Professional Documents

Culture Documents

1000 Lit Per Hour, With LPS, Revised Proposal, 12 May 2016

Uploaded by

Mohamed Sayed AbdoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1000 Lit Per Hour, With LPS, Revised Proposal, 12 May 2016

Uploaded by

Mohamed Sayed AbdoCopyright:

Available Formats

PESCO BEAM

Date:12 May 2016 Page 1 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

This is a revised proposal made to Mr. Marwan El Newehy, Executive Manager, Arabian

Company for Services (ACS), 12 Elmurshedy Towers, Bavaria City Ring Road Katameya,

Cairo, Egypt (Tel: +201003222332) for a Used lubricating Oil system that can process 1000 lit/hr

of Used lubricating oil as feed. The proposed plant is complete with all processing equipment that

will recover one cut of lube (distillate) after separating the water, light fuel and asphalt extender in

the Short path distillation system. The proposal includes a regenerative media based lube polishing

system that will polish the distilled base lubes to produce a stable base lube product that will not

darken on keeping.

The proposal also includes the utility packages of Thermic fluid heater, Evaporative cooling tower

and Instrument air compressor. The plant will be fully automated and controlled through a control

computer (PLC) which is included in the scope of PESCO BEAM. Environment mitigation to handle

the VOC’s from the process is part of the system proposed. However, no system to handle the

recovered water is included as part of the scope quoted for.

PESCO BEAM is an international organization having its primary offices in Roanoke, Virginia, USA

and Chennai, India. The plant that is proposed is performance guaranteed and the guarantee is

based on our experience of having supplied more number of operating used oil re-refineries, world-

wide, than any other company. The system offered is the result of this global experience.

All information and details given in this proposal are confidential and should not be copied or

shared with anyone without the express permission of PESCO BEAM except for the purpose of

ordering the system with PESCO BEAM.

PESCO BEAM will be pleased to answer any questions on this proposal and thank ACS, Egypt for

the opportunity to participate in this project.

For PESCO BEAM Environmental Solutions Pvt Ltd

A.Subramaniam

Managing Director & Co-Founder.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 2 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

ONE VIEW OF A PESCO BEAM USED OIL RE-REFINERY

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 3 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

BASIS

PROCESSING CAPACITY:

The plant is designed and sized to process 1000 lit per hour of used lube oil feed on a continuous

basis (8000 hrs per year).

FEED CHARACTERISTICS:

The output specifications are based on a typical feed which will be Used motor oil and having

mostly about 5% water. The product recovery percentage given in this proposal is however based

on an average 5% water and calculated on dry basis (after removal of 5% of water) so that the

percentage of water in feed, will not influence the recovery data.

PRODUCTS:

From a typical feed as specified above, the plant will produce the following on dry basis:

~ 14% Lights [Mixture of Naphthalene, Gasoline, Kerosene, Diesel];

~ 70% or more of medium and longer chain hydrocarbons as one cut of distillate;

~ 16% Asphalt extender which will contain the solids and Asphaltenes.

Note: The product rate and characteristics are completely dependent on the feed properties. Thus

if the feed is predominantly long chain hydrocarbons or lube oil of heavier grade, such will be the

distillate.

TYPICAL KEY PARAMETERS OF FEED

Typical key data of feed considered is as follows:

Water content Not more than 5%

Viscosity at 40 deg C 83 to 85 cSt

Viscosity at 100 deg C 10 to 12 cSt

Sulfur 0.89%

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 4 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

PRODUCT SPECIFICATIONS

Based on a typical feed, typical product data is as follows:

Lights [a mixture of naphthalene, toluene, benzene, xylene, Kerosene & Diesel]

Parameter Method Value

Kinematic Viscosity @ 40 deg C max. Cst ASTM D 445 3.3

Cetane 60 – 70

Flash Point, deg C ASTM D 93 <10

Calorific Value, Mj / kg, minimum 45

Sulphur % wt, maximum ASTM D 1551 0.7

Water % vol., maximum ASTM D 95 0.25

Color, maximum ASTM D 1600 4

Density @ 15 deg C, kg/l, maximum ASTM D 1298 0.8

Carbon residue, % wt, maximum ASTM D 189 1.0

Pour point, maximum, deg C ASTM D 97 15

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 5 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

Re-refined and Polished base lube analysis*

Tests Method Results

Distillate Polished product

Appearance Visual Dark honey colored Clear brown liquid

Density @ 15oC, Kg/Lit Gravimetry ~0.85 ~0.85

Conradson Carbon ASTM D 189-06 0.14 0.14

Residue, % wt

ASTM Color ASTM D 1500-07 ~6 ~4

Flash point (COC), oC ASTM D 92-05a >210 >210

Copper strip corrosion @ ASTM D 130 1a 1a

100oC

Total Acid Number, mg ASTM D 974-07 0.11 0.11

KOH/g

Total Base Number, mg ASTM D 974-07 1.63 1.63

KOH/g

Pour Point, oC ASTM D 97-07 Less than minus 15 Less than minus 15

Sulphur, % wt / ppm ASTM D 4297-03 ~ 0.83% ~ 0.75%

Viscosity, Kinematic at ASTM D 445-06 ~ 45 -50 ~ 45 - 50

40oC, cSt

Ash Content, % wt ASTM D 482-07 0.01 0.01

*These data may be used as guiding values and are not performance guarantees. Depends on

feed properties. Performance guarantee figures are given later in this proposal as an annexure.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 6 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

Residual: #6 Industrial Boiler Fuel or Asphalt extender

Parameter Method Value

Viscosity @ 40o C: CsT, maximum ASTM D. 445 95

Density at 15o C, kg/l, maximum ASTM D.1298 0.98

Sulphur % wt ASTM D. 1551 1.5

Water % vol., maximum ASTM D. 95 0.1

Flash Point, oC, minimum 70o C

Color Black, opaque

Carbon Residue % wt, maximum ASTM D.4530 12%

TAN mg/KOH/g ASTM D.974 Nil

Pour Point, maximum ASTM D.97 18o C

Calorific Value, MJ/Kg, minimum 43.8

Metals Ppm

Lead 10-120,000

Calcium 6000-38000

Barium 20-16000

Zinc 6000-15000

Iron 100-6000

Phosphorus 1100-6000

Magnesium 350-5000

Copper 10-1200

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 7 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

THE PROCESS AND PLANT: BRIEF NARRATIVE

Distillation & Evaporation System

The feed pump will pump the used lube oil feed stream into the forced circulation evaporator loop.

In this loop the water, aromatics and diesel / kero fractions will evaporate. These fractions will exit

the loop, condense in the condenser, and drop into the decanting light ends receiver circuit. The

lights which will be a mixture of naphtha, kero and diesel fractions, and recovered water will be

pumped to storage via a differential density level controlled arrangement.

The dirty de-watered feed will be pumped into the wiped film evaporator. The medium-and long

chain hydrocarbons will vaporize and will exit through a condenser to a product receiver and will be

pumped to storage. The residual, which contains the solids and tars (asphalt extender), flows by

gravity out of the evaporator to a pump, from where it will be pumped to its storage.

A vacuum skid consisting of vacuum pumps and boosters and several accessories will supply

vacuum as required, to the different stages of the process.

The source of process heat will be thermic fluid heater, which will be supplied by PESCO BEAM.

Cooling water at the required temperature and flow will be supplied using a Cooling tower, also

part of PESCO BEAM’s scope of supply.

Compressed Instrument grade @ 20 cfm at 7 bar pressure will be required for operating the

pneumatic instruments of the system and will be supplied by PESCO BEAM.

The plant offered is complete with a thermal oxidation system for preparing the VOC emissions

from the process to be fed to the heater box of the thermic fluid heater for complete combustion

before being exhausted to the stack.

The system will be supplied fully assembled on several painted carbon steel skids with all hot

surfaces insulated. The skids will be prewired and piped complete with the instruments and

controls with flanged terminal connections that will be ready to be hooked to field piping. The plant

will be PLC controlled for automatic operation through a control computer. All the electrical and

electronic components on the skid will be flame proof, suitable for gases in Groups II A & B.

Included will also be non-explosion proof control panels containing all the necessary thermal

overloads and control modules, all for remote location [more than 50 feet from the skid]. All the

wetted surfaces will be Carbon steel (Boiler quality) unless otherwise specified. The system will

come insulated and ready to hook up to the infrastructure of Thermic fluid, cooling water,

electricity, instrument air, and storage tanks. The system can be located outside even though we

recommend a roof and side cover for protection from winds and sand storms.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 8 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

Lube polishing system (LPS):

The LPS offered will polish the distillate recovered from the system. At rated feed rate of wet oil at

1000 lph, lube fraction distillate recovered will be ~ 700 lph and the polishing system will accept

this as the feed rate. Reduction in color from a feed rate color of ~ 6 to a product color of 4 and

removal of odour will be the performance of the LPS offered. The recovered oil will be a stable

base oil. It should however be noted that lighter colored product can be achieved but at the cost of

capacity.

About 10 - 12% of the feed to the LPS will not be available as polished product. Less than 2% will

be the invisible loss as vapor during the reactivation process and the balance will be collected as

the liquid residue during the reactivation phase. This will be recycled to the feed tank. It should be

noted that this recycle is needed as the system removes color and other odour causing

ingredients. It should also be noted that when the plant is operated for lower polished product color,

shorter polishing times, more frequent drains/reactivation will be required and therefore more

material will be recycled.

The LPS operates in two phases:

1. Processing Phase: In this phase, the oil is polished by forced percolation through "adsorptive

media" columns. The system comprises of multiple banks of multiple columns each.

2. Reactivation Phase: After the polishing cycle, the media beds are usually quite saturated and

the feed and product color approach each other. This justifies reactivation. The media is

reactivated in the columns and a quantity of oil is collected and pumped for reprocessing

(drain). VOC’s that are generated during this reactivation phase are treated in the Thermal

oxidizer and fed to the fire box of the thermic fluid heater for complete combustion.

The system shall be fully assembled on heavy duty steel bases. The system will be designed to be

operated through a PLC.

It needs to be noted that when the media is spent, it needs to be replaced. Such replacement of

the media will be once in ~180 days depending on the type of oil being processed and the care

with which the system is operated. The spent media is a non-hazardous land fill and will have no

oil – it will pose no disposal issue and the quantity will be a small amount as it needs to be

disposed only once in 4-6 months. Combined with the excellent quality & stability of the polished

base lube, this feature renders the regenerative lube polishing system offered, unique and of very

special design. It also needs to be highlighted that this system is very different from the standard

systems offered by others, both in its process, design, fluid mechanics and operation.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 9 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

ENVIRONMENTAL IMPACT

Exhaust from the plant:

1. The exhaust from the vacuum pump vent, and Lube polishing system: These will consist of

VOC’s and some sulfur compounds. The total flow rate is low, and will depend on the types

of oil being processed, but because they can cause odor they will be handled via a thermal

oxidation piping train (TOX) and sent to the fire box of the thermic fluid heater for complete

combustion. An active carbon filter alternative is provided and the vent will be automatically

diverted to the carbon filter if the Thermic fluid heater trips.

Recovered water:

At 5% water in feed, ~ 50 lit/hr water (recovered from the feed oil) containing trace (<2%)

hydrocarbons needs to be disposed off by the client in the existing ETP or as appropriate. No

equipment is included in the scope of this proposal for this disposal.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 10 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

SCOPE OF PESCO BEAM

(Please see attached PFD for further clarity)

Item head Deliverables

System Engineering 1. Plant layout on plot plan.

(to be provided in a 2. Foot print with load data

phased manner after 3. Electrical lists

commercial closure of 4. Final documentation of all supplies which will include Operation

contract) & Maintenance manuals which will include ordering

specifications for all spares.

Supplies 1. Skid mounted processing plant complete with equipment and

interconnecting piping within each of the skids.

2. All measuring and control instruments for the processing plant

within each of the above skids.

3. All electrical and instrument cabling inside each of the skids

terminated in skid junction boxes on the skid.

4. Thermal oxidation system consisting of the piping train and

alternate carbon canisters to handle the VOC and feed it into

the thermic fluid heater of client.

5. Regenerative Lube polishing system, skid mounted complete

with its internal wiring, instrumentation, controls.

6. Motor Control Center (panels) for remote location for the

processing plant supplied by PESCO BEAM.

7. PLC controller and control computer for the processing plant

fully integrating the plant with utilities and tank farm operation.

8. Used oil feed pump with its motor for location in the tank farm.

9. Thermic fluid heater (Hot oil generator) complete with

modulating burner and controls.

10. Evaporative cooling tower.

11. Cooling water circulation pump with its motor for location near

the Cooling tower.

12. Thermic fluid circulation pump with its motor for location near

the thermic fluid heater.

13. Thermic fluid expansion tank with all necessary piping.

14. Thermic fluid dump tank.

Services 1. Discussion with your project engineer at site for finalizing the

site layout.

2. Start-up and Commissioning of the plant.

3. Training in plant operation: Will be provided during

commissioning. We expect that adequate numbers of properly

qualified and experienced crew will be available to receive this

training in the process and control of the plant.

4. Follow-up visits to site if needed on per diem basis.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 11 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

BATTERY LIMITS OF PESCO BEAM

(Please see attached PFD for further clarity)

The following narration is to clearly mention the battery limits of each unit that is being supplied to

you as part of this proposal. Please refer PFD attached for additional clarity:

Item head Battery limit

Process skids Flanged connections for the entry and exit of process

fluid, Thermic fluid, Cooling water and Instrument air.

Electrical and Instrumentation junction box(es) that will

have all the instrument and electrical wiring of that

skid, terminated as per terminal strip numbering

Feed pump Stand alone pump with motor mounted on a base

frame for location in the tank farm.

Thermic fluid heater Flanged entry for the fuel;

Flanged entry for the VOC’s from the TOX;

Flanged connection for the entry and exit of the

Thermic fluid;

Flanged exit for the exhaust from the heater.

Thermic fluid heater circulation Flanged entry and exit of the Thermic fluid.

pump

Cooling tower Entry and exit of the water to and from the tower;

Blow down valve outlet

Cooling water circulation pump Flanged entry and exit of the water from the pump.

Motor Control Center (Process Fully wired stand-alone control centers with all wiring

MCCs) terminated inside the MCC according to terminal strip

numbering.

PLC Controller (Process) Fully wired center, stand alone, with control computer

and control card.

Regenerative Lube polishing Flanged connections for the entry and exit of the oil to

system (LPS) be polished, Cooling water, Recycle, exhaust gases to

Thermal oxidation system;

Marshalling box(es) that will have all the instrument

and electrical wiring of that skid, terminated as per

terminal strip numbering.

Thermal Oxidation system Flanged connection for the entry of VOC vapours from

Vacuum skid, Tank farm and LPS;

Flanged connection for the exit of these vapours into

the fire box of thermic fluid heater / fail safe-carbon

canisters.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 12 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

CLIENT SCOPE OF WORK

(Please see attached PFD for further clarity)

Item head Deliverables

Engineering 1. Supply of plot plan of site;

2. All civil engineering designs, foundation designs, building

designs;

3. Electrical design and engineering for incoming power, and

electrical house ready for distribution of this power;

4. Plumbing and sanitation engineering for the project;

5. Fire safety design and engineering;

6. Air conditioning design and engineering;

7. Laboratory design and engineering.

Tank farm 1. Fabrication and erection of all tanks in the tank farm;

2. Supply and erection of all tank farm pumps as per process

requirement to be discussed and agreed upon;

3. Supply and mounting of all tank farm instruments that will

be integrated with the PLC, again as per P&ID to be

provided.

Yard piping 1. Fabrication and erection of Interconnecting piping between

thermic fluid heater, Cooling tower and Instrument Air

compressor and the processing plant;

2. Fabrication and erection of Interconnecting piping between

tank farm, utilities and processing plant;

3. Insulation as required, of the above piping

Field electrical and 1. Laying and termination of electrical wires and cables from

Instrumentation wiring electrical house equipment to the various points in the plant

and to the plant MCCs.

2. Laying and terminating all instrumentation cabling between

panel/PLC and skids/tank farm/utilities/piping as needed.

Plant chimney 1. Fabrication and erection of main chimney and any other

auxiliary chimneys of the plant.

Other Supply 1. Developed land with all civil and structural works, access

platforms, walk ways;

2. Electrical house with necessary switch gear and panels

ready for distribution of power to all points in the site;

3. All civil works and foundations;

4. Cable trenches as required for piping, wiring distribution;

5. Concrete slabs as necessary;

6. Water storage sump/tank;

7. Used oil receipt arrangement;

8. Product load out arrangement;

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 13 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

9. Fully functional laboratory;

10. Lighting and air-conditioning for 24 hr operation;

11. Fire safety equipment and all related accessories as

erected and conforming to local regulations;

12. Continuous feed to plant, fuel, water, all lubricants and

greases as per PESCO BEAM recommendation, Feed oil of

appropriate quality and quantity; Thermic fluid;

13. Activated carbon as per quantity and quality to be specified.

Services 1. Erection of all PESCO BEAM supplies.

2. Connecting PESCO BEAM supplies to utilities and tank

farm.

3. Furnished air-conditioned accommodation for two/three

engineers/technicians near site during their visits for pre-

erection site discussions, supervision of erection/loop

checks/start-up/commissioning/training of your operators;

4. Transport for our engineers to and from site during visit and

their stay at site;

5. All applicable taxes, duties and permits at destination

country;

6. All required licenses, permits for the project;

7. Dealing with all local authorities on all issues related to the

project and site work;

8. Transport from Chennai Port, Shipping insurance, Receipt

at port of destination, clearing, local transport, receipt at

site, unloading and safe keeping of all PESCO BEAM

supplies;

9. Providing adequate and appropriately skilled personnel pre

and post start-up.

10. Providing appropriate communication facilities like internet

connectivity and a working desk to our site personnel during

project tenure.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 14 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

SUPPLY CONDITIONS

1. The various items in the scope of supply of PESCO BEAM will be skid mounted or if shipped

as loose items [like instruments that will damage during transit], packed carefully for sea-

worthy transport.

2. These will be sent in container, as per a packing list that will accompany each supply and also

be provided with the shipping documents.

3. The skids will be loaded in PESCO BEAM shop [Chennai, India] on local road transport for

transport to Port of Origin (Chennai, India).

4. As freight costs vary based on several conditions, it is our usual practice to forward actual

costs to the client prior to shipment. PESCO BEAM has not included in its scope, the following:

a. Sea Freight from Port of origin to Port of destination.

b. Shipping / Transit insurance.

c. Receipt and clearance at Port of destination.

d. Transport from port of destination to site.

e. Any and all related insurance.

5. For purposes of estimating freight, the shipment can be considered to involve:

a. 7 Open top 40 foot containers (out gauge); and,

b. 1 Open top 40 foot container (in gauge).

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 15 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

UTILITY REQUIREMENT

No Item head Quantity Period Remarks

1 Space 15m x 15m One time Does not include space

RCC Pad for required for tank farm,

Distillation – utilities, control room.

needs no

roof

16m x 15m Side walls of the shed

RCC pad needs to be open to allow

with roof for cross ventilation.

LPS.

2 Electric power

2.1 Connected load, 440V, 3ph, 50Hz ~ 150 kW One time Only for PESCO BEAM

scope of supply.

2.2 Consumed power ~110 kW Per hour Only for PESCO BEAM

scope of supply.

3 Fuel as LDO for the Thermic fluid 80 lit Per hour

heater

4 First fill & Make up water for First fill will be 7500 lit and evaporation loss make-up will

Cooling tower be 250 lit per day.

5 Instrument air (Client scope) 20 cfm compressed air at 7 bar and minus 40 deg C dew

point.

6 Caustic for dosing 3.5 lph of 25% caustic in water (Sp Gr of 1.25)

First fill and make-up requirements of other major consumables;

No Item head Quantity Period Remarks

1 Thermic fluid first fill ~ 5000 lit Assumes a particular layout.

2 Polishing media ~9,000 kg Once in Actual cycle time can be

~120 to more or less depending on

180 days feed. First fill with supply. $

4.00 per kg F.O.B US Port.

3 Activated Carbon

3.1 First fill 660 kg First fill US$ 2.00/kg F.O.B. Chennai,

India.

3.2 Replacement requirement 330 kg 3 months Cyclic replacement

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 16 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

COMMERCIAL TERMS OF OFFER

BASIS OF All prices are in US Dollars, FOB Chennai, India. All applicable duties in

PRICES country of destination, shipping charges, transit insurance, freight from port of

discharge to site, any insurance for such carriage will be extra to your account.

SHIPPING The system will be ready for shipping within six months from the start date as

defined below. This includes 1 week of QC at our shop by engineer from the

US.

START DATE The Start date of the contract will be the later date of the following events:

1. Signing of the contract by both parties

2. Receipt of down payment and Letter of Credit

PAYMENT All remittances shall be by wire transfer to PESCO-BEAM Environmental

TERMS Solutions as per transfer information to be provided:

10% as down payment with your order

Balance through a transferable, irrevocable letter of credit drawn on a first

class bank. The letter of credit will allow transshipment as all shipment from

Chennai will get transshipped at other ports on their voyage. This Letter of

Credit will pay as follows:

10% against completion of engineering as witnessed by an engineering

meeting at Chennai. Engineering documents will be handed over and

signed off as complete and will be the document witnessed by the LC

for payment;

30% when work on the manufacturing is 50% comp0lete and witnessed

by the following:

All major raw materials will be ordered and fabrication

work on all the equipment will be under progress;

All pumps, valves and instruments will be ordered.

30% when complete plant is ready for shipping and inspected by your

engineer at our shop. The inspection will also be signed off by our US

engineer and such inspection report will be the document that will

trigger the payment through the LC;

5% when the plant is erected at site and is ready for commissioning;

5% when the plant is commissioned or 120 days from shipping,

whichever is earlier and against an Indemnity bond issued by PESCO

BEAM, indemnifying ACS against defects in performance, for a period

of 12 months from the date of commissioning.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 17 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

WARRANTY/ The system is guaranteed to generally perform as specified in this offer.

GUARANTEE Specific performance guarantee parameters will be agreed to after feed quality

is tested and will be demonstrated over a 24 hr run during commissioning. An

indicative document is annexed with this proposal.

The following provisions will have to be made while checking the guarantees:

All customer supplied utilities match requirements specified.

A PESCO BEAM representative is present during start-up for 2 weeks

The customer’s employees will work as per instructions given by our

commissioning engineer, follow good engineering practices and follow

the operation and instruction manual in running and maintaining the

plant.

The plant supplied is Guaranteed to perform as specified in this proposal.

Components will be guaranteed by PESCO BEAM for a period of One year

from the date of receipt at Port of destination plus 30 days to allow for erection

and start-up, or from the date of commissioning – whichever is sooner - normal

wear and tear exempted. If commissioning is delayed due to fault of PESCO-

BEAM then the date of commissioning will be the start date of the warranty

period, no matter when that is. Seals and bearings and indicating lamp bulbs

will carry only a limited warranty of 60 days unless specified otherwise by the

manufacturers. If they fail within this period they will be shipped free of any

cost. The warranty on component and accessory items not manufactured by

PESCO BEAM is that extended by the manufacturer of such component or

accessory.

Our liability is also limited to replacement or repair of any defective

components and we are not liable for any damage to personnel, property or

loss in production.

SYSTEM The manufacture is envisaged under our stage-wise internal inspection. Your

INSPECTION company representatives are welcome and encouraged to inspect the

completed system prior to shipment. That way all questions can be answered

and any last minute changes made, prior to the system leaving our plant. No

third party inspection is envisaged unless specifically accepted by PESCO

BEAM.

AMENDMENTS Should any changes in scope of supply be required after the contract is signed

OR CHANGES / LOC released, we reserve the right to have the price and terms adjusted to

accommodate the change. If the changes required are of major nature and

cannot be implemented, we reserve the right, not to implement such changes.

FORCE The performance of this Agreement, except for the payment of money for

MAJEURE services already rendered, may be suspended by either party in the event the

performance of obligations are prevented by a cause or causes beyond the

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 18 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

reasonable control of such party. Such causes shall include, but not be limited

to, acts of God, acts of war, riot, fire, explosion, accident, flood, or sabotage;

lack of adequate fuel, power, raw materials, labor or transportation facilities;

governmental laws, regulations, requirements, orders or actions; breakage or

failure of machinery or apparatus; national defense requirements; injunctions or

restraining orders; labor trouble, strike, lockout or injunction (provided that

neither party shall be required to settle a labor dispute against its own best

judgment).

The party asserting a right to suspend performance under this Section must,

within a reasonable time after he has knowledge of the effective cause, notify

the other party of the cause for suspension, the performance suspended, and

the anticipated duration of suspension. Upon receipt of such notice advising of

a material or indefinite suspension of performance, and if such suspension

substantially impairs the value of this Agreement to him, a party may, within a

reasonable time (not to exceed thirty days), terminate this Agreement. If such

notice of termination is not provided, this Agreement will lapse with respect to

any performance suspended hereunder.

The party asserting a right to suspend performance hereunder shall advise the

other party when the suspending event has ended, and when performance will

be resumed.

JURISDICTION The contract resulting from this proposal will be governed by the laws of the

Republic of India.

VALIDITY This offer is valid till 27 May 2016 and will be valid beyond this date only if it is

duly extended in writing by PESCO BEAM.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 19 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

PRICE SCHEDULE

All figures in US Dollars

Item head Value in US$

Used motor Oil re-refining system as described in this proposal complete

with Lube polishing System and utility package of Thermic fluid heater,

cooling tower and Instrument air dryer.

996,000

[ US$ Nine hundred and ninety six thousand]

Per diem rates for the deputation of engineers / technicians beyond what is contracted

Compensation for our Engineer/Technicians for site work, beyond what has $500

been stated as part of this proposal will be per day (8 hrs)

Travel expenses, Supplies and Materials, Special Handling, Subcontract and Specialty services

will be at Cost + 12%

Payment terms for above service: 100% as an advance for the time you require them

Other conditions: If it is an extension of their stay at site, no to and fro charges will need to be paid.

Otherwise, to and fro economy class air fare, boarding and food for the period of stay as well as

free local transport will be paid by you. They should also have access to international telephone(s),

fax and internet facilities.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

PESCO BEAM

Date:12 May 2016 Page 20 of 20

Revised proposal for a Used lubricating oil re-refinery of 1000 lit/hr processing capacity

Client: Arabian Company for Services, Cairo, Egypt

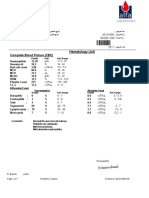

ANNEXURE 1: PERFORMANCE GUARANTEES

Such guarantees will be the average data from a 24 hour run of the plant during commissioning

and after the plant stabilizes. These data will be based on operator log/field data and laboratory

analysis.

1. Capacity of the distillation section of the plant: 1000 lph feed rate on a continuous basis with a

lube distillate yield of 70% on a dry basis.

2. Lube polishing System capacity: Feed rate of 700 lph

3. Lube oil distillate / Polished lube key properties based on feed data given in this proposal:

Tests Method Results

Distillate Polished product

ASTM Color ASTM D 1500-07 ~6 ~ 4.0

Flash point (COC), oC ASTM D 92-05a >210 >210

Viscosity, Kinematic at ASTM D 445-06 50 50

40oC, cSt

4. Utilities:

4.1. Fuel consumption: 80 lph

4.2. Power consumption: 110 kW/Hr averaged over 24 hrs.

PESCO BEAM Environmental Solutions Inc.,

US Office: 1005 Industry Circle, S. E, Roanoke, VA 24013. Tel: +1 540 206 2788; Fax: +1 540 206 2791.

India Office: 136 Thodugadu Village, Sriperumbudur 602105. Tel: +91 44 271 55 555; Fax: +91 44 271 55 502

Web site: www.pescobeam.com

You might also like

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Turbine Oil PresentationDocument30 pagesTurbine Oil PresentationVahidNo ratings yet

- Rop 10 Ton Per Day Internal Tanpa LahanDocument26 pagesRop 10 Ton Per Day Internal Tanpa Lahanhadi prasetio100% (1)

- Dewmare Marine Oil 4040Document1 pageDewmare Marine Oil 4040ednsmnNo ratings yet

- Mobil1-ESP - Formula 5w-40Document2 pagesMobil1-ESP - Formula 5w-40Leonardo DiazNo ratings yet

- Compare WFE TFE Dan Vacuum - OKDocument5 pagesCompare WFE TFE Dan Vacuum - OKimronmasfruriNo ratings yet

- Cat Biodiesel Presentation-NY - 03-13-07Document27 pagesCat Biodiesel Presentation-NY - 03-13-07Pablo Luis Pérez PostigoNo ratings yet

- Engine Oil Test Results and Recommendations To Interkels - 07082019Document2 pagesEngine Oil Test Results and Recommendations To Interkels - 07082019Georgina SuleNo ratings yet

- Aqualub 3040 Sae 30 TBN 40Document1 pageAqualub 3040 Sae 30 TBN 40selett0No ratings yet

- Repsol DXR 8 - 1 v1 15w40Document1 pageRepsol DXR 8 - 1 v1 15w40thrharsrgNo ratings yet

- Emd645 Mi1750 PDFDocument4 pagesEmd645 Mi1750 PDFAmin AminiNo ratings yet

- WL CNG MOTOR ENGINE OIL PDS - AsdDocument1 pageWL CNG MOTOR ENGINE OIL PDS - AsdAung Myat ThuNo ratings yet

- HPR Diesel 20w-60 (Mineral)Document2 pagesHPR Diesel 20w-60 (Mineral)faisiiNo ratings yet

- 4220-110411-000 Performance Test Procedure QassimDocument13 pages4220-110411-000 Performance Test Procedure QassimqaiserNo ratings yet

- Pds Etro 4plus 2022.01Document1 pagePds Etro 4plus 2022.01Samee84No ratings yet

- Lubrico Titanium C6 Hoja TecnicaDocument1 pageLubrico Titanium C6 Hoja TecnicaArnaldo EscalonaNo ratings yet

- LUBRIZONIC LZ-1622 Hydraulic Oil AdditiveDocument1 pageLUBRIZONIC LZ-1622 Hydraulic Oil AdditiveMuhammad WaqasNo ratings yet

- Requirements and Oil Quality: Installation ManualDocument10 pagesRequirements and Oil Quality: Installation ManualABDUL REHMAN PIPRANINo ratings yet

- Rentar Fuel Catalyst BrochureDocument4 pagesRentar Fuel Catalyst BrochureMuhammad Asim ShabbirNo ratings yet

- Power-DI Plus: Supreme Performance Heavy Duty Diesel Engine OilDocument2 pagesPower-DI Plus: Supreme Performance Heavy Duty Diesel Engine Oilgal182avaNo ratings yet

- High Solid PU Dispersion FormulationDocument3 pagesHigh Solid PU Dispersion FormulationBudhi NuryantoNo ratings yet

- Eastman 2380 Tech SheetDocument2 pagesEastman 2380 Tech SheetAndy MaxNo ratings yet

- Fuel From WasteDocument20 pagesFuel From Wasteviswam100% (1)

- Technical Data Sheet Heavy Aromatics: Garosol 150: Ganga Rasayanie (P) LTDDocument1 pageTechnical Data Sheet Heavy Aromatics: Garosol 150: Ganga Rasayanie (P) LTDUnpublished PoemaNo ratings yet

- Test Specifications For Biodiesel FuelDocument6 pagesTest Specifications For Biodiesel FuelYariela CedeñoNo ratings yet

- Enviro+ DPF Cleaner: Product Code Pack Size Carton QtyDocument2 pagesEnviro+ DPF Cleaner: Product Code Pack Size Carton QtyGary LittleNo ratings yet

- SP Marino LC 5040: Lubricating Oil For Slow Speed 2-Stroke Engine CylindersDocument2 pagesSP Marino LC 5040: Lubricating Oil For Slow Speed 2-Stroke Engine CylindersSinh LeNo ratings yet

- Everest 170 Synthetic Refrigeration Lubricant: Data SheetDocument3 pagesEverest 170 Synthetic Refrigeration Lubricant: Data SheetPhan Thiện HảoNo ratings yet

- Tds 1112105 enDocument2 pagesTds 1112105 enCadar CatalinNo ratings yet

- Sae 20W50 Dana Semi Synthetic Oil Gasoline Engine PDFDocument2 pagesSae 20W50 Dana Semi Synthetic Oil Gasoline Engine PDFChemilomNo ratings yet

- Gas Compressor OilDocument1 pageGas Compressor OiltribolasNo ratings yet

- Elite Evolution POWER 4 5W-30: LubricantsDocument1 pageElite Evolution POWER 4 5W-30: Lubricantstehnicar1No ratings yet

- Product Data Sheet: Mobil Jet Oil IIDocument2 pagesProduct Data Sheet: Mobil Jet Oil IIGiang NguyenNo ratings yet

- Mirr Turbo Deo Api CH-4 Sae 10W-30, 15W-40 & 20W-50 TDSDocument2 pagesMirr Turbo Deo Api CH-4 Sae 10W-30, 15W-40 & 20W-50 TDSSimon CloveNo ratings yet

- PDS Pso Gearled EpDocument1 pagePDS Pso Gearled EpMuhammad EhsanNo ratings yet

- Hhi HSM SL 14 001Document15 pagesHhi HSM SL 14 001PranabNo ratings yet

- TDS Sinopec HP-R Grease enDocument2 pagesTDS Sinopec HP-R Grease ennghiaNo ratings yet

- Operator Training-Eng (Compatibility Mode)Document31 pagesOperator Training-Eng (Compatibility Mode)jendriko100% (1)

- Esso Torque Fluid 62: Product DescriptionDocument2 pagesEsso Torque Fluid 62: Product Descriptionhoussem houssemNo ratings yet

- Tds 1111147 enDocument2 pagesTds 1111147 enCadar CatalinNo ratings yet

- Nexbase Base - Oils - 2018 - Online - 0Document6 pagesNexbase Base - Oils - 2018 - Online - 0RMascilNo ratings yet

- REPSOL GXR EURO 5W40 v1 1Document1 pageREPSOL GXR EURO 5W40 v1 1Yousra MenotyNo ratings yet

- Mobil Delvac 1 5W-40 (PDS)Document3 pagesMobil Delvac 1 5W-40 (PDS)Vikram SinghNo ratings yet

- Diesel Engine Oil Sae 40Document2 pagesDiesel Engine Oil Sae 40Wahib AlbazNo ratings yet

- 6) Pyrocrat - Systems PresantationDocument26 pages6) Pyrocrat - Systems Presantationdvmahida78No ratings yet

- MIRR TO-4 Transmission Oils 50, 40 & 30Document2 pagesMIRR TO-4 Transmission Oils 50, 40 & 30MATHEW JOSENo ratings yet

- Cepsa Diesel Turbo 15W40Document1 pageCepsa Diesel Turbo 15W40RamonNo ratings yet

- Dana Lubricants Factory LLC - Lubricants Lubricating Engine Oil Manufacturer in Dubai UAEDocument24 pagesDana Lubricants Factory LLC - Lubricants Lubricating Engine Oil Manufacturer in Dubai UAEankurdanaNo ratings yet

- LZ 7077 Pds PDFDocument4 pagesLZ 7077 Pds PDFNadia Salem100% (2)

- LZ 7077 Pds PDFDocument4 pagesLZ 7077 Pds PDFNadia SalemNo ratings yet

- BiodieselFuelQuality NelsonDocument43 pagesBiodieselFuelQuality NelsonManisha JourwalNo ratings yet

- Indian Standard Specification For Petroleum Products-2019Document15 pagesIndian Standard Specification For Petroleum Products-2019Ganesh BhandaryNo ratings yet

- PDS - ETRO 6plus - 2022.01Document1 pagePDS - ETRO 6plus - 2022.01Sawan TaylorNo ratings yet

- MAK Hydrol CEDocument2 pagesMAK Hydrol CEannamalailubesNo ratings yet

- 209-Titan PSW 12Document2 pages209-Titan PSW 12jafaristsNo ratings yet

- AP IN Mobil Super Diesel TM CI 4 Plus 15W40Document2 pagesAP IN Mobil Super Diesel TM CI 4 Plus 15W40Sandeep NikhilNo ratings yet

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- D1308 Overhead Line - 20191126140042Document2 pagesD1308 Overhead Line - 20191126140042Mohamed Sayed Abdo0% (1)

- Att HMB1Document111 pagesAtt HMB1Mohamed Sayed AbdoNo ratings yet

- LabDocument3 pagesLabMohamed Sayed AbdoNo ratings yet

- Corona Virus Rotation Plan Rev 5Document2 pagesCorona Virus Rotation Plan Rev 5Mohamed Sayed AbdoNo ratings yet

- Exhibitors List XXXIX FinalDocument110 pagesExhibitors List XXXIX FinalMohamed Sayed AbdoNo ratings yet

- Equipment:: (Feed 120000 Bbl/yr About 14000 M /yr)Document8 pagesEquipment:: (Feed 120000 Bbl/yr About 14000 M /yr)Mohamed Sayed AbdoNo ratings yet

- حوار مع صديقى الملحد PDFDocument47 pagesحوار مع صديقى الملحد PDFمحمد مصطفى لولحNo ratings yet

- Component Properties (Sheets: 1) 2. Molar Material BalancesDocument2 pagesComponent Properties (Sheets: 1) 2. Molar Material BalancesMohamed Sayed AbdoNo ratings yet

- Sulfiding CurveDocument4 pagesSulfiding CurveMohamed Sayed AbdoNo ratings yet

- LayoutDocument1 pageLayoutMohamed Sayed AbdoNo ratings yet

- 2018 Work Rotation Schedule: January 2018Document8 pages2018 Work Rotation Schedule: January 2018Rose AriantiNo ratings yet

- Component Properties (Sheets: 1) 2. Molar Material BalancesDocument2 pagesComponent Properties (Sheets: 1) 2. Molar Material BalancesMohamed Sayed AbdoNo ratings yet

- Log 20190305Document66 pagesLog 20190305Mohamed Sayed AbdoNo ratings yet

- U.27-ARU1 Performance MonitoringDocument32 pagesU.27-ARU1 Performance MonitoringMohamed Sayed AbdoNo ratings yet

- U22 Equations SampleDocument4 pagesU22 Equations SampleMohamed Sayed AbdoNo ratings yet

- Energy Analyzer-Print ShukaierDocument27 pagesEnergy Analyzer-Print ShukaierMohamed Sayed AbdoNo ratings yet

- Furnace Efficiency: Fuel OilDocument3 pagesFurnace Efficiency: Fuel OilMohamed Sayed AbdoNo ratings yet

- U22 Equations SampleDocument4 pagesU22 Equations SampleMohamed Sayed AbdoNo ratings yet

- Furnace Efficiency: Fuel OilDocument3 pagesFurnace Efficiency: Fuel OilMohamed Sayed AbdoNo ratings yet

- Medium Voltage Motor Auto Re-Start Logic Review Report: Process Technology Department T-PRTER # 0001 4/3/2019Document7 pagesMedium Voltage Motor Auto Re-Start Logic Review Report: Process Technology Department T-PRTER # 0001 4/3/2019Mohamed Sayed AbdoNo ratings yet

- Energy Analyzer-Print ShukaierDocument7 pagesEnergy Analyzer-Print ShukaierMohamed Sayed AbdoNo ratings yet

- Energy Analyzer-Print BelayiemDocument7 pagesEnergy Analyzer-Print BelayiemMohamed Sayed AbdoNo ratings yet

- Energy Analyzer-Print QarunDocument7 pagesEnergy Analyzer-Print QarunMohamed Sayed AbdoNo ratings yet

- Product SpecificationDocument4 pagesProduct SpecificationMohamed Sayed AbdoNo ratings yet

- Nylon 6 Avey PDFDocument296 pagesNylon 6 Avey PDFMohamed Sayed AbdoNo ratings yet

- Scan May 7, 1802Document1 pageScan May 7, 1802Mohamed Sayed AbdoNo ratings yet

- Quzhou Bote Chemical Co., LTD.: Caprolactam QuotationDocument3 pagesQuzhou Bote Chemical Co., LTD.: Caprolactam QuotationMohamed Sayed AbdoNo ratings yet

- Waste Lube Oil TreatmentDocument5 pagesWaste Lube Oil TreatmentMohamed Sayed AbdoNo ratings yet

- MSDS Lube OilDocument4 pagesMSDS Lube OilMohamed Sayed AbdoNo ratings yet

- Fouling Calculation in Heat ExchangerDocument218 pagesFouling Calculation in Heat Exchangerteguh hady aNo ratings yet

- E-Up Electrical SystemsDocument48 pagesE-Up Electrical SystemsRepo_67No ratings yet

- Majid CVDocument7 pagesMajid CVAbdul Ahad LoneNo ratings yet

- Steam Generator PerformanceDocument7 pagesSteam Generator Performancervkumar61No ratings yet

- T 231Document20 pagesT 231HoàngViệtAnhNo ratings yet

- Ce GatebooknewDocument1 pageCe GatebooknewVipulNo ratings yet

- Design and Layout Problem For A Combined GasDocument119 pagesDesign and Layout Problem For A Combined GasAshley Espeso VeluzNo ratings yet

- 2008-11-14 Installation Manual - Multi V Plus II Outdoor Unit - mfl46912303Document247 pages2008-11-14 Installation Manual - Multi V Plus II Outdoor Unit - mfl46912303experthvachomeNo ratings yet

- Preservation Procedure 1Document18 pagesPreservation Procedure 1Sreni Excel Macros100% (5)

- Fundamentals of Psychrometrics SI, 2nd Ed PDFDocument180 pagesFundamentals of Psychrometrics SI, 2nd Ed PDFZaw Moe Khine100% (2)

- Project ReportDocument48 pagesProject ReportShally ShreyeNo ratings yet

- Classified2016 10 2626534Document9 pagesClassified2016 10 2626534sasikalaNo ratings yet

- Instrument AirDocument11 pagesInstrument AirShariq Ali100% (1)

- BLR Manual - All - R1 PDFDocument235 pagesBLR Manual - All - R1 PDFJayson MallariNo ratings yet

- Good Practice Guide To Energy Conservation For Hotels in Hong KongDocument53 pagesGood Practice Guide To Energy Conservation For Hotels in Hong Kongゴミ 太郎No ratings yet

- Okanagan College Centre of ExcellenceDocument11 pagesOkanagan College Centre of ExcellenceLouis Lee Wee PengNo ratings yet

- Riverhead News-Review Service Directory: June 16, 2016Document7 pagesRiverhead News-Review Service Directory: June 16, 2016TimesreviewNo ratings yet

- DOAS AshraeJournal 0508 PDFDocument6 pagesDOAS AshraeJournal 0508 PDFmefaisal75No ratings yet

- 4 29 15Document20 pages4 29 15greercitizenNo ratings yet

- Vykon HvacDocument284 pagesVykon HvacJose RodriguezNo ratings yet

- MECE 4365: Heating, Ventilating, and Air Conditioning Spring 2015Document4 pagesMECE 4365: Heating, Ventilating, and Air Conditioning Spring 2015FELOMINO LLACUNA JR.No ratings yet

- Subaru - Impreza Service ManualDocument90 pagesSubaru - Impreza Service ManualSunthron Somchai100% (2)

- Solar Energy GreenhousesDocument6 pagesSolar Energy GreenhousesjulienclotNo ratings yet

- Robatherm RMC-RZ EngDocument48 pagesRobatherm RMC-RZ Engtanbqtb030% (1)

- Service Bulletin: Heater/Air Conditioner Cab Control Board Fuse - CX, CV, CH and CL Models With Bergstrom Hvac UnitDocument3 pagesService Bulletin: Heater/Air Conditioner Cab Control Board Fuse - CX, CV, CH and CL Models With Bergstrom Hvac UnitPhil B.No ratings yet

- Double Skin Modular Air Handling Unit: Product CatalogueDocument54 pagesDouble Skin Modular Air Handling Unit: Product CatalogueYasinta Dewi PradinaNo ratings yet

- 2014 MVB & XTherm Service SchoolDocument118 pages2014 MVB & XTherm Service Schoolmalcivar67No ratings yet

- Hamden Consent OrderDocument10 pagesHamden Consent OrdermbrackenburyNo ratings yet

- Thumb Rules-14 (Quick Reference Demand-Diversity Factor) : Electrical Notes & ArticlesDocument7 pagesThumb Rules-14 (Quick Reference Demand-Diversity Factor) : Electrical Notes & ArticlesJIMMY ANTONYNo ratings yet

- M.SC Sugar Tech SyllabusDocument39 pagesM.SC Sugar Tech SyllabusCandra AvengerzNo ratings yet