Professional Documents

Culture Documents

Heat Resistant Alloy HN Data Sheet

Uploaded by

Azize RazamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Resistant Alloy HN Data Sheet

Uploaded by

Azize RazamCopyright:

Available Formats

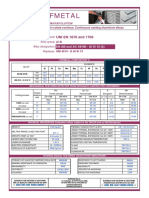

25 Commerce Road, Orillia, Ontario, Canada L3V 6L6

Phone (705) 325-2781 Fax (705) 325-5887

ALLOY DATA SHEET HEAT RESISTANT ALLOY

HN REVISION: 04/91

DESCRIPTION

HN alloy is an austenitic Fe-Ni-Cr alloy with long term creep rupture properties that are intermediate between

those of HK40 and HP40 alloys. Carburization resistance is better than that of HK40 but oxidation resistance is

generally lower making the alloy suitable for long service at 2000 oF

COMPOSITION

C Mn Si Cr Ni Mo P S

Min % 0.2 19 23 - - -

Max % 0.5 2.0 2.0 23 27 0.5 0.03 0.03

APPLICATIONS

Tube supports and hangers; heat treatment fixtures and trays; furnace skids; furnace rolls.

PRODUCT FORMS

Horizontal and vertical centrifugal castings; static castings.

PHYSICAL PROPERTIES CARBURIZATION

Density (lbs/in3) 0.283 RESISTANCE

Melting Point(oF) 2500 (Gas-1064 hours @ 1760oF)

Thermal Conductivity 7.5 @ 212oF ALLOY WEIGHT GAIN

(Btu/h/ft2/ft/oF) 14.5 @ 1600oF GRADE mg/mm2

15.2 @ 1800oF HH 0.58

Thermal Expansion 9.7 @ 70-1400oF HK 0.56

(10-6in/in oF) 9.9 @ 70-1600oF HN 0.43

10.1 @ 70-1800oF HP 0.20

10.2 @ 70-2000oF HT 0.38

MECHANICAL PROPERTIES (Typical Values)

70 1400 1600 1800 2000 oF ASTM Spec.A297

U.T.S. K.S.I. 68 - 20 12 6 63 Min.

Y.S. K.S.I. 38 - 14 10 5

El. % 13 - 37 51 55 8 Min.

SERVICE TEMPERATURE

The alloy is suitable for service at temperatures up to approximately 2000 oF.

COMPARATIVE OXIDATION RATES (mm / year)

(500 hour cyclic tests)

GRADE 1832 1922 2012 2102 2204 oF

HK <0.1 0.22 0.95 3.5 12.7

HN 0.11 0.38 1.2 3.5 9.6

HP <0.1 0.25 0.64 1.5 3.4

HEAT RESISTANT ALLOY HN Page 2

WELDABILITY

HN alloy has good weldability by the SMAW, GTAW and GMAW processes

CREEP-RUPTURE PROPERTIES

Long term creep-rupture properties were extrapolated from Larson-Miller Parameter versus stress plots,.

RUPTURE-STRESS-KSI

HOURS 1400 1500 1600 1700 1800 1900 2000 2100 oF

100 AVG. 10.9 8.0 5.8 4.35 2.6 1.55

1,000 AVG. 10.2 7.4 5.4 3.6 2.1 1.25 0.74

10,000 AVG. 10.2 7.2 5.1 3.3 1.9 1.1

100,000 AVG. 7.35 5.1 3.2 1.75 1.13 0.44 0.22

CREEP-STRESS-KSI

%/HOUR 1400 1500 1600 1700 1800 1900 2000 2100 oF

0.0001 AVG. 6.3 3.8 2.4 1.6 1.04

Note: Creep and rupture stresses are subject to periodic revisions as the results from long term tests become

available.

COMPARATIVE 100,000 HOUR RUPTURE STRESSES - K.S.I.

ALLOY 1400 1500 1600 1700 1800 oF

H K 40 6.11 4.12 2.58 1.59 0.96

HN 7.35 5.1 3.2 1.75 1.13

HP 7.63 5.38 3.74 2.63 1.38

RELATED SPECIFICATIONS

ASTM: A 297 (HN); A608 (HN40)

Nearest wrought grade: None.

HEAD OFFICE, FOUNDRY & INTERNATIONAL SALES

Kubota Metal Corporation, Fahramet Division

25 Commerce Road, P.O. Box 1700,

Orillia, Ontario, Canada, L3V 6L6.

Phone (705) 325-2781

Fax (705) 325 5887

You might also like

- Heat Resistant Alloy HK40 Data SheetDocument2 pagesHeat Resistant Alloy HK40 Data SheethawyegNo ratings yet

- Astm A-297 HPDocument2 pagesAstm A-297 HPeduardo_exsys100% (1)

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- KHR35CT heat resistant alloy data sheetDocument2 pagesKHR35CT heat resistant alloy data sheetFebri Ramdani NugrahaNo ratings yet

- Material Alloy KHR32CDocument2 pagesMaterial Alloy KHR32CKHNo ratings yet

- CA6NMDocument2 pagesCA6NMjoene3No ratings yet

- Heat Resistant Alloy HU Data SheetDocument2 pagesHeat Resistant Alloy HU Data Sheetgorane11No ratings yet

- Cd-4Mcu: Alloy Data SheetDocument2 pagesCd-4Mcu: Alloy Data SheetFlowline PumpsNo ratings yet

- 17-4 Fi Us enDocument10 pages17-4 Fi Us ennaeem akramNo ratings yet

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Document6 pagesDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderNo ratings yet

- Contact Material Beryllium Nickel Be NiStrip360 PDFDocument4 pagesContact Material Beryllium Nickel Be NiStrip360 PDFImags GamiNo ratings yet

- Alloy 360 Data SheetDocument4 pagesAlloy 360 Data SheetImags GamiNo ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- Raffmetal aluminium alloy guideDocument2 pagesRaffmetal aluminium alloy guideDhamodaran RNo ratings yet

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07No ratings yet

- Sandvik 254 SMO Datasheet for Seamless Tube and PipeDocument9 pagesSandvik 254 SMO Datasheet for Seamless Tube and PipeReadersmoNo ratings yet

- LFBCW510L TN enDocument4 pagesLFBCW510L TN endrgilleNo ratings yet

- Aluminum Brass Specifications for Condenser TubesDocument1 pageAluminum Brass Specifications for Condenser Tubesm_f_deathNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- 17 4 PHDocument2 pages17 4 PHParag NaikNo ratings yet

- Quality 16Mncr5: Lucefin GroupDocument2 pagesQuality 16Mncr5: Lucefin GroupPrasadNo ratings yet

- 34CrMo4 steel properties and heat treatment guideDocument2 pages34CrMo4 steel properties and heat treatment guideStefan GhNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- High-alloy creep resistant stick electrode for 9% Cr steelsDocument1 pageHigh-alloy creep resistant stick electrode for 9% Cr steelsmisthahNo ratings yet

- Stainless Steel 1.4828 Material Data SheetDocument3 pagesStainless Steel 1.4828 Material Data SheetAvn PrasadNo ratings yet

- Haynes: Hastelloy W AlloyDocument4 pagesHaynes: Hastelloy W AlloyLuiz FernandoNo ratings yet

- 1816 Nicr 4Document2 pages1816 Nicr 4Rebekah WilsonNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- Datasheet-Sanicro-69-En-V2022-10-26 14 - 22 Version 1Document7 pagesDatasheet-Sanicro-69-En-V2022-10-26 14 - 22 Version 1Agustin CesanNo ratings yet

- 630 (17-4) Precipitation Hardening Stainless Steel BarDocument4 pages630 (17-4) Precipitation Hardening Stainless Steel Barehudingram6535No ratings yet

- 34 CR Mo 4Document2 pages34 CR Mo 4ceca nikolicNo ratings yet

- Technical Specifications for HS 10-4-3-10 High Speed SteelDocument1 pageTechnical Specifications for HS 10-4-3-10 High Speed Steelmarko9292No ratings yet

- 20 MN CR 5Document2 pages20 MN CR 5sansmgNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document1 pageRaffmetal: UNI EN 1676 and 1706swaroop NalamNo ratings yet

- Aisi 9254 - Spring SteelDocument2 pagesAisi 9254 - Spring SteelSergio100% (1)

- Interlloy Grade 8620 Case Hardening SteelDocument3 pagesInterlloy Grade 8620 Case Hardening Steelajitchavan2150No ratings yet

- 03112015000000B - Boehler FOX NiCr 70 NB - CeDocument1 page03112015000000B - Boehler FOX NiCr 70 NB - CeFlori MovNo ratings yet

- AISI 1035 cs46Document2 pagesAISI 1035 cs46Russell ShacklefordNo ratings yet

- 1 3243hs652513 PDFDocument1 page1 3243hs652513 PDFmarko9292No ratings yet

- Technical specifications for HS 6-5-2C high speed steelDocument1 pageTechnical specifications for HS 6-5-2C high speed steelmarko9292No ratings yet

- Datasheet-Sandvik-3r60-En-V2020-12-10 07 - 47 Version 1Document7 pagesDatasheet-Sandvik-3r60-En-V2020-12-10 07 - 47 Version 1Bruno AlfanoNo ratings yet

- Sandvik 2RE69 Stainless Steel DatasheetDocument9 pagesSandvik 2RE69 Stainless Steel DatasheetMuzammilNo ratings yet

- 16MnCr5 SpesifikasiDocument2 pages16MnCr5 SpesifikasibagusalienNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- 17-4PH Technical DataDocument7 pages17-4PH Technical DataKir VinNo ratings yet

- Material Alloy KHR35CLDocument2 pagesMaterial Alloy KHR35CLIebe Seventynine50% (2)

- Quality 102Cr6: Lucefin GroupDocument1 pageQuality 102Cr6: Lucefin GroupPaulo ZechinNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- 16 Ni CR 11Document2 pages16 Ni CR 11ceca nikolicNo ratings yet

- BF Runner Mix 20 MT VesuviusDocument3 pagesBF Runner Mix 20 MT VesuviusSaumit PalNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Analytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryFrom EverandAnalytical Chemistry of Zirconium and Hafnium: International Series of Monographs in Analytical ChemistryNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- 243 RegulatorDocument24 pages243 RegulatorDavid Somogyi DovalNo ratings yet

- International Standard: Petroleum Products - Determination of Pour PointDocument12 pagesInternational Standard: Petroleum Products - Determination of Pour PointAzize RazamNo ratings yet

- F 36 - 15Document4 pagesF 36 - 15juan fNo ratings yet

- F 22 - 13Document5 pagesF 22 - 13Azize Razam100% (1)

- Tension and Vacuum Testing Metallized Ceramic Seals: Standard Test Method ForDocument4 pagesTension and Vacuum Testing Metallized Ceramic Seals: Standard Test Method ForAzize RazamNo ratings yet

- F 34 - 13Document5 pagesF 34 - 13Azize RazamNo ratings yet

- F31-12 Standard Specification For Nickel-Chromium-Iron Sealing AlloysDocument4 pagesF31-12 Standard Specification For Nickel-Chromium-Iron Sealing AlloysAndré BerninzonNo ratings yet

- F 21 - 14Document6 pagesF 21 - 14Azize RazamNo ratings yet

- F 24 - 09 (2015) PDFDocument4 pagesF 24 - 09 (2015) PDFAzize RazamNo ratings yet

- F 18 - 12 PDFDocument5 pagesF 18 - 12 PDFAzize RazamNo ratings yet

- Flexible Barrier Packaging: Standard Terminology Relating ToDocument4 pagesFlexible Barrier Packaging: Standard Terminology Relating ToAzize RazamNo ratings yet

- Measuring Diameter or Thickness of Wire and Ribbon For Electronic Devices and LampsDocument5 pagesMeasuring Diameter or Thickness of Wire and Ribbon For Electronic Devices and LampsAzize RazamNo ratings yet

- Heat Treatment of Metals PDFDocument12 pagesHeat Treatment of Metals PDFAzize RazamNo ratings yet

- Filler Material Selection GuideDocument32 pagesFiller Material Selection GuidemaknileNo ratings yet

- 1 Typical Duties of Welding InspectorsDocument7 pages1 Typical Duties of Welding InspectorsSampath KumarNo ratings yet

- Glossary of Leadership DefinitionsDocument18 pagesGlossary of Leadership DefinitionsAzize RazamNo ratings yet

- Bubble Formation in Aluminium Alloy During Electron Beam WeldingDocument4 pagesBubble Formation in Aluminium Alloy During Electron Beam WeldingAzize RazamNo ratings yet

- C.F.C ProductsDocument46 pagesC.F.C ProductsLoc van NguyenNo ratings yet

- Series FV: Cantilever Sump PumpsDocument4 pagesSeries FV: Cantilever Sump PumpsFranciscoNo ratings yet

- Sliver On Rolled AlluminiumDocument1 pageSliver On Rolled AlluminiumPEEYUSH MISHRANo ratings yet

- Cre Exp 10 Lab Report (PFR)Document10 pagesCre Exp 10 Lab Report (PFR)sukhmani100% (1)

- Nmea 0183 Sentences Not Recommended For New DesignsDocument19 pagesNmea 0183 Sentences Not Recommended For New DesignsyleuppiNo ratings yet

- Choi 2012Document5 pagesChoi 2012tuanhoa123No ratings yet

- Exploring The Limits of Buffering Process For Both Standard and Micro TubesDocument5 pagesExploring The Limits of Buffering Process For Both Standard and Micro TubesDenisTarasNo ratings yet

- Brochure Ftir Cary 630 5990-8570en Us AgilentDocument12 pagesBrochure Ftir Cary 630 5990-8570en Us AgilentMarcela RobayoNo ratings yet

- HW3 20220367 신동민Document4 pagesHW3 20220367 신동민sdongmin488No ratings yet

- Mid Term Exam With Solutions PDFDocument15 pagesMid Term Exam With Solutions PDFAr Mark RoblesNo ratings yet

- 5054 w16 QP 11 PDFDocument20 pages5054 w16 QP 11 PDFMuhammad SaifNo ratings yet

- Is 8851 1994sulphurDocument8 pagesIs 8851 1994sulphurPrashantha NandavarNo ratings yet

- How To Calculate Filler Metal ConsumptionDocument3 pagesHow To Calculate Filler Metal ConsumptionASHIL PRABHAKAR100% (2)

- Aqa MM1B W QP Jun11Document20 pagesAqa MM1B W QP Jun11CindyVortexNo ratings yet

- NR13HELPPT - RTF Page 1 of 17: Help BrainDocument17 pagesNR13HELPPT - RTF Page 1 of 17: Help BrainXuân Hòa NguyễnNo ratings yet

- Reinforced Concrete Chapter 3 SolutionsDocument5 pagesReinforced Concrete Chapter 3 SolutionsFofer Fofe100% (1)

- Ex3 - Fire Under Concrete Slab - Compos PDFDocument64 pagesEx3 - Fire Under Concrete Slab - Compos PDFEmra MerdićNo ratings yet

- Gas Well Testing TypesDocument19 pagesGas Well Testing TypesKhalidNo ratings yet

- Desiccant Dehumidifier MDC 18000: Forget Humidity For Ever!Document4 pagesDesiccant Dehumidifier MDC 18000: Forget Humidity For Ever!Mourad AhmadNo ratings yet

- Ultrasound - Clinical Science Questions and AnswersDocument2 pagesUltrasound - Clinical Science Questions and AnswersSaqibKhan100% (8)

- Calculate Mass of Air, Pressure at Pool Bottom, Breathing UnderwaterDocument2 pagesCalculate Mass of Air, Pressure at Pool Bottom, Breathing UnderwaterHaffiz AtingNo ratings yet

- TakengonDocument11 pagesTakengonTeguh PriadiNo ratings yet

- 38-Character for Sheet Metal Cutting DocumentDocument14 pages38-Character for Sheet Metal Cutting Documentkolla satishNo ratings yet

- Stone Column - LectureDocument52 pagesStone Column - LecturePratik ParekhNo ratings yet

- Sky Air Seasonal Classic Conductos Baja Silueta Serie DDocument1 pageSky Air Seasonal Classic Conductos Baja Silueta Serie DmiroNo ratings yet

- ST5012-Design of Sub StructuresDocument15 pagesST5012-Design of Sub StructuresNarayanan Moorthy33% (3)

- Validation of ENVI-met PMV Values by In-Situ Measuremen TsDocument6 pagesValidation of ENVI-met PMV Values by In-Situ Measuremen TsHendra CesmamulyaNo ratings yet

- X-Rays: Click To Add TextDocument43 pagesX-Rays: Click To Add TextAhmedNo ratings yet

- 6.3 Reversible ReactionsDocument5 pages6.3 Reversible Reactionssukomol baruaNo ratings yet

- Major Earthquake and Volcano HotspotsDocument41 pagesMajor Earthquake and Volcano HotspotsClark Justine LigaoNo ratings yet