Professional Documents

Culture Documents

APCO. S-200a Air Release Valve

Uploaded by

Alberto DiazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APCO. S-200a Air Release Valve

Uploaded by

Alberto DiazCopyright:

Available Formats

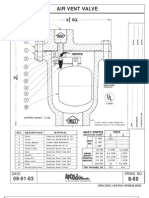

200A AIR RELEASE VALVE

ALVE

DELRIN ASTM D4181

DELRIN ASTM D4181

DELRIN ASTM D4181

DATE DRWG. NO.

09-01-03 S-200A

SPECIFICATIONS OTHER SIDE

September 1, 2003

SPECIFICATIONS

SPECIFICATIONS

200A AIR RELEASE VALVE

The Air Release Valve shall operate (open) while pressurized, allowing entrained air to escape from the water

pipeline, pump or reservoir tank thru the air release orifice. After entrained air escapes thru the air release

orifice, the valve orifice shall be closed by a needle mounted on the compound lever mechanism actuated by

a CONCAVE FLOAT to prevent water from escaping. The air release valve will then stay closed until more

air accumulates in it and the opening cycle will repeat automatically.

The needle shall be Buna-N for tight shut-off and be resilient to prevent seepage due to pipeline or pump

vibrations.

The Air Release Valve compound internal lever mechanism shall be all Stainless Steel or Bronze or Delrin

(Engineer to select one). All other internals must be stainless steel. The stainless steel float must be CON-

CAVE and sufficiently buoyant to operate water and be SPURT FREE.

The valve shall withstand 500 psi test pressure and have a 3/16" orifice for operating (opening) pressure up

to 150 psi. The venting capacity @ 150 psi shall be 55º CFFAM.

All materials of construction shall be certified in writing to conform to A.S.T.M. specifications as follows:

Body & Cover Cast Iron ASTM A126 Gr. B

Concave float patented Stainless Steel ASTM A240 T304

Needle Buna-N Nitrile Rubber

Internal Linkage Stainless Steel (Engineer to Select One) ASTM A296, T316

or Bronze ASTM B584

or Delrin ASTM D4181

Exterior Paint Universal Metal Primer

Note: Other materials available.

Valve to be APCO 200A Air Release Valve as manufactured by Valve & Primer Corporation, Schaumburg,

Illinois, U.S.A.

1420 S. Wright BLVD. Schaumburg, IL 60193-4599

847-524-9000 FAX 847-524-9007 800-323-6969

WEBSITE: www.apcovalves.com EMAIL: factory@apcovalves.com

You might also like

- Combination Air Valves Guide for PipelinesDocument4 pagesCombination Air Valves Guide for PipelinesFelipe OliverosNo ratings yet

- Apco Air Valve GuideDocument12 pagesApco Air Valve Guideanon_711152122No ratings yet

- APCO Air Valve 613Document4 pagesAPCO Air Valve 613jones0055No ratings yet

- Air Valves ValmaticDocument28 pagesAir Valves Valmaticnimm1962100% (1)

- Air Vacuum ValvesDocument4 pagesAir Vacuum ValvesmariuspiNo ratings yet

- Actuadores Neumáticos e HidraulicosDocument8 pagesActuadores Neumáticos e HidraulicosdavidnpsNo ratings yet

- SERIES 3000: Angle Surge Relief ValveDocument6 pagesSERIES 3000: Angle Surge Relief ValveMd Aamir AnsariNo ratings yet

- Cat.# 90-8M0060852 Power Trim AssemblyDocument2 pagesCat.# 90-8M0060852 Power Trim AssemblyAlex DiazNo ratings yet

- Deluge Valve Technical DataDocument16 pagesDeluge Valve Technical DataNata 1986No ratings yet

- Avk Saudi National Price ListDocument46 pagesAvk Saudi National Price Listjanpaul2481No ratings yet

- Peerless Pump Horizontal & Inline Fire Pump SelectionDocument14 pagesPeerless Pump Horizontal & Inline Fire Pump Selectionاحمد الجزار2007No ratings yet

- OZKAN Butterfly ValvesDocument11 pagesOZKAN Butterfly ValvesAhmed AbdelwaneesNo ratings yet

- Forbes Marshall Consultancy specifications for compressed air accessoriesDocument2 pagesForbes Marshall Consultancy specifications for compressed air accessoriessppatilNo ratings yet

- CLKMC 0109 UsDocument4 pagesCLKMC 0109 UsRioga RiogaNo ratings yet

- Bombas DDDDocument3 pagesBombas DDDVladimir E. BalvinNo ratings yet

- Bv421 Pressure Reducing ValveDocument4 pagesBv421 Pressure Reducing ValveFAIYAZ AHMEDNo ratings yet

- Bomba Goulds 3X4 - E213h513 PDFDocument18 pagesBomba Goulds 3X4 - E213h513 PDFRoger ChavezNo ratings yet

- AVK Resilient Seated Gate ValvesDocument36 pagesAVK Resilient Seated Gate ValvesCarel De JagerNo ratings yet

- Apco Vacuum Reliefair Inlet Valves Avr 1500 PDFDocument8 pagesApco Vacuum Reliefair Inlet Valves Avr 1500 PDFTanmoy Dutta100% (1)

- Air Release 2014Document4 pagesAir Release 2014Aly AnisNo ratings yet

- CompanyPresentationScrewpumps PpsDocument87 pagesCompanyPresentationScrewpumps PpsbagibagifileNo ratings yet

- Proportional Pressure Control Valves Series P2 & 4VP01Document12 pagesProportional Pressure Control Valves Series P2 & 4VP01abuzer1981No ratings yet

- Instrument ListDocument266 pagesInstrument ListdevsysNo ratings yet

- Basic Pump SizingDocument50 pagesBasic Pump SizingRizaldiSaputraNo ratings yet

- MarlinDocument28 pagesMarlincumpio425428No ratings yet

- Deluge Valve - SD-DVH2Document16 pagesDeluge Valve - SD-DVH2Vijay Gaikwad0% (1)

- Hydromatic: Submersible Sewage PumpDocument10 pagesHydromatic: Submersible Sewage Pumpاحمد همامNo ratings yet

- Pressure Reducing Valve CatalogueDocument4 pagesPressure Reducing Valve CatalogueSteveNo ratings yet

- Theory Application and Sizing of Air ValvesDocument9 pagesTheory Application and Sizing of Air ValveskcplemmonsNo ratings yet

- IIT-Intake and Exhaust Manifold DesignDocument28 pagesIIT-Intake and Exhaust Manifold DesignVasudev GuptaNo ratings yet

- Friction Loss On SuctionDocument2 pagesFriction Loss On SuctionSathish LingamNo ratings yet

- Clyde IsoglideDocument2 pagesClyde IsoglideShaisone ShoopNo ratings yet

- Cooling System Surge Analysis With AFT ImpulseDocument2 pagesCooling System Surge Analysis With AFT ImpulsektejankarNo ratings yet

- Pneumatic Air Booster Pump PDFDocument10 pagesPneumatic Air Booster Pump PDFMaxNo ratings yet

- Air Valve 460Document6 pagesAir Valve 460amrezzatNo ratings yet

- Apco Air Release Valves Arv Arv Air Release Valves Sales 600Document4 pagesApco Air Release Valves Arv Arv Air Release Valves Sales 600RashedNo ratings yet

- BFP ARC Valve FunctionDocument6 pagesBFP ARC Valve FunctionVenkat ShanNo ratings yet

- Air in Pipelines 1-19Document9 pagesAir in Pipelines 1-19BhuvanaNo ratings yet

- Pressure Surges and Air Valve Specification PDFDocument22 pagesPressure Surges and Air Valve Specification PDFTONNo ratings yet

- ELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDocument17 pagesELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDSdds0% (1)

- Manual 99 LDDocument20 pagesManual 99 LDCristianNo ratings yet

- Vertical Turbine Pump InstallationDocument34 pagesVertical Turbine Pump InstallationElaine Aubrey BardelosaNo ratings yet

- Product Overview - LeuschDocument32 pagesProduct Overview - Leuschprihartono_diasNo ratings yet

- PSI PumpsDocument12 pagesPSI PumpsagiacomuzoNo ratings yet

- Articoli API 610 9 EditDocument26 pagesArticoli API 610 9 EditmariasofiarossiNo ratings yet

- Dry Screw Vacuum PumpsDocument12 pagesDry Screw Vacuum PumpsJitendra KadamNo ratings yet

- Design Input - Pressure Reducing ValveDocument8 pagesDesign Input - Pressure Reducing ValvekausikrNo ratings yet

- Gas Jet Pump Paper Oct03 Ipa03 e 059Document11 pagesGas Jet Pump Paper Oct03 Ipa03 e 059kglorstadNo ratings yet

- Pump Course Material Chapter 2Document16 pagesPump Course Material Chapter 2engr victorNo ratings yet

- BODP-C workover preparation package materials listDocument391 pagesBODP-C workover preparation package materials listTerenceLimNo ratings yet

- Dynamic Testing of CheckvalveDocument10 pagesDynamic Testing of Checkvalveamirthraj74No ratings yet

- US-4406-8000093951 D-HSEF - CurveDocument6 pagesUS-4406-8000093951 D-HSEF - CurveAdrian DragusinNo ratings yet

- Duplex StrainersDocument1 pageDuplex StrainersBossman Instruments TechnologyNo ratings yet

- Pump Specification Weights and Measurements: Dorothy WaiteDocument14 pagesPump Specification Weights and Measurements: Dorothy WaiteJuan Pablo SanchezNo ratings yet

- Air Release Valve - APCODocument2 pagesAir Release Valve - APCOBaraa' KahlawiNo ratings yet

- Air / Air / Air / Air / Air / V V V V VA A A A Acuum Cuum Cuum Cuum Cuum V V V V VAL AL AL AL Alve VE VE VE VEDocument2 pagesAir / Air / Air / Air / Air / V V V V VA A A A Acuum Cuum Cuum Cuum Cuum V V V V VAL AL AL AL Alve VE VE VE VEnazar750No ratings yet

- APCO #50 air vent valve specsDocument2 pagesAPCO #50 air vent valve specsAhmad MarthaNo ratings yet

- AV2000_ThermostaticAirVentDocument1 pageAV2000_ThermostaticAirVentauxiliar.termicaNo ratings yet

- 1824 000 PI SPC 0003 - 7 - IFP - CleanedDocument22 pages1824 000 PI SPC 0003 - 7 - IFP - CleanedJudith HidalgoNo ratings yet

- Bimetallic Steam TrapsDocument2 pagesBimetallic Steam Trapsasad_naqviNo ratings yet

- Flowrox ValveDimensions ENGDocument32 pagesFlowrox ValveDimensions ENGAlberto DiazNo ratings yet

- Flowrox ValveDimensions ENGDocument32 pagesFlowrox ValveDimensions ENGAlberto DiazNo ratings yet

- B7 GB AZ Boerger Sugar 0513Document4 pagesB7 GB AZ Boerger Sugar 0513Alberto DiazNo ratings yet

- Englisch WerkstoffberichtDocument10 pagesEnglisch WerkstoffberichtAlberto DiazNo ratings yet

- Flowrox PC-pump D-Series Datasheet ENGDocument2 pagesFlowrox PC-pump D-Series Datasheet ENGAlberto DiazNo ratings yet

- Ceram C0+CTDocument1 pageCeram C0+CTAlberto DiazNo ratings yet

- Flowrox LPP-T Hose DatasheetDocument2 pagesFlowrox LPP-T Hose DatasheetAlberto DiazNo ratings yet

- Progressive Cavity Pump Technical Data SheetDocument2 pagesProgressive Cavity Pump Technical Data SheetAlberto DiazNo ratings yet

- Flowrox PC-pump EL-series Datasheet ENGDocument2 pagesFlowrox PC-pump EL-series Datasheet ENGAlberto Diaz100% (1)

- Flowrox LPP D Hose DatasheetDocument2 pagesFlowrox LPP D Hose DatasheetAlberto DiazNo ratings yet

- Anodo de SacrificioDocument1 pageAnodo de SacrificioAlberto DiazNo ratings yet

- Cat Extract mts40 Mts40e Namex Letter 0511 PDFDocument10 pagesCat Extract mts40 Mts40e Namex Letter 0511 PDFAlberto DiazNo ratings yet

- Recubrimiento CeramicoDocument6 pagesRecubrimiento CeramicoAlberto DiazNo ratings yet

- Englisch WerkstoffberichtDocument2 pagesEnglisch WerkstoffberichtAlberto DiazNo ratings yet

- Balmoral RWH HH Direct ManualDocument8 pagesBalmoral RWH HH Direct ManualAlberto DiazNo ratings yet

- Septic Tank Installation ManualDocument12 pagesSeptic Tank Installation Manualingeni0sNo ratings yet

- Balmoral RWH HH Direct ManualDocument8 pagesBalmoral RWH HH Direct ManualAlberto DiazNo ratings yet

- Englisch WerkstoffberichtDocument2 pagesEnglisch WerkstoffberichtAlberto DiazNo ratings yet

- Bls Underground InstallationDocument1 pageBls Underground InstallationAlberto DiazNo ratings yet

- Balmoral Bunded Tank InstallationDocument4 pagesBalmoral Bunded Tank InstallationAlberto DiazNo ratings yet

- 0703PE22 Diseño de SuavizadoresDocument4 pages0703PE22 Diseño de SuavizadoresAlberto DiazNo ratings yet

- Energy Recovery VentilationDocument16 pagesEnergy Recovery VentilationAlberto DiazNo ratings yet

- Approved Plumbing Materials Standards TableDocument4 pagesApproved Plumbing Materials Standards TableAlberto DiazNo ratings yet

- REDO - Product Information 05.05-Engl PDFDocument22 pagesREDO - Product Information 05.05-Engl PDFAlberto DiazNo ratings yet

- 0703PE22 Diseño de SuavizadoresDocument4 pages0703PE22 Diseño de SuavizadoresAlberto DiazNo ratings yet

- Energy Recovery VentilationDocument16 pagesEnergy Recovery VentilationAlberto DiazNo ratings yet

- Calidad Del Agua Decreto-UruDocument16 pagesCalidad Del Agua Decreto-UruAlberto DiazNo ratings yet

- REDO - Product Information 05.05-Engl PDFDocument22 pagesREDO - Product Information 05.05-Engl PDFAlberto DiazNo ratings yet

- A134 PDFDocument4 pagesA134 PDFAlberto DiazNo ratings yet

- 24.PVC Drainage Pipes PDFDocument9 pages24.PVC Drainage Pipes PDFAlberto DiazNo ratings yet

- Design of Slab in SAP2000Document3 pagesDesign of Slab in SAP2000Sandip BudhathokiNo ratings yet

- 1b. PET - RawMaterials-SAMEA March 2008Document29 pages1b. PET - RawMaterials-SAMEA March 2008Muhammad Noman MehboobNo ratings yet

- Checklist For Fire Fighting Works: Metec Design and Construction Engineers India Privite LimitedDocument1 pageChecklist For Fire Fighting Works: Metec Design and Construction Engineers India Privite LimitedBalaNo ratings yet

- COE10102, Forms of CorrosionDocument60 pagesCOE10102, Forms of CorrosionامينNo ratings yet

- Carbon & Stainless Steel Flange Dimensions & WeightsDocument3 pagesCarbon & Stainless Steel Flange Dimensions & Weightssanitary valves aomiteNo ratings yet

- Tender Boq For Proposed Ins Branch New DelhiDocument6 pagesTender Boq For Proposed Ins Branch New DelhiSakthi VeeraNo ratings yet

- Quotation For Layer Equipment With Capacity 55000 Hens - Janey PDFDocument16 pagesQuotation For Layer Equipment With Capacity 55000 Hens - Janey PDFNasim KurdistanNo ratings yet

- Asme Section Ii A-2 Sa-1008 Sa-1008mDocument10 pagesAsme Section Ii A-2 Sa-1008 Sa-1008mAnonymous GhPzn1xNo ratings yet

- Cracks Phenomenonon HousesDocument22 pagesCracks Phenomenonon HousesSarah MendezNo ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- Cement Concrete Pavement ConstructionDocument6 pagesCement Concrete Pavement ConstructionAmit Singh80% (5)

- JZ LSR Catalog AllDocument27 pagesJZ LSR Catalog AllJZ HuangNo ratings yet

- Trial Mix RecordDocument6 pagesTrial Mix Recordfaeez zainNo ratings yet

- Mapethene Ta GB PDFDocument4 pagesMapethene Ta GB PDFJM SubionNo ratings yet

- Pohokura DeckDocument54 pagesPohokura DeckLynn BishopNo ratings yet

- E.2.2 Sheet Metal WorkingDocument18 pagesE.2.2 Sheet Metal WorkingMesfin SisayNo ratings yet

- Check List For Site Construction WorksDocument65 pagesCheck List For Site Construction WorksUmar Farooq91% (11)

- Construction of Flexible PavementDocument5 pagesConstruction of Flexible PavementSaad IrfanNo ratings yet

- Termination Catalog Dragon NEWDocument141 pagesTermination Catalog Dragon NEWRaulNo ratings yet

- Phase Diagram of Fe-Fe3CDocument25 pagesPhase Diagram of Fe-Fe3CIram MustaviNo ratings yet

- Chapter 2 - CompositesDocument42 pagesChapter 2 - CompositesAmmar SafwtNo ratings yet

- Technical Data Sheet: Primerless MMA AdhesivesDocument3 pagesTechnical Data Sheet: Primerless MMA AdhesivespronavNo ratings yet

- PI-Pagoda Tents and AccessoriesDocument2 pagesPI-Pagoda Tents and AccessoriesManishh Venkateshwara RaoNo ratings yet

- Technical Specification: 20' X 8' X 8'6" ISO 1CC TYPE Steel Dry Cargo ContainerDocument24 pagesTechnical Specification: 20' X 8' X 8'6" ISO 1CC TYPE Steel Dry Cargo Containerhareesh13hNo ratings yet

- BCH Enclosure Price List JULY2017Document18 pagesBCH Enclosure Price List JULY2017rcv436No ratings yet

- Product Features: Why Is Shrinkkomp Superior To Conventional Non-Shrinking Grout?Document3 pagesProduct Features: Why Is Shrinkkomp Superior To Conventional Non-Shrinking Grout?saiemNo ratings yet

- WOOD As A BUILDING MATERIAL 2Document9 pagesWOOD As A BUILDING MATERIAL 2Jays Tioxon IIINo ratings yet

- Engineering Materials - Mechanical Engineering Multiple Choice Questions and Answers For Competitive ExamsDocument37 pagesEngineering Materials - Mechanical Engineering Multiple Choice Questions and Answers For Competitive Examsahmish kabbaxeNo ratings yet

- 6-17-0002 STD Spec For Steel Work of Fired Heater & APH SystemDocument13 pages6-17-0002 STD Spec For Steel Work of Fired Heater & APH Systemvmraj2001No ratings yet

- SL - No. Unit Rate. QuantityDocument6 pagesSL - No. Unit Rate. QuantityNaveen RevannaNo ratings yet