Professional Documents

Culture Documents

Properties of Non Ferrous Metal Uses of Ferrous Metal: School of Civil Engineering and Surveying

Uploaded by

Hadhi Hassan Khan0 ratings0% found this document useful (0 votes)

16 views1 pageThis research poster summarizes key information about ferrous and non-ferrous metals used in engineering. It discusses the properties and applications of malleable cast iron, wrought iron, steel, aluminum, copper, zinc, and lead. Pictures show examples of how these metals are used in tools, buildings, vehicles, and infrastructure. The poster provides a helpful overview of important metals and their structural and material properties for engineering and construction applications.

Original Description:

poster of construction material

Original Title

Poster Metal

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis research poster summarizes key information about ferrous and non-ferrous metals used in engineering. It discusses the properties and applications of malleable cast iron, wrought iron, steel, aluminum, copper, zinc, and lead. Pictures show examples of how these metals are used in tools, buildings, vehicles, and infrastructure. The poster provides a helpful overview of important metals and their structural and material properties for engineering and construction applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 pageProperties of Non Ferrous Metal Uses of Ferrous Metal: School of Civil Engineering and Surveying

Uploaded by

Hadhi Hassan KhanThis research poster summarizes key information about ferrous and non-ferrous metals used in engineering. It discusses the properties and applications of malleable cast iron, wrought iron, steel, aluminum, copper, zinc, and lead. Pictures show examples of how these metals are used in tools, buildings, vehicles, and infrastructure. The poster provides a helpful overview of important metals and their structural and material properties for engineering and construction applications.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Research Poster of Metals as Engineering Material

School of Civil Engineering and Surveying

Introduction Uses of Ferrous Metal Properties of Non Picture of Use

Ferrous is an adjective used to indicate the presence of iron. The word

Malleable Cast Iron

• It is used in Automobile industries for making rear-axle

Ferrous Metal Metals

is derived from the Latin word ferrum "iron"). Ferrous metals include Aluminum Properties:

housing, steering-gear housing, hubs, and pedals, etc.

steel and pig iron (with a carbon content of a few percent) and alloys Following are some important properties of this metal.

• It is used in Railway equipment of a great variety.

of iron with other metals (such as stainless steel). The term non- It is very ductile and can be transformed into any shape by rolling,

• It is used in Agricultural machinery making and carpentry

ferrous is used to indicate metals other than iron and alloys that do not stamping, extruding, forging, drawing, and spinning.

tools.

contain an appreciable amount of iron. It can also be cast into any shape by any method of casting, i.e., die Fig 4 structure steel shape

Type of ferrous metals casting, chill casting, and sand casting.

Pig iron is the intermediate product of smelting iron ore with a high- It has a tensile strength of about 900kg/cm2 in the annealed condition.

carbon fuel such as coke, usually with limestone as a flux. Charcoal It can be improved to 1600kg/cm2 by the hard-rolling method.

and anthracite have also been used as fuel. Aluminum is highly resistant to corrosion. When exposed to moist air,

Pig iron has a very high carbon content, typically 3.5–4.5%, which aluminum forms a thin film of oxide at the top, which is impervious to

Fig 1 tool makes from Malleable Cast Iron

makes it very brittle and not useful directly as a material except for air/moisture, and thus saves the metal from further corrosion.

Wrought Iron Fig 5 Rectangular steel frame, of the Willis building contrasted

limited applications. An ingot is a material, usually metal, that is cast Copper against the diagrid frame at 30 St Mary Axe, London,

Because of the above set of properties, wrought iron is extensively

into a shape suitable for further processing. This is due to some of the useful properties of copper. Some of the

used as a material for making plates, sheets, pipes, tubes, etc.

WROUGHT IRON is Manufactured by melting & refining iron to a most important properties of copper are as under:

It is also used in buildings, railways, and marine industries

high degree of purity. Then, molten metal is poured into a ladle and It has excellent joining properties, i.e., it can be joined by almost all

mixed with hot slag. The fluxing action of the slag causes a spongy the common methods: welding, soldering, brazing and riveting.

mass to form which is processed by rolling & pressing. It is only iron- It has a very high electrical conductivity.

bearing material containing slag. It’s a low carbon steel (less than It has good resistance to corrosion.

0.1% carbon by weight containing a small amount of slag, Zinc

usually less than 3%. It contains small amount of manganese (less Following are some important properties of Zinc.

Fig 1 tool makes from Malleable Cast Iron

than 0.1%) and silicon (0.2%). It’s ductility is lower than steel. It’s It is whitish and has bright lustre.

Steel

tensile strength is lower. It has a density of 7.14 g/ml.

Due to these properties, Steel is used as a structural material in all Fig 6 Interior partition walls made with cold formed

Steel is an alloy that consists mostly of iron and has a carbon content Its melting point is 419 centigrade and boiling point is 907 centigrade. steel

types of situations.

between 0.2% and 2.1% by weight, depending on the grade. Carbon is It has a tensile strength of 700-1400 kg/cm2.

the most common alloying material for iron, but various other alloying

Steel is a versatile material of modern age. Its properties can be

varied over a wide range by varying its composition and by

Commercial zinc (spelter) is easily attacked by acids. Bibliography

elements are used, such as manganese, chromium, vanadium, and Zinc surface is covered by a dull basic zinc carbonate in moist air.

subjecting it to various mechanical and heat treatment processes. 1. An, J., Farha, O.K., Hupp, J.T., Pohl, E., Yeh, J.I. and Rosi, N.L., (2012).

tungsten. Steel with increased carbon content can be made harder and Lead Metal-adeninate vertices for the construction of an exceptionally porous

metal-organic framework. Nature communications, 3, p.604

stronger than iron, but such steel is also less ductile than iron. Steel is The metallic lead has following properties. 2. Hornbostel, C., (1991). Construction materials: Types, uses and

. applications. John Wiley & Sons.

an alloy of iron and carbon. Pure iron’s strength remarkably increases It has bluish Grey color. 3. James, A.N., 1992. Soluble materials in civil engineering. Ellis Horwood.

4. Blanc, A., McEvoy, M. and Plank, R. eds., (1993). Architecture and

when alloyed with carbon. The tensile strength increases with It has typically brilliant lustre. construction in steel. Taylor & Francis.

5. Domone, PLJ, Illston, J M (2010).Construction materials: their nature

increasing carbon content but the ductility reduces. Steel having its It has a high density – 11.35 g/cm3. and behaviour.

6. Jackson, N and Dhir, R K (1996). Civil Engineering Materials (5th

properties because of the presence of carbon alone is called “Plain It is very good to resistance to corrosion. Edition), Macmillan.

carbon steel”

Fig 3 steel bar for R.C.C construction

You might also like

- Ferrous and Non Ferrous MetalsDocument16 pagesFerrous and Non Ferrous Metalssonu100% (1)

- Bcme Textbook Important QuestionsDocument13 pagesBcme Textbook Important QuestionsMahindra ChelliNo ratings yet

- Hwno.5 - Bsa1c - Saylon - Efraine AndreaDocument22 pagesHwno.5 - Bsa1c - Saylon - Efraine Andreaefraineandrea.saylonNo ratings yet

- Building Material ScienceDocument1 pageBuilding Material ScienceHarsh Raj JainNo ratings yet

- Steel: Building MaterialDocument12 pagesSteel: Building MaterialAnayNo ratings yet

- 5.1 MetallicDocument31 pages5.1 MetallicFARAH AYUNIE BINTI JASNI KM-PensyarahNo ratings yet

- Group 7: Steel and Steel Alloy What Is Metal?Document4 pagesGroup 7: Steel and Steel Alloy What Is Metal?Kent Clark VillaNo ratings yet

- Metal As Building MaterialDocument11 pagesMetal As Building MaterialJM BildNo ratings yet

- Metal Lecture NotesDocument8 pagesMetal Lecture Notesbsnow5325No ratings yet

- 150 Sample-Chapter PDFDocument25 pages150 Sample-Chapter PDFMochammad Waris SNo ratings yet

- CH 7 MetalsDocument16 pagesCH 7 MetalsNirose ChhukanNo ratings yet

- Engineering Materials NotesDocument25 pagesEngineering Materials NotesRoobanesh ManoharanNo ratings yet

- IRON - Module - 02Document27 pagesIRON - Module - 02Asna AbbasNo ratings yet

- BMC MergedDocument93 pagesBMC Mergedkevin tomNo ratings yet

- Ime Module 4Document32 pagesIme Module 4Prakhyath MNo ratings yet

- Metal and Metal Alloys NotesDocument18 pagesMetal and Metal Alloys NotesKshitij SaojiNo ratings yet

- Capili Jefferson 13Document12 pagesCapili Jefferson 13Christian Al EncarnacionNo ratings yet

- Construction Material: (Metallic Materials)Document28 pagesConstruction Material: (Metallic Materials)adeliene 25No ratings yet

- CBSE - 12 - English - Art Integrated ProjectDocument7 pagesCBSE - 12 - English - Art Integrated ProjectAnusha75% (4)

- Construction and Construction Materials MetalsDocument49 pagesConstruction and Construction Materials MetalsAleyna ErolNo ratings yet

- English Art Intergeated ProjectDocument7 pagesEnglish Art Intergeated ProjectNaresh JagarwalNo ratings yet

- Metals: Manashi SP Adhikari, Yugesh Subedi Chhetri, Bidhi Shrestha, Bidit DabadiDocument15 pagesMetals: Manashi SP Adhikari, Yugesh Subedi Chhetri, Bidhi Shrestha, Bidit Dabadibidhi shresthaNo ratings yet

- Ferrous and Non FerrousDocument5 pagesFerrous and Non FerrousMishel P. FerolinoNo ratings yet

- Hwno.5 Bsa-1a AlcantaraDocument22 pagesHwno.5 Bsa-1a AlcantaraAngel Mine AlcantaraNo ratings yet

- Engineering MaterialsDocument18 pagesEngineering MaterialsAhmed ElkomyNo ratings yet

- Module 2 emDocument8 pagesModule 2 emGowda KadurNo ratings yet

- Metals 2023 2024Document36 pagesMetals 2023 2024Joshua TupasNo ratings yet

- 7 Steel and Steel AlloysDocument3 pages7 Steel and Steel AlloysKent Clark VillaNo ratings yet

- Mechanical MaterialDocument19 pagesMechanical MaterialcacaNo ratings yet

- Group 5 - Written ReportDocument17 pagesGroup 5 - Written ReportVeeNo ratings yet

- Lesson 05Document12 pagesLesson 05Lia CambangayNo ratings yet

- Ferrous and Non Ferrous MetalsDocument3 pagesFerrous and Non Ferrous MetalsTalle Gabua100% (1)

- Cast IronDocument6 pagesCast IronSegun TalabiNo ratings yet

- Metallographic Preparation of Cast Iron: Application NotesDocument6 pagesMetallographic Preparation of Cast Iron: Application NotesmarianaNo ratings yet

- Non Ferrous MetalsDocument6 pagesNon Ferrous MetalsChrissaNo ratings yet

- 2.b Poster - Ferrous Material and AlloyDocument1 page2.b Poster - Ferrous Material and AlloyChristian Dave RoneNo ratings yet

- ULO2 BDocument4 pagesULO2 BKaris DemetriaNo ratings yet

- Metal and Metal Alloys NotesDocument18 pagesMetal and Metal Alloys Notesrutuja75% (4)

- Unit 6-Metals & Non-MetalsDocument8 pagesUnit 6-Metals & Non-MetalsRahul KumarNo ratings yet

- Mse Notes - Unit - 3Document11 pagesMse Notes - Unit - 3337-ME- KIRTHAN DEVADIGANo ratings yet

- OML753 UNIT 1 Classification Metal and AlloysDocument36 pagesOML753 UNIT 1 Classification Metal and AlloysSiva RamNo ratings yet

- MicroprojectDocument13 pagesMicroprojectomkar digamabar sonone0% (1)

- METALSDocument48 pagesMETALSMian Afzaal 72No ratings yet

- Unit - 2 Ferrous - Non Ferrous MaterialDocument15 pagesUnit - 2 Ferrous - Non Ferrous MaterialKrishna SomaniNo ratings yet

- Metal and AlloysDocument20 pagesMetal and AlloysShifat RashidNo ratings yet

- Rigon PentecostesDocument9 pagesRigon PentecostesMarlNo ratings yet

- Iron and It's TypesDocument12 pagesIron and It's TypesSakshi SharmaNo ratings yet

- Ferrous Alloys & Non - Ferrous AlloysDocument11 pagesFerrous Alloys & Non - Ferrous AlloysMuath A, RadhwanNo ratings yet

- Reviewer Chapter 3-4Document2 pagesReviewer Chapter 3-4Kyle BullandayNo ratings yet

- Bgtech 1 Research Paper Ferrous and Non Ferrous Metals: Far Eastern University Institute of Architecture and Fine ArtsDocument23 pagesBgtech 1 Research Paper Ferrous and Non Ferrous Metals: Far Eastern University Institute of Architecture and Fine ArtsRousseau Pierre LouisNo ratings yet

- Agricultural Machinery Design - Construction MaterialsDocument4 pagesAgricultural Machinery Design - Construction Materialskirbey0% (1)

- Engineering Materials: Learning ObjectivesDocument11 pagesEngineering Materials: Learning Objectives38Zeeshan ZameerNo ratings yet

- Workshop Technology (PDFDrive)Document125 pagesWorkshop Technology (PDFDrive)Bishal KumarNo ratings yet

- MetalsDocument8 pagesMetalsAnna KateurinaNo ratings yet

- Iron (Pig Iron, Cast Iron, Wrought Iron)Document18 pagesIron (Pig Iron, Cast Iron, Wrought Iron)Bhanu Pratap SinghNo ratings yet

- Types of MetalsDocument14 pagesTypes of MetalsThabiso MmesoNo ratings yet

- UNIT 2 PPT 1Document42 pagesUNIT 2 PPT 1neha yarrapothuNo ratings yet

- Preserving MetalsDocument22 pagesPreserving MetalsLaila KaderNo ratings yet

- BT Presentation 5 MetalsDocument48 pagesBT Presentation 5 Metalsjoanna libananNo ratings yet

- Img 6891Document1 pageImg 6891Hadhi Hassan KhanNo ratings yet

- Img 6887Document1 pageImg 6887Hadhi Hassan KhanNo ratings yet

- Chap7 Signal LOSDocument34 pagesChap7 Signal LOSHadhi Hassan KhanNo ratings yet

- Health Inequalities in UKDocument9 pagesHealth Inequalities in UKHadhi Hassan KhanNo ratings yet

- Urban Transportation PlanningDocument1 pageUrban Transportation PlanningHadhi Hassan KhanNo ratings yet

- Img 6888Document1 pageImg 6888Hadhi Hassan KhanNo ratings yet

- Img 6892Document1 pageImg 6892Hadhi Hassan KhanNo ratings yet

- Img 6895Document1 pageImg 6895Hadhi Hassan KhanNo ratings yet

- Img 6890Document1 pageImg 6890Hadhi Hassan KhanNo ratings yet

- Img 6886Document1 pageImg 6886Hadhi Hassan KhanNo ratings yet

- Img 6893Document1 pageImg 6893Hadhi Hassan KhanNo ratings yet

- Img 6894Document1 pageImg 6894Hadhi Hassan KhanNo ratings yet

- Img 6889Document1 pageImg 6889Hadhi Hassan KhanNo ratings yet

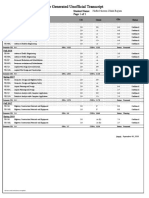

- Unofficial DMC ReportDocument1 pageUnofficial DMC ReportHadhi Hassan KhanNo ratings yet

- Unofficial DMC ReportDocument1 pageUnofficial DMC ReportHadhi Hassan KhanNo ratings yet

- 4.9 Dfis & Nbfcs Consolidated Financial Position Assets / LiabilitiesDocument4 pages4.9 Dfis & Nbfcs Consolidated Financial Position Assets / LiabilitiesHadhi Hassan KhanNo ratings yet

- Unofficial DMC Report PDFDocument1 pageUnofficial DMC Report PDFHadhi Hassan KhanNo ratings yet

- Quotation Notice: For The Printing of Provisional Certificate and Continuation SheetDocument1 pageQuotation Notice: For The Printing of Provisional Certificate and Continuation SheetHadhi Hassan KhanNo ratings yet

- 1nbp611 2511Document1 page1nbp611 2511Hadhi Hassan KhanNo ratings yet

- University of Turbat: Tender NoticeDocument1 pageUniversity of Turbat: Tender NoticeHadhi Hassan KhanNo ratings yet

- Unofficial DMC ReportDocument1 pageUnofficial DMC ReportHadhi Hassan KhanNo ratings yet

- Unofficial DMC ReportDocument1 pageUnofficial DMC ReportHadhi Hassan KhanNo ratings yet

- Unofficial DMC Report PDFDocument1 pageUnofficial DMC Report PDFHadhi Hassan KhanNo ratings yet

- Unofficial DMC ReportDocument1 pageUnofficial DMC ReportHadhi Hassan KhanNo ratings yet

- Abdc ListDocument40 pagesAbdc ListHadhi Hassan KhanNo ratings yet

- Unofficial DMC ReportDocument1 pageUnofficial DMC ReportHadhi Hassan KhanNo ratings yet

- hrmt3 Assessment Guide - 2020Document11 pageshrmt3 Assessment Guide - 2020Hadhi Hassan KhanNo ratings yet

- Unofficial DMC ReportDocument1 pageUnofficial DMC ReportHadhi Hassan KhanNo ratings yet

- Unofficial DMC ReportDocument1 pageUnofficial DMC ReportHadhi Hassan KhanNo ratings yet

- Unofficial DMC ReportDocument1 pageUnofficial DMC ReportHadhi Hassan KhanNo ratings yet

- Lore Skills: Engineering (Mental 0% Base Training Only)Document3 pagesLore Skills: Engineering (Mental 0% Base Training Only)Remi Andre Foseid ThoresenNo ratings yet

- Callister Solution PDFDocument47 pagesCallister Solution PDFi origaMNo ratings yet

- Corrosion Engineering - Lecture 2Document26 pagesCorrosion Engineering - Lecture 2Ali A AlRazzakNo ratings yet

- US8034246 PatentDocument9 pagesUS8034246 PatentCatalina SarriaNo ratings yet

- Trugrid Structural Final DraftDocument27 pagesTrugrid Structural Final DraftrogerngcyNo ratings yet

- Shape Deposition Manufacturing and Multijet ModelingDocument13 pagesShape Deposition Manufacturing and Multijet ModelingRitam GangulyNo ratings yet

- Astm B 233Document4 pagesAstm B 233Ryan LasacaNo ratings yet

- Plasma MachiningDocument34 pagesPlasma MachiningMonil DaveNo ratings yet

- Industry Classification Benchmark (ICB)Document2 pagesIndustry Classification Benchmark (ICB)Xbox FlashingNo ratings yet

- LSS Revision Booklet Y10Document27 pagesLSS Revision Booklet Y10Gary DarrenNo ratings yet

- Corrosion Rate Investigation Due To Stray CurrentDocument69 pagesCorrosion Rate Investigation Due To Stray CurrentN'FNo ratings yet

- ,MMNBGDocument6 pages,MMNBGAnonymous FW5PVUp100% (1)

- Janaki Ram. CVDocument13 pagesJanaki Ram. CVdkannanapkNo ratings yet

- Steel Coding SystemDocument5 pagesSteel Coding SystemWell LojuminNo ratings yet

- Siavashi 12 PHDDocument231 pagesSiavashi 12 PHDVikash SinghNo ratings yet

- Prospecting For OresDocument8 pagesProspecting For OresDindin WahidinNo ratings yet

- E Waste Recycling in Malaysia PDFDocument16 pagesE Waste Recycling in Malaysia PDFwahco008No ratings yet

- CRM 2020 Critical FactsheetsDocument819 pagesCRM 2020 Critical FactsheetsMatteo ContiNo ratings yet

- An Overview of The Corrosion Aspect of Dental Implants (Titanium and Its Alloys)Document4 pagesAn Overview of The Corrosion Aspect of Dental Implants (Titanium and Its Alloys)anilsamuel0077418No ratings yet

- 6 Jun 2017 IGEM 2016 Key in Enquiry 10 Oct 2016Document36 pages6 Jun 2017 IGEM 2016 Key in Enquiry 10 Oct 2016rexNo ratings yet

- RIMCDocument22 pagesRIMCAmol Chikhale67% (3)

- HAST 230 BrochureDocument30 pagesHAST 230 BrochureSusheel GuptaNo ratings yet

- Study of Constituents of An AlloyDocument18 pagesStudy of Constituents of An AlloyMohammed Anis RahmanNo ratings yet

- Chemical Review Before Li Ion Batteries PDFDocument24 pagesChemical Review Before Li Ion Batteries PDFAditya HuseinNo ratings yet

- Ultipor® III Filter Elements DescriptionDocument3 pagesUltipor® III Filter Elements DescriptionjeliocNo ratings yet

- Design of Flexible Bush Pin Coupling For Asamnew PRORESSDocument13 pagesDesign of Flexible Bush Pin Coupling For Asamnew PRORESSLewi100% (1)

- B - Tech CHEMICAL 2010 2011 2012Document63 pagesB - Tech CHEMICAL 2010 2011 2012Ssheshan PugazhendhiNo ratings yet

- Steelworks Products and Tinsmithing ToolsDocument39 pagesSteelworks Products and Tinsmithing ToolsEli SuarezNo ratings yet

- Ancient Indian Metallurgy - Indian ScripturesDocument9 pagesAncient Indian Metallurgy - Indian ScripturesBaldev RamNo ratings yet

- Heat Generation and Temperature Prediction in Metal Cutting: A Review and Implications For High Speed Machining.Document19 pagesHeat Generation and Temperature Prediction in Metal Cutting: A Review and Implications For High Speed Machining.SoudeepSahaNo ratings yet