Professional Documents

Culture Documents

Asme B36 - 19M PDF

Uploaded by

Eme Eme LorcaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme B36 - 19M PDF

Uploaded by

Eme Eme LorcaCopyright:

Available Formats

A.

N A M E R I C A NN A T I O N ASL T A N D A R D

Stainless Steel Pipe

ANSIIASME B36.19M-1985

REAFFIRMED 1994

FOR CURRENT COMMlllEE PERSONNEL

PLEASE SEE ASME MANUAL A S 1 1

SPONSORED A N O P U B L I S H E D B Y

T H EA M E R I C A NS O C I E T Y O F M E C H A N I C A LE N G I N E E R S

United

Engineering

Center 3 4 5 East 47th

Street N e w York, N. Y. 1 O 0 1 7

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

S T D - A S M E B 3 b - L S M - E N G L L785 m 0757b70 Ob20888 088 m

Date of Issuance: November 29, 1985

This Standard will be revised when the Society approves the issuance of a new edition.

There will be no addenda or written interpretations of the requirements of this Standard

issued to thisEdition.

This code or standard was developed under procedures accredited as meeting the criteria for

American National Standards. The Consensus Committee that approved the code or standard was

balanced to assure that individuals from competent and concerned interestshave hadan opportunity

to participate. The proposed code or standard was made available for public review and comment

which provides an opportunityfor additionalpublic inputfromindustry, academia, regulatory

agencies, and the public-at-large.

ASME does not "approve," "rate," or "endorse" any item, construction, proprietary device, or

activity.

ASME does not take any position with respect to the validity of any patent rights asserted in

connection with any items mentioned in this document, and does not undertake to insure anyone

utilizing a standardagainst liability for infringement ofany applicable Letters Patent, nor assume any

such liability. Users of a codeor standard are expressly advisedthat determination of the validity of

any such patentrights, andthe riskof infringement of such rights, is entirelytheir own responsibility.

Participation by federal agency representativeb) or personls) affiliated with industry is not to be

interpreted as government or industry endorsement of this code or standard.

ASME accepts responsibility for only those interpretations issued in accordance with governing

ASME procedures and policies which precludetheissuanceofinterpretations by individual

volunteers.

No part of this document may be reproduced in any form,

in an electronic retrieval system or otherwise,

without the prior written permission of the publisher.

Copyright O 1985 by

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved

Printed in U.S.A.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

FOREWORD

(This Foreword is not part of ANSUASME 836.19M-1985.)

This Standard for corrosion resistant piping, designated categorically as stainless, is

based on the same principles that formed the background for thedevelopment of ANSI/

ASME B36.10M, Welded and Seamless Wrought Steel Pipe, and reference is made to this

source of information.

The wall thicknesses shown for Schedules 40s and 80s are identical with those of Sched-

ules 40 and 80 in ANSVASME B36.10M except in the 12 in. size in Schedule 40s and the 10

in. and 12 in. sizes in Schedule 80s. The thickness for these three sizes corresponds to wall

thicknesses of Standard wall and Extra-Strong wall.

The more recent development of the highly alloyed stainless steels has brought about a

minor conflict with convention. With thesenewer materials, theneed for standardsis just as

great and thepresent typesof threads are just as satisfactory, but the basic cost of the metal

is much higher and the art of fusionwelding has developed concurrently. The characterof

stainless steel permits thedesign of thin-wall pipingsystems without fearof early failure due

to corrosion, and theuse of fusion welding to joinsuch piping has eliminatedthe necessity

of threading it. For these reasons, thewall thickness dimensions shown under Schedule10s

have been developed, based on the conventional formula, but then modified to correspond

to the nearest Birmingham Wire Gage (B.W.G.) number.

Following publicationof the 1949 edition theredeveloped a demandfor a still lighter wall

pipe. A Schedule5s was determined cooperatively by representatives of chemical compan-

ies, processing industries, and manufacturersof welding fittings. This was endorsed by the

ASA Chemical Industry Correlating Committee and the Manufacturers Standardization

Society of the Valve and Fittings Industry. The new schedule was included in the revised

standard which was approved by ASA (now ANSI) on April 7, 1952.

In 1956 it was recommended that thewall thickness of 12 in. 5s be lessened, and a new re-

vision of the standardwas issued shortly afterits approval by ASA (now ANSI)on Febru-

ary 27, 1957. In this fourth edition, dimensionswere expanded beyond 12 in. pipe size by

inclusion of, and reference to, ASTM Specification A 409. This revision was approved by

ASA (now ANSI) on October 29, 1965.

The B36 Standards Committee membershipwas asked in March 1970 for recommenda-

tions asto what action should be taken on ANSI B36.19-1965 since, accordingto ANSI pro-

cedures, this standard was due forrevision or reaffirmation. TheB36 Standards Committee

recommended reaffirmation. This actionwas approved by the Secretariat and by the Amer-

ican National Standards Institute on May 26, 1971.

In 1975 the B36 Standards Committee undertook a review of the standard,considering its

acceptability and usefulness. The results were favorable; some editorial refinements and

updating were proposed alongwith the incorporation of factors forconversion to S1 (met-

ric) units. Therevision was approved by the Standards Committee, the Secretariat, and sub-

sequently the American National Standards Institute on October 4, 1976.

This standard was revised in 1984 to include S1 metric dimensions. The outside diameter

and wall thicknesses were converted to millimeters by multiplying the inch dimensions by

25.4. Outside diameters larger than 16 in. were rounded to the nearest 1 mm, and outside

iii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

diameters 16 in. and smaller were rounded to the nearest 0.1 mm. Wall thicknesses were

rounded to thenearest 0.01 mm. These converted and roundedSI metric dimensions were

added in Table 2A. A formulacalculate

to the SI metric plain end mass, kg/m, using SI met-

ric diameters and thicknesses, was added toSection 5 . The SI metric plain end masswas cal-

culated for each size and thickness, and added in Table 3A.

These changesin the standardwere approved by the Standards Committee, the Sponsor,

andtheAmericanNationalStandardsInstitute,and it was designatedanAmerican

National Standard on October 7, 1985.

iv

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

S T D O A S M E B3b.LSM-ENGL L785 0757b70 Ob2089L b 7 2 m

ASME STANDARDS COMMITTEE B36

Standardization of Wrought Steel Pipe

(The following is theroster of the Committee at the time

of approval of this Standard.)

OFFICERS

F. G. Doar, Chairmen

W. R. Daisak, Secretary

COMMITTEE PERSONNEL

AMERICAN BUREAU OF SHIPPING

J. Tlratto. American Bureau of Shipping, New York, New York

AMERICAN GAS ASSOCIATION, INC.

R. Jackson, Northwest Central Pipeline Corp., Oklahoma City, Oklahoma

L. T. Ingds, Alternate, American Gas Association, Inc., Arlington, Virginia

AMERICAN IRON AND STEEL INSTITUTE

R. P. Stripay, United States Steel Corp., Pittsburgh, Pennsylvania

ELECTRIC LIGHT AND POWER GROUP

F. G. Doar, Southern Company Services Inc., Birmingham, Alabama

J. P. Markey. Alternate, Edison Electric Institute, Washington, D.C.

MANUFACTURERS STANDARDIZATION SOCIETY OF THE VALVE AND FITTINGS

INDUSTRY

R. A. Schmktt. Ladish Co., Cudahy, Wisconsin

MECHANICAL CONTRACTORS ASSOCIATION OF AMERICA

J. H. Zink, Heat & Power Corp., Baltimore, Maryland

OIL COMPANIES MATERIALS ASSOCIATION

J. W. Strawson, Liaison, Engineer Equipment & Material Users Association,

London, England

PIPE FABRICATION INSTITUTE

J. S. Cole, ITT Grinnell Industrial Piping Inc., Kernersville, North Carolina

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

S T D - A S M E B 3 b - L S M - E N G L L985

O759b70

Ob20672

507

CONTENTS

...

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

StandardsCommitteeRoster. .............................................. v

1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 Permissible Variations ................................................ 1

5 eights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6 PipeThreads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7 Wall Thickness Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Tables

1 Specifications for Pipe With ASTM Designationsand Titles of Standard

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Dimensions of Welded and Seamless Stainless Steel Pipe . Customary

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2A Dimensions of Welded and Seamless Stainless Steel Pipe . SI Units . . . . . . . . 4

3 Nominal Weights of Steel Pipe,PlainEnds - Customary Units . . . . . . . . . . . . 5

3A Nominal Weights of Steel Pipe,PlainEnds - SI Units . . . . . . . . . . . . . . . . . . . 6

vii

Previous page is blank.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ANSVASME 836.1 SM-1 985

AN AMERICAN NATIONAL STANDARD

AN AMERICAN NATIONAL STANDARD

STAINLESS STEEL PIPE

1 SCOPE 3 MATERIALS

This Standardcovers the standardizationof dimen- The dimensional standards for pipe described here

sions of welded and seamless wrought stainless steel are for products covered in the ASTM specifications

pipe. listed in Table 1.

The wordpipe is used as distinguished fromtube to

apply to tubular products of dimensions commonly

used for pipeline and piping systems. Pipe dimensions 4 PERMISSIBLE VARIATIONS

of sizes 12 and smaller have outside diameters numeri-

cally larger than the corresponding size. In contrast, Variations in dimensions differ depending upon the

the outside diametersof tubes arenumerically identi- method of manufactureemployed in making thepipe

cal to the size number for all sizes. to the various specificationslisted in Table l. Permis-

The wall thicknesses for sizes 14 through 22 inclu- sible variations for dimensions are indicated in each

sive of Schedule los, for size 12 of Schedule 40S, and specification.

for sizes 10 and 12 of Schedule 80s are not the same as

those of ANSVASME B36.1OM. The s u f f i “S” in

the Schedule Number is used to differentiate B36.19M 5 WEIGHTS

pipe from B36.10M pipe. ANSVASME B36.10M in-

cludes other pipe thicknesses whichare also commer- The nominal weights’ of steel pipe are calculated

cially available with stainless steel material. values and are tabulated in Table 3. The nominalplain

end weight, lb/ft, is calculated using the following

formula:

where

2 SIZE

Wpe nominal plain end weight rounded to the

=

The size of all pipein Tables 2 through 3A is identi- nearest 0.01 lb/ft

fied by the nominal pipe size. D = outside diameter to the nearest 0.001 in. (The

The manufacture of pipe in the inch nominal sizes symbol D is to be usedfor O.D. only in math-

of Ys-12 inclusive is based on a standardized outside ematical equations or formulas.)

diameter (O.D.). This O.D. was originally selected so r = specified wall thickness rounded to the near-

that pipewitha standard O.D. and havinga wall est 0.001 in.

thickness which was typical of the period would have The nominal plain end mass, kg/m, is calculated

an inside diameter (I.D.) approximately equal to the using the following formula:

nominal size. Although there is no such relation be-

tween the existing standard thicknesses - O.D. and WPe = 0.02466(0 - t)t

nominal size - these nominal sizes and standard

O.D.’s continue in use as “standard.”

The manufactureof pipe innominal sizes of 14 and ‘The different grades of stainless steel have different specific densi-

larger proceeds on thebasis ofan O.D. corresponding ties and hence may weigh more or less than the values listed in this

to the nominal size. table would indicate [see Table 3, General Note (c)].

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ANSVASME 836.19M-1985

AN AMERICAN NATIONAL STANDARD STAINLESS STEEL PIPE

TABLE 1 SPECIFICATIONS FORPIPE WITH ASTM DESIGNATIONS AND

TITLES OF STANDARD SPECIFICATIONS

ASTM

Designation Title

A 312 Specification

for Seamless

andWelded Austenitic Stainless

Steel

Pipe

A 358 Specification

for Electric-Fusion-Welded Austenitic Chromium-Nickel Alloy

Steel Pipe for High-Temperature Service

A 376 Specification

for Seamless Austenitic Steel

Pipe for High-Temperature

Central-Station Service

A 409 Specification

for Welded

Large

Diameter Austenitic Steel

Pipe for Corro-

sive or High-Temperature Service

where Schedules 5s and 10s wall thicknesses do not permit

Wpe = nominal plain end mass rounded to the near- threading in accordance with ANSUASME B1.20.1.

est 0.01 kg/m

D = outside diameter to the nearest 0.1 mm for

outsidediameterswhichare 16 in.and

smaller and 1.0 mmforoutsidediameters

7 WALL THICKNESS SELECTION

larger than 16 in. (The symbol D is to be used

for O.D. only in mathematical equations or When the selection of wall thickness depends pri-

formulas.) marily upon capacity to resist internal pressure under

t = specified wall thickness rounded to the near- given conditions, the designer shall compute theexact

est 0.01 mm value of wall thicknesssuitable forconditionsfor

which the pipe is required as prescribedin detail in the

NOTE: 1 in. = 25.4 m m ; 1 lb/ft = 1.4895 kg/m

ASME Boiler andPressure Vessel Code, ANSI/

ASME B3 1 Code forPressure Piping, or other similar

codes, whichever governs the construction. A thick-

6 PIPE THREADS

ness will then be selected from the schedules of nomi-

Unless otherwise specified, the threads of threaded nal thickness contained in Tables 2 and 2A to suit the

pipeshall conform to ANSVASME B1.20.1, Pipe value computed to fulfill the conditions for which the

Threads, General Purpose (Inch). pipe is desired.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ANSIIASME'636.19M-1986

STAINLESS STEEL PIPE AN AMERICAN NATIONAL STANDARD

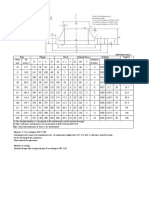

TABLE 2 DIMENSIONS OF WELDED AND SEAMLESS STAINLESS STEEL

PIPE - CUSTOMARY UNITS

inch

Nominal Wall Thickness, in.

Outside

Nominal

pipe' Diameter. Schedule Schedule Schedule Schedule

Size in. 5s (1) 10s (1) 40s BOS

'la 0.405 ,.. 0.049 0.068 0.095

'14 O. 540 ... 0.065 0.088 0.1 19

7.9 0.675 ... 0.065 0.091 O. 126

v2 0.840 0.065 0.083 o. 1o9 0.147

3l4 1 .O50 0.065 0.083 0.113 O. 154

1 1.31 5 0.065 0.109 0.133 0.1 79

1 '14 1.660 0.065 0.109 o. 1 4 0 0.191

1 '12 1 .goo 0.065 0.109 O. 145 o. 200

2 2.375 0.065 0.109 0.154 0.21 8

2 'h 2.875 0.083 o. 120 O. 203 0.276

3 3.500 0.083 0.120 0.216 0.300

3% 4.000 0.083 0.120 0.226 0.31 8

4 4.500 0.083 o. 120 0.237 0.337

5 5.563 o. 1o9 0.134 0.258 0.375

6 6.625 0.109 0.1 34 0.280 0.432

8 8.625 0.109 O. 148 0.322 O. 500

10 10.750 0.134 0.165 0.365 0.500 (2)

12 12.750 0.1 56 O. 180 0.375 (2) O. 500 (2)

14 14.000 0.1 56 O. 188 (2) , ... ...

16 16.000 O. 165 0.188 (2) ... ...

18 18.000 O. 165 O. 188 (2) ... ...

20 20.000 0.188 0.218 (2) ,.. ...

22 22.000 O. 188 0.218 12) ... ...

24 24.000 0.218 0.250 ... ...

30 30.000 0.250 0.312 ... ...

GENERAL NOTES:

(a) 1 in. = 25.4 mm

(b) For tolerances, see Section 4.

NOTES:

( 11 Schedules 5s and 1OS wall thicknesses do not permit threading in accordancewith ANSI/

ASME B1.20. l .

(21 These dimensions do not conform to ANSVASME B36.10M.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ANSVASME 836.19M-1985

AN AMERICAN NATIONAL STANDARD STAINLESS STEEL PIPE

TABLE 2A DIMENSIONS OF WELDED AND SEAMLESS STAINLESS STEEL

PIPE - SI UNITS

Inch

Nominal Wall Thickness, mm

Outside

Nominal

Diameter, Pipe Schedule Schedule Schedule Schedule

Size mm 5s (1I 10s (1) 405 805

‘I0 10.3 ... 1.24 1.73 2.41

’

14 13.7 2.24

... 1.65 3.02

318 17.1 2.31

... 1.65 3.20

‘12 21.3 1.65 2.1 1 2.77 3.73

31~ 26.7 1.65 2.1 1 2.87 3.91

33.4 1 3.38

1.65 2.77 4.55

1‘14 42.2 1.65

3.56 2.77 4.85

1‘I2 48.3 3.68

1.65 2.77 5.08

60.3 2 3.91

1.65 2.77 5.54

2 ‘I2 73.0 5.16

2.1 1 3.05 7.01

88.9 3 2.1 1

5.49 3.05 7.62

101.6 3 2.1 1

5.74 3.05 8.08

1 4 14.3 2.1 1

6.02 3.05 8.56

141.3 5 2.77

6.55 3.40 9.53

6 168.3 2.77

1 7.1 3.40 10.97

219.1 8 2.77

8.18 3.76 12.70

273.1 10 3.40

9.27 4.19 12.70 (2)

323.9 12 3.96(2) 9.53 4.57 12.70 (2)

355.6 14 3.96 4.78 (2) ... ...

406.4 16 4.19 4.78 (2) . . . . . .

457 18 4.19 (2) 4.78 . . . . .

508 20 4.78 5.54 (2) . . . . . .

559 22 4.78 5.54 (2) . . . . . .

610 24 5.54 6.35 . . .

762 30 6.35 7.92 . . .

GENERAL NOTES:

(a) 25.4 mm = 1 in.

(bl For tolerances, see Sectlon 4.

NOTES:

(1) Schedules 5 s and 10s wall thicknesses do not permit threading In accordance with ANSIí

ASME 61.20. l.

(2) These dimensions do not conform toANSVASME B36.10M.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ANSUASME B36.19M-J 985

STAINLESS STEEL PIPE AN AMERICAN NATIONAL STANDARD

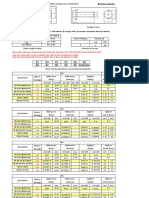

TABLE 3 NOMINAL WEIGHTS OF STEEL PIPE, PLAIN ENDS -

CUSTOMARY UNITS

Inch

Weight of Steel Pipe, Plain Ends, lb/h

Nominal

Plw Schedule Schedule

schedule Schedule

Size 55 1os 40s 80s

'le 0.19 0.24 0.31

'14 ... 0.33 0.42 0.54

Y8 ... 0.42 0.57 0.74

'I2 0.54 0.67 0.85 1 .o9

3l4 0.69 0.86 1.13 1.47

1 0.87 1.40 1.68 2.1 7

1 '14 1.11 1 .81 2.27 3.00

1'I2 1.28 2.09 2.72 3.63

2 1.61 2.64 3.65 5.02

2 'Il 2.48 3.53 5.79 7.66

3 3.03 4.33 7.58 10.25

3 '12 3.48 4.97 9.1 1 12.51

4 3.92 5.61 10.79 14.98

5 6.36 7.77 14.62 20.78

6 7.60 9.29 18.97 28.57

8 9.93 13.40 28.55 43.39

10 15.19 18.65 40.48 54.74

12 20.98 24.17 49.56 65.42

14 23.07 27.73 ... ...

16 27.90 31.75 ... ...

18 31.43 35.76 *.. ...

20 39.78 46.06 ...

22 43.80 50.71 ... ...

24 55.37 63.41 ... ...

30 79.43 98.93 ... ...

GENERAL NOTES:

(a) 1 Ib/h = 1.4895 kglm

(b) Weights are given in pounds per linear foot and are for carbon steel pipe with plain ends.

(c) The different grades of stainless steel permit considerable variations in weight.The ferritic

stainless steels may be about 5% less, and the austeniticstainless steels about 2% greater

than thevalues shown in thistable, which are based on weights for carbonsteel.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ANSIASME 838.19M-1985

AN AMERICAN NATIONAL STANDARD STAINLESS STEEL PIPE

TABLE 3A NOMINAL WEIGHTS OF STEEL PIPE, PLAIN ENDS -

SI UNITS

Inch

Weight of Steel Pipe, Plain Ends, kg/m

Nominal

dule Schedule Schedule Schedule Pipe

Size 5s 1os 40s 805

'IS 0.28 0.37 0.47

'14 ... 0.49 0.63 0.80

=la 0.63 0.84 1.10

'I2 0.80 1.o0 1.27 1.62

1.O3 1.28 1.69 2.20

1 1.30 2.09 2.50 3.24

1 l/4 1.65 2.70 3.39 4.47

1 112 1.91 3.1 1 4.05 5.41

2 2.40 3.93 5.44 7.48

2v 2 3.69 5.26 8.63 11.41

3 4.51 6.45 11.29 15.27

31'2 5.18 7.40 13.57 18.63

4 5.84 8.36 16.07 22.32

5 9.47 11.57 21.77 30.97

6 11.32 13.84 28.26 42.56

8 14.79 19.96 42.55 64.64

10 22.63 27.78 60.3 1 96.01

12 31.25 36.00 73.88 132.08

14 34.36 41.30

16 41.56 47.29

18 46.81 53.26

20 59.25 68.61 ...

22 65.24 75.53 ... ...

24 82.47 94.45 ... ...

30 118.31 147.36 ... ...

GENERAL NOTES:

(at 1.4895kgim = 1Ib/ft

(b) Weights are given in kilograms per meter and are for carbon steel pipe wtth plain ends.

(c) The dlfferent grades of stainless steel permit considerable variations in weight. The ferritic

stainless steels may be about 5% less, and the austenitic stamless steels about 2 % greater

than the values shown in this table, which are based on weights lor carbon steel.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AMERICANNATIONAL STANDARDS FOR PRODUCT SIZES

Preferred Thicknesses for Uncoated Thin Flat Metals (Under

0.250 In.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 832.1-1 952(R1983)

Preferred Diameters for Round Wire - 0.500 Inches and

Under. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B32.2-1969(R1979)

Preferred Metric Sizes for Flat Metal Products. . . . . . . . . . . . . . . . . B32.3M-1984

Preferred Metric Sizes for Round, Square, Rectangle and

Hexagon Metal Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B32.4M-1980

Preferred Metric Sizes for Tubular Metal Products Other

Than Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B32.5-I 977(R1983)

Preferred Metric Equivalentsof Inch Sizes for Tubular Metal

Products Other Than Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B32.6M-1984

Welded and Seamless Wrought Steel Pipe. . . . . . . . . . . . . . . . . . . B36.1 OM-1985

Stainless Steel Pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B36.19M-1985

The ASME Publications Catalog shows a complete list of all

Standards published

by the Society.

The catalog and binders for holding these Standardsare available upon request.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- Flange AS4087 AS2129 BS Table DEDocument2 pagesFlange AS4087 AS2129 BS Table DEadamNo ratings yet

- ASME B36.19M-2004 (R2010) - UnlockDocument14 pagesASME B36.19M-2004 (R2010) - UnlockadprimNo ratings yet

- KIL3012 - WEEK 3 - 24.9.19 (Student Copy)Document84 pagesKIL3012 - WEEK 3 - 24.9.19 (Student Copy)EdNo ratings yet

- Hardness Conversion ChartDocument34 pagesHardness Conversion ChartAshutosh SinghNo ratings yet

- A338 Steel StandardDocument2 pagesA338 Steel StandardguilhermehsssNo ratings yet

- Fabrication of Counter-Jib Ballast Blocks GuideDocument14 pagesFabrication of Counter-Jib Ballast Blocks GuideNirmalya SenNo ratings yet

- Add02 1060.1Document14 pagesAdd02 1060.1Diego Calderón AlvaradoNo ratings yet

- Overallstructure PDFDocument11 pagesOverallstructure PDFChhoan NhunNo ratings yet

- Is 2041Document8 pagesIs 2041hhr2412No ratings yet

- Astm f1548 1994Document6 pagesAstm f1548 1994dharlanuctcomNo ratings yet

- Asme B18.1.1 2001Document12 pagesAsme B18.1.1 2001Jesse ChenNo ratings yet

- FCA Nozzle Non-Slam Check Valve CatalogueDocument16 pagesFCA Nozzle Non-Slam Check Valve CataloguePatricio AcuñaNo ratings yet

- Product Categories: Fittings, Valves, Clamps & Accessories For Hose, Pipe and TubeDocument35 pagesProduct Categories: Fittings, Valves, Clamps & Accessories For Hose, Pipe and TubeRaj DomadiyaNo ratings yet

- Mech Malleable Iron Fittings Catalogue PDFDocument12 pagesMech Malleable Iron Fittings Catalogue PDFics companyNo ratings yet

- Seamless and Welded Carbon Steel Water-Well Pipe: Standard Specification ForDocument12 pagesSeamless and Welded Carbon Steel Water-Well Pipe: Standard Specification ForKamlesh Vaishnav100% (1)

- A694 A694m-16 PDFDocument4 pagesA694 A694m-16 PDFandresNo ratings yet

- Understanding Australian Flange Standards and Pressure RatingsDocument6 pagesUnderstanding Australian Flange Standards and Pressure Ratingsharikrishnanpd33270% (1)

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- 10742Document10 pages10742satish3393No ratings yet

- Astm 787Document6 pagesAstm 787Anderson TeixeiraNo ratings yet

- HTTP WWW - Wermac.org Fittings Buttweld Fittings Part5Document4 pagesHTTP WWW - Wermac.org Fittings Buttweld Fittings Part5prabu prasad100% (1)

- Sec 05100 - Structural SteelDocument10 pagesSec 05100 - Structural Steeltiju2005hereNo ratings yet

- Wrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForDocument8 pagesWrought Austenitic Stainless Steel Piping Fittings: Standard Specification FormilecsaNo ratings yet

- Dimensions For Fabricated Steel Water Pipe Fittings: AWWA StandardDocument32 pagesDimensions For Fabricated Steel Water Pipe Fittings: AWWA StandardNelson MejiaNo ratings yet

- ASME Code Sections for Nuclear ComponentsDocument10 pagesASME Code Sections for Nuclear Componentspsbgolf04No ratings yet

- Petersenplgpckrcats PDFDocument112 pagesPetersenplgpckrcats PDFEdixon ZambranoNo ratings yet

- Pipe ScheduleDocument1 pagePipe SchedulePrasitPrasittimongkolNo ratings yet

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- NPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'Document3 pagesNPS - 'Nominal Pipe Size' and DN - 'Diametre Nominal'harisNo ratings yet

- Induction Motor SimulationDocument8 pagesInduction Motor SimulationSalah RiahiNo ratings yet

- AISI Type 304L Stainless Steel Material Data - 12676Document1 pageAISI Type 304L Stainless Steel Material Data - 12676Ian Pillay100% (1)

- Pipe Wall Thickness, Hoop Stress and Sustain Stress QuestionDocument10 pagesPipe Wall Thickness, Hoop Stress and Sustain Stress QuestionSharun SureshNo ratings yet

- GMAW Guide for Welding Copper-Base AlloysDocument2 pagesGMAW Guide for Welding Copper-Base AlloysMaulana Mufti MuhammadNo ratings yet

- Jeremias INSTALL DS-GOV PDFDocument28 pagesJeremias INSTALL DS-GOV PDFjudi sierNo ratings yet

- ANSI Fittings WeightsDocument42 pagesANSI Fittings Weightsmatthewwalls4386No ratings yet

- Dimensions of Bolts and Nuts BS3692Document6 pagesDimensions of Bolts and Nuts BS3692azam RazzaqNo ratings yet

- Dimensions of Weld Neck Flanges and Stud Bolts ASME B16.5 NPS 3Document1 pageDimensions of Weld Neck Flanges and Stud Bolts ASME B16.5 NPS 3Hanafi MansorNo ratings yet

- Pipe Schedules and Wall ThicknessesDocument2 pagesPipe Schedules and Wall ThicknessesPGHOSH11100% (1)

- Indian Standard: Specification For Steel ScaffoldingsDocument27 pagesIndian Standard: Specification For Steel Scaffoldingshari6krishnanNo ratings yet

- ASME B16.10 Face To Face and End To End Dimension of ValvesDocument39 pagesASME B16.10 Face To Face and End To End Dimension of ValvesOlieev100% (1)

- Brass Rods - High Tensile Brass Rod, Forging Brass Rod, Free Cutting Brass Rod ManufacturerDocument6 pagesBrass Rods - High Tensile Brass Rod, Forging Brass Rod, Free Cutting Brass Rod Manufacturerk4kuldeepNo ratings yet

- Cupola Malleable Iron: Standard Specification ForDocument4 pagesCupola Malleable Iron: Standard Specification Forali ahmedNo ratings yet

- Bolt Standard BS 3692Document1 pageBolt Standard BS 3692Mai Xuan Truong0% (1)

- AMRI ISORIA 10 Type Series Booklet Data PDFDocument20 pagesAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- Day 6 Welding Process, Electrode - FCAW, GTAW & SAWDocument65 pagesDay 6 Welding Process, Electrode - FCAW, GTAW & SAWRohit Kamble100% (1)

- Standards Scope PDFDocument6 pagesStandards Scope PDFaravindhcamNo ratings yet

- Bolt Pocket ChartDocument2 pagesBolt Pocket ChartAlex LaraNo ratings yet

- .Ar - Catalogo Mangueras Oleohidraulicas PDFDocument40 pages.Ar - Catalogo Mangueras Oleohidraulicas PDFMatiasNo ratings yet

- A126-04 (2014) Gray Iron Castings For Valves, Flanges, and Pipe FittingsDocument3 pagesA126-04 (2014) Gray Iron Castings For Valves, Flanges, and Pipe FittingsJosh HansenNo ratings yet

- As 5081-2008 Hydraulically Operated Automatic Control Valves For Waterworks PurposesDocument7 pagesAs 5081-2008 Hydraulically Operated Automatic Control Valves For Waterworks PurposesSAI Global - APACNo ratings yet

- Asme B16.26 PDFDocument13 pagesAsme B16.26 PDFRuben Dario Mamani Arellano100% (1)

- Process & Piping Design Section Plug Valves Technical SpecificationDocument14 pagesProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- Connection Adapters For Pressure Measuring Instruments Model 910.14Document6 pagesConnection Adapters For Pressure Measuring Instruments Model 910.14sbmmkushanNo ratings yet

- Lista Spec Mss SPDocument4 pagesLista Spec Mss SPginursamadNo ratings yet

- BS 4825-5 - 2009 - Stainless Steel Tubes and Fittings For The Food Industry - Recessed Ring JointsDocument24 pagesBS 4825-5 - 2009 - Stainless Steel Tubes and Fittings For The Food Industry - Recessed Ring JointsroburtrNo ratings yet

- B36.19M 1985 Stainless Steel Pipe PDFDocument13 pagesB36.19M 1985 Stainless Steel Pipe PDFMadidj_2014No ratings yet

- Ansi B36.19Document13 pagesAnsi B36.19BimaNo ratings yet

- Asme B36.10M PDFDocument31 pagesAsme B36.10M PDFSubhash KumarNo ratings yet

- b16 10Document39 pagesb16 10Gustavo FamaNo ratings yet

- b16 34Document121 pagesb16 34Gustavo Fama100% (2)

- Figure Os1700: Keystone Knife Gate ValvesDocument6 pagesFigure Os1700: Keystone Knife Gate ValvesEme Eme LorcaNo ratings yet

- Válvula de Cuchillo Ac CarbonoDocument2 pagesVálvula de Cuchillo Ac CarbonoEme Eme LorcaNo ratings yet

- Willamette Vmc-2200 Cone Valves: Instruction February 2015Document12 pagesWillamette Vmc-2200 Cone Valves: Instruction February 2015Eme Eme LorcaNo ratings yet

- Bombas VerticalesDocument64 pagesBombas VerticalesNicolas Iturrieta BerriosNo ratings yet

- Bombas VerticalesDocument64 pagesBombas VerticalesNicolas Iturrieta BerriosNo ratings yet

- HV CTO Catalog 9AKK107307 RevC en 09-2020 LowerDocument104 pagesHV CTO Catalog 9AKK107307 RevC en 09-2020 LowerEme Eme LorcaNo ratings yet

- Dragflow ProdDocument16 pagesDragflow ProdAssef Zraoura100% (1)

- Dragflow-Datasheet El12.5ss eDocument1 pageDragflow-Datasheet El12.5ss eEme Eme LorcaNo ratings yet

- Dragflow-Datasheet El12.5ss eDocument1 pageDragflow-Datasheet El12.5ss eEme Eme LorcaNo ratings yet

- MV Drop TestDocument5 pagesMV Drop Testrajinipre-1No ratings yet

- Program in Mathcad to Thin Rectangular PlatesDocument12 pagesProgram in Mathcad to Thin Rectangular PlatesPedro Luis Garcia VillegasNo ratings yet

- Building Maintenance TrainingDocument6 pagesBuilding Maintenance TrainingMedian HpNo ratings yet

- PNS 35 Part 1 - PVC Ins. Cu Wires Cable Rated Voltage 600V - THHN - THW - TWDocument24 pagesPNS 35 Part 1 - PVC Ins. Cu Wires Cable Rated Voltage 600V - THHN - THW - TWshivam dwivedi100% (1)

- Exp 4 Chem 17 LabDocument7 pagesExp 4 Chem 17 LabGabrielle CatalanNo ratings yet

- Introduction to PCA and FA: Dimension Reduction ToolsDocument29 pagesIntroduction to PCA and FA: Dimension Reduction ToolsPushpaRasnayakeNo ratings yet

- PSV Calculations FlareDocument0 pagesPSV Calculations FlareSrinivas BobbyNo ratings yet

- All Rac α Tocopheryl Acetate (Vitamin E Acetate) RM COA - 013Document2 pagesAll Rac α Tocopheryl Acetate (Vitamin E Acetate) RM COA - 013ASHOK KUMAR LENKANo ratings yet

- X3 HydrostaticForceOnPlaneSurfaces BautistaDerwinDanielDocument18 pagesX3 HydrostaticForceOnPlaneSurfaces BautistaDerwinDanielNadine Pascual100% (2)

- Summative Test (Physics)Document3 pagesSummative Test (Physics)Allen Paul GamazonNo ratings yet

- Eurotherm 2116Document156 pagesEurotherm 2116jessicrmNo ratings yet

- M/M/1 Queues With Working Vacations (M/M/1/WV) : L.D. Servi, S.G. FinnDocument12 pagesM/M/1 Queues With Working Vacations (M/M/1/WV) : L.D. Servi, S.G. FinnSadek AlaouiNo ratings yet

- An Introduction To Fractional CalculusDocument29 pagesAn Introduction To Fractional CalculusFredrik Joachim GjestlandNo ratings yet

- Water Chemistry PDFDocument24 pagesWater Chemistry PDFravichan_2010No ratings yet

- Electromagnetism: Angelito A. Silverio, EceDocument79 pagesElectromagnetism: Angelito A. Silverio, EceAlmari SantosNo ratings yet

- Elementarysurvey PDFDocument167 pagesElementarysurvey PDFStanley OnyejiNo ratings yet

- Karthik Vickraman: Work ExperienceDocument1 pageKarthik Vickraman: Work ExperienceVishaal KannaNo ratings yet

- Parameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisDocument9 pagesParameter Adaptation of Reduced Order Models For Three-Dimensional Flutter AnalysisAtsis PapadopoulosNo ratings yet

- 2-Gantry Girder Design For Total Dead Load of 175 TonsDocument11 pages2-Gantry Girder Design For Total Dead Load of 175 TonsHarnoor Singh AulakhNo ratings yet

- DC30-010 - ODYSSEY Operator Manual - Rev PDocument92 pagesDC30-010 - ODYSSEY Operator Manual - Rev PYolanda Peña100% (1)

- Nitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's EncyclopediaDocument49 pagesNitric Acid - Nitrous Acid - Nitrogen Oxides - Ullman's Encyclopediapoly6icsNo ratings yet

- Voelz - Newton and Einstein at The Foot of The CrossDocument14 pagesVoelz - Newton and Einstein at The Foot of The CrossEric W. RodgersNo ratings yet

- KNX Fan Coil Actuator REG-K, Light Grey: CharacteristicsDocument1 pageKNX Fan Coil Actuator REG-K, Light Grey: CharacteristicsRazvan RazNo ratings yet

- ConvectionDocument4 pagesConvectionFaheem Fiaz ChohanNo ratings yet

- 2018 Book FractographyAndFailureAnalysis PDFDocument172 pages2018 Book FractographyAndFailureAnalysis PDFDavid Casarrubias A100% (4)

- 11 HW ChemistryDocument6 pages11 HW ChemistryJ BalanNo ratings yet

- Corrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárováDocument6 pagesCorrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárovárachidradouaniNo ratings yet

- Lesson 6-4 Homework Examples 17, 21, 27Document2 pagesLesson 6-4 Homework Examples 17, 21, 27Jay-anne CruzNo ratings yet

- Math 070838Document13 pagesMath 070838Jeric Boy GarampilNo ratings yet

- Energy-Momentum Tensor For The Electromagnetic Field in A Dispersive MediumDocument17 pagesEnergy-Momentum Tensor For The Electromagnetic Field in A Dispersive MediumSamrat RoyNo ratings yet