Professional Documents

Culture Documents

X Series With Advance Micro and Tier 4i Engine Trouble Codes Diagnosis

Uploaded by

Rafael SolaresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X Series With Advance Micro and Tier 4i Engine Trouble Codes Diagnosis

Uploaded by

Rafael SolaresCopyright:

Available Formats

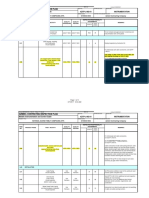

CHANGING THE SETPOINT OPERATING THE MANUAL DEFROST CYCLE

1. Turn unit On/Off switch on.

1. Turn unit On/Off Switch on.

THERMOGUARD PP-VI

2. Press Up and Down Arrow keys to chose 2. Press the Mode key to display [dEF].

the new setpoint. MICROPROCESSOR

3. Press the Enter key. The display will

3. Press the Enter key. The display will briefly show [LOAD], and then the unit will

THERMOGUARD PP-VI 1

enter a defrost cycle. The defrost cycle will

briefly show [LOAD], and then the new TEMPERATURE

setpoint will reappear. terminate automatically.

CYCLE

COOL

SENTRY

HEAT

! ALARM

DEFROST

MODULATION

SELECTING CYCLE SENTRY HIGH SPEED

IN-RANGE VIEWING TEMPERATURE

OR CONTINUOUS MODE SETPOINT

DISPLAYS

1. Turn unit On/Off switch on. 1. Turn the unit On/Off switch on.

2. Press the Mode key to display [CYCLS] 2. Press the Select key to view the

and [YES] or [NO]. temperature display screens as follows:

[DIS.A] Discharge Air Temperature

3. Press the Up or Down Arrow key to [TPDF] Temperature Differential

select the desired mode. [YES] = Cycle MODE HOURS GAUGES PRETRIP [COIL] Evaporator Coil Temperature

Sentry mode, [NO] = Continuous mode. [AMB.T] Ambient Air Temperature

[SPR.1] Spare Sensor 1

4. Press the Enter key. The display will [SPR.2] Spare Sensor 2

SELECT SETPOINT ENTER CODE CLEAR

briefly show [LOAD], and then the new ALARM

[DAS.X] DAS sensors - If present

mode will reappear.

VIEWING GAUGE DISPLAYS

1. Turn the unit On/Off switch on.

STARTING THE ENGINE

1. Turn the unit On/Off switch on. If no 2. Press the Gauge key to view the gauge

ot h er key is pre ssed, t he en gine w ill display screens as follows:

ON

automatically preheat and start in about 10 [WAT.T] Engine Water Temp

seconds. [OIL.P] Engine Oil Pressure Status

OFF [AMPS] Battery Current Flow

CAUTION: The engine starts

CAUTION: WHEN

SWITCH IS ON, UNIT [BATV] Battery Voltage

MAY START ANYTIME

automatically in both Cycle Sentry and [RPM] Engine RPM

Continuous mode any time the On/Off [CTM.P] Compressor Temp (Screw only)

switch is turned on. [SUC.P] Suction Pressure (ETV only)

[DIS.P] Discharge Pressure (ETV only)

TK 50754-2-PC 07 December 1999

[ETV.P] ETV Valve Position (ETV only)

ALARM CODES ALARM CODES

VIEWING & CLEARING ALARM 00 No Fault 52 Heat Circuit

CODES 02 Evaporator Coil Sensor 53 Economizer Valve

1. If the Alarm Icon is on, alarm conditions 03 Return Air Sensor 54 Test Mode Timeout

have been detected. 04 Discharge Air Sensor 55 Check Engine Speeds

05 Ambient Air Sensor 61 Battery Check

06 Engine Water Temp Sensor 62 Ammeter Out of Calibration Range

2. Press the Code key to display the alarm

07 Engine RPM Sensor 63 Engine Stopped - Reason Unknown

code. Press the Code key again to display 09 High Evaporator Temp 64 Pretrip Reminder

any additional alarm codes. Always record 10 High Discharge Pressure 66 Low Engine Oil Level

any alarm codes shown. 11 Unit Controlling on Discharge Air Sensor 67 Liquid Line Solenoid

12 Sensor Shutdown 70 Hourmeters Exceed 99999

4. After the alarm condition has been 13 Check Sensor Calibration 71 Hourmeter 4 Exceeds set limit

corrected, press the Code key to display the 15 Glow Plug Check 72 Hourmeter 5 Exceeds set limit

alarm code again. When the alarm code is 17 Engine Failed to Crank 73 Hourmeter 6 Exceeds set limit

shown in the display, press the Clear key to 18 High Engine Water Temp 74 Micro Reverted to Default Settings

19 Low Engine Oil Pressure 75 Internal Fault Code, Dealer Resettable

clear the alarm.

20 Engine Failed to Start 76 Internal Fault Code, Dealer Resettable

21 Cooling Cycle Check 77 Internal Fault Code, Dealer Resettable

22 Heating Cycle Check 78 Internal Fault Code, Dealer Resettable

RUNNING A PRETRIP TEST 23 Cooling Cycle Fault 79 Data Log Overflow

1. Turn the unit On/Off Switch on. 24 Heating Cycle Fault 80 Compressor Temperature Sensor

25 Alternator Check 81 High Compressor Temperature

2. Clear all alarm codes. 26 Check Refrigeration Capacity 82 High Compressor Temperature Shutdown

28 Pretrip Abort 83 Low Coolant Temperature

29 Defrost Damper Circuit 84 Restart Null

3. Before the engine starts, press the 31 Oil Pressure Switch 85 Forced Unit Operation

Pretrip key. The Pretrip prompt screen [PrE 32 Refrigeration Capacity Low 87 Suction Pressure Transducer

TRIP] will appear. 33 Check Engine RPM 89 ETV Circuit

35 Run Relay Circuit 109 Discharge Pressure Transducer

4. Press the Enter key to start a Pretrip test. 36 Electric Motor Failed to Run

The display will briefly show [LOAD] and 37 Check Engine Water Level

then the test will begin. 38 Electric Phase Reversed

39 Water Valve

40 High Speed Circuit ADDITIONAL INFORMATION

5. The Pretrip test is fully automatic. When

41 Engine Water Temperature Check

it is complete [PASS], [CHEC] or [FAIL] will 42 Unit Forced to Low Speed For additional information consult the

appear on the display. 43 Unit Forced to Low Speed Modulation Thermo King Operating, Maintenance, Parts

44 Fuel System Check

and Diagnostic Manuals for your unit.

6. If [CHEC] or [FAIL] appears, display and 45 Hot Gas Circuit

correct any alarm codes and repeat the test. 46 Air Flow Check

48 Check Belts/Clutch

50 Reset Clock

You might also like

- Canon EOS R6: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandCanon EOS R6: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- Operating The Thermoguard Up V Microprocessor PDFDocument2 pagesOperating The Thermoguard Up V Microprocessor PDFJuan Carlos Alarcon Galeano100% (1)

- Fujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandFujifilm X-T5: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- TG VI Pocket CardDocument2 pagesTG VI Pocket Cardfelix3189100% (1)

- OM System "Olympus" OM-1: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsFrom EverandOM System "Olympus" OM-1: Pocket Guide: Buttons, Dials, Settings, Modes, and Shooting TipsNo ratings yet

- UP-IV Pocket CardDocument2 pagesUP-IV Pocket Cardfelix3189100% (1)

- Operating The Thermoguard Up T Microprocessor PDFDocument2 pagesOperating The Thermoguard Up T Microprocessor PDFkelvhalim100% (2)

- Fallas 4mx80hvec (Si12-102)Document5 pagesFallas 4mx80hvec (Si12-102)Daniel SiGlockNo ratings yet

- Operating The Thermoguard Multi-Temp Μp-Iv Microprocessor: Manual Defrost Cycle Changing The SetpointDocument2 pagesOperating The Thermoguard Multi-Temp Μp-Iv Microprocessor: Manual Defrost Cycle Changing The SetpointAdal Vera100% (2)

- Changing The Setpoint: Manual Defrost Cycle: Viewing Prompt and Display ScreensDocument2 pagesChanging The Setpoint: Manual Defrost Cycle: Viewing Prompt and Display ScreensAngel Siso100% (1)

- ÃÀÖÞ-Multi-VRFWireless Remote Controller YB1FA C OkDocument16 pagesÃÀÖÞ-Multi-VRFWireless Remote Controller YB1FA C OkLaurentiu LapusescuNo ratings yet

- Fallas 4mkd90bvma (Si12-308a)Document4 pagesFallas 4mkd90bvma (Si12-308a)Daniel SiGlockNo ratings yet

- LCACDocument25 pagesLCACgroperalexandruNo ratings yet

- UserManual 068Document2 pagesUserManual 068ekrem matikNo ratings yet

- Owners Manual - Controller Remote - r51 E-30 - New 0Document5 pagesOwners Manual - Controller Remote - r51 E-30 - New 0Makar Va.No ratings yet

- Rcom RC4 1-N 2 GBDocument10 pagesRcom RC4 1-N 2 GBMbpiroskaNo ratings yet

- Manual Termostato LC AuDocument22 pagesManual Termostato LC AumasterclimaxNo ratings yet

- Reemote-C-man MC ENDocument12 pagesReemote-C-man MC ENOlger Saul Alfaro DuarteNo ratings yet

- Ldu 15Document4 pagesLdu 15Slobodan GerićNo ratings yet

- BRC2C51Document1 pageBRC2C51Lei ZhangNo ratings yet

- Support Manual - 1 Kanto Seiki ControllerDocument2 pagesSupport Manual - 1 Kanto Seiki ControllerWheat State welding LLC JeremyNo ratings yet

- MRSD Support Manual 1Document2 pagesMRSD Support Manual 1XM WNo ratings yet

- Innovair Mini Split Remote Control User Manual English 4Document11 pagesInnovair Mini Split Remote Control User Manual English 4Christtian MontoyaNo ratings yet

- Braemar TH523N Owners Manual (EN)Document36 pagesBraemar TH523N Owners Manual (EN)Gisell ZapataNo ratings yet

- EnDocument42 pagesEnEmil AlexandruNo ratings yet

- 01-RM12ABGE - Owners Manual (A-07-19)Document12 pages01-RM12ABGE - Owners Manual (A-07-19)Vitor BuenoNo ratings yet

- User Manual: Temperature Controller-Cw301Document19 pagesUser Manual: Temperature Controller-Cw301manteniemiento m100% (1)

- SMXHT Keypad/Display For DX Basic Operation & Programmer'S Pocket GuideDocument2 pagesSMXHT Keypad/Display For DX Basic Operation & Programmer'S Pocket GuideDamir MilisaNo ratings yet

- Manual de Usuario Htw-Yan1f1-EngDocument10 pagesManual de Usuario Htw-Yan1f1-EngJonathan Hernán Valderrama RamírezNo ratings yet

- Buttons On Remote Controller: ON/OFF Button Button SWING Button MODE Button ButtonDocument6 pagesButtons On Remote Controller: ON/OFF Button Button SWING Button MODE Button ButtonRoshan KarnaNo ratings yet

- Xwa11v v8 2 01-3110Document8 pagesXwa11v v8 2 01-3110lopez IvánNo ratings yet

- User Manual Kaden Cassette Air Conditioner RemoteDocument16 pagesUser Manual Kaden Cassette Air Conditioner RemoteȘargu CostelNo ratings yet

- Remote Control Manual PDFDocument8 pagesRemote Control Manual PDFgilbert kiprutoNo ratings yet

- Premier Remote Control ManualDocument8 pagesPremier Remote Control ManualRodrigoFaríasVelosoNo ratings yet

- Universal Human Values and Professional EthicsDocument10 pagesUniversal Human Values and Professional EthicsTricker KingNo ratings yet

- Termostato TRANEDocument14 pagesTermostato TRANECarolina LopezNo ratings yet

- Samsung Air Conditioner ManualDocument36 pagesSamsung Air Conditioner ManualoriginaljohnboyNo ratings yet

- Air-Conditioner Remote Controller InstructionsDocument18 pagesAir-Conditioner Remote Controller InstructionsLoren BakerNo ratings yet

- Vdocuments - MX Horno Secado Dhg9140a LuzerenDocument8 pagesVdocuments - MX Horno Secado Dhg9140a LuzerenAdrian Desiderio Mendoza BaureNo ratings yet

- Remote Control Manual Remote Control Manual: ContentDocument9 pagesRemote Control Manual Remote Control Manual: ContentDirt FilterNo ratings yet

- RS9110 - Operation Manual - FinalDocument20 pagesRS9110 - Operation Manual - FinaljohnredaabNo ratings yet

- Operating Guide: Starting The Refrigeration Unit User ModeDocument2 pagesOperating Guide: Starting The Refrigeration Unit User ModeAnonymous NYymdHgyNo ratings yet

- Manual Smart Thermostat Ct100Document12 pagesManual Smart Thermostat Ct100Chérif Malainy KagniNo ratings yet

- Toshiba 52-62hmx94svm Service ManualDocument39 pagesToshiba 52-62hmx94svm Service ManualKenwood TrioNo ratings yet

- Daikin FDR - Manual Operational Remote PDFDocument1 pageDaikin FDR - Manual Operational Remote PDFVAN MUHNo ratings yet

- Manual Operational RemoteDocument1 pageManual Operational RemoteVAN MUHNo ratings yet

- IRK IRK Infrared User Manual (TN408LC in China)Document1 pageIRK IRK Infrared User Manual (TN408LC in China)Jaime HuertaNo ratings yet

- Ater Chillers: Operating and Maintenance ManualDocument68 pagesAter Chillers: Operating and Maintenance ManualDelmiro MartinNo ratings yet

- Service Technical Guide: MS-A08ND - MU-A08ND - MS-A10ND - MU-A10ND - MS-A12ND - MU-A12ND - MS-A15ND - MU-A15NDDocument8 pagesService Technical Guide: MS-A08ND - MU-A08ND - MS-A10ND - MU-A10ND - MS-A12ND - MU-A12ND - MS-A15ND - MU-A15NDtorqueuNo ratings yet

- Cooling Heating: 6. General Description. 6.1. Adjustment - 3. Outputs Carrying CapacityDocument1 pageCooling Heating: 6. General Description. 6.1. Adjustment - 3. Outputs Carrying CapacityCARLOSNo ratings yet

- Controller OM MWH M08019010002 (For MWH010-150DRP)Document16 pagesController OM MWH M08019010002 (For MWH010-150DRP)Raden Ipan Saputra100% (1)

- Carel Pjez Field GuideDocument2 pagesCarel Pjez Field GuideFrio GobalNo ratings yet

- Paradox Magellen User GuideDocument34 pagesParadox Magellen User GuideMorne GNo ratings yet

- Wire Controller of Air Conditioner: ModelDocument10 pagesWire Controller of Air Conditioner: ModelMiguel cejasNo ratings yet

- KJR 12BDocument31 pagesKJR 12BJordi Compte García0% (1)

- Air Conditioning Owners Manual LevanteDocument15 pagesAir Conditioning Owners Manual LevanteEllaNo ratings yet

- CAUTION: Eye Damage May Result From Direct: Adjusting The Alarm Set Points) - Press and Hold ToDocument2 pagesCAUTION: Eye Damage May Result From Direct: Adjusting The Alarm Set Points) - Press and Hold ToSomkiat K. DonNo ratings yet

- La Crosse WT8100 ClockDocument2 pagesLa Crosse WT8100 ClockJulie KalpoNo ratings yet

- Manual Usuario Gree ConductosDocument36 pagesManual Usuario Gree ConductosBmw x5 e46No ratings yet

- Whirlpool MWDocument8 pagesWhirlpool MWНикита ЖуравлевNo ratings yet

- X Series With Advance Micro and Tier 4i Engine Trouble Codes Diagnosis PDFDocument329 pagesX Series With Advance Micro and Tier 4i Engine Trouble Codes Diagnosis PDFRafael Solares100% (1)

- OPTIONS MANUAL Intellisys Option Dryer Option High Dust Option Outdoor Module Option PORO OptionDocument7 pagesOPTIONS MANUAL Intellisys Option Dryer Option High Dust Option Outdoor Module Option PORO OptionRafael SolaresNo ratings yet

- MC68HC11PH8 PDFDocument264 pagesMC68HC11PH8 PDFRafael SolaresNo ratings yet

- Sony HCD Gtr333 Gtr555 Gtr777 Gtr888 DiagramaDocument130 pagesSony HCD Gtr333 Gtr555 Gtr777 Gtr888 DiagramaCiclismo Sexta Región88% (8)

- B4 GEGuarantee LM6000 PFDocument7 pagesB4 GEGuarantee LM6000 PFJulian JairNo ratings yet

- Forming RollingDocument3 pagesForming RollingAvinash JhaNo ratings yet

- Concrete Mix Design Final 7654Document11 pagesConcrete Mix Design Final 7654talatzahoorNo ratings yet

- Fosroc Auramix 300 AdmixtureDocument2 pagesFosroc Auramix 300 Admixture892513822950% (2)

- K en Lvi Er 12-Alce WebDocument12 pagesK en Lvi Er 12-Alce Webalexns84No ratings yet

- Hydro Power PlantDocument93 pagesHydro Power PlantAnonymous gb6ARMgNo ratings yet

- Mortard EDocument2 pagesMortard EQuoc AnNo ratings yet

- AgisDocument20 pagesAgisFabian Andres Blanco GNo ratings yet

- Younis and Abdelati With HeaderDocument6 pagesYounis and Abdelati With HeaderScott MelgarejoNo ratings yet

- Giudeca SocialDocument36 pagesGiudeca SocialCristiDuca-DamianNo ratings yet

- Wood Door Submittal SheetsDocument9 pagesWood Door Submittal SheetsIwan PermanaNo ratings yet

- Presentasi AkhirDocument27 pagesPresentasi AkhirHanggoro Tri Aditya100% (1)

- ANKO h264 Series DVR User Installation Operation ManualDocument61 pagesANKO h264 Series DVR User Installation Operation ManualartcreativeNo ratings yet

- Kep B 023304Document475 pagesKep B 023304LuzioNeto100% (1)

- DRC GAC GAB Commax Comax Videointerfon Bloc Post Exterior Manual Instalare PDFDocument37 pagesDRC GAC GAB Commax Comax Videointerfon Bloc Post Exterior Manual Instalare PDFpedroso76No ratings yet

- Cycle Time of Transit Mixer: DateDocument3 pagesCycle Time of Transit Mixer: DateAtulJainNo ratings yet

- 030 PDFDocument4 pages030 PDFherrerafaridNo ratings yet

- Auc Asme ProgramDocument2 pagesAuc Asme ProgramyasserosmanNo ratings yet

- Reverse Logistics and Closed-Loop Supply Chain of Waste Electrical and Electronic Equipment (WEEE) E-Waste A ComprehDocument29 pagesReverse Logistics and Closed-Loop Supply Chain of Waste Electrical and Electronic Equipment (WEEE) E-Waste A ComprehSergioNo ratings yet

- Fur An Flex 6 PP BrochureDocument2 pagesFur An Flex 6 PP Brochureseptimiu89No ratings yet

- AutoCAD Customization, CAD Customization, AutoLISP, AutoCAD VBADocument6 pagesAutoCAD Customization, CAD Customization, AutoLISP, AutoCAD VBAcaddsoftNo ratings yet

- International Journal of Fatigue: C.M. Manjunatha, Ramesh Bojja, N. Jagannathan, A.J. Kinloch, A.C. TaylorDocument7 pagesInternational Journal of Fatigue: C.M. Manjunatha, Ramesh Bojja, N. Jagannathan, A.J. Kinloch, A.C. TaylorAnonymous 7hZOclNo ratings yet

- Boq Andheri For Piles and Pile CapsDocument2 pagesBoq Andheri For Piles and Pile Capsnavinderpal67% (3)

- P94 1398Document2 pagesP94 1398JoseGarzaNo ratings yet

- GrindingDocument1 pageGrindingRohit SinghNo ratings yet

- Chain Coupling PDFDocument3 pagesChain Coupling PDFFrandi BarasaNo ratings yet

- NR24A-SR Datasheet En-Gb PDFDocument3 pagesNR24A-SR Datasheet En-Gb PDFWagesusilo23121986_No ratings yet

- Parts Manual: 938H Wheel LoaderDocument1,181 pagesParts Manual: 938H Wheel LoaderDaniel Henrique PiovesaniNo ratings yet

- House With SteelDocument8 pagesHouse With SteelMike LojoNo ratings yet

- AZITP-J-902-01 Rev 00 Metallic Instrument and Control CableDocument5 pagesAZITP-J-902-01 Rev 00 Metallic Instrument and Control CableVinay YadavNo ratings yet