Professional Documents

Culture Documents

Automatic Garbage Collector Machine: S. A. Karande S. W. Thakare S. P. Wankhede A. V. Sakharkar

Uploaded by

pramo_dassOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automatic Garbage Collector Machine: S. A. Karande S. W. Thakare S. P. Wankhede A. V. Sakharkar

Uploaded by

pramo_dassCopyright:

Available Formats

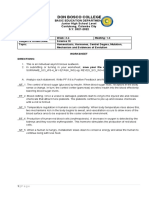

IJSRD - International Journal for Scientific Research & Development| Vol.

6, Issue 01, 2018 | ISSN (online): 2321-0613

Automatic Garbage Collector Machine

S. A. Karande1 S. W. Thakare2 S. P. Wankhede3 A. V. Sakharkar4

1,2,3

B.E Student 4Assistant Professor

1,2,3,4

Department of Mechanical Engineering

1,2,3,4

MPCOE Bhilewada, Bhandara, India

Abstract— In this project the proposal concept is to reduce garbage flow to residential sites where they are burnt in a way

the human effort in garbage cleaning in seaways by of getting rid of them, thereby causing climate change. The

automated system. Now a days even though automation plays drainage systems are cleaned when there is no water in them

an important role in all industrial areas in the proper dumping i.e. when it is not raining, but when it is raining the drainage

of waste material from industrial and domestic areas are still systems cannot be cleaned because of the sharp conditions of

challenging task and faces many problems to doing the task. the rain which no one would volunteer to endure to ensure

Drainage pipes are using for the dumping and unfortunately garbage does not enter into the drainage system.

sometimes there may be loss of human life while doing the

work of cleaning the garbage in drainage pipes. To reduce this II. PROPOSED SYSTEM

problem and to save the human life and human effort we The machine is placed in the drain so that only water is

design mechanism “Automatic garbage collector machine”. flowing through lower grids, like bottle waste, like cloth

We design our project to use this in effective way to control waste which floating on water and etc. the waste like a bottle

the dumping or disposal wastages and with and with the is floating in drain are lifted by teeth which connected to the

cleaning of gaseous substances and the process of garbage chain. This chain is connected to a motor which drives the

cleaning and it also reduce spreading of diseases to human chain. When the motor starts rotating then chain also rotated

being. then also starts to rotate teeth to lift up. The waste garbage is

Key words: Automatic Garbage Collector Machine, Drainage lifted by teeth and the waste material is stored in a collector.

Pipes, Fabrication

I. INTRODUCTION

Automatic drainage water cleaning and control system using

auto mechanism proposed to overcome the real time

problems. With the continued progress of industries, the

problem of sewage water must be urgently resolved due to the

increasing sewage problems from industries of the

surrounding environment. The waste and gases produced

from the industries are very harmful to human beings and to

the environment. Our proposed systems are to cleaning and

maintain the drainage level using auto mechanism technique. Fig. 2.1: Proposed System

Auto mechanism is the major controlling unit and the

drainage level is monitor by municipal. In this system we

used motor, chain, driver, bucket, and frame.Water is a basic

necessity of humans and all living beings there is a plenty of

water on earth but that is not suitable for human use. Clean

water is more important if used for some purpose. The

impurities present in water can cause hazardous and disease.

As long as the seaways system is considered the function of

the main drainage system is to collect, transport and dispose

of the water through an outfall or outlet. Impurities in

drainage water can be only like empty bottles, polythene

bags, and papers. etc. These impurities present in drainage

water can cause blockage or the drainage system. The

seaways system can be cleaned time to time manually or such

a system can be designed that will automatically throw out

wastages and will keep the water clean. The project is

designed to keep clean the drainage system and helps to

smooth working of the system. This project automatically

Fig. 2.3: Fabrication of the system

cleans the garbage in the water in the drainage system each

time any wastage appears and this form an efficient and easy

to cleaning the drainage system and preventing the blockage. III. DETAILS OF WORK

It also reduces labour work and improves the quality of water 1) It has been decided that project should make considering

that is cleaned. If the garbage are allowed to flow they will the use of electronic system under the guidance of

end up flowing down to recreational beaches used for tourism respective subject a specialized person.

purposes making ascent not pleasurable to the eyes else these

All rights reserved by www.ijsrd.com 1382

Automatic Garbage Collector Machine

(IJSRD/Vol. 6/Issue 01/2018/379)

2) Search has been made for the need of efficient V. DESIGN DESCRIPTION

technology by finding the problem faced by the different Assortment comprises of use of logic guideline, important

system. data, and creative energy for the advancement of new

3) It has been found that in various technologies are cost- component to work the particular capacity with most great

effective and slow in response. economy and effectiveness. Thus having outline approach

4) Group has come up with the concept of fabrication of must be embraced. The total plant work has been into in two

automatic garbage collector system which will be less parts.

costly. System Design

5) A different type of equipment electronics component has

Mechanical Design

been found and their working has been studied.

A. System Design

IV. WORKING Frame work configuration is for the most f the parts concerns

The automated mechanism is basically designed to filter out the different physical limitation and ergonomics, space

the solid waste of the running drains and hence removing the necessary, game plan of different on casing at frame work,

possibility of any blockage of the flowing waste water. The numbers of controls, man-machine collaboration, position of

turbine is the power (rotation) generating elements that controls, extent of change, workplaces, add up to weight of

function on the hydraulic power and hence then drive the machine and significantly more.

chain mechanism. The power generated by the turbine is B. Mechanical Design

being transmitted through the sprocket-chain arrangement

from turbine shaft to mechanism drive shaft and hence the In mechanical design the components are listed down and

chain mechanism is being driven. The chain mechanism is stored on the basis of their obtain the design in two categories

being fitted with the wire mesh filter that just picks up the namely.

solid waste while the liquid waste flows through the Designed parts

mechanism .The size of mechanism holes can be adjusted in Parts to be purchased

order to decide the different size of solid waste we are Mechanical outlines stage is mostly important to use from the

working on. The system is being adjusted at an angle so that perspective of originator as the entire achievement of venture

mechanism is able to hold the solid waste the storage box is relies on upon the right plan examination of the issue

kept where the solid waste is collected and later the box can numerous preparatory options are killed amid this stage.

be cleaned to remove the collected waste. Creator ought to have sufficient learning about physical

properties of material load stresses and disappointment. He

A. System Flow Diagram ought to recognize all insides and outer powers following up

The methodology used for whole processing of automatic on machine part.

garbage collector machine is given below; this methodology 1) Advantages

given about which work is carried out by the system. It is the 1) It is available at very low cost.

standard process of mechanism, it shows in simplest manner. 2) It operates easily.

3) Simple in construction.

4) It can be portable.

5) It works long time

2) Disadvantages

1) Due to the connection between wire brush and wheel

therefore small sound and vibration is occurring.

2) Width of the mechanism is limitation as it can clean drain

width up to its width only.

3) Cannot withstand higher loads.

3) Application

1) It can work as part of BMC

2) It can be utilized to separate plastic thermocol from

sewage.

3) It can be use to separate the sewage from water.

4) The machine maximally worked in 5 feet in length.

VI. CONCLUSION

The deplete squander water cleaner machine is planned and

made by utilizing gear changing and shaft coupling rule. It

comprise fundamentally DC equipped engine, shafts,

squander expulsion plant, clean receptacle, course, sprocket

and chains. Construction materials are effortlessly available,

creates work (development and maintenance) simple to build.

Fig. 4.1: System Flow Diagram

All rights reserved by www.ijsrd.com 1383

Automatic Garbage Collector Machine

(IJSRD/Vol. 6/Issue 01/2018/379)

ACKNOWLEDGMENT

The author would like to thank Prof. Akshay V. Sakharkar,

those gives us a good guideline for work throughout

numerous consultations. We would also like to expand our

deepest gratitude to all those who have directly and indirectly

guided us in Completing this work.

REFERENCES

[1] V.S. Bagul, Y.D.Jadhav, S.N.Bachhav and

B.A.Bhandane,automatic drainage cleaning system,

volume2, issue2,february 2017

[2] Sathiyakala, S. Flora Grace, P.Maheswari, S.

majithaBhanu, R.Muthu Lakshmi Vol. 4, issue 2,

Febbruary 2016.

[3] Dr. K.Kumaresanm.e,ph.d.., PrakashS,Rajkumar. P.

Sakthivel.C, Suugumar.G issn:2362 (iceiet-2016)

[4] Department of civil Engineering Michael Ok-

paraUniversity of AgrricultureUmudikeAbia State

Maarch2014.

[5] Prof. NitinSall, CHouple Mohammed ZaidSadique,

PrathmeshGawed, Shiraz Qureshi and Sunil Singh

Bhadautiya Vol.4 Issue 2, February 2016.

[6] Yadav, D. (2009). Garbage disposal plant mired in

controversy . India Times ,TNN 19 Feb 2009 .61 Bha-

rat, K .and G.A. Mihalika, when experts agree : us-ing

non-a_ liated experts torankpolpular topics .ACM trans .

Inf.Syst, 20(1), (2002), pp.47-58.

[7] Design and Data hand book for Mechanical Engi-neers

by K Mahadevan and K Balaveerareddy. Fourth edition

2013.

All rights reserved by www.ijsrd.com 1384

You might also like

- The Fabrication of A Sandboni: A Coastal Cleaning SystemDocument57 pagesThe Fabrication of A Sandboni: A Coastal Cleaning SystemColeen TorresNo ratings yet

- Res 2Document20 pagesRes 2Nicolette BingtanNo ratings yet

- Automated Arduino-Based Plastic Bottle CompressorFINALDocument15 pagesAutomated Arduino-Based Plastic Bottle CompressorFINALGrace Saagundo DubdubanNo ratings yet

- Final Paper - Group 3Document64 pagesFinal Paper - Group 3Diana Mae JavierNo ratings yet

- CHAPTER-II - CapstoneDocument19 pagesCHAPTER-II - CapstonePatricia Ann100% (1)

- River Float Waste Cleaning AutomationDocument6 pagesRiver Float Waste Cleaning AutomationSreekanth PagadapalliNo ratings yet

- Sprinkle Subsurface Drip Irrigation SystemDocument6 pagesSprinkle Subsurface Drip Irrigation SystemRodolfo Castro Jr.No ratings yet

- Chapter II Group 1 2.0 (Autosaved) - FinalDocument12 pagesChapter II Group 1 2.0 (Autosaved) - FinalReign Assley Faye ComiaNo ratings yet

- Smart Garbage BinDocument10 pagesSmart Garbage BinHarvey Agustin UyNo ratings yet

- 1-Agricultural Waste Peels As Versatile Biomass For Water Purification - ADocument28 pages1-Agricultural Waste Peels As Versatile Biomass For Water Purification - ARodybeth Cruz67% (3)

- Waste Management Practices On The Island of Mindanao PhilippinesDocument8 pagesWaste Management Practices On The Island of Mindanao PhilippinesEm NueraNo ratings yet

- Central Taytay Senior High School - Stand Alone Computerized Record Management SystemDocument85 pagesCentral Taytay Senior High School - Stand Alone Computerized Record Management SystemRolando BelarminoNo ratings yet

- PORTABLE SOLAR (Photovoltaic Module) FAN: Liceo de Cagayan University Junior High School DepartmentDocument18 pagesPORTABLE SOLAR (Photovoltaic Module) FAN: Liceo de Cagayan University Junior High School DepartmentJanica ZialcitaNo ratings yet

- Solar Powered LED Lantern For Developing CountriesDocument34 pagesSolar Powered LED Lantern For Developing CountriesAkhlak HossainNo ratings yet

- Capstone Module 1 LITERATURE REVIEWDocument3 pagesCapstone Module 1 LITERATURE REVIEWJessica AngayenNo ratings yet

- Impacts of Water Shortage On Barangays Cabuynan, Malaguicay, and Picas of Tanauan, LeyteDocument8 pagesImpacts of Water Shortage On Barangays Cabuynan, Malaguicay, and Picas of Tanauan, Leyteeirene gomez100% (1)

- Properties of Concrete Mixes With Waste GlassDocument14 pagesProperties of Concrete Mixes With Waste GlassJenny ValderramaNo ratings yet

- Graded (50 Points) : I. Short Response Essay. Answer The Following Items Briefly and Succinctly. (10 Points Each)Document3 pagesGraded (50 Points) : I. Short Response Essay. Answer The Following Items Briefly and Succinctly. (10 Points Each)Mia GallegoNo ratings yet

- How to Empower Children in the World: Earth Leaders for Environmental MonitoringFrom EverandHow to Empower Children in the World: Earth Leaders for Environmental MonitoringNo ratings yet

- Review of Related LiteratureDocument3 pagesReview of Related LiteratureJohn TacordaJrNo ratings yet

- Jessie Boy Arzadon Jaquias: Education and CredentialsDocument2 pagesJessie Boy Arzadon Jaquias: Education and CredentialsA-arr Ola BeronillaNo ratings yet

- SIPDocument29 pagesSIPJohn Bryan AldovinoNo ratings yet

- QuestionnaireDocument6 pagesQuestionnaireSHIELA MAE PAGLINAWAN100% (1)

- Yield Performance of TomatoDocument71 pagesYield Performance of Tomatojingky SallicopNo ratings yet

- Gerneral Physics ReviewerDocument4 pagesGerneral Physics ReviewerQueenie LucasNo ratings yet

- RRLDocument8 pagesRRLRuel Elido100% (1)

- Final EcoSortDocument57 pagesFinal EcoSortBryan De GuzmanNo ratings yet

- Nature of SIPDocument112 pagesNature of SIPAnonymous OSwdeyDrNo ratings yet

- D. Newton's Law of Motion: (Not Directly Stated)Document3 pagesD. Newton's Law of Motion: (Not Directly Stated)low keiNo ratings yet

- Development of A Hydroelectric Mobile Phone ChargerDocument8 pagesDevelopment of A Hydroelectric Mobile Phone ChargerAudrey RoqueNo ratings yet

- Sample SIP PaperDocument49 pagesSample SIP PaperCHRISTINE FRANCOISE GURANGONo ratings yet

- Sci w3 4 m1 3 Task WsDocument10 pagesSci w3 4 m1 3 Task WsAnton Joaquin PatulotNo ratings yet

- The Strategies That Saved Grade 12 Stem Students From Procrastinating: A Correlational Analysis Between Girls and BoysDocument72 pagesThe Strategies That Saved Grade 12 Stem Students From Procrastinating: A Correlational Analysis Between Girls and BoysNadine Rebolledo50% (2)

- Organic Use of Carabao Excrement As An Alternative Air Deodorizer With Lemon ExtractDocument17 pagesOrganic Use of Carabao Excrement As An Alternative Air Deodorizer With Lemon ExtractDeanna Crisostomo BalceNo ratings yet

- Abm - PR2 (Carandang, Quijano, de Castro, Hernandez, Perfinian)Document43 pagesAbm - PR2 (Carandang, Quijano, de Castro, Hernandez, Perfinian)Angelica CarandangNo ratings yet

- Improvised Vaccuum Cleaner CarDocument10 pagesImprovised Vaccuum Cleaner CarCharlie ReynonNo ratings yet

- Automated Waste Segregator Bin202020Document10 pagesAutomated Waste Segregator Bin202020MANOJ KNo ratings yet

- Plastic Strips As An Admixture For Concrete Mix Group 1Document23 pagesPlastic Strips As An Admixture For Concrete Mix Group 1Harvey roqueNo ratings yet

- 1) Gen - Physics 2-Module 1Document6 pages1) Gen - Physics 2-Module 1Ma. Alyzandra G. LopezNo ratings yet

- The Learning Styles of Grade 12 Stem Students Amidst The Global PandemicDocument84 pagesThe Learning Styles of Grade 12 Stem Students Amidst The Global PandemicSheina Mae TacazonNo ratings yet

- Philippine Normal University - Center For Teaching and LearningDocument41 pagesPhilippine Normal University - Center For Teaching and LearningFritz Ren KeifferNo ratings yet

- Capstone Formatrevised 1Document70 pagesCapstone Formatrevised 1Ivy Dianne PascualNo ratings yet

- Bagong ResearchDocument39 pagesBagong ResearchRed AaronNo ratings yet

- CHAPTER 1 Formative QuizDocument10 pagesCHAPTER 1 Formative QuizAnne ValenzonaNo ratings yet

- Piesole Chapters 1 5Document65 pagesPiesole Chapters 1 5Gloriane, Sean Gemuel B.No ratings yet

- Phy2 11 - 12 Q3 0101 FDDocument16 pagesPhy2 11 - 12 Q3 0101 FDEllyNo ratings yet

- De Guzman, Aaron Choco S-Critical ReviewDocument3 pagesDe Guzman, Aaron Choco S-Critical ReviewAaron Choco De GuzmanNo ratings yet

- Fruit BatteryDocument37 pagesFruit BatteryIreena GomezNo ratings yet

- Electromagnetic Power BankDocument11 pagesElectromagnetic Power BankSaravanan SukumaranNo ratings yet

- Automatic Waste Segregation Machine Chapter 1 and 2Document58 pagesAutomatic Waste Segregation Machine Chapter 1 and 2James Aeriel LayosNo ratings yet

- CapstoneDocument6 pagesCapstoneJunard Hans BagnisenNo ratings yet

- Magnetic Field Due To The Circular Coil AxiallyDocument6 pagesMagnetic Field Due To The Circular Coil AxiallyMegh Raj KhadkaNo ratings yet

- Outline Essay Group 11 (Revisi Thesis Statement)Document3 pagesOutline Essay Group 11 (Revisi Thesis Statement)Febi AndrianiNo ratings yet

- Dynamo As Electric GeneratorDocument10 pagesDynamo As Electric GeneratorQu33n ZyNo ratings yet

- AlternatorDocument16 pagesAlternatorMitz Mae DatuNo ratings yet

- Capstone Research PaperDocument5 pagesCapstone Research PaperRalph ZeusNo ratings yet

- Capstone: Stem-Based ResearchDocument29 pagesCapstone: Stem-Based ResearchHeindrich Lloyd Mendoza BasiNo ratings yet

- Automatic Drain CleanerDocument3 pagesAutomatic Drain CleanerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Fabrication of Automated Drain Cleaner IJERTCONV6IS04051 PDFDocument2 pagesDesign and Fabrication of Automated Drain Cleaner IJERTCONV6IS04051 PDFSathish.SNo ratings yet

- 2STM - JoMA E DUSTBINDocument8 pages2STM - JoMA E DUSTBINBhairavi MoreNo ratings yet

- Project Report On Robotic ArmDocument8 pagesProject Report On Robotic Armpramo_dassNo ratings yet

- Wiper Motor SensorDocument68 pagesWiper Motor Sensorpramo_dassNo ratings yet

- Background of The StudyDocument17 pagesBackground of The Studypramo_dassNo ratings yet

- Solar Panels Cleaning System ReportDocument26 pagesSolar Panels Cleaning System Reportpramo_dass0% (2)

- 4 - Stresses Due To Shrink Fit Between 2 CylindersDocument4 pages4 - Stresses Due To Shrink Fit Between 2 Cylinderspramo_dassNo ratings yet

- Group 7 Robotic ArmDocument39 pagesGroup 7 Robotic Armpramo_dassNo ratings yet

- Clutch Palte - 1Document48 pagesClutch Palte - 1pramo_dassNo ratings yet

- Disc Brake-ReportDocument51 pagesDisc Brake-Reportpramo_dass100% (2)

- Comparative Study Of"Connecting Rod by Finite Element Analysis Using Composite Materials"Document38 pagesComparative Study Of"Connecting Rod by Finite Element Analysis Using Composite Materials"pramo_dassNo ratings yet

- Connecting RodDocument36 pagesConnecting Rodpramo_dass0% (1)

- Finite Element Analysis On Hybrid Composite Wheel RimDocument11 pagesFinite Element Analysis On Hybrid Composite Wheel Rimpramo_dassNo ratings yet

- Study On Mechanical Behaviour of Banana Fiber Reinforced Epoxy CompositesDocument30 pagesStudy On Mechanical Behaviour of Banana Fiber Reinforced Epoxy Compositespramo_dassNo ratings yet

- Advanced Android Controlled Pick and Place Robotic ARM Using Bluetooth TechnologyDocument9 pagesAdvanced Android Controlled Pick and Place Robotic ARM Using Bluetooth Technologypramo_dassNo ratings yet

- Arm Move FixedDocument45 pagesArm Move Fixedpramo_dassNo ratings yet

- ProjectarsDocument36 pagesProjectarspramo_dassNo ratings yet

- Design and Development of A Tomato Slicing MachineDocument7 pagesDesign and Development of A Tomato Slicing Machinepramo_dassNo ratings yet

- Design and Fabrication of An Automatic Window Cleaning RobotDocument6 pagesDesign and Fabrication of An Automatic Window Cleaning Robotpramo_dassNo ratings yet

- 360 Degree Fire Fighting Protection SystemDocument20 pages360 Degree Fire Fighting Protection Systempramo_dass100% (5)

- Wheel MachineDocument114 pagesWheel Machinepramo_dassNo ratings yet

- Plagiarism Checker X Originality Report: Similarity Found: 30%Document7 pagesPlagiarism Checker X Originality Report: Similarity Found: 30%pramo_dassNo ratings yet

- Planning Analysis and Designing of ShoppDocument63 pagesPlanning Analysis and Designing of Shopppramo_dass100% (1)

- Rim Design CompositeDocument28 pagesRim Design Compositepramo_dassNo ratings yet

- New Concept of WheelchairDocument32 pagesNew Concept of Wheelchairpramo_dassNo ratings yet

- Vrtical ImpellerDocument63 pagesVrtical Impellerpramo_dassNo ratings yet

- Experimental and Numerical Analysis of Different Aerodynamic Properties of Circular CylinderDocument6 pagesExperimental and Numerical Analysis of Different Aerodynamic Properties of Circular Cylinderpramo_dassNo ratings yet

- Report 1Document50 pagesReport 1pramo_dassNo ratings yet

- Cleaning and PainitngDocument36 pagesCleaning and Painitngpramo_dassNo ratings yet

- Al - Metal MatrixDocument38 pagesAl - Metal Matrixpramo_dassNo ratings yet

- Chapter-1: Automatic Rain Wiper SystemDocument54 pagesChapter-1: Automatic Rain Wiper Systempramo_dassNo ratings yet

- Saint Albert Polytechnic College, Inc. Bachelor of Science in Office AdministrationDocument15 pagesSaint Albert Polytechnic College, Inc. Bachelor of Science in Office AdministrationAustin Grey Pineda MacoteNo ratings yet

- Mathematics ExcerciseDocument74 pagesMathematics Excerciseserge129100% (1)

- The Doppler EffectLDocument2 pagesThe Doppler EffectLintan100% (1)

- Gear Whine Prediction With CAE For AAMDocument6 pagesGear Whine Prediction With CAE For AAMSanjay DeshpandeNo ratings yet

- Jenkins Course Slides PDFDocument96 pagesJenkins Course Slides PDFkamal.tejnani5613100% (2)

- 009 Installation of Pumps Risk AssessmentDocument2 pages009 Installation of Pumps Risk Assessmentgangadharan000100% (13)

- A Modified Newton's Method For Solving Nonlinear Programing ProblemsDocument15 pagesA Modified Newton's Method For Solving Nonlinear Programing Problemsjhon jairo portillaNo ratings yet

- Critical Point of View: A Wikipedia ReaderDocument195 pagesCritical Point of View: A Wikipedia Readerrll307No ratings yet

- IRJES 2017 Vol. 1 Special Issue 2 English Full Paper 038Document6 pagesIRJES 2017 Vol. 1 Special Issue 2 English Full Paper 038liew wei keongNo ratings yet

- Gower SlidesCarnivalDocument28 pagesGower SlidesCarnivalBình PhạmNo ratings yet

- Observation Method in Qualitative ResearchDocument42 pagesObservation Method in Qualitative Researchsantoshipoudel08No ratings yet

- #Stopableism: Reduksi Stigma Kepada Penyandang Disabilitas Melalui Intervensi Bias ImplisitDocument15 pages#Stopableism: Reduksi Stigma Kepada Penyandang Disabilitas Melalui Intervensi Bias ImplisitDennis SuhardiniNo ratings yet

- Elements of PresentationDocument11 pagesElements of PresentationSubham .MNo ratings yet

- The Evolution of Management TheoryDocument49 pagesThe Evolution of Management TheoryAnjali MeharaNo ratings yet

- Control Panel Manual 1v4Document52 pagesControl Panel Manual 1v4Gustavo HidalgoNo ratings yet

- Reserach MethoodolgyDocument38 pagesReserach MethoodolgyShubashPoojariNo ratings yet

- Comparision BRC IFS QMS 22K From BV PDFDocument44 pagesComparision BRC IFS QMS 22K From BV PDFAhmedElSayedNo ratings yet

- Disneyland (Manish N Suraj)Document27 pagesDisneyland (Manish N Suraj)Suraj Kedia0% (1)

- Vertical Axis Wind Turbine ProjDocument2 pagesVertical Axis Wind Turbine Projmacsan sanchezNo ratings yet

- Developing An OutlineDocument18 pagesDeveloping An OutlineEnrico Dela CruzNo ratings yet

- 500 Grammar Based Conversation Question12Document16 pages500 Grammar Based Conversation Question12Ivo Barry Ward100% (1)

- 27 EtdsDocument29 pages27 EtdsSuhag PatelNo ratings yet

- MATH 6 Q4 Module 8Document17 pagesMATH 6 Q4 Module 8Amor DionisioNo ratings yet

- Bergson, The Philosophy of ChangeDocument104 pagesBergson, The Philosophy of ChangeSoha Hassan Youssef100% (2)

- Gerin Bagaslino - 52417512Document13 pagesGerin Bagaslino - 52417512Gerin BagaslinoNo ratings yet

- Heat and Cooling LoadDocument2 pagesHeat and Cooling LoadAshokNo ratings yet

- Lesson Plan ComsumerismDocument6 pagesLesson Plan ComsumerismMan Eugenia50% (4)

- EC861Document10 pagesEC861damaiNo ratings yet

- Gender InequalityDocument9 pagesGender InequalityRhzNo ratings yet