Professional Documents

Culture Documents

Revisiting Some Rules of Thumb

Uploaded by

hamidrezaee008Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Revisiting Some Rules of Thumb

Uploaded by

hamidrezaee008Copyright:

Available Formats

Cover Story Part 1.

DISTILLATION:

Revisiting Some

Rules of Thumb

Heuristics regarding optimal reflux ratio and number

of stages, as well as the selection of the feed stage,

C. M. Lek

Singapore Armed Forces get some reassessment here, consistent with

G. P. Rangaiah and K. Hidajat changes in the relative costs of equipment and energy

National University of Singapore

istillation is the most common tion emerges: that the cost of a column Generally speaking, the number of

D unit operation for separating

liquid mixtures into valuable

and/or high purity products. It

is also one of the most energy-

intensive operations. Hence, optimiza-

tion of distillation-column design and

operation should get high priority.

designed by shortcut calculations can

be reduced substantially by optimiz-

ing the location of the feed stage.

Laying the groundwork

The reflux ratio is a key variable, af-

fecting both the capital cost and the

theoretical stages at the optimal reflux

has been stated as being on the order

of twice the minimum number of theo-

retical plates (corresponding to total

reflux), and the optimal reflux ratio,

Ropt, as being in the range of 1.1 to 1.5

times the minimum reflux ratio, Rmin

Numerous distillation heuristics operating cost of a column. As the re- [1]. A study described in this magazine

(rules of thumb) for quick optimiza- flux increases, the number of stages over 30 years ago [19] evaluated a

tion have emerged over the years. For and the column height both decrease large number of cases, mainly via

instance, heuristics on optimal reflux but the flowrates in the column and, shortcut methods, and stated that Ropt

ratio as a certain multiple of the mini- consequently, its diameter increase. lies between 1.1 and 1.6 times Rmin,

mum reflux ratio have been widely Despite that diameter increase, the the lower value being favored by high

used as quick tools to estimate opti- capital cost of the column generally relative volatilities. Conversely, rela-

mum reflux ratio. decreases as the reflux increases, be- tive volatilities closer to unity and

However, changes over time in the cause the savings in tower height sharper separations were said to re-

relative cost of equipment and energy more than offset the cost of the in- quire higher values of Ropt/Rmin within

(which affects operating cost) can af- crease in diameter. However this is the above range. Since then, many ar-

fect the validity of such rules of not the case at very high reflux ratios. ticles and books have recommended

thumb. Meanwhile, it has now become And as alternatives having succes- estimates of Ropt/Rmin for various situ-

more feasible to assess their validity, sively higher reflux ratios are com- ations, as summarized in Table 1. The

as today’s availability of commercial pared with each other, there is a par- range of recommended Ropt/Rmin val-

simulators and high-speed computers ticular, high ratio at which the capital ues in the open literature is 1.05 to 1.6,

allows rigorous and thus more-accu- cost of the column begins to rise again with the lower value for systems in-

rate distillation calculations be car- [7]. In addition, the capital as well as volving refrigerants and the higher

ried out with relative ease. the operating costs for the reboiler value for systems using cooling water.

This article assesses the validity of and condenser will rise in proportion Despite the diversity in ranges in

optimal-reflux-ratio and other heuris- to the vapor rate in the column. Table 1, the use of a rule-of-thumb on

tics in light of recent cost data, by con- Column optimization, therefore, re- optimal reflux ratio as a certain multi-

sidering seven binary and six multi- flects a balance between (1) the capi- ple of the minimum reflux ratio has

component systems. Distillation tal cost, which decreases (to a certain been widespread and, indeed, has

columns for each of the 13 have been point, as just discussed) as reflux in- proved beneficial over recent decades

designed and optimized by both short- creases, and (2) the operating cost, as a quick method to estimate opti-

cut (heuristics-based) calculations which increases as the reflux in- mum reflux ratio. But as mentioned

and rigorous simulations. In addition creases. The total cost is minimum at earlier, the relative costs of equipment

to the reassessment, a key observa- an intermediate reflux ratio. and energy (which affects utilities)

50 CHEMICAL ENGINEERING WWW.CHE.COM SEPTEMBER 2004

TABLE 2. DETAILS OF BINARY EXAMPLES

Example Components Feed Mole Feed Column Product Purity

No.* Fraction Conditions Pressure Specifications (mole%)

1 Benzene 0.45 700 lb-mol /h, Pcond : 0.98 atm Top : 92% Benzene

Toluene 0.55 1 atm , sat. liq. Preb : 1 atm Btm : 95% Toluene

2 i-Butane 0.233 30,000 bbl/d, Pcond : 42 psia Top : 91.7% i-Butane

n-Butane 0.767 50 psia, sat. liq. (refrigerant) Btm : 90% n-Butane

Preb : 50 psia

3 Propylene 0.5045 84.2 m3/d, Pcond : 1.798 MPa Top : 96.2% Propylene

Propane 0.4955 1.86 MPa, sat. liq. Preb : 1.86 MPa Btm : 91.1% Propane

4 Acetone 0.5 500 lb-mol /h, Pcond : 0.98 atm Top : 91% Acetone

Water 0.5 1 atm, 55% vap Preb : 1 atm Btm : 97.8% Water

5 n-Hexane 0.55 200 kmol/h, Pcond : 0.98 atm Top : 95% n-Hexane

p-Xylene 0.45 1 atm, 50% vap Preb : 1 atm Btm : 97% p-Xylene

6 Methanol 0.54 10,000 lb/h, Pcond : 0.98 atm Top : 99% Methanol

1,4-Dioxane 0.46 1 atm, sat. liq. Preb : 1 atm Btm : 98% Dioxane

7 Methanol 0.7 12,000 lb/h, Pcond : 0.98 atm Top : 99% Methanol

Water 0.3 1 atm, sat. liq. Preb : 1 atm Btm : 99% Water

*Sources for Examples: 1 and 2 from Peters and Timmerhaus (1991); 3 and 4 from King (1980); 5 to 7 from Doherty and Malone (2000).

Items in italics indicate unavailable specifications, or ones modified to allow column optimization by varying the reflux ratio.

Thermodynamic package used: Peng-Robinson for Eamples 1, 2, 3 and 5; and NRTL for Examples 4, 6 and 7.

Cooling water for cold utility unless stated otherwise.

Pcond = pressure at condenser; Preb = pressure at reboiler

have been changing, particularly dur- TABLE 1. RECOMMENDED VALUES FOR THE

ing the latter years of that time period. OPTIMUM-TO-MINIMUM REFLUX RATIO IN THE LITERATURE

Furthermore, some of the early stud- Reference Ropt/Rmin Remarks

ies on optimal reflux ratio were based Van Winkle and Todd, 1.1 to 1.6 Lower values for high relative

on shortcut calculation methods or 1971 [19] volatilities

graphical correlations, whereas today, Brian,1972 [1] 1.1 to 1.5

rigorous calculations (with more-accu- Frank,1977 [4] 1.05 to 1.1 Low-level refrig. (< -150°F)

rate results) can be made with ease. 1.1 to 1.2 High-level refrig.

Such calculations can assess the 1.2 to 1.3 Water- and air-cooled condensers

suitability of the heuristics on opti-

Zdonik,1977 [21] 1.25 Generally accepted

mum reflux ratio with current cost

1.1 to 1.2 With increased energy costs

data and, if necessary, update those

heuristics. Furthermore, it is possible King,1980 [7]; Walas, 1987 [20] 1.2

to determine whether, and how, the Thompson,1980 [15] 1.2 to 1.3 Common fractionators

capabilities of commercial simulators Perry, others, 1997 [13] 1.1 to 1.5 Petroleum-distillation columns

for rigorous distillation simulation 1.1 to 1.2 Refrig. is involved

can also be used for optimizing reflux 1.2 to 1.4 Cooling-tower water used in con-

ratio. Both of these questions are ad- densers

dressed in what follows, by consider- McCormick and Roche, 1.05 to 1.10 Low-level refrig. (-300 to -150°F)

ing industrially relevant applications 1979 [9] 1.10 to 1.20 High-level refrig. (-150 to 50°F)

that involve both binary and multi- 1.2 to 1.5 Cooling water

component mixtures. Along the way, 1.4 to 1.5 Air cooling

we also scrutinize the validity of some McCormick and Roche, 1.05 to 1.2

other heuristics for distillation-col- 1997 [10]

umn design. Peters, others, 2003 [12] 1.2 to 1.25

Equations and data for sizing and

costing of columns, including reboilers ponents (Table 2); the others involve The selected examples cover a wide

and condensers, are taken from the multiple components (Table 3). Be- range of design and operating condi-

open literature. This study is limited sides showing the components, Tables tions. Some operate at high pressures,

to simple (but not necessarily binary) 2 and 3 specify feed conditions, col- others at atmospheric pressure. A few

columns, each with a single feed umn pressure and product specifica- require a refrigerant as the cold util-

stream and two product streams. tions for each system. In a few cases, ity. The number of stages for the ex-

the specifications were either unavail- amples ranges from 9 (short columns)

Examples and procedures able in the original references or were to more than 100 (tall columns).

The 13 distillation examples also come modified to suit the needs of this study Steady state simulation and design

from the open literature, for the most (for instance, the reflux ratio should of column for each example is done

part. Seven examples have two com- not have a specified value). using HYSYS, the simulation system

CHEMICAL ENGINEERING WWW.CHE.COM SEPTEMBER 2004 51

TABLE 3. DETAILS OF MULTICOMPONENT EXAMPLES

Example Components Feed Feed Column Product Purity

No.* Mole Conditions Pressure Specifications

Fraction (Mole %)

8 Nitrogen 0.0020 140.85 kmol/h, Pcond : 1,378 kPa Top : 0.6% n-Butane

CO2 0.0046 4,000 kPa, (refrigerant) Btm : 2% Propane

Methane 0.2412 sat. liq. partial condenser

Ethane 0.2576 (vapor distillate)

Propane 0.2561 Preb : 1,413 kPa

i-Butane 0.1219

n-Butane 0.1166

9 Propylene Oxide 0.0129 618.5 kmol/h, Pcond : 103 kPa Top : 2 X 10-5 %

Propylene Glycol 0.2296 120 kPa, sat. liq. Preb : 117 kPa Propylene Glycol

Water 0.7575 Btm : 0.5% Water

10 Propene 0.2158 1,000 lb-mol/h, Pcond : 97 psia Top : 4.74% 1-Butene

Propane 0.1817 100 psia, (refrigerant) Btm : 2.54% Propane

1-Butene 0.2010 sat. liq. Preb : 100 psia

n-Butane 0.2312

n-Pentane 0.1703

11 Acetone 0.20 1,000 kmol/h, Pcond : 0.98 atm Top : 2% Ethanol

Methanol 0.20 101.3 kPa, Preb : 1 atm Btm : 2% Methanol

Ethanol 0.20 sat. liq.

Water 0.20

1-Butanol 0.20

12 Propylene 0.0005 538 m.t./d, Pcond : 431.5 kPa Top : 1% n-pentane

Propane 0.0002 6.29 atm, Preb : 470.7 kPa Btm : 1% n-butane

1,3-Butadiene 0.3060 sat. liq.

n-Butane 0.4160

n-Pentane 0.2773

13 Ethane 0.0005 15m.t./h, Pcond : 1,380 kPa Top : 2% Propane

Propylene 0.9500 1,457.4 kPa, Preb : 1,450 kPa Btm : 50% Propene

Propane 0.0450 sat. liq.

Propadiene 0.0030

n-Butane 0.0015

*Sources of Examples: 8 and 9 from HYSYS Documentation; 10 from Van Winkle and Todd (1971);

11 from Ishii and Otto (2001); 12 and 13 from typical petrochemical industries.

Items in italics indicate unavailable specifications, or ones modified to allow column optimization by varying the reflux ratio.

Thermodynamic package used: Peng-Robinson for Examples 8, 10, 12 and 13; UNIQUAC for Example 9; and NRTL for Example 11.

Cooling water for cold utility unless stated otherwise.

Pcond = pressure at condenser; Preb = pressure at reboiler

readily available to the authors. For ferent from that obtained earlier by half foot. This practice results in a

predicting the mixture properties, an shortcut calculations. lower vapor velocity and, hence, a

appropriate thermodynamic model After each rigorous simulation, the more conservative estimate.

(fluid package) is selected for each ex- column, condenser and reboiler are Tray spacing, S depends on the col-

ample based on the recommendations sized, and their combined cost is esti- umn diameter, and is at least 0.5 m

given in the HYSYS documentation, mated for optimization. The sizing for the sake of cleaning the trays [16].

and then verified by comparing its pertains to the height and diameter of Our designs take into account recom-

predictions with the experimental the distillation column and the design mendations [18] that the tray spacing

vapor-liquid equilibrium (VLE) data of the condenser and reboiler. The col- should be 0.5 m for columns with di-

in Reference [5]. Footnotes to Tables 2 umn diameter depends mainly on the ameters up to 1 m, and that for wider

and 3 spell out the thermodynamic velocity of the vapor stream within columns, spacing should be a function

models thus selected. the column: to avoid excessive liquid of column diameter:

For each example, the shortcut col- entrainment or a high pressure drop,

S = 0.5D0.3

umn in HYSYS is first used to esti- the maximum gas velocity, Vmax, is

mate Rmin, and the number of theoret- calculated in meters per second by the The column height, H, is deter-

ical stages and the feed stage location following equation [14]: mined by multiplying the number of

for the chosen reflux ratio. These val- real trays by S and adding an extra

Vmax = [-0.171S2 + 0.27S - 0.047]

ues then serve as the basis for rigor- space of 1.5 to 3 m (5 to 10 ft) both at

3 [(rliq - rvap)/rvap]1/2

ous simulation of the column with re- the top of the tower for vapor-liquid

boiler and either total or partial where S is tray spacing in meters and disengagement and at the bottom for a

condenser (the latter is the choice rliq and rvap are the liquid and vapor liquid sump [3]. An overall efficiency

when the feed contains non-condens- density, respectively. of 70% is used to calculate number of

able components). To satisfy the prod- In our examples, the vapor velocity real trays from the number of ideal

uct specifications of each example in used for actual design is typically 80% trays in the simulation.

Tables 2 and 3, HYSYS adjusts the re- of Vmax. Because columns are custom- The heat transfer areas of the con-

flux ratio and other quantities suit- arily fabricated in increments of 0.5 ft densers is estimated assuming an

ably. Thus, the reflux ratio obtained in diameter, D, the diameters calcu- overall heat transfer coefficient of 510

by rigorous simulation is slightly dif- lated are rounded up to the nearest W/(m2)(K) [13]. For the reboilers, a

52 CHEMICAL ENGINEERING WWW.CHE.COM SEPTEMBER 2004

TABLE 4. SELECTED RESULTS FROM RIGOROUS SIMULATION AND OPTIMIZATION OF ALL 13 EXAMPLES

Example Number of Feed Annualized Operating Total Ropt Rmin@ Ropt/Rmin Nmin@

Stages* Stage# Capital Cost, Cost,

Cost, $/yr $/yr $/yr

1 21 10 57,741 364,533 422,274 1.362 1.261 1.08 5.3

2 65 34 316,353 10,752,075 11,068,428 10.36 10.00 1.04 13.3

3 102 72 199,542 197,489 397,031 18.63 15.08 1.24 47.7

4 9 8 31,145 59,013 90,158 0.365 0.348 1.05 1.7

5 9 5 29,018 94,197 123,215 0.540 0.381 1.42 2.2

6 23 21 46,517 110,516 157,034 1.135 0.764 1.49 6.1

7 23 19 57,188 296,692 353,880 0.798 0.484 1.65 6.1

8 25 11 54,695 170,794 225,489 0.491 0.441 1.11 8.7

9 21 18 77,954 795,940 873,900 0.080 0.050 1.60 5.3

10 18 8 55,025 902,703 957,729 0.961 0.778 1.24 3.9

11 48 19 194,885 1,343,503 1,538,388 2.019 1.730 1.17 10.0

12 25 13 75,286 428,830 504,117 0.771 0.727 1.06 8.0

13 105 42 452,312 1,617,538 2,069,850 6.081 5.215 1.17 37.0

* Excluding reboiler and condenser.

# Counted from the top with condenser as zero.

@ Minimum reflux ratio and minimum number of stages (excluding reboiler and condenser) obtained from shortcut calculations.

Cost totals may not agree with cost components due to rounding.

conservative heat flux of 35,490 W/m2, contain two separately escalating com- 3. Collect column data (for example,

suggested by Reference [3], is used to ponents. One is due to materials and temperatures, flowrates, exchanger

estimate the required areas. labor, which inflates at a rate typified duties) in Excel

by the CEPCI, and the other is energy 4. Based on those data, find the size

Estimates of the costs (fuel) cost, which escalates at a differ- and the cost the column, reboiler

Fixed capital is the capital needed for ent rate. In this study, fuel price is and condenser in Excel

the plant to be ready for startup, and taken to be $2.516/GJ based on a typi- 5. Sort the costing results for the user

it represents the capital cost of all cal price of $0.40/gal for residual fuel oil to identify the optimal point.

equipment, including installation and in January 2002 (from http://www.

auxiliaries, that are needed for the eia.doe.gov/oil_gas/petroleum/data_ What was found

complete process operation. Bare- publications/petroleum_marketing_ The results of minimizing the total

module cost equations, expressed as a monthly/pmm.html) with a heating cost of each column by varying both

function of characteristic size of value of 42 GJ/m3 [18]. All other cost the number of stages and feed stage

equipment by Reference [17], are data are also in U.S. dollars, and the are summarized in Table 4. In this

used for estimating the capital cost of column is assumed to operate for 8,500 table and Table 5, the number of

the columns, condensers and reboil- hours per year (97% onstream time). stages excludes the reboiler and the

ers. However, these correlations are condenser; they and the feed stage

in many cases applicable for certain Varying the reflux ratio refer to theoretical or equilibrium

size ranges only. In examples where We wish to find the reflux ratio that is stages. The feed stage is counted from

the size of the equipment exceeds the optimal while continuing to meet the the column top, with the condenser

upper limit, then the usage of the given product specifications, but the counted as zero.

minimum number of multiple units of only way to do so in the rigorous simu- Values of Ropt/Rmin for many of the

that upper-limit size within the ap- lation is by changing number of stages examples fall within the range of 1.05

plicable range is assumed, for a con- and feed stage. It was found that these to 1.6 as suggested in the literature

servative estimate. two quantities could not be used as de- (Table 1); the exceptions are Exam-

As the cost data are historical and cision variables in the built-in opti- ples 2 and 7 with Ropt/Rmin equaling

subject to inflation, the Chemical En- mizer of HYSYS. Following a sugges- 1.04 and 1.65 respectively.

gineering Plant Cost Index (CEPCI) is tion from Hyprotech’s support group, Examples 1, 4 to 10, and 12 require

used to update capital and operating Visual Basic programs were devel- short towers with 9 to 25 theoretical

costs to January 2002 (CEPCI = oped for optimizing the column by stages, which results in low capital

390.3). Annualized capital costs are varying the number of stages and/or cost. Example 2 entails a very high op-

found using an annualization factor of the location of the feed stage (in larger erating cost, as the separation re-

15% to account for depreciation, inter- steps initially over a wider range, and quires a refrigerant and very large ex-

est and maintenance associated with then in single steps over a shorter changer duties; also, the tall column

the equipment. range). The steps in the Visual Basic and multiple heat exchangers for the

The operating cost for distillation Program are as follows: large feedrate of 30,000 bbl/day mean

columns consists mainly of utility costs 1. Select total number of stages, Nt, a high capital cost.

for heating in the reboiler and cooling and the feed stage, Nf Example 3 involves the difficult sep-

in the condenser. In the examples, util- 2. Transfer Nt and Nf to HYSYS, and aration of propylene and propane, thus

ity costs are estimated using cost equa- instruct HYSYS to perform a rigor- requiring a tower of over 100 ideal

tions given in Reference [18], which ous simulation stage and hence incurring a large capi-

CHEMICAL ENGINEERING WWW.CHE.COM SEPTEMBER 2004 53

Cover Story

tal cost. As for Example 10, al- TABLE 5. RESULTS BY SHORTCUT CALCULATIONS WITH ROPT/RMIN = 1.2,

though the column is short, a large FOLLOWED BY RIGOROUS SIMULATION AND FEED-STAGE OPTIMIZATION

feed rate of 1,000 mol/h and a sepa- Example Results for Ropt/Rmin = 1.2 Results for Ropt/Rmin = 1.2

ration requiring a refrigerant result after feed stage optimization

in a high operating cost. Examples Number of Feed % Increase Feed % Increase Ropt/Rmin

11 and 13 process large quantities stages stage in total cost Stage in total cost

of feed; accordingly, the bulk of the 1 15 7 3.1 7 3.1 1.19

total cost lies in the operating cost. 2 29 20 11.4 20 11.4 1.18

The optimal number of stages is 3 97 58 3.5 68 1.1 1.29

expected to be close to twice the 4 8 3 71.5 7 1.8 1.10

minimum number of stages [12]. 5 9 4 0.1 5 0 1.42

However, the results in Table 4 6 18 10 19.8 16 1.7 1.70

(Column 2 and last column) show 7 18 8 16.1 14 1.7 1.80

that this heuristic is generally not

8 25 14 3.1 11 0 1.11

valid.

9 25 25 29.0 22 0.2 1.40

To test the validity of the heuris-

tic saying that Ropt/Rmin equals 1.1 10 12 6 4.2 5 3.6 1.34

to 1.6, the column for each example 11 25 13 15.0 11 12.2 1.45

is first designed in accordance with 12 22 10 0.9 11 0.4 1.09

successive shortcut column calcula- 13 78 42 12.1 28 4.1 1.27

tions to estimate the number of Note: % increase in total cost is from the minimum total cost shown in Table 4.

stages and the feed stage assuming

that Ropt/Rmin equals 1.1 to 1.6 in in- that the feed stage from the shortcut feed stage optimization via minimizing

crements of 0.1; these estimates are calculations (for instance, for the reflux ratio. This equivalence is to

followed by a rigorous simulation and Ropt/Rmin equaling 1.2 in Table 5) is be expected, as the total cost is often

cost estimation. For each case, percent very different from the feed stage in dominated by operating cost when the

increase in total cost from the mini- Table 4, even if the total number of total number of stages is fixed.

mum total cost in Table 4 is calculated. stages is comparable. After the feed stage optimization,

Results from this extensive study In fact, Reference [7] points out that the feed-stage location, the Ropt/Rmin

show that the variation in percent in- the guideline for optimal feed stage is value and the percent increase in total

crease in total cost depends on the ex- that the ratio of key-component mole cost for Examples 1, 2, 5, 10 and 12

ample; it is within 11% in five exam- fractions in the liquid on the feed are comparable to those with the feed

ples (1, 5, 8, 10 and 12), but is stage should be close to the corre- stage determined by the shortcut cal-

significantly more in other examples. sponding ratio in the liquid part of the culations. On the other hand, the total

A reasonable value for Ropt/Rmin feed. The key-ratio plot in Figure 1 for cost decreases dramatically in Exam-

within 1.1 to 1.6 is 1.2. Results for this Example 4 indicates that the feed- ples 4, 6, 7, 9 and 13. In the other

particular case (Columns 2 to 4 in stage location should be closer to the three examples (Nos. 3, 8 and 11), too,

Table 5) show that the increase in reboiler. The feed stage in the opti- the total cost decreases, by about 3

total cost is in the range of 0.1% to mized design is consistent with the percentage points.

about 70%, and the average increase heuristic given in Reference [7]. Thus, after the feed stage optimiza-

is about 14% for all 13 examples. A recent reference [8] states that the tion to minimize the reflux ratio, the

Thus, although the heuristic on optimal feed location for a specified increase in total cost (from the mini-

Ropt/Rmin equaling 1.1 to 1.6 seems to total number of stages and separation mum total cost shown in Table 4) is

be valid in five out of the 13 examples minimizes the reflux ratio (and there- less than 4.1% for all examples except

tested, these results nevertheless show fore the reboiler and condenser duties). Nos. 2 and 11. The optimal total num-

the potential for reducing the total col- In accordance with this guideline, the ber of stages and reflux ratio for these

umn cost by further optimization. feed stage for the case of Ropt/Rmin two examples (Table 4) are different

equaling 1.2 in Table 5 is optimized by from those for Ropt/Rmin equaling 1.2

Revelations about the feed stage varying the feed stage in the rigorous (in Table 5).

In addition to the above findings, a simulation and finding the reflux ratio In other words, column design by

closer analysis of the results for vari- to achieve the desired separation. shortcut calculations can be improved

ous Ropt/Rmin values indicated that These optimized results after feed significantly by changing the feed

the feed stage given by shortcut col- stage optimization are shown in the stage to minimize reflux ratio for the

umn calculations can be inappropri- last three columns of Table 5. same total number of stages found for

ate. The most extreme case is Exam- A separate exercise was carried out Ropt/Rmin equaling 1.2. This change

ple 4, for which increase in the total to optimize the feed stage by minimiz- can be carried out easily with the aid

cost ranged from 70 to 260% with ing total cost for the case of Ropt/Rmin of a simulator, because it does not in-

Ropt/Rmin in the range 1.1 to 1.6. One equaling 1.2 for all examples. These re- volve sizing and cost estimation of the

can see from the optimized results sults are identical to those obtained by column, condenser and reboiler.

54 CHEMICAL ENGINEERING WWW.CHE.COM SEPTEMBER 2004

Authors

C.M. Lek is currently an En-

gineering Officer in the Sin-

gapore Armed Forces. Mr.

Lek received his bachelor’s

degree in chemical engineer-

ing from the National Univer-

sity of Singapore in 2003 with

second class honors (Upper

Division). The work reflected

in this article began as his se-

nior-year research project,

and continued after comple-

tion of that project. Mr. Lek has a particular in-

terest in software development.

G.P. Rangaiah is an Associ-

ate Professor in the Dept. of

Chemical and Biomolecular

Engineering, National Uni-

versity of Singapore (Singa-

pore 119260; Phone: [65]

6874-2187; email: Ranga-

iahGP@nus.edu.sg). He

worked for Engineers India

Ltd. (New Delhi) for two

years, and has been lecturing

at the National University of

Singapore since 1982. His research interests are

in process control, modeling and optimization.

He has supervised nine research fellows/assis-

FIGURE 1.This plot, relevant to Example 4, relates the column stage number with the tants and more than 20 postgraduate theses, has

key ratio for the liquid at that stage, for both shortcut and optimized design published about 70 papers in international jour-

nals, and has presented nearly 50 papers in con-

ferences. He received his baccalaureate, masters

Summarizing the conclusions age 14% higher than the minimum at- and doctorate degrees in chemical engineering

from India’s Andhra University, IIT Kanpur and

Column optimization through rigor- tainable by rigorous simulation and Monash University, respectively.

ous simulation, sizing and costing optimization. However, the design in Kus Hidajat is an Associate

Professor in the Dept. of

commonly gives an Ropt/Rmin value in this case can often be improved sub- Chemical and Biomolecular

the range of 1.1 to 1.6. Also, the stantially by optimizing the feed stage Engineering, National Uni-

versity of Singapore (email:

heuristic that the optimal number of (for a specified number of stages and chehidak@nus.edu.sg). He

stages is twice the minimum number separation), and the total cost of a col- has been lecturing at the Na-

tional University of Singa-

is generally not valid. umn can be reduced to within 4% of pore since 1983. His research

interests are in simulated-

Shortcut (as opposed to rigorous) the minimum. moving-bed adsorptive sepa-

calculations using the heuristic, In a few cases, potential exists for ration processes with or with-

out reaction, plus modeling and optimization,

Ropt/Rmin = 1.1 to 1.6, produce further cost reduction by varying both and catalytic membranes. He has supervised

columns whose total cost is generally the number of stages and feed stage, four research fellows/assistants and 26 post-

graduate theses, has published about 65 papers

more than the minimum. For the spe- and simulating the column rigorously. in international journals, and has presented

cific case of Ropt/Rmin equaling 1.2, the These findings are applicable to sim- about 40 papers in conferences. He received his

baccalaureate and doctorate degrees in chemical

total cost of a column by shortcut cal- ple columns with a single feed stream engineering in the U.K., from the University of

Manchester Institute of Science and Technology

culations (followed by rigorous simu- and two product streams only. n (UMIST) and the University of Cambridge, re-

lation, sizing and costing) is on aver- Edited by Nicholas P. Chopey spectively.

References

1. Brian, P. L. T., “Staged Cascades in Chemi- 9. McCormick, J. E. and Roche, E. C., Continu- 15. Thompson, R. E., McCabe-Thiele Methods –

cal Processing”, Prentice-Hall, New Jersey, ous Distillation: Separation of Multicompo- Advanced Topics, in “AIChEMI Modular In-

1972. nent Mixtures, in Schweitzer, P. A., Ed., struction. Series B, Stagewise and Mass

“Handbook of Separation Techniques for Transfer Operations”, American Institute of

2. Doherty, M. F. and Malone, M. F., “Concep- Chemical Engineers”, McGraw-Hill, New Chemical Engineers, New York, 1980.

tual Design of Distillation System”, Mc- York, 1979.

Graw-Hill, New York, 2000. 16. Treybal, R. E., “Mass-Transfer Operations”,

10. McCormick, J. E. and Roche, E. C., Continuous 3rd Ed., McGraw-Hill, New York, 1980.

3. Douglas, J. M., “Conceptual Design of Chem- Distillation: Separation of Binary Mixtures, in

ical Process”, McGraw-Hill, Singapore,1988. 17. Turton, R., “Analysis, Synthesis and Design

Schweitzer, P. A., Ed., “Handbook of Separa- of Chemical Processes”, Prentice Hall PTR,

4. Frank, O., Shortcuts for Distillation Design, tion Techniques for Chemical Engineers”, 3rd New Jersey. 1998.

Chem. Eng., p.111, March 14, 1977. Ed., McGraw-Hill, New York, 1997.

11. Peters, M. S. and Timmerhaus, K. D., “Plant 18. Ulrich, G. D., “A Guide to Chemical Engi-

5. Gmehling, J., Onken, U. and Arlt, W., Design and Economics for Chemical Engi- neering Process Design and Economics”,

“Vapor-Liquid Equilibrium Data Collection”, neers”, 4th Ed., McGraw-Hill, New York, Wiley, New York, 1984.

Dechema, Frankfurt, 1977. 1991. 19. Van Winkle, M. and Todd, W. G., Optimum

6. Ishii, Y. and Otto, F. D., An Efficient Simul- 12. Peters M.S., Timmerhaus K.D. and West Fractionation Design by Simple Graphical

taneous Correction Procedure for Multicom- R.E., "Plant Design and Economics for Methods, Chem. Eng., p. 136, Sept. 20, 1971.

ponent, Multistage Separation Calculations Chemical Engineers", 5th Ed., McGraw-Hill, 20. Walas, S. M., Rules of Thumb, Chem. Eng.,

for Non-Ideal Systems, Computers and New York, 2003. p. 75, Mar 16, 1987.

Chemical Eng. 25, 1285–1298, 2001.

13. Perry, R. H., Green, D. W. and Maloney, J. 21. Zdonik, S. B., Techniques for Saving Energy

7. King, C. J., “Separation Processes”, 2nd Ed., O., Eds., “Chemical Engineers’ Handbook”, in Processes and Equipment” Chem. Eng., p.

McGraw-Hill, New York, 1980. 7th Ed., McGraw-Hill, New York, 1997. 99, July 4, 1977.

8. Khoury, F.M., "Predicting the Performance 14. Sinnott, R. K., in “Coulson & Richardson's

of Multistage Separation processes", 2nd Chemical Engineering”, Vol. 6, 2nd Ed., But-

Ed., CRC Press, Boca Raton, Fla., 1999. terworth-Heinemann, Boston, 1993.

CHEMICAL ENGINEERING WWW.CHE.COM SEPTEMBER 2004 55

You might also like

- Distillation Column Design FactorsDocument2 pagesDistillation Column Design FactorsArunkumarNo ratings yet

- Correlations For Conversion Between True and Reid Vapor Pressures (TVP and RVP) - Campbell Tip of The MonthDocument6 pagesCorrelations For Conversion Between True and Reid Vapor Pressures (TVP and RVP) - Campbell Tip of The MonthAMITH OKNo ratings yet

- Basic Data & Course Rules of ThumbDocument10 pagesBasic Data & Course Rules of ThumbKavitha NachammaiNo ratings yet

- Sizing Packed TowersDocument7 pagesSizing Packed Towersrzq_andikaNo ratings yet

- Optimal Selection of Operating Pressure For Distillation ColumnsDocument17 pagesOptimal Selection of Operating Pressure For Distillation ColumnssamandondonNo ratings yet

- Design of Torque ArmDocument16 pagesDesign of Torque ArmRonak PanchalNo ratings yet

- Technip Separations PDFDocument50 pagesTechnip Separations PDFProcess Engineer100% (1)

- Trol/restricted/course/fourth/course/mo Dule3-1.html: Module 3.1: Control of Distillation ColumnsDocument14 pagesTrol/restricted/course/fourth/course/mo Dule3-1.html: Module 3.1: Control of Distillation ColumnsRimeli RoychoudhuryNo ratings yet

- Molecular Sieve Dehydration OptimizationDocument24 pagesMolecular Sieve Dehydration Optimizationotis-a6866No ratings yet

- Intro To DistillationDocument33 pagesIntro To Distillationcallielizza100% (1)

- Optimize Batch Distillation V2Document6 pagesOptimize Batch Distillation V2Ajaykumar TiwariNo ratings yet

- Propylene-Propane - Howat Swift - McCabe ThieleDocument19 pagesPropylene-Propane - Howat Swift - McCabe ThieleFred FaberNo ratings yet

- Propylene DistillationDocument10 pagesPropylene DistillationPriyam NayakNo ratings yet

- Basics of Distillation: V. K. KapoorDocument62 pagesBasics of Distillation: V. K. Kapoorstardeepakrati100% (1)

- Engineering Design Guidelines Distillation Column Rev4Document24 pagesEngineering Design Guidelines Distillation Column Rev4zackii90No ratings yet

- PlantWIde McAvoyDocument19 pagesPlantWIde McAvoydesigat4122No ratings yet

- Aspen Utilities - Refinery EngineersDocument72 pagesAspen Utilities - Refinery EngineersUrcan GeorgianaNo ratings yet

- Hydrogenation Reactor DesignDocument10 pagesHydrogenation Reactor DesignasdfNo ratings yet

- Distillation Column ModellingDocument1 pageDistillation Column ModellingChem.EnggNo ratings yet

- (Distillation) - Towers Malfunctions (Kister)Document22 pages(Distillation) - Towers Malfunctions (Kister)Ana Lua100% (1)

- Troubleshooting A C3 Splitter TowerDocument7 pagesTroubleshooting A C3 Splitter TowerAhmed SeliemNo ratings yet

- Ulman Part 10Document1,000 pagesUlman Part 10Yana RahmadaniNo ratings yet

- 4460 Aspen Notes 2011Document24 pages4460 Aspen Notes 2011ClauDio MaRciànoNo ratings yet

- Thermosiphon ReboilersDocument3 pagesThermosiphon ReboilersMuhammadNo ratings yet

- Efficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer ChemtechDocument31 pagesEfficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer Chemtechmisscolgate100% (1)

- Design and Control of Condensate-Throttling ReboilersDocument12 pagesDesign and Control of Condensate-Throttling ReboilerscymyNo ratings yet

- Significance of Debutanizer Reflux RatioDocument2 pagesSignificance of Debutanizer Reflux RatioMuhammadUsmanSaeedNo ratings yet

- Pinch TechDocument32 pagesPinch TechDaniel Puello Rodelo100% (1)

- Distillation Tray SelectionDocument4 pagesDistillation Tray Selectionchemsac2No ratings yet

- Stripping Notes PDFDocument28 pagesStripping Notes PDFnimi khalidNo ratings yet

- Technip Separations PDFDocument60 pagesTechnip Separations PDFProcess EngineerNo ratings yet

- Select The Right ReboilerDocument2 pagesSelect The Right ReboilerSteven A McMurray100% (2)

- PDF FileDocument50 pagesPDF FileHussein AyoubNo ratings yet

- Binary Interaction ParametersDocument16 pagesBinary Interaction ParametersSchöberl ErichNo ratings yet

- Temperature, Pressure Measurements Solve Column Operating ProblemsDocument5 pagesTemperature, Pressure Measurements Solve Column Operating ProblemsHari PrasadNo ratings yet

- Sizing Tank Blanketing Regulators Tank Storage Magazine Jan - Feb 2015 PDFDocument3 pagesSizing Tank Blanketing Regulators Tank Storage Magazine Jan - Feb 2015 PDFSUBHOMOYNo ratings yet

- Brochure Valves For Chemical and Petrochemical ProcessesDocument32 pagesBrochure Valves For Chemical and Petrochemical ProcessesBastian DwiNo ratings yet

- Comparison of Advanced Distillation Control Methods: Final Technical ReportDocument47 pagesComparison of Advanced Distillation Control Methods: Final Technical ReportAjit Jadhav0% (1)

- SIT-Excel For Chemical EngineersDocument9 pagesSIT-Excel For Chemical EngineerskrishnaNo ratings yet

- EjectorsDocument7 pagesEjectorsashirwad shetty50% (2)

- Valves: 1 - Gate 2 - Plug 3 - Globe 4 - Ball 5 - Butterfly 6 - Diaphragm 7 - Pinch 8 - Relief 9 - CheckDocument1 pageValves: 1 - Gate 2 - Plug 3 - Globe 4 - Ball 5 - Butterfly 6 - Diaphragm 7 - Pinch 8 - Relief 9 - CheckAhmad DeyabNo ratings yet

- Kister - Troubleshoot Packing Maldistribution Upset Part 1, Temperature Surveys and Gamma ScansDocument8 pagesKister - Troubleshoot Packing Maldistribution Upset Part 1, Temperature Surveys and Gamma ScansgonzalezpcjNo ratings yet

- 1993 - Distillation Column TargetsDocument12 pages1993 - Distillation Column TargetsOctaviano Maria OscarNo ratings yet

- Predict Distillation Tray Efficiency: Reactions and SeparationsDocument7 pagesPredict Distillation Tray Efficiency: Reactions and SeparationsJohn AnthoniNo ratings yet

- Interfacial Heat Transfer Coefficients of Various Vapors in Direct Contact CondensationDocument11 pagesInterfacial Heat Transfer Coefficients of Various Vapors in Direct Contact CondensationJesse Haney IIINo ratings yet

- CEeNews2 04 PDFDocument6 pagesCEeNews2 04 PDFJohn AnthoniNo ratings yet

- 35 - Waste ManagementDocument131 pages35 - Waste Managementsunggwan kimNo ratings yet

- Distillation Column Control DesignDocument22 pagesDistillation Column Control DesignAnand Dudheliya0% (1)

- APC and Ethylene RTO - 160713Document35 pagesAPC and Ethylene RTO - 160713Andy LuthorNo ratings yet

- Chemical Engineering Course Outlines - Effective From Fall 2013Document45 pagesChemical Engineering Course Outlines - Effective From Fall 2013Khan AaghaNo ratings yet

- How To Minimise Scaleup DifficultiesDocument6 pagesHow To Minimise Scaleup Difficultieskishore.charuNo ratings yet

- Scale-Up - Right First TimeDocument4 pagesScale-Up - Right First TimeDoddappa Anekal0% (1)

- Distillation Column ReportDocument27 pagesDistillation Column Reportvaqif100% (1)

- Process Analytics in Ethylene Production PlantsDocument11 pagesProcess Analytics in Ethylene Production PlantsIka SulistyaningtiyasNo ratings yet

- Extractor Flowsheet Definition: - Objective - Create A Graphical FlowsheetDocument20 pagesExtractor Flowsheet Definition: - Objective - Create A Graphical Flowsheetyoly10No ratings yet

- Energy and Process Optimization for the Process IndustriesFrom EverandEnergy and Process Optimization for the Process IndustriesNo ratings yet

- Distillation PDFDocument6 pagesDistillation PDFAmit SawantNo ratings yet

- Cul Faz 1984Document10 pagesCul Faz 1984ViolitaNo ratings yet

- Control Engineering Practice: Vishal Mahindrakar, Juergen HahnDocument11 pagesControl Engineering Practice: Vishal Mahindrakar, Juergen HahnLAURA KATHERINE CENTENO JAIMESNo ratings yet

- Efficient Opération of N Ha Plant at Reduced RatesDocument16 pagesEfficient Opération of N Ha Plant at Reduced RatesNabiya ZahidNo ratings yet

- Luyben 2009Document12 pagesLuyben 2009Cefiro Santibañez VelasquezNo ratings yet

- 03 CNSRVDocument33 pages03 CNSRVaerospace7030No ratings yet

- 英文版 PDFDocument13 pages英文版 PDFSeverina MallariNo ratings yet

- Plantwide Control-A Review and A New Design Procedure: Challenge ProcessDocument32 pagesPlantwide Control-A Review and A New Design Procedure: Challenge Processhamidrezaee008No ratings yet

- Lu 2011Document9 pagesLu 2011hamidrezaee008No ratings yet

- Serra 2003Document10 pagesSerra 2003hamidrezaee008No ratings yet

- IJE - Volume 32 - Issue 7 - Pages 901-907Document7 pagesIJE - Volume 32 - Issue 7 - Pages 901-907hamidrezaee008No ratings yet

- Design and Control of Diphenyl Carbonate Reactive Distillation Process With Thermally Coupled and Heat-Integrated Stages ConfigurationDocument69 pagesDesign and Control of Diphenyl Carbonate Reactive Distillation Process With Thermally Coupled and Heat-Integrated Stages Configurationhamidrezaee008No ratings yet

- Conceptual Design For Chemical ProcessesDocument50 pagesConceptual Design For Chemical ProcessesAudrey Patrick KallaNo ratings yet

- Conservation Equations SSDocument12 pagesConservation Equations SSPrince Israel EboigbeNo ratings yet

- Plantwide Control Systems Design and Evaluation Applied To Biodiesel ProductionDocument10 pagesPlantwide Control Systems Design and Evaluation Applied To Biodiesel Productionhamidrezaee008No ratings yet

- Optimal Design and Plantwide Control of Novel Processes For Di-N-Pentyl Ether ProductionDocument26 pagesOptimal Design and Plantwide Control of Novel Processes For Di-N-Pentyl Ether Productionhamidrezaee008No ratings yet

- DWC PaperDocument19 pagesDWC Paperrawalians1No ratings yet

- Design and Plantwide Control of N-Butyl Acrylate Production ProcessDocument17 pagesDesign and Plantwide Control of N-Butyl Acrylate Production Processhamidrezaee008No ratings yet

- An Overview On Controllability Analysis of Chemical ProcessesDocument17 pagesAn Overview On Controllability Analysis of Chemical Processeshamidrezaee008No ratings yet

- Conceptual Design For Chemical ProcessesDocument50 pagesConceptual Design For Chemical ProcessesAudrey Patrick KallaNo ratings yet

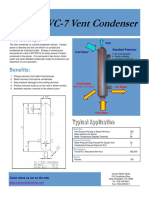

- VC-7 Vent Condenser: The ConceptDocument2 pagesVC-7 Vent Condenser: The Concepthamidrezaee008No ratings yet

- OP95033FUDocument8 pagesOP95033FUhamidrezaee008No ratings yet

- WhydeaerateDocument6 pagesWhydeaeratearif_saleh_2No ratings yet

- Boilermate Boiler BookDocument6 pagesBoilermate Boiler Bookhamidrezaee008No ratings yet

- Om DatasetsDocument19 pagesOm Datasetshamidrezaee008No ratings yet

- App3Document2 pagesApp3hamidrezaee008No ratings yet

- Reflex Pressure Vessels Design and CalculationDocument52 pagesReflex Pressure Vessels Design and CalculationcsharpplusNo ratings yet

- Valmorida 2018 IOP Conf. Ser. - Earth Environ. Sci. 102 012081Document8 pagesValmorida 2018 IOP Conf. Ser. - Earth Environ. Sci. 102 012081hamidrezaee008No ratings yet

- Shell-and-Tube Heat Exchangers R. Shankar Subramanian: AdvantagesDocument10 pagesShell-and-Tube Heat Exchangers R. Shankar Subramanian: AdvantagesCherry May SerionNo ratings yet

- Minimum Energy Distillation Columns Sequence For ADocument6 pagesMinimum Energy Distillation Columns Sequence For Ahamidrezaee008No ratings yet

- Heat ExchangersDocument48 pagesHeat ExchangersRiccat Shio'TangNo ratings yet

- Shell& Tube HT DesignDocument8 pagesShell& Tube HT Designvsraochemical1979100% (1)

- Shell and Tube HX Basic CalculationDocument35 pagesShell and Tube HX Basic Calculationวรศิษฐ์ อ๋องNo ratings yet

- Python (Dictionary)Document54 pagesPython (Dictionary)shahrukhkr.gptNo ratings yet

- About Ramfs Rootfs InitramfsDocument7 pagesAbout Ramfs Rootfs InitramfsNavaneethNo ratings yet

- Itp582b-515-01-Ib 2Document12 pagesItp582b-515-01-Ib 2Cara & Drei Amazing JourneyNo ratings yet

- Suárez y Melián 2021 Fluted Triangular Non Stemmed PointsDocument22 pagesSuárez y Melián 2021 Fluted Triangular Non Stemmed PointsJuliaNo ratings yet

- Unit 4 Rate of Reaction AnswersDocument38 pagesUnit 4 Rate of Reaction Answersareyouthere92No ratings yet

- FM Testbank Ch08Document6 pagesFM Testbank Ch08David LarryNo ratings yet

- WBSETCL Suggestive Paper..Document10 pagesWBSETCL Suggestive Paper..Pà PáïNo ratings yet

- Study of Selected Petroleum Refining Residuals Industry StudyDocument60 pagesStudy of Selected Petroleum Refining Residuals Industry StudyOsama AdilNo ratings yet

- Appendix15B - RE Wall Design ChecklistDocument6 pagesAppendix15B - RE Wall Design ChecklistRavi Chandra IvpNo ratings yet

- Design-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingDocument8 pagesDesign-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingtazzorroNo ratings yet

- Ultima X Series Instruction Manual - enDocument141 pagesUltima X Series Instruction Manual - enStefano EsmNo ratings yet

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Document28 pages21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniNo ratings yet

- Handout E.15 - Examples On Transient Response of First and Second Order Systems, System Damping and Natural FrequencyDocument14 pagesHandout E.15 - Examples On Transient Response of First and Second Order Systems, System Damping and Natural FrequencyRishikesh BhavsarNo ratings yet

- DBM PC SpecificationDocument11 pagesDBM PC SpecificationkesharinareshNo ratings yet

- Ac Machinery FormulasDocument4 pagesAc Machinery FormulasNhilNo ratings yet

- On The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignDocument8 pagesOn The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignJiyang WangNo ratings yet

- Basic of Statistical DataDocument15 pagesBasic of Statistical DatacataiceNo ratings yet

- Comparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistanDocument10 pagesComparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistannithyaNo ratings yet

- Emulsions: - Part 1 Preparation Methods (Some) PropertiesDocument52 pagesEmulsions: - Part 1 Preparation Methods (Some) PropertieschandramohanNo ratings yet

- Bis 12894 - 2002Document7 pagesBis 12894 - 2002rabindora6588100% (1)

- Thermal Radiation System: Instruction Manual and Experiment Guide For The PASCO Scientific Model TD-8553/8554A/8555Document28 pagesThermal Radiation System: Instruction Manual and Experiment Guide For The PASCO Scientific Model TD-8553/8554A/8555CoupeyNo ratings yet

- CHP.32 Coulombs - Law Worksheet 32.1 AnswersDocument2 pagesCHP.32 Coulombs - Law Worksheet 32.1 AnswerslucasNo ratings yet

- O Level Physics 2023-2025 ATP TipsDocument7 pagesO Level Physics 2023-2025 ATP TipsAmy WolmesNo ratings yet

- Opsis Technique Eng 2007Document4 pagesOpsis Technique Eng 2007sukumariicbNo ratings yet

- Production ManagementDocument14 pagesProduction Managementavinasss1963_3707255No ratings yet

- Danfoss FC 301-302 AngDocument268 pagesDanfoss FC 301-302 AngkudakwasheNo ratings yet

- Management - Ch06 - Forecasting and PremisingDocument9 pagesManagement - Ch06 - Forecasting and PremisingRameshKumarMurali0% (1)

- Main Impeller Types: Basic Principles and Types of PumpsDocument9 pagesMain Impeller Types: Basic Principles and Types of PumpsThinagaran N ManiamNo ratings yet

- Offshore Riser CalculationDocument10 pagesOffshore Riser CalculationSergio MuñozNo ratings yet