORT - TTMC - Jayanagar PDFKRISHNA YELDINo ratings yet

- Lecture 5 Slides PDFDocument29 pagesLecture 5 Slides PDFlinamohdzhor4815No ratings yet

- Urban Road Safety Audit - 200614 PDFDocument172 pagesUrban Road Safety Audit - 200614 PDFKRISHNA YELDINo ratings yet

- Irc - Gov .In .SP .019.2001Document84 pagesIrc - Gov .In .SP .019.2001KRISHNA YELDINo ratings yet

- Appendiix G5 - Traffic Impact AssessmentDocument55 pagesAppendiix G5 - Traffic Impact AssessmentKRISHNA YELDINo ratings yet

- IRC 009 - Traffic Census On Non-Urban RoadsDocument36 pagesIRC 009 - Traffic Census On Non-Urban RoadsKRISHNA YELDINo ratings yet

- Govlawircy1972sp09 0 PDFDocument16 pagesGovlawircy1972sp09 0 PDFAmeen SyedNo ratings yet

- Tia GuideDocument78 pagesTia GuideLXN 6176No ratings yet

- ON AND Road: Design TrafficDocument48 pagesON AND Road: Design Trafficsakthi priyaNo ratings yet

- Traffic Impact Assessment: O'Callaghan Moran & Associates Mchale Facility, Ballinrobe, Co. MayoDocument24 pagesTraffic Impact Assessment: O'Callaghan Moran & Associates Mchale Facility, Ballinrobe, Co. MayoKRISHNA YELDINo ratings yet

- Guidance On Road MarkingsDocument17 pagesGuidance On Road MarkingsKRISHNA YELDINo ratings yet

- Parking BasicsDocument20 pagesParking BasicsKRISHNA YELDINo ratings yet

- Fundamentals and History of Cybernetics 2Document46 pagesFundamentals and History of Cybernetics 2izzul_125z1419No ratings yet

- Reading Passage 1: You Should Spend About 20 Minutes On Questions 1-12 Which Are Based On Reading Passage 1Document2 pagesReading Passage 1: You Should Spend About 20 Minutes On Questions 1-12 Which Are Based On Reading Passage 1Melisa CardozoNo ratings yet

- 5th Issue October 10Document12 pages5th Issue October 10The TartanNo ratings yet

- DatasheetDocument2 pagesDatasheetTesfay Zemuy GebrekidanNo ratings yet

- Cascaded Transformers:: Figure 1.basic 3 Stage Cascaded TransformerDocument3 pagesCascaded Transformers:: Figure 1.basic 3 Stage Cascaded TransformeryugendraraoknNo ratings yet

- Amerisolar Ficha TecnicaDocument2 pagesAmerisolar Ficha Tecnicapepo222No ratings yet

- (L4) - (JLD 3.0) - Semiconductors - 30th DecDocument66 pages(L4) - (JLD 3.0) - Semiconductors - 30th DecAshfaq khanNo ratings yet

- PSS Report206Document90 pagesPSS Report206Abhishek TiwariNo ratings yet

- Performance of Trinidad Gas Reservoirs PDFDocument11 pagesPerformance of Trinidad Gas Reservoirs PDFMarcus ChanNo ratings yet

- Lecture 5Document33 pagesLecture 5nic_nishantNo ratings yet

- Valve Operation and System DesignDocument208 pagesValve Operation and System DesignWalter José de Miranda100% (8)

- HIU Range Design GuideDocument24 pagesHIU Range Design Guidesachinsaklani23No ratings yet

- AVEVA VPRM Internationalisation SupportDocument25 pagesAVEVA VPRM Internationalisation SupportShahfaraz Ahmad0% (1)

- Der 484Document84 pagesDer 484Rohit SainiNo ratings yet

- Dn7064519 - Installing Flexi Cabinet For IndoorDocument63 pagesDn7064519 - Installing Flexi Cabinet For Indoorlettymc100% (1)

- Dokumen - Tips Cfm56 7 B AnswerbookDocument75 pagesDokumen - Tips Cfm56 7 B AnswerbookOnur YayNo ratings yet

- Operating Instructions Back Pressure Regulator Series: BPR: Holter RegelarmaturenDocument19 pagesOperating Instructions Back Pressure Regulator Series: BPR: Holter Regelarmaturenamin100% (2)

- Lesson Plan 2Document3 pagesLesson Plan 2api-260894328No ratings yet

- NovaSeq X - Site PreparationDocument3 pagesNovaSeq X - Site Preparationlifir67730No ratings yet

- Đề luyện tập 5Document5 pagesĐề luyện tập 5Nguyễn Duy TânNo ratings yet

- HRTC RoutesDiverted Via KiratpurManali Four LaneDocument9 pagesHRTC RoutesDiverted Via KiratpurManali Four Lanepibope6477No ratings yet

- ABB Surge Arrester MWK - Data Sheet 1HC0075865 E01 ABDocument5 pagesABB Surge Arrester MWK - Data Sheet 1HC0075865 E01 ABsriniNo ratings yet

- EV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)Document31 pagesEV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)TekkieNo ratings yet

- Be Katalog-Grabenfr 2013 Engl RZ KleinDocument36 pagesBe Katalog-Grabenfr 2013 Engl RZ Kleincherif100% (1)

- PresPrescient3 Extinguishing Control Panelcient 3 SLDocument4 pagesPresPrescient3 Extinguishing Control Panelcient 3 SLIgor NedeljkovicNo ratings yet

- HDPE Pipe InstallationDocument7 pagesHDPE Pipe InstallationJeferson Binay-an100% (1)

- A Grand Vision of Man's Role in Colonizing The Universe: BooksDocument3 pagesA Grand Vision of Man's Role in Colonizing The Universe: Bookspeter lonterNo ratings yet

- Argumentative EssayDocument20 pagesArgumentative EssayLuthfi MaullanaNo ratings yet

- TD62382APG, TD62382AFG: 8Ch Low Input Active Sink DriverDocument11 pagesTD62382APG, TD62382AFG: 8Ch Low Input Active Sink DriverDiego GrisalesNo ratings yet

- Illustrative Worked Examples Commentary of Irc: 6-2017Document2 pagesIllustrative Worked Examples Commentary of Irc: 6-2017jatin singlaNo ratings yet