Professional Documents

Culture Documents

Calculo de NSR PDF

Uploaded by

ingminero20090 ratings0% found this document useful (0 votes)

40 views13 pagesOriginal Title

Calculo de NSR.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views13 pagesCalculo de NSR PDF

Uploaded by

ingminero2009Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

Geoscience Canada

Volume 18. Number 4

Net Smelter Return

Models and Their Use in

the Exploration,

Evaluation and

Exploitation of

Polymetailic Deposits

Raymond Goldie

Richardson Greenshields of Canad Limited

Suite 1400, 130 Adelaide St. W.

Toronto, Ontario MSH 1TB

Poter Tredger

Tedgco Mineral Services

‘Suite 1400, 25 Adelaide St. E

Toronto, Ontario MBC 1Y2

ABSTRACT

Asan aid visualizing a mineral deposit the

tive spatial dimensions are often reduced

to two, by projection onto plans or sections.

Similarly, the concentrations ofiflerent met-

alsin the deposit can be represented in a

single dimension through the use ofa com-

mon denominator, the Net Smelter Return

(NSR) per tonne. NSR is defined as the

proceeds from the sale of mineral products

ater deducting off-site processing and dis-

Inibution costs

In sulphide deposits in which the econom-

iemetals are principally copper, nickel, mo-

Iyodenum or platinum group metals, amine’:

receipts (the NSR) usualy correspond to

about 86%-60% of the gross value of the

metals contained inthe ore This figuredrops

{toaround 40% for ores with significant quan-

tities offead or nc. The presence of old or

siver inthe ore wil generally increase these

percentages.

‘An NSR model of a deposi is @ represen-

tation which atterpts to approximate the ac-

tal NSR which would be derved ffom ex-

Dlottation of the mineralization being model-

led. NSRS are calculated from estimates of

‘grades, recoveries, concentrate treatment

schedules and commodity prices.

‘With the adventot cheap, readly availabe

‘computer processing, itis now practicable

for geologists to routinely use NSR models.

A the exploration stage, NSR models pro-

vide a uselul basis for presentation and com

parison of dril-hole assays. Atthe evaluation

‘stage ofa project, NSR models are helpful in

‘the estimation of optimum grades, recov-

‘ties, and procuction rates. Al the explota-

tion stage, NSR models provide a rigorous

basis for grade contr

‘A widely used alternative to the NSR per

tonne as acommon denominator the “equit-

alent grade” (eg, "gold-equivalent” of “cop-

per-equivalent’),is misleading and should be

avoided,

INTRODUCTION

The Net Smetter Return (NSR)is e measure

of the value of ore. For example, inthe in-

‘come statements of most Canadian mining

‘companies, the top line (‘sale", “not cals

“ravenues" oF "not revenues") is generally

the NSR, which is defined ae the proceeds

{rom the sale of mineral products after de-

ducting all off-mine costs relating to the

transportation, treatment and sale of those

products

In the Preface of Ore Deposit Models,

Roberts and Sheahan (1988) noted that

“there are two components to an ore deposit

‘modal: the empirical model, whicn consists

ofan assemblage of data including observa-

tional data. which characterizes the deposit

‘and @ conceptual model tempts 10

Interpret the data through a unifying theory

‘of genesis”. NSR models ae simlar to other

‘ore deposits models: the empirical compo-

rent is based on an assemblage of data

obtained from operating mines; the cones

{ual component provides the economic geo-

logist with a ramework forthe evaluation of

specific projects,

‘An NSR model of a mineral deposit is a

representation which altompls to approx:

mate the actuol NSR which would be derived

{ror exploitation ofthe mineralization boing

modeled. NSRs serve two main purposes

forthe economic geologist (a) they provide a

‘common denominator forthe comparison of

assays from polymetaic deposits; and (b)

‘thoy instil a heafthy awareness of the ecc-

omic factors which determine the value of

‘Comparison of assays. AS an aid in visu-

alizng a mineral deposit, the three spatial

dimensions are often reduced to two, by

projection onto plans or sections. Simtarly,

‘concentrations of aiiarent metals a poly-

‘metallic deposit can be represented in a

‘single dimension through the use ofa com-

‘mon cenomnator. The best such common

denominator i the NSR per tonne.

‘A widely used alternative to the NSR per

tonne is “equivalent grade’, in which con-

‘centrations of itfereatmetals are converted

to one metal equivalent according to the'r

{elative prices. This common denominator

suffers from two disadvantages: (8) it as-

‘sumes tha treatmentcosts and metallosses

in processing are the same for all com

rmodities; and (2) despite Mutuating metal

159

prices, the equivalence factors tend to for-

fever remain attheirintialycalculatedlevels.

‘Awaronoss of economic factors. The use

‘OINSRS forces geologists to considera wise

range of factors which determine whether or

rota mineral depositcan bemined profitably.

INSRs are determined natonly by ore grades,

but also by mill recoveries, concentrate

‘grades, concentrate treatment charges,

freight costs and metal prices. In the early

‘exoloration stages of a project, rough as-

‘sumptions are acceptable. However, n more

‘advanced stages of evaluation, careful es

timation ofthese factors becomes crtically

Important. NSR models highlight questions

= patticularly those pertaining to miner-

‘alogy — which must be considered in any

project evaluation.

This paper outlines the calculation of

INSR fora variety of concentrate types de

‘ved from polymetalic ores, and Mustrates

‘applications of the NSR concept in three

‘areas: exploration, evaluation and exploit.

tion

NOMENCLATURE

‘The grades of metals contained inthe ore fed

o.a mi are termed mil hoad grades or mit

heads. In the mull, ore is crushed, ground,

1nd then treated by various processes 10

‘separate and concentrate the valuable min-

frais. The end products from the rill are

concentrates ang failings. Concentrates

‘coniain economic metals) at grades higher

than those in the mil feed; tangs contain

the remainder of the treated mill feed. The

most important process in producing con-

Centratesiecilferential Notation, which takes

‘advantage of the metalic surface properties

‘of most sulphides and native metals. Conso-

quently, most oxide, hydroxide, carbonete

{and silicate minerals such as chrysocala

(copper), gahnite(zino), nickebferous olivine

(ickel), and even some suiphides (such as

the nickel mineral, violarite) cannot be ce-

covered by conventional flotation tech-

riques. The miling of apolymetalic ore gen-

erally results Inthe production of more than

fone concentrate. A buk concontrate is one

which contains significant quantities of more

than one economic metal. The mil racovery

of a metal aqualsthe amount of metal report:

ing to the concentrates, as 3 proportion of

the total amount n the mill ads.

Concentrates are shipped to smelters

andlor refineries, where the contained met-

als are extracted and pusiled. A smelter wil

not pay orallof the metal the concentrates

which t treats: metals for which the miner is

paid are termed payable or accountable

metals

‘As an example, consider alead-zinc-iver

Core containing 100 g/t Ag In the mil, 50% of

the siver reports to the lead concentrat

30% to the zine concentrate and 20% to

tallings. The ead smeiter pays for 85% ofthe

siver in the lead concentrate, bul the zine

160

rofinery gives no siver credits, Therelore:

‘contained siver = 100 gt Ag

recovered silver = 80 g/t Ag

(Go. 100 g/t Ag «(50% + 30%))

payable siver = 425 g/t Ag

ie. (100 git Ag » 50% = BS%))

‘The Net Smeitor Raturnofa tonne otorais

‘equal tothe proceeds rom the sale of miner-

‘al products derives trom thal ore, after de-

‘ucting all related charges incurred outside

the mine property. Such charges include

‘concentrate transportation costs. smeiting,

Felinng, insurance and marketing costs.

‘The gross value of a tome of ore is the

value of the economic meta's contained in

the ore

‘We define the mine netback of a tonne of

ere astheratioo! the NSRiothe gross value

NSRs AND MINE NETBACKS

FOR TYPICAL CONCENTRATES

In terms of total wrid production, the tr

‘oat important types of base metal concer

tates are copper ead and zinc concentrates.

Because of ther relevance to Canada, butk

lead-2ine, molybdenum, nickel, bulk nickel

‘copper, platinum group metais (PGM) an tn

‘concentrates ate also discussed below.

Copper in Copper Concentrates

‘The most common copper ore mineral is

chalcopyrite, which als 's the major copper

mineral in most copper concentrates. The

‘average grace of the 32 Canadian copper

‘concentrates listed in the Mining Source-

‘book (1985 to 1990 editions, published an-

wally by the Canadian Mining Journal| was

2.9% Cv. The concentrates ftom the Beth-

lenem and Lornex mils at Highland Vatey

British Columbia, graced 40% Cu and were

the only ones to exceed the 34.6% Cu con

tent of stoichometne chaleopyrite. Borne

stoichiometrically 63.3% Cu, is an important

‘ore mineral al Highland Valley.

‘A mine shipping copper concentrate to a

smelter typically faces a variety of off-site

costs or deductions:

(@) Payable cooper, usualy 10 fo 14 “units”

Jess than the copper contained in the

concentrate

(A unit’ isone percentage point. Thus, 2 10

Unit deduction in a concentrate grading

23.9% Cu would mean that (23.8-10)23.,

(0F 05.8% of the contained copper would be

ald fo)

‘4.10 unit decuction is characteristic of low

‘grade concentrates (say, 20% Cu}; higher-

‘grade concentrates are usually subject to

higher deductions (e.g. Reynard, 1991),

(0) Smetting fees, expressed as dollars per

‘ty tonne of concentrate

{6) Penattes, imposed by the smelter if the

concentrate contains unduly high con-

centrations of certain substances.

(6) Retning charges, expressed as cenis per

‘pound of payable copper.

(©) Freight charges, expressed as dalars per

Wet tome of concentrate.

(1) Insurance costs, marketing expenses and

physical losses of concentrate during trans-

portation.

‘Copper concentrate sales contracts may

alow smetters to participate in some of the

benefits should copper prices nis. n a typ=

cal price participation arrangement, the cop-

per refining charge increases by a percen

tage ofthe amount by which the copper price

exceeds @ negotiated trigger price. Ocea

sionaly, contracts also provide for lower re-

finng charges when the copper price falls

below the vigger price (Reynard, 1991),

‘When expressed per pound of payable

copper, deductions (a) (b) and e) decine as

the grade of the concentrate increases.

Thus, all ese being equal, an ore grading

415% Cu containad in Dorrie is more vali-

‘able than an ore with the same grade con-

tained in chalcopyrite, because bornite

makes alugher rade concentratethan does

cchaleopyr

Inallof the examples of NSR calculations

‘which flow, dollar amounts are in US dolars

‘and it's assumed that: the deposits ae ree-

Sonably accessible, with 9 freight charge of

'S3sitonne of wet concentrate; the concen:

trates contain 20% moisture; 9 stondard de-

duction of 2.0% of he valve of payable met

‘als cavers item (7) above; and thatthe con-

centrates contain fow concentrations of

oleterious materials.

INSR Calculation for Copper

‘Copper concentrate terms fuctuate depenc-

ing on the supplyidemanc balance the

‘concentrate market. A typical 1990 copper

‘schedule was: 100% ofthe contained.copper

payable after a1 Ounitdeduction: asmetting

fee of $70icry tonne; and a refining fee of

50.090 with price participation of 10% of the

‘amount by which the price of copper ex-

‘ceeded $0.901b, With a copper price al the

1990 average spottevel ($1.21) and agrede

Of 239% Cu, a dry tonne of typical copper

concentrate contained 22046 = 22.9/100 =

‘5121 = $698 worth of copper. However, pay-

fable copper was worth 22046 » (23.910)

100 ~ $121 = $6t1onae. After our 2% al-

fowance for ingurance, marketing and metal

losses duting transportation, not payablcop-

por was $599itonne. Smelting charges were

's70ldry tonne of concentrate, the refining

charge was 22046 » (23.9-10} 1100 «

{0.09+0.031) = $8titry tonne, and eight

charges were S3Bldry tonne, Because some

‘ofthe concentrates osten route, the mine's

‘smelting and reining charges ona net payable

basis ware sighlly lower than as shown

‘above: to accourt for this, we assume @ 2%

‘eduction ine refining charge, to S60Htome.

INSR. therefore, was $599 - $70 $60 $08 =

‘$43ittonne of concentrate, representing

{676% ofthe value of the copper in the copper

‘concentra

in the 30 operations cited in the Mining

‘Sourcebook (1985-1990 editions}, an aver

‘age of 84.7% ofthe copper contained in the

mil feed was recovered to copper concen-

trates. Applying this mil recovery to the

above example, the typical mine netbock

was 676% » 847% = 57% ofthe gross value

‘ofthe copper contained inthe ore. Column A

fof Table 7 summarizes the foregoing terms

‘and calculations.

Lead in Lead Concontrates

Load treatment charges may be expressed,

‘as in the case of copper as a smelter charge

{per tonne of concentrate) plus a refining

charge (per pound of payable metal). Alter-

natively, a smelter might quote a single

charge for treatment (smelting plus refining)

per tonne afconcentate. Lead smelters usu-

ally particpate In 15%-28% of any upward or

donnard moves in lead prices. Price par-

Uicipation works as folows: the priceoflead

were to rise by 10% above a reference level

‘and ifthe smelters price participation were

‘set af 20%, the smelting charge per tonne

‘would tse by 2%

‘Column Bin Table 1 summarizes the load

treatment terms prevalent in 1990 and the

NSR calculation. AS shown, a typical nel

bbock for @ Canadian lead mine was 35% of

the gross value ofthe loadin its oe.

Zinc in Zine Concontrates

Some facities are able to produce refined

zine direcily from concentrates. Hence,

‘weatment fees for zinc ate commonly 1

ported as a singe fure per tonne of con-

Centrate, rather than as a separate smelting

charge and a tefining charge. AS was the

case with copper, treatment fees decine

(when expressed per pound of payable zinc)

2 the grade of the concentrate increases,

Furthermore, zinc plants penalize zine con-

cenitates which ae high ron. Thus, alelse

beng equal, an ore grading 10% Zn, with the

2ne conlained iniron-poor ephalerit, s more

valuable than an ore grading 10% Zn, wih the

ZEne contained in on ich ephaleite

Like load smelters, zinc plants generally

participate in moves in meatal prices. One

‘such arrangement is shown in Columa G of

‘Table 1. Years ago, zinc plants recovered

‘only 85% of the zinc in the concentrates. In

‘comparison, the recovery at a modern zinc

plant is about 939%, However itis stl stan-

{ard practice forthe pfantto pay only 85% of

the contained zinc: the diference of 8% is

‘considered to be part ofthe smelting fee

(Column Cin Table 1 summarizes the 1280

2ing treatment terms and the NSR calcula:

tion, Typical Canadian zinc ores yielded a

443% mine netoack

Gold and Sliver in

‘Copper, Lead and Zine Concentrates

Lemieux of at. (1988) have estimated that

‘only 49% ofthe gold contained in Canadas

total reserves of base metal ores wil be

acqvered to concentrates. It is diffcul to

justify this conclusion — or its extension to

‘silver — because fow operations publish the

Geoscience Canada Volume 18 Number 4

diettbuton of precious metals among the

diferent mil products. Two operations which

do pubishthese data are the Trout Lakemine

in Manitoba (Healey and Petruk. 1980; Ming

‘Sourcebook, 1985 0 1990 esitions) and the

Brunswick #12 mine in New Brunswick

Grunswick Mining and Smelting Lid 1980).

‘The Trout Lake data show hatin 1989, 74.5%

ofthe contained gold was recovered: 59.2%

to cooper concentrate and 15.3% to zinc

Concentrate, Brunswick’ figures show that

in 1969, mill heads graced 109.5 g/t Ag, and

thet 56.3% of this amount was recovered:

22% to lead concentrate, 264% to copper

concentrate and 67% to bulk concentrate.

Precious metals in base metal concen-

trates are subject o a series of charges and

deductions by smelters and refineries. For

example, we estimate thal about 87% of the

gold recovered at Trout Lake would have

been payable, and that god refining charges

in 1989 were about 13% of the gold price.

Hence, the mine netback onthe gold content

Of this ore would have been about 745% x

87% x (100%-13%) = 64%. Similarly, at

Brunswick, about 92% ofthe recovered siver

\wouichave been payable. Since siverrefning

charges in 1869 were about 75% ofthe siver

price. themineretbeck on thesivercontentof

Brunswick's ore would have been about

158 39% x 92% x (100%-75%) = 48%.

‘Atypical schedule for gold in @ copper or

lead concentrate would provide that the

miner be paid the lesser of (a) 90% of the

Contained gold or (b)the gold content of the

concentrate less 10 git Au. A typical

‘iver payment schedule for such concen-

Uuates would be 95% ofthe siver content of

the concentrate, lass 25 git Ag. For 8 zinc

concentrate. payment I usually for the

esea of elthor a) B0% ofthe contained gold

‘and 90% of the contained siver, or (b) the

precious metal cortent of the concentrate

lege 9 deduction of 12 g/t Au and 110 g/t Ag

Both gold and siver are subject to refining

charges (currently about $0.30-$0.400 for

slver and $5.00-88 O0er for gol).

‘These schedules have two important

Implications:

(() Precious metals are moce valuable ifihey

reportto copper ortead concentratesthan to

2ine concentra,

(2) A deposttin which the precious metatsall

port toa single concentrate is more valu-

‘able than a similar deposit in which the pre

cious metals report to several concentrates.

Thus, an important task for an economic,

geologist is to evaluate the habitat of pre

lous metalsin a potential orebody (Beruvé,

1982; Gasparin, 1980, Potruk, 1989). For

‘example, inclusions of gold in chalcopyrite

Fe worth more than inclusions of gold in

sphaleite.

Other Conetituente of

‘Copper, Lead and Zine Concentrates

‘Tho owner of a metallurgially complex

‘erebody must do a lt of comparison shop-

ping because smelters vary widely in their

‘treatment terms for other constituents of

concentrates. One smelter, for example,

‘may pay forthe lead and zine contained in 2

‘copper concentrate, minus 3 units. For the

‘same concentrate, another smelter may

charge a penalty of $2.50 per unit for the

‘contained lead and zine beyond a deduction

‘f4 units of combined lead and zinc, Further

more, when cadmium prices are low (eg.

below $100%b), a smeiter might penalize 3

miner for the cadmium in zine concent

Yet, when cadmium prices ore high (eg,

above $3,00ib), the same smeltor might pay

‘a credit for the seme cadmium in tho same

ine concentrate

(Other than for some special bulk concen-

trates (see below), tis 2 good approximation

{0 assume that copper, lead and zinc wil

have no value Ifthey report to concentrates

‘other than their respective concentrates.

Dirty" constituents — especialy antimony,

bismuth, arsenic, furine, cadmium, mercu-

'y, selenium. tellrium an thalium —gener-

ally result in penalties, Typcally, such penal-

{las are in the order of $10-$40 per tonne per

Unit of antimony, arsenic or bismuth. For

mercury, penalties are hundreds of dotars

per tonne per unit, Minimum concentrations,

below which no penalties are charged, range

from 0% to 3% for diferent materisis and

diferent smelters. High concentrations of

Iron, water or silica may also attract

penalties,

“The Equity Siver and Samatosum opera:

tions in British Columbia end the Ok Todi

mine in Papua New Guinea ilustrate the

importance of considering penally charges

in assessing the economic potential of a

deposit. Ar Equity ivr, 78% of the ant

‘mony (Sb) and 21% ofthe arsenic (As) inthe

Southern Tail zone reported to the copper.

siver-gold concentrate. As 2 result thiscon-

‘contrate graded 70% Sb and 4.0% As and

‘was judged to be unsaleatle. Equity Siver

‘consiructedateachplant which. withvarying

‘degrees of success, reduced the grades 10

‘0.8% Sb and 2.0% As. Although subject to

penalties, this material was acceptable to a

Japanese smelter which had the right to

Teject material containing over 5.0% Sb. Ar

ter mining the Southern Tal zone, Equity

Sliver moved on tothe Main zone. Concer

trates produced from the Main zone aver.

‘aged3.0%-3 5% Sband0.30%-0.35% As. It

was more economical to ship unleached

‘concentrates trom the Main zone than to

‘continue operating the leach plant Dayton,

1982; Edwards, 1986.

‘There are lwo main mineralized zones at

the Samatosum doposit:the Discovery zone

‘andthe Siver zone. The Discovery zone has.

reported recorves of 240,000 tonnes grading

72 git Ag plus other metals. It aiso containe

8.0% As. Altnough such concentrations of

arsenicmightbe worth special reatmentin a

larger deposit (as was the case with Equity,

Siver’s Southern Tal zone), thay wil goner-

ally destroy he economies ofa small depos-

It Indeed, the Discovery zone has no! been

18

mined. However, the Silver zones in produc-

tion because, although the copper-siver

‘gold concentrate is rich in both Sb and As,

Ihe ore grade and tonnage are sufficiently

high to make tis zone cornmercial

Coppergold ores at Ok Tedi are of two

main types, porphyry and skarn. All of Ok

‘Ted's ore is rich in fuoring; the skarn ore

especially 20 (3,000 ppm F is typical), How-

fever, most smelters impose penalties on

copper concentrates containing more than

500 ppm F. By carefully blending mil feed,

(Ok Teds operators have been generally suc-

‘cossful in maintaining Muorine levels in the

concentrates at just below 500 ppm F

Bulk Lead-Zine Concentrates:

A bulk concentrate is ane contalning signif

cant quantities of more than one economic

metal. When pelymetalic orebodies are

small or when they Nave high grades but

complex mineralogy, it may be cheaper to

ship a bulk concentrate and suffer 3 lower

smelter return than toinstal and operate the

‘equipment necessary to provide a cleaner

separation of minerals. A "standard™ butk

Concentrate, which would be cited in estab-

lishing @ base price in smelter contracts,

‘would contain about 30% Zn and 15% Pb.

Only one producer of bulk lead-zinc con-

centrates is listed inthe Mining Sourcebook

(1985 to 1980 editions): Brunswick Mining

‘and Smelting Ltd, which produces a zinc-

lead-liver bulk concentrate in addition to

‘copper, lead and zinc concentrates. In 1989,

tho bulk concentrate averaged 33.2% Zn,

19.8% Ph and 390 git Ag (Brunswick Mining

ang Smelting Ltd, 1990). This concentrate is

soldtea European smelter Payable levels of

metals are as folows: 2ine, 85% o less 7

Unite: lead, 95% or less Suns; svar, 95% oF

less 100 git (M. Power, Noranda Treasury.

pers. comm. 1988), In all cases, the appto-

Palate caduction i the one which results in

‘the least amount payable,

In recent years, Duk lead-zinc concen-

trates have become more marketable. This

development nas enhanced the prospects

for the McArthur River zinclead-siver pro-

ject in Northern Territory. Australia (Gerrard,

1990), and has also benefited the Red Dog

tine in Alaska, Red Dog produces zinc

‘concentrate, alead-siver concentrate and a

bulk lead-zine-sver concentrate (Millbank

1990),

Column D in Tale 1 presents 1990 treat-

‘moat terms and the mine netback fora hypo

thetic! producer of abulklead-2inc concen-

Irate, assuring arocovery to concantratoof

{85% for both lead and zinc. Note that smelt-

ing charges (per tonne of concentrate) are

similar to those for zine concentrates, In this

‘ca80, the mina netback ss 33% ofthe gross

value ofthe lead and zinc in the ore.

Molybdenum Concentrates

Concentrates are priced on theit contained

rmolyodenum, but at @ discount to the price

quoted for molyodic oxide. This discount,

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Diseño de Planta MineraDocument31 pagesDiseño de Planta MineraSabina Zegarra100% (2)

- ConfirmaciónDocument2 pagesConfirmacióningminero2009No ratings yet

- ACAD Plano Referencias Zonas de Bonanza Actualizado 2D-Model PDFDocument1 pageACAD Plano Referencias Zonas de Bonanza Actualizado 2D-Model PDFingminero2009No ratings yet

- ACAD Muestreo 2018PLANO MUESTREO NIVEL INFERIOR-INTERMEDIO - Model PDFDocument1 pageACAD Muestreo 2018PLANO MUESTREO NIVEL INFERIOR-INTERMEDIO - Model PDFingminero2009No ratings yet

- Genesis Del Deposito Mina Animas PDFDocument96 pagesGenesis Del Deposito Mina Animas PDFingminero2009No ratings yet

- RECORRIDODocument1 pageRECORRIDOingminero2009No ratings yet

- Ejemplo Basico - Mecanizar MinaDocument10 pagesEjemplo Basico - Mecanizar Minaingminero2009No ratings yet

- Ejemplo Basico - Mecanizar Mina PDFDocument81 pagesEjemplo Basico - Mecanizar Mina PDFingminero2009No ratings yet

- La ANH en Cumplimiento de Su ObjetoDocument1 pageLa ANH en Cumplimiento de Su Objetoingminero2009No ratings yet

- Manual 23 K-Led23hd3Document16 pagesManual 23 K-Led23hd3ingminero2009No ratings yet

- SecadorDocument1 pageSecadoringminero2009No ratings yet

- EY Library Mining Metals Investment Guide 2019 2020 PDFDocument92 pagesEY Library Mining Metals Investment Guide 2019 2020 PDFCesar PeiranoNo ratings yet

- Copia de PlantillagestionproyectoDocument42 pagesCopia de Plantillagestionproyectoingminero2009No ratings yet

- GEMADocument4 pagesGEMAAUGUSTO MONDRAGONNo ratings yet

- TALLER IRR 2017 Feb 2018 Version DefinitivaDocument18 pagesTALLER IRR 2017 Feb 2018 Version Definitivaingminero2009No ratings yet

- 2m Tierras 171218Document1 page2m Tierras 171218ingminero2009No ratings yet

- Departamentos Municipios 171218Document332 pagesDepartamentos Municipios 171218ingminero2009No ratings yet

- Planeamiento Estrategico MineroDocument38 pagesPlaneamiento Estrategico Mineroingminero2009100% (1)

- Tabla Ley de Transparencia ANH 2018Document5 pagesTabla Ley de Transparencia ANH 2018ingminero2009No ratings yet

- BalanceDocument5 pagesBalanceingminero2009No ratings yet

- Planeamiento Estrategico MineroDocument38 pagesPlaneamiento Estrategico Mineroingminero2009100% (1)

- Planeamiento Estrategico MineroDocument3 pagesPlaneamiento Estrategico Mineroingminero2009No ratings yet

- EXTRATEGIADocument24 pagesEXTRATEGIAingminero2009No ratings yet

- Formato Evaluacion de Desempeño ModeloDocument6 pagesFormato Evaluacion de Desempeño Modeloingminero2009100% (1)

- Sostenimiento de MinaDocument4 pagesSostenimiento de Minaingminero2009No ratings yet

- Control Estados JacklegDocument14 pagesControl Estados Jacklegingminero2009No ratings yet

- Sam Interno Sgym Abril 2018Document62 pagesSam Interno Sgym Abril 2018ingminero2009No ratings yet

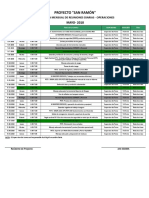

- Programa Mensual de Reuniones Diarias - MAYO 2018 OperacionesDocument1 pagePrograma Mensual de Reuniones Diarias - MAYO 2018 Operacionesingminero2009No ratings yet

- Inventario Bodega Mina MayoDocument20 pagesInventario Bodega Mina Mayoingminero2009No ratings yet