Professional Documents

Culture Documents

MTX R 0000000005 Capacitor Bank Sizing

Uploaded by

nknfiveCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MTX R 0000000005 Capacitor Bank Sizing

Uploaded by

nknfiveCopyright:

Available Formats

1 EXECUTIVE SUMMARY

This report captures the methodology and calculations performed for sizing the capacitor banks

for Urban Mining power system facility in San Macros, Texas. This is a greenfield project and it

is desired to correct the power factor to limit the reactive power consumption at a minimum.

Capacitor bank were sized and results are presented in a tabular format in order to achieve

desired power factors of 0.85, 0.9 and 0.97.

2 DATA USED IN CALCULATIONS

Data presented in equipment utility motor requirements list and the latest electrical one-line

diagram dated 12/21/18 provided to MTX Systems Engineering was used in the calculations.

Appendix A and B presents the load flows onelines of the scenarios 250T and 1000T

respectively. Load data available for each of the panel boards in the system indicated are

indicated on the one lines.

Appendix C provides a list of data provided to MTX Systems Engineering for evaluation of the

power system. Two columns are added with comments for final completion of the capacitor

bank system evaluation.

MTX-R-000000005 – Capacitors Bank Sizing

3 POWER FACTOR CORRECTION STUDY

3.1 General Procedure

AC electrical equipment typically consumes two types of power: active power (kW) and reactive

power (kVAr):

• The active power P (in kW) is the real power transmitted to loads such as motors, lamps,

heaters, computers, etc. The electrical active power is transformed into mechanical

power, heat or light.

• The reactive power Q (in kVAr) is used only to power the magnetic circuits of machines,

motors, and transformers.

The apparent power S (in kVA) is the vector combination of active and reactive power

The circulation of reactive power in the electrical network has major technical and economic

consequences. For the same active power P, higher reactive power means higher apparent

power, and thus a higher current must be supplied. The circulation of active power over time

results in active energy (in kWh). The circulation of reactive power over time results in reactive

energy (kVArh). Electric utilities bill both these energies and at the same time, electrical

infrastructure may need to be upsized to allow the circulation of reactive power.

For these reasons, there is a great advantage in generating reactive energy at the load level in

order to prevent the unnecessary circulation of current in the network. This is what is known as

“power factor correction”. This is obtained by the connection of capacitors, which produce

reactive energy in opposition to the energy absorbed by loads such as motors. The result is a

reduced apparent power and an improved power factor.

The required power factor correction (Qc) can be calculated using vector subtraction as

illustrated below.

𝑄𝑐 = 𝑃. (𝑡𝑎𝑛𝜑 − 𝑡𝑎𝑛𝜑′ )

Where,

𝜑 = 𝑐𝑜𝑠 −1 (𝑖𝑛𝑖𝑡𝑖𝑎𝑙 𝑝𝑜𝑤𝑒𝑟 𝑓𝑎𝑐𝑡𝑜𝑟)

𝜑1 = 𝑐𝑜𝑠 −1 (𝑑𝑒𝑠𝑖𝑟𝑒𝑑 𝑝𝑜𝑤𝑒𝑟 𝑓𝑎𝑐𝑡𝑜𝑟)

MTX-R-000000005 – Capacitors Bank Sizing

3.2 Calculations

Real and Reactive power data was obtained from a load flow calculation using SKM Power

System. Same software tool was used for calculating each power factor correction capacitor

bank.

The tables below capture the current power factor and the results with of the required capacitor

banks, along with the recommended rounded values to the next size up for each bank. Table 4

below captures three scenarios for the desired capacitor banks for a power factor of 0.85, 0.90

and 0.97.

The calculations are performed for scenarios of 1000T and 250T and results are tabulated as

below.

3.2.1 Scenario-1: Plant with loads running for 250T phase.

Table 1 Data from Load flow Calculations

Switchboard kW kVAr Current PF

E-MSBA 764 557 0.808

E-MSBB 1325 1000 0.798

MSBC 853 630 0.804

MSBD 780 575 0.805

Table 2 Calculation Results

Capacitor bank required in kVAr

Switchboard for PF =0.85 for PF =0.90 for PF =0.97

E-MSBA 83.65 187.16 365.81

E-MSBB 179.07 358.48 668.09

MSBC 101.14 216.62 415.89

MSBD 91.20 196.88 379.26

Table 3 Recommended Capacitor Bank Sizes

Recommended sizes in kVAr

Switchboard for PF =0.85 for PF =0.90 for PF =0.97

E-MSBA 100 200 400

E-MSBB 200 400 700

MSBC 150 250 450

MSBD 100 200 400

MTX-R-000000005 – Capacitors Bank Sizing

3.2.2 Scenario-2: Plant with loads running for 1000T phase.

Table 4 Data from Load flow Calculations

Switchboard kW kVAr Current PF

E-MSBA 3180 2330 0.807

E-MSBB 2705 2044 0.798

MSBC 1313 978 0.802

MSBD 780 575 0.805

Table 5 Calculation Results

Capacitor bank required in kVAr

Switchboard for PF =0.85 for PF =0.90 for PF =0.97

E-MSBA 359.45 790.04 1533.11

E-MSBB 367.51 733.83 1365.98

MSBC 164.63 342.40 649.19

MSBD 91.20 196.88 379.26

Table 6 Recommended Capacitor Bank Sizes

Recommended sizes in kVAr

Switchboard for PF =0.85 for PF =0.90 for PF =0.97

E-MSBA 400 800 1600

E-MSBB 400 800 1400

MSBC 200 350 700

MSBD 100 200 400

MTX-R-000000005 – Capacitors Bank Sizing

APPENDIX-A LOAD FLOW ONE-LINE DIAGRAMS

(SCENARIO-1: 250T CAPACITY)

MTX-R-000000005 – Capacitors Bank Sizing

APPENDIX-B LOAD FLOW ONE-LINE DIAGRAMS

(SCENARIO-2: 1000T CAPACITY)

MTX-R-000000005 – Capacitors Bank Sizing

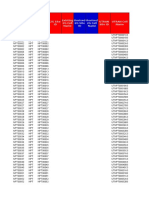

APPENDIX-C EQUIPMENT UTILITY MOTOR REQUIREMENTS

MTX-R-000000005 – Capacitors Bank Sizing

You might also like

- Pm0504 Mud Fault Data FormDocument1 pagePm0504 Mud Fault Data FormnknfiveNo ratings yet

- Soil Report Al AinDocument102 pagesSoil Report Al AinnknfiveNo ratings yet

- 61G15, F.A.C: As of August 10, 2018Document75 pages61G15, F.A.C: As of August 10, 2018nknfiveNo ratings yet

- Vendors ListDocument4 pagesVendors ListnknfiveNo ratings yet

- Q-438222 Urban Mining - Phase 2 - REV0 - DNDocument14 pagesQ-438222 Urban Mining - Phase 2 - REV0 - DNnknfiveNo ratings yet

- HVCapacitors ApplicationGuide en 32044A LTR 2018 04 R001 LRDocument26 pagesHVCapacitors ApplicationGuide en 32044A LTR 2018 04 R001 LRnknfiveNo ratings yet

- Capacitors - LMVPFC ApplicationGuide EN 974I LTR 2018 04 R001 - LR PDFDocument56 pagesCapacitors - LMVPFC ApplicationGuide EN 974I LTR 2018 04 R001 - LR PDFnknfiveNo ratings yet

- Pages From 1415aaph-33kv Gis Single Line DiagramDocument1 pagePages From 1415aaph-33kv Gis Single Line DiagramnknfiveNo ratings yet

- Mv-Swgr-Tie: Spare SpareDocument1 pageMv-Swgr-Tie: Spare SparenknfiveNo ratings yet

- Protection Study SOWDocument1 pageProtection Study SOWnknfiveNo ratings yet

- Ba REG D en 2016 07 WebDocument432 pagesBa REG D en 2016 07 WebnknfiveNo ratings yet

- SLDDocument5 pagesSLDnknfiveNo ratings yet

- Krishna Namala - ResumeDocument1 pageKrishna Namala - ResumenknfiveNo ratings yet

- A-11184 - Detailed Scope of WorkDocument56 pagesA-11184 - Detailed Scope of WorknknfiveNo ratings yet

- Furse - Flat Tape SystemDocument12 pagesFurse - Flat Tape SystemnknfiveNo ratings yet

- Line Protection With L60Document93 pagesLine Protection With L60nknfiveNo ratings yet

- Substation Work SpecifiationDocument98 pagesSubstation Work SpecifiationnknfiveNo ratings yet

- S Aa Cps MV LV Prot (Rev 0 2015)Document46 pagesS Aa Cps MV LV Prot (Rev 0 2015)nknfiveNo ratings yet

- Abb Ge Cross ReferenceDocument4 pagesAbb Ge Cross ReferencenknfiveNo ratings yet

- S Aa Cps MV LV Prot (Rev 0 2015)Document46 pagesS Aa Cps MV LV Prot (Rev 0 2015)nknfiveNo ratings yet

- ETAP 3-ph Fault - CompleteDocument12 pagesETAP 3-ph Fault - CompletenknfiveNo ratings yet

- 1TWD026202S0101Document25 pages1TWD026202S0101nknfiveNo ratings yet

- Relay Logic Diagram SampleDocument16 pagesRelay Logic Diagram SamplenknfiveNo ratings yet

- 1TWD026202N0101Document65 pages1TWD026202N0101nknfiveNo ratings yet

- Protection Relay Coordination Study - Comments From Middle East ClientDocument4 pagesProtection Relay Coordination Study - Comments From Middle East ClientnknfiveNo ratings yet

- ETAP Sample Report - Complete LGDocument12 pagesETAP Sample Report - Complete LGnknfiveNo ratings yet

- Relay ATS IO ListDocument7 pagesRelay ATS IO ListnknfiveNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Allgon 7740.00Document2 pagesAllgon 7740.00Vlad ManNo ratings yet

- Engine PDFDocument254 pagesEngine PDFtipo333194% (18)

- Chapter 08 Discrete State Process ControlDocument32 pagesChapter 08 Discrete State Process ControlJosé Blanco MendezNo ratings yet

- Ee3015 PDFDocument1 pageEe3015 PDFRovick TarifeNo ratings yet

- ReVox A77 Serv Man CompleteDocument114 pagesReVox A77 Serv Man CompleteCristian CotetNo ratings yet

- BM207 Design of Electronic CirsuitsDocument2 pagesBM207 Design of Electronic CirsuitsnidalNo ratings yet

- P30series (메뉴얼)Document72 pagesP30series (메뉴얼)Luân ThànhNo ratings yet

- 1 - Manual NA003 M64 Version 01.11.01C - enDocument115 pages1 - Manual NA003 M64 Version 01.11.01C - enelektrocentarNo ratings yet

- 3D Holographic Projection TechniqueDocument26 pages3D Holographic Projection TechniqueGagan Shrivastava0% (1)

- 4G Database Myanmar 20160621 V1Document73 pages4G Database Myanmar 20160621 V1Boby SharifNo ratings yet

- June15 10EE56 PDFDocument2 pagesJune15 10EE56 PDFrama KrishnaNo ratings yet

- Ofc LedDocument6 pagesOfc LedVignesh DevanNo ratings yet

- Parker Moduflex MicroDocument12 pagesParker Moduflex MicroEdison FerreiraNo ratings yet

- ESYS50-lab4e-sg Oscilloscope Gerardo SanchezDocument6 pagesESYS50-lab4e-sg Oscilloscope Gerardo SanchezGerardo SanchezNo ratings yet

- SEMIKRON DataSheet SKiiP 03NAC12T4V1 25232540Document5 pagesSEMIKRON DataSheet SKiiP 03NAC12T4V1 25232540salesiano05No ratings yet

- Latch UpDocument4 pagesLatch UpSaurabh MishraNo ratings yet

- Electrical Thumb RuleDocument24 pagesElectrical Thumb RulemkdholkiyaNo ratings yet

- Tutorial StellaDocument19 pagesTutorial StellaCaioGomesNo ratings yet

- Flow Meter Bul - 90901e ReducedDocument20 pagesFlow Meter Bul - 90901e ReducedanuraeNo ratings yet

- Aftron - Split AC Unit SpecDocument2 pagesAftron - Split AC Unit Specjhay rarezaNo ratings yet

- Synopsis SamsungDocument12 pagesSynopsis SamsungShivam ThakurNo ratings yet

- 07 July 1969 PDFDocument100 pages07 July 1969 PDFclanonNo ratings yet

- Abb MCCDocument76 pagesAbb MCCfridjatNo ratings yet

- LM117 Voltage RegulatorDocument26 pagesLM117 Voltage Regulatore_bahamondesNo ratings yet

- Radio Frequency SystemDocument8 pagesRadio Frequency SystemMAnohar KumarNo ratings yet

- Seaga Od24 Instruction ManualDocument42 pagesSeaga Od24 Instruction ManualMarco MolinaNo ratings yet

- MECH261 Control Principles: Tutorial #3Document27 pagesMECH261 Control Principles: Tutorial #3Krushnasamy SuramaniyanNo ratings yet

- Drude Model: Successes and LimitationsDocument4 pagesDrude Model: Successes and LimitationsNeeraj Mosawa67% (6)

- Transmi Finals Set BDocument10 pagesTransmi Finals Set BKerwin TejucoNo ratings yet

- Vibration TesterDocument7 pagesVibration Tester07Andhika IqbalNo ratings yet