Professional Documents

Culture Documents

AJOOFT Fitting Catalog

Uploaded by

thoavitOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AJOOFT Fitting Catalog

Uploaded by

thoavitCopyright:

Available Formats

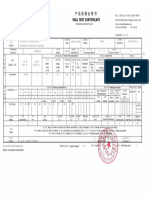

special

steel

Special Steel Business Division

Special Steel

With state-of-art facilities, world-class Established in 1997, SeAH Besteel provides exceptionally functional high-grade special steels. Equipped with

a highly automated-integration manufacturing process and continuous operation excellence initiatives, we

technologies and craftsmanship, aim at being one of the most research-intensive steel-making companies.

Venturing away from the status-quo, we are a global leading special steel supplier providing better solutions

SeAH Besteel supplies more than and value to customers, through our price and quality competitiveness.

high-quality products and services,

we provide better solutions.

Special Steel

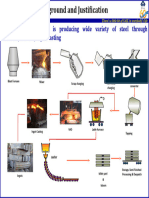

Manufacturing Process (Special Steels)

SeAH’s optimized and continuously-modernized manufacturing process enables us to make unrivalled offers to

satisfy customer needs and requirements, and to maintain our leading position in a highly competitive market.

Melting & Casting Rolling Inspection & Conditioning

EAF #1 LHF #1 RH Continuous Bloom VH Mill #1, #2

Casting #1

Cooling Bed

Walking Beam Furnace Cogging Mill Hot Scarfing

#1, #2

Round Bar

Large Bar Mill

Heat Treatment Straightening & Inspection

(Ann., Nor., QT) Deburring (UT,MT,

EAF #2 LHF #2 VD #1 Continuous Bloom Grinding,VI)

Inspection Square

Casting #2

(MT, Grinding, VI) Bar

Cooling Bed

Walking Beam Furnace Roughing Mill Intermediate Mill RSB

Continuous Billet Casting

Bar In Coil Inspection Coil

(MT, VI)

EAF #3 LHF #3 VD #2

Forging Secondary Processing

Round Bar

Inspection Machining Round Bar

Ingot Casting Reheating Forging Heat Treatment Machining Inspection (UT,MT, - Drawing

Furnace (UT, VI) Grinding,VI) - Peeling

Square - Polishing

Bar

Special Steel

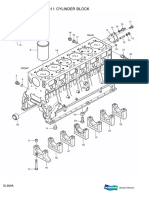

Material / Application Manufacturing Capacity

Business Area Classification Steel Parts Steel Specifications Offered (steel product names) Size (mm) Length (m)

Category Surface Heat Treatment Note

Crank Shaft SCM440H, S40MS1V, 44MNSIVS6 From TO From TO

Connecting Rod S36CVS2, S70CVS1 Produced sizes and lengths may

differ for each process.

Engine Cam Shaft SUM43, SM45C, 50CRMO4 BS 19.0 350.0 4.5 7.2

Possible non-conditioning production

Piston 38MNSIVS5 LA up to 14.5m of over Φ200

Pully FA

SM10C Round

PM 20.0 120.0 4.0 6.8 SA

Gear SCR420HB, SCM920HVSI, SCR420H1 Bar

Transmission NOR

Shaft SCM920HVSI, SCR420HB, SCR420H

Rolled SRA RT applied to forgings of over

Bar RT 120.0 155.0 4.5 8.0

Outer Race UC1, S53CCF, S53CRB FPA Φ155mm

QT

Inner Race, Spider SCR420H, SCM420H CD 20.0 50.8 4.0 6.9

Automobile

Tripod Housing XC45, XC55, XC48, S53CCF

Square Bar 83.0 250.0 4.5 7.2

Drive Shaft 38B3, SAE10B38 (M2)

Axle Shaft SAE1038R, SAE51B35, AISI1541 Wire Rod 16.0 38.0

Chassis Spindle 1524HMOD, SAE1043M

Wheel Hub S40CV, S55CR BS 150.0 850.0 8.0

Round LA

Knuckle SCM440H, SCR440H Bar FA

RT 130.0 830.0 8.0

Rack Bar S45CS1-QD, SAE1141M Forged SA

Tie Rod SM43C Bar Square Bar 130.0 750.0 8.0

NOR

SRA

Pinion Gear SAE1552MOD QT

Shape Forged Bar 8.0 Quotation upon request

Link 15B36M (1), SAE10B35M, SMNB3H-1

Undercarriage, Chassis Cylinder Rod SM45C (S), SBNH75 Bloom 510 x 390 3.5 5.5

Pin S43BCH, SCR440B

Ingot 3.3 ton 23.6 ton SRA

Engine, Transmission Crank Shaft SCR440 Semi-

LA

Construction, Finished Square Billet FA Non-Conditioning 4.5–11.0m

Cylinder, Head SCM415 (420) 160.0 180.0 8.0 12.0

Heavy Equipment

Through Bolt SNCM630, SNCM439 Minimum length of 9.5m for Φ170

Breaker Round Billet 150.0 210.0 6.6 12.0

Chisel SCM440, AE4140 or less

Piston SNCM26V, SNCM439 Die forging (cold) Outer Race / Tripod Housing

Construction Material Tunnel Girder

Structural Part Stay Bolt, Stud Bolt SCM440, SNCM439 Rolled

Shipbuilding Mooring Chain R4 (S), R3S, R5

Chain

Anchor Chain SBC690, R3, SBC490

Automobile Inner, Outer Race STB2, 100CRMNSI6-4 (A), SCR420HQ

Bearing Heavy Equipment Bearing Hub S55CR, GRADE55, GRADE70 Black Surface Peeled Bar

Industrial Machines Cam Lobe 100CR6

Gear 42CRMO4, 18CRNIMO7-6+FP, SM45C

Forged

General Machinery Shaft SM45C, 34CRNIMO6

Industrial Machines Bolt, Nut SM45C, SAE10B30

Injection Molding

Screw SALCRMO1

Machine

Drill Collar Bar, Oil Tool 4145M, 4145H MOD, AISI4145 MOD

Drilling Tool Round Bar Square Bar

Tool Joint 4137M (A)

Petrochemistry

Oil Transfer Equipment Seamless Pipe J55, X52, A106 B&C

Semi-Finished

Automobile Leaf Spring SUP9 (D,A)

Spring Heavy Equipment Coil Spring SUP11D, XK92M48S

Industrial Machines Torsion Bar SAE9254

Bloom Square Billet Round Billet Ingot

Home Appliances Shaft SUM32F, SM45C

Special Steel

Main Facilities Products

SeAH is a leading supplier of the highest quality steel products that are engineered for operational reliability in

Electric Arc Furnace Degassing

various industries, including automotive, industrial machinery and energy. The objective of SeAH’s on-going product

Equipment No 4 ea Equipment No 4 ea and process innovation initiative is to strengthen our competitiveness in the high-purity steel market. To that end,

Type Eccentric Bottom Tapping Type Ruhrstahl Heraeus, we were a pioneer in introducing state-of-art manufacturing facilities in the Koreasteel industry with regard to, for

(Clean steel production) Vacuum Degassing

example, RH refining and large continuous bloom casters.

Transformer Capacity 65MVA Degree of vacuum 0.8mbar

Electrode Size 22inch (550mm) Vacuum Time 10~25min

Automotive parts Construction / Industrial machinery Energy

Melting Capacity 100ton (3), 150ton (1) Melting Capacity 100ton (3), 150ton (1)

RH VD

Continuous Bloom Casting Continuous Billet Casting 1 Continuous Billet Casting 2

Equipment No 2 ea Equipment No 1 ea Equipment No 1 ea

Type Curved Type Type Curved Type Type Curved Type

Bloom Size □390 x 510mm Billet Size □160 & 180mm Billet Size □160 & 180mm

Bloom Length 3,500 ~ 5,600mm Billet Length 6,000~12,000mm Ø150~210mm

Casting Speed 0.4 ~ 0.6m/min Casting Speed 1.4 ~ 2.8m/min Billet Length 6,000~12,000mm

Strand 2 strands Strand 3 strands Casting Speed 1.4 ~ 2.8m/min

Strand 5 strands Forged Bar Round Bar

Continuous Billet Casting 1

Continuous Billet Casting 2

Large Square Bar Peeled, Drawn Bar

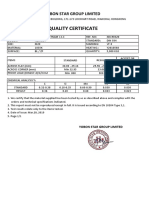

Certificates

System

Quality Management Environment Energy Management Health and Safety Health and Safety

System Management system System Management System Management System

ISO/TS 16949 ISO 14001 ISO 50001 OHSAS 18001 KOSHA 18001

Classification

KR ABS BV CCS DNV

Ingots & Blooms & Billets Ingots & Blooms & Billets Ingots & Blooms & Billets Ingot Casting Ingots & Blooms

Rolled Bars Rolled Bars Rolled Bars Crank Throw Rolled Bars

Mooring & Anchor Mooring & Anchor Mooring & Anchor Mooring & Anchor

Chain Bars Chain Bars Chain Bars Chain Bars

Forgings Forgings Forgings Forgings

Crank Throw Crank Throw Crank Throw Crank Throw

GL NK RINA RS Lloyd´s

Ingots & Blooms Ingots Ingots & Blooms Rolled Bars Ingots & Blooms & Billets

Rolled Bars Rolled Bars Rolled Bars Anchor Chain Bars Rolled Bars

Anchor Chain Bars Chain Bars Anchor Chain Bars Mooring & Anchor

Forgings Forgings Forgings Chain Bars

Crank Throw Crank Throw Crank Throw Forgings

Crank Throw

Product

Head Office Changnyeong Plant

SeAH Tower 29th floor, 45 Yanghwa-ro, Mapo-gu, Seoul 100, Daehapsaneopdanji-ro, Daehap-myeon,

T 82-2-6970-2000 F 82-2-6970-2181 Changnyeong-gun, Gyeongsangnam-do, Korea

T 82-55-530-8500 F 82-55-530-8543

Gunsan Plant

KS JIS PED ASME KEPIC 522, Oehang-ro, Gunsan-si, Jeollabuk-do, Korea Busan Operation

KS D 3752 JIS G 4051 Forgings, Material Organization Material

T 82-63-460-8114 F 82-63-460-8560 3rd floor ,617-800 Hakgam-daero 267beon-gil, Sasang-gu,

KS D 3867 JIS G 4053 Forged Bars and Organization

JIS G 3101 Rolled Bar Manufacturing and Busan, Korea 28

Supplying of Forgings http://www.seahbesteel.co.kr T 82-51-313-2259 F 82-51-311-2105

You might also like

- Bars and Wire Rods PDFDocument32 pagesBars and Wire Rods PDFhorascanmanNo ratings yet

- Reference - Cladding Process PDFDocument24 pagesReference - Cladding Process PDFJRodNo ratings yet

- JFE Linepipe PDFDocument64 pagesJFE Linepipe PDFTrần Tiến ĐắcNo ratings yet

- Clad Steel Plate: Cat - No.C1E-009-04Document24 pagesClad Steel Plate: Cat - No.C1E-009-04RaghNo ratings yet

- Complete Process Flow Chart: Stainless Steel Long ProductsDocument1 pageComplete Process Flow Chart: Stainless Steel Long ProductsThanh Ngoc LeNo ratings yet

- Presentationon IrontosteelmakingDocument29 pagesPresentationon IrontosteelmakingEric PhanNo ratings yet

- Nippon Imp Diagramas de FlujoDocument4 pagesNippon Imp Diagramas de FlujodiegoNo ratings yet

- Carbon & Alloy SteelDocument10 pagesCarbon & Alloy SteelMaswindo CikarangNo ratings yet

- Ferrous Extractive Metallurgy: Dr. / Amr Basuony Saad EldeebDocument19 pagesFerrous Extractive Metallurgy: Dr. / Amr Basuony Saad Eldeebفوزي خلفNo ratings yet

- Raw Material Process Flow (SeAH)Document2 pagesRaw Material Process Flow (SeAH)Vianjani AldoeNo ratings yet

- Steel Making IntroductionDocument17 pagesSteel Making IntroductionHari sadu100% (2)

- Over-View of Iron & Steel Making: Sr. Manager, Technology Group Theis Precision Steel India Pvt. LTDDocument29 pagesOver-View of Iron & Steel Making: Sr. Manager, Technology Group Theis Precision Steel India Pvt. LTDSarahNo ratings yet

- Hot Rolled Steel SheetDocument40 pagesHot Rolled Steel SheetsyaefulNo ratings yet

- JFE Structural SteelDocument38 pagesJFE Structural SteelboysitumeangNo ratings yet

- Manufacturingprocessof Long ProductsDocument4 pagesManufacturingprocessof Long ProductsRoberto RoeselNo ratings yet

- B1e 001Document40 pagesB1e 001Sontosh BhattacharjeeNo ratings yet

- Hot Rolled Steel SheetDocument40 pagesHot Rolled Steel SheetAilynNo ratings yet

- KurashikiDocument2 pagesKurashikidiyan tahsenNo ratings yet

- Tabel Baja Gunung GarudaDocument36 pagesTabel Baja Gunung Garudahaidar alquthbaniNo ratings yet

- Rolling Mills and Strip Processing Lines: Capital Market Days 2007Document40 pagesRolling Mills and Strip Processing Lines: Capital Market Days 2007Vikanshu bansalNo ratings yet

- Steel Making Overview (MR Amit Sarkar)Document52 pagesSteel Making Overview (MR Amit Sarkar)Murali Krishna ENo ratings yet

- Jfe Sawl Pipe: Cat - No.E1E-016-02Document20 pagesJfe Sawl Pipe: Cat - No.E1E-016-02Berny Guzmán ArayaNo ratings yet

- JFE Pipe Making PDFDocument20 pagesJFE Pipe Making PDFDhim131267No ratings yet

- Nscguide2012 - e - 61-Flow Production Nippon SteelDocument2 pagesNscguide2012 - e - 61-Flow Production Nippon SteelAgustine SetiawanNo ratings yet

- Accelerated Cooling of Steel Plates The Time Has CDocument8 pagesAccelerated Cooling of Steel Plates The Time Has CZulfa Ilham BasyarahilNo ratings yet

- Hardfacing Wires: For Steel Mill RollsDocument16 pagesHardfacing Wires: For Steel Mill RollsRaviTeja BhamidiNo ratings yet

- Slabbrochure Baosteel PDFDocument36 pagesSlabbrochure Baosteel PDFKetnipha SukwannawitNo ratings yet

- Cladded MaterialDocument26 pagesCladded Materialabdalla el-saadaneyNo ratings yet

- ZLYToolCatalogue EndmillsDocument31 pagesZLYToolCatalogue Endmillssb15mcsNo ratings yet

- Product Catalogue Pt. GRDDocument40 pagesProduct Catalogue Pt. GRDkrisna monicaNo ratings yet

- Japanese SectionsDocument27 pagesJapanese SectionsDuy NamNo ratings yet

- T GRP Catalogue 28102021Document80 pagesT GRP Catalogue 28102021Muhammad FadhilNo ratings yet

- Cold Rolling (DG Teori Detil)Document32 pagesCold Rolling (DG Teori Detil)Baginda HamzahNo ratings yet

- Repair and Maintenance Weld Overlay Solutions For Steel MillsDocument28 pagesRepair and Maintenance Weld Overlay Solutions For Steel MillsMike CheNo ratings yet

- Arvedi Brief Presentation Modernisation ProgrammeDocument30 pagesArvedi Brief Presentation Modernisation ProgrammeKetnipha SukwannawitNo ratings yet

- Accelerated CoolingDocument7 pagesAccelerated CoolingHarikrishnan N SivaprasadNo ratings yet

- 037 042 PDFDocument6 pages037 042 PDFDevendra Kumar KumawatNo ratings yet

- JNF12 Hales 2380 PDFDocument18 pagesJNF12 Hales 2380 PDFagilan89No ratings yet

- Iron and Steel Making ProcessDocument22 pagesIron and Steel Making Processmaghfira100% (1)

- Norma Saph440 9Document24 pagesNorma Saph440 9Marcos FerreiraNo ratings yet

- Overview of Bokaro Steel Plant: Suman SourabhDocument48 pagesOverview of Bokaro Steel Plant: Suman SourabhabhishekNo ratings yet

- ANGLE BAR SIZES in The PhilippinesDocument5 pagesANGLE BAR SIZES in The PhilippinesjeffersondomagasNo ratings yet

- Overview of Steel Making: Mr. Amit SarkarDocument51 pagesOverview of Steel Making: Mr. Amit SarkarSagar Jadhav100% (1)

- China Steel PDFDocument38 pagesChina Steel PDFKalpeshNo ratings yet

- Tata Steel - ColornovaDocument28 pagesTata Steel - ColornovaGabriel CamargoNo ratings yet

- Transformer Manufactuing Process Flow-ChartDocument1 pageTransformer Manufactuing Process Flow-ChartMohammed ShoaibNo ratings yet

- Junction Activity Description: Shallow ManholeDocument12 pagesJunction Activity Description: Shallow Manholeray agaciaNo ratings yet

- Steel Making ProcessDocument1 pageSteel Making Processsdtd.ranchiNo ratings yet

- D1e 001Document40 pagesD1e 001Himindra ChaaubeNo ratings yet

- Rane Madras Flow ChartDocument2 pagesRane Madras Flow ChartrathanNo ratings yet

- Zhihao Jiang: Ersonal NformationDocument7 pagesZhihao Jiang: Ersonal NformationjjjNo ratings yet

- RK-RB UkDocument3 pagesRK-RB UkpamururamuNo ratings yet

- Drilling Mitsubishi CatalogueDocument187 pagesDrilling Mitsubishi CatalogueAmanTiwaryNo ratings yet

- Equal Angle Bar, Equal Angle SteelDocument2 pagesEqual Angle Bar, Equal Angle Steel20-08702No ratings yet

- Hfy2 E1890 CPF1WT WLD SPC 0008Document3 pagesHfy2 E1890 CPF1WT WLD SPC 0008Firas AlbaweiNo ratings yet

- Suscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, AquíDocument3 pagesSuscribete GRATIS A La Revista: SOLDADURA LATINOAMERICA, AquíadelNo ratings yet

- 200 A (Main Lugs) 600 V Multiple Position - 200 A Per PositionDocument4 pages200 A (Main Lugs) 600 V Multiple Position - 200 A Per PositionPRABHU SHANKAR MNo ratings yet

- Benkan - Welding PipeFittings-CatalogueDocument12 pagesBenkan - Welding PipeFittings-CatalogueEng Saber MohamedNo ratings yet

- Chung Chi WasherDocument1 pageChung Chi WasherthoavitNo ratings yet

- DIN933 M16x50 PLAINDocument1 pageDIN933 M16x50 PLAINthoavit100% (1)

- Pyro-Bloc M Module Manual DD 31052016Document20 pagesPyro-Bloc M Module Manual DD 31052016thoavitNo ratings yet

- Hex Nut M20Document1 pageHex Nut M20thoavitNo ratings yet

- U ChannelDocument1 pageU ChannelthoavitNo ratings yet

- Attachment 1. REVDocument2 pagesAttachment 1. REVthoavitNo ratings yet

- Catalog (Special Steel)Document5 pagesCatalog (Special Steel)thoavitNo ratings yet

- Attachment 1. REVDocument2 pagesAttachment 1. REVthoavitNo ratings yet

- E1815-08 (2013) E1 Standard Test Method For Classification of Film Systems For Industrial RadiographyDocument7 pagesE1815-08 (2013) E1 Standard Test Method For Classification of Film Systems For Industrial RadiographythoavitNo ratings yet

- AJOOFT Fitting CatalogDocument6 pagesAJOOFT Fitting CatalogthoavitNo ratings yet

- Tkis Bridge Agreement: Doc. Title: Rev.: A Doc. No.: BID-AMPT - .Document2 pagesTkis Bridge Agreement: Doc. Title: Rev.: A Doc. No.: BID-AMPT - .thoavitNo ratings yet

- List of Plate & SectionDocument8 pagesList of Plate & SectionthoavitNo ratings yet

- AD-120ES Parts PN-450160Document73 pagesAD-120ES Parts PN-450160naokito AkemiNo ratings yet

- Service: Polo/Vento 2014-2018Document294 pagesService: Polo/Vento 2014-2018hiramfgarciaNo ratings yet

- Main Principles of Pumps SelectionDocument14 pagesMain Principles of Pumps SelectionMMM000No ratings yet

- X15532Document3 pagesX15532Anibal Jose Cruz LarezNo ratings yet

- Spare Parts CatalogueDocument563 pagesSpare Parts CatalogueRoberto Juniior Mendoza DiazNo ratings yet

- 273243957-DENSO-Common-Rail-Isuzu-6HK1-6SD1-Service-Manual-Pages Backup PDFDocument9 pages273243957-DENSO-Common-Rail-Isuzu-6HK1-6SD1-Service-Manual-Pages Backup PDFjwd100% (1)

- 1 Land Rover Freelander MY2001 Parking Heater Install TD4Document4 pages1 Land Rover Freelander MY2001 Parking Heater Install TD4Florin ConstantinNo ratings yet

- FQP 16.11.18 Vol-I - BoilerDocument90 pagesFQP 16.11.18 Vol-I - Boilerashis chatterjeeNo ratings yet

- Agricultural Power and Machinery - DCSuministrado - QUESTIONS 2011Document4 pagesAgricultural Power and Machinery - DCSuministrado - QUESTIONS 2011Gladys Ruth Paypa100% (3)

- ECU Kits OBD System Wiring Diagram 06V180818Document2 pagesECU Kits OBD System Wiring Diagram 06V180818Roberto HernandezNo ratings yet

- Como Instalar Una Bomba SumergibleDocument23 pagesComo Instalar Una Bomba Sumergibleoscar_m_avilaNo ratings yet

- 188-9901 Grupo de Valvula de Inversao Do VentiladorDocument29 pages188-9901 Grupo de Valvula de Inversao Do VentiladorGilson RodriguesNo ratings yet

- Neutral Wires. These Wires Are Color Coded For Easy Identification. Hot Wires Are Black or RedDocument17 pagesNeutral Wires. These Wires Are Color Coded For Easy Identification. Hot Wires Are Black or Redvalerie candoNo ratings yet

- 416 BACKHOE LOADER 5PC06192-10761 (MACHINE) POWERED BY 4.236 DIESEL ENGINE (SEBP1843 - 00) - Sistemas y Componentes1 PDFDocument3 pages416 BACKHOE LOADER 5PC06192-10761 (MACHINE) POWERED BY 4.236 DIESEL ENGINE (SEBP1843 - 00) - Sistemas y Componentes1 PDFArturo Sanchez100% (1)

- 20 Throttle Switch (TS) : Checking Pedal Switch OperationDocument1 page20 Throttle Switch (TS) : Checking Pedal Switch OperationJuan Manuel Cividanes AlonsoNo ratings yet

- Gen00139-01 Wa600-8 Wheel LoaderDocument100 pagesGen00139-01 Wa600-8 Wheel LoaderJuan Araya BarrazaNo ratings yet

- DAKE Press Model 75 H - 907003Document6 pagesDAKE Press Model 75 H - 907003mark_dayNo ratings yet

- Line List (Ibr)Document3 pagesLine List (Ibr)vtbkNo ratings yet

- Four Cylinder Four Stroke Petrol Engine With Hydraulic Dynamometer Test Rig ManufacturerDocument2 pagesFour Cylinder Four Stroke Petrol Engine With Hydraulic Dynamometer Test Rig Manufacturersuri surendraNo ratings yet

- M - Series Alo Loader WSM en PDFDocument84 pagesM - Series Alo Loader WSM en PDFFrançois CharrièreNo ratings yet

- Application Manual, Kurbota EngineDocument364 pagesApplication Manual, Kurbota EngineEl Haji Roku88% (8)

- Manual SharonDocument84 pagesManual SharonJose Ramirez DiazNo ratings yet

- 703 Control InstructionsDocument11 pages703 Control InstructionsJacyra Camargo AlvesNo ratings yet

- WSS220Document1 pageWSS220Favio Lopez MuñozNo ratings yet

- Refrigerant Piping Design Guide Daikin AG 31-011 LRDocument78 pagesRefrigerant Piping Design Guide Daikin AG 31-011 LRRm Moh0% (1)

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocument1 pageDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectfebousNo ratings yet

- C22-Yb60-D-7770 - 1 Sa3-Ps2, Butterfly Valve, Pneumatic Wiring SchematicsDocument4 pagesC22-Yb60-D-7770 - 1 Sa3-Ps2, Butterfly Valve, Pneumatic Wiring SchematicssartajNo ratings yet

- Technical Large RoofTopsDocument48 pagesTechnical Large RoofTopsnairam2003No ratings yet

- DOOSAN DL300A WHEELED LOADER Service Repair Manual PDFDocument45 pagesDOOSAN DL300A WHEELED LOADER Service Repair Manual PDFdfjjskemmdm86% (7)

- c18 Parts Manual600kvaDocument156 pagesc18 Parts Manual600kvankr4726923No ratings yet