Professional Documents

Culture Documents

Chongchaikit, Puthwattana - 2006 - The Effect of Humidity On Partial Discharge Measurement

Uploaded by

dennyyusufOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chongchaikit, Puthwattana - 2006 - The Effect of Humidity On Partial Discharge Measurement

Uploaded by

dennyyusufCopyright:

Available Formats

The Effect of Humidity on Partial Discharge Measurement

Supawat Naprasert, Somboon Chongchaikit, Surapol Puthwattana

Department of Electrical Engineering, Faculty of Engineering

Chulalongkorn University

254 Phyathai Road, Patumwan, Bangkok Thailand, 10330

E-mail: supawat9ghotmail.com

Abstract factors as mentioned above especially the humidity.

For this reason, understanding the effect of humidity is

This paper is a study of the effect of humidity on useful for partial discharge analysis.

partial discharge measurement in rotating machine. As

we know, partial discharge measurement is effected by EXPERIMENTAL DESCRIPTION

several factors and the humidity is one of the most

important factors. To study the effect of humidity on Stator bar model without artificial defect is called

partial discharge test, slot defect stator bar models perfect bar model which is shown in figure 1 It

were manufactured for data acquisition at 40°0, 60% consists of copper strand, insulation, low-resistance

and 70°0 relative humidity respectively. The data were semiconductor, high-resistance semiconductor and

then analyzed by visual inspection to see the difference aluminum bar. Three perfect stator bars models (named

of three dimension distribution of Hj1( ,q) and two S1, S2 and S3) were formed to study the effect of

humidity. Perfect stator bar (S1) was tested at 60%

dimension distribution of Hqmax( Si5), Hqn( Si5), Hn( i ), relative humidity, perfect stator bar (S2) was tested at

H(q) and H(p). Statistical values were also calculated 60% relative humidity whereas perfect stator bar (S3)

in order to compare the trend of those parameters at was tested at 40°0o, 60% and 70°0 relative humidity

each level of relative humidity. The test result shows successively. Twenty measurements from each bar

that visual inspection in the same stator bar model at have been performed at 6.6 kV and then were

each level of relative humidity has different patterns. scratched to simulate slot defect stator bar models.

In addition, the statistical parameters change upon the

variation of relative humidity. Therefore, partial Low resistance

semi condulctor

Aluminum bar

discharge measurement without consideration on Nvl...UU..UUUL

Copp?er strand

humidity can lead to misinterpretation.

L---L-

INTRODUCTION r-

Generator is one of the critical components in power

plant and power generating system. Therefore, an in isulation

appropriate maintenance program should be applied to High resistance

semiconductor

the generator in order to make power system more

reliable and to prevent generator at early stage before Fig. 1 Perfect stator bar model

failure. Most of the troubles concerning the generator

occurred during an operation comes from stator Artificial defect

winding deterioration and continuous deterioration of Low resistance

semiconductor Aluminum bar

stator winding can ultimately result in generator \ / eCopper strand

failure. Many tests can be performed to assess the

stator winding condition that help to better a

maintenance plan and one of those tests is partial

discharge measurement. Since the partial discharge has

significant effect on the insulation life, a new partial

Insulation

discharge detector has been developed for monitoring High resistance

the condition of electrical insulation. Partial discharge semiconductor

measurement using digital techniques which makes

more complex functions can be calculated easily and Fig.2 Slot defect stator bar model

yield many different parameters [1],[2]. Each

parameter gives specific information which leads to To simulate the progress of slot degradation, the

better evaluation and possesses more advantages than semiconductor layer covering stator surface of the

conventional techniques. Although partial discharge same bar was scratched at different defect sizes and

test is one of the most effective tools used to assess the was tested again. Firstly, slot defect stator bar model

condition of insulation, it is influenced by several

1-4244-0189-5/06/$20.00 ©2006 IEEE. 57

(SI) was scratched at three different defect sizes which The second parameter is kurtosis representing the

are 2x5 cm2, 2x10 cm2 and 2x15 cm2 to simulate a sharpness of the distribution. If the distribution has the

lower degradation level comparing to slot defect stator same sharpness as a normal distribution, Ku = 0. If it is

bar model (S2) and each defect size was tested at 60% sharper than normal, Ku > 0, and if it is flatter, Ku < 0.

relative humidity while slot defect stator bar model The kurtosis is defined as equation 2[3].

(S2) was scratched at three different defect sizes of

2x10 cm2, 2x20 cm2 and 2x30 cm2 to simulate a higher

degradation level comparing to slot defect stator bar Ku =

N (qi -A)4 Pi (2)

model (SI) and each defect size was also tested at 60% itl

relative humidity. The last slot defect stator bar model

(S3) was scratched at four different defect sizes (2x5 The Ku+ and Ku - are the kurtosis of distribution in

cm2, 2x7.5 cm2, 2x10 cm2 and 2x15 cm2) and each the positive and negative half of the voltage cycle

defect size was tested at 4000 relative humidity. In respectively.

addition, slot defect stator bar model (S3) with the

defect size of 2x15 cm2 was tested at 60% and 70°O The third is fractal analysis[4]. In particular, the fractal

relative humidity as well to study the effect of method processes two parameters: the fractal

humidity on partial activity at the same defect size. dimension and the lacunarity. The fractal dimension

corresponds to the roughness of a surface of three

PARTIAL DISCHARGE ANALYSIS dimension distribution. The fractal dimension (D) is

derived from equation 3.

The data from each stator bar was analyzed by visual

inspection and compared the difference of the three N(L) = KL-D (3)

dimension distribution, H1( S7 ,q) which displays the

relationship between discharge magnitude (q), The lacunarity could be compared to the density of

discharge intensity (n) and phase angle( i ). The surface of three dimension distribution. A low value

corresponds to an empty surface; a high value

following two dimension distributions were also corresponds to a dense surface. The lacunarity (A) is

processed: the maximum pulse height Hqmax( $7) the defined as equation 4.

mean pulse height Hqn( S ), the pulse count Hj( z) , the

number of discharge vs. discharge magnitude H(q) and A=M2(L)-[M(L)2]

the number of discharge vs. discharge energy H(p).All (4)

[M(L)2 ]

distributions of each stator bars which were testes at

4000, 60% and 7000 relative humidity were compared where M(L) is the mean and M2(L) is the variance of

to study the effect of humidity on partial discharge the number of sites per box. N(L) is the mean of boxes

measurement. Although the distributions have per site, K is a constant and L is the length of box.

characteristic shapes which vary upon the size of the

defect, it's quite difficult to observe the change of TEST RESULTS AND DISCUSSION

these distributions, Thus the following statistical

parameters are also calculated to observe the change of Figure 3,4 and 5 show the results of partial discharge

parameters when the degradation progresses. measurement of slot defect stator bar model (S3) tested

at 4000, 60% and 7000 relative humidity respectively. It

The first parameter is skewness which represents the is clearly visible that partial discharge activity at 4000

asymmetry of the distribution. If the distribution is relative humidity is quite differ from partial discharge

symmetric, Sk = 0, if it is asymmetry to the left, Sk > activity at 60% and 7000 relative humidity noticing

0, if it is asymmetry to the right, Sk < 0. The skewness from the higher discharge magnitude and the number

is defined as equation 1[3]. of the pulse count. Visual comparison of the test

results at 60% and 7000 relative humidity show some

Sk

N

Y (qi-p) 3Pi (1

differences, but it is quite difficult to quantify these

differences. Figure 15,16 and 17 show skewness,

i=1 I kurtosis and fractal analysis of slot defect bar model

(S3). They show the change of statistical parameters

Where qj is the record value and p1 is the probability of upon the variation of humidity. Figure 6 to 14 show all

frequency of appearance for that value qj in time statistical parameters of slot defect stator bar models

window i, Vt is the mean value E qi. pi, and ca is the (S1, S2 and S3) tested at 60%, 60% and 40% relative

variance CG2 = ( qij )2. pi. The Sk+ and Sk- are the humidity respectively. The results show that both

skewness of distribution in the positive and negative skewness and kurtosis of a lower degradation model

half of the voltage cycle respectively. (S1) cannot be used as tools to show the trend of

insulation degradation while in a higher degradation

1-4244-0189-5/06/$20.00 ©2006 IEEE. 58

model (S2) tested at the same humidity a better trend Sk+ vs. Sk- Plot of Hqn at Different Defect Sizes

could be shown. Nevertheless, fractal analysis of all 1.7

models (S 1, S2 and S3) shows the best trend of 1.6

1.5

insulation degradation, even though the partial Sk- 1.4

* PerfectBar#Sl

M DefectBar #S(2x5cm')

discharge activity is low. Figure 8,11 and 14 of model 1.3

1.2

A Defect Bar #Sl(2xlOcm')

S3 show that all statistical parameters can show the 1.1

|X Defect Bar #Sl(2xl5cm')

trend of insulation degradation, even though both 1 1.1 1.2 1.3 1.4 1.51.6 1.7 1.81.9 2

skewness and kurtosis cannot show the trend of Sk+

insulation degradation at high relative humidity.

Fig.6 Sk plot of SI model at different defect sizes

Sk+ vs. Sk- Plot of Hqn at Different Defect Sizes

1.7

1.6

7 * Perfect Bar #S2

k 114Defect Bar #S2(2xlOcr)

1.3 |A Defect Bar #S2(2x20cm')

Defect Bar

1.2 x X #S2(2x3Ocm')

1.1

1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2

Sk+

Fig.7 Sk plot of S2 model at different defect sizes

Fig.3 S3 model at 4000 relative humidity Sk+ vs. Sk- Plot of Hqn at Different Defect Sizes

1.7

1.6 * Perfect Bar #S3

1.5 Defect Bar #S3(2x5cm')

Sk 14 A Defect Bar #S3(2x7.5cm')

1.3 ! *!x Defect Bar #S3(2xlOcm')

#S3(2xl5cm')

1.

13 Defect Bar

1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2

Sk+

Fig.8 Sk plot of S3 model at different defect sizes

Ku+ vs. Ku- Plot of Hqn at Different Defect Sizes

-1.5 -0.5 0.5 1.5

-0.2

# Perfect Bar #SI1

04

Defect Bar #S1(2x5cm')

Ku-

Fig.4 S2 model at 60% relative humidity

06

A Defect Bar #S1(2x7.5cm')

-0.8 X Defect Bar #Sl(2xlOcm')

-1

.,A -1.2

-1.4

Ku+

Fig.9 Ku plot of SI model at different defect sizes

Ku+ vs. Ku- Plot of Hqn at Different Defect Sizes

-1.5 -0.5 0.5 1.5

-0.2

I0 4 * Perfect Bar #S2

I

Ku- -0.6 * Defect Bar #S2(2xlOcm')

I* * -0.8A,Defect Bar #S2(2x20cm')

I~~~~

K1 X Defect Bar #S2(2x3Ocm')

1u4

Ku+4

Fig.5 SI model at 60% relative humidity

Fig. 10 Ku plot of S2 model at different defect sizes

1-4244-0189-5/06/$20.00 ©2006 IEEE. 59

Ku+ vs. Ku- Plot of Hqn at Different Defect Sizes Ku+ vs. Ku- Plot of Hqn at 40%, 60% and 70% Relative Humidity

-1.5 -0.5 0.5 1.5 -2 -1 0 1 2

-0.2 -0 .2 * Defect Bar #S3 (2xI 5 cm2)

-0.4 * Perfect Bar #S3 Ku -0. 4 40% Relative Humidity

Ku- -0.6 * Defect Bar #S3(2x5cm') -0.6 N DefectBar#S3 (2x1cm)

*0 Defect Bar #S3(2x7.5cm') -0.8 60% Relative Humidity

XDefect Bar #S3(2xl Ocm) A DefectBar#S3 (2x1cm)

-1 70% Relative Humidity

O12 Defect Bar #S3(2xl5cm')

-1.2 -1.2

-1.4 -1.4

Ku+ Ku+

Fig. 11 Ku plot of S3 model at different defect sizes Fig. 16 Ku plot of S3 model at different humidity

Fractal Analysis at Different Defect Sizes Fractal Analysis at 40%, 60% and 70% Relative Humidity

2.4

2235 2.4

2.3 2.36

2.32 * Defect Bar #S3 (2xI cm)

2 2.25 -Perfect Bar #SI

2.2 E Defect Bar #SI(2xScm) 2.28

=,72.24- 40% Relative Humidity

2.15 *ADefect Bar #SI2x7.5cm') * Defect Bar #S3 (2xI1cm)

60% Relative Humidity

2.1 XDefect Bar #S1(2xIOcm) 5 2.16

a2.12-

2°5

2.05 2 08

2.04

A Defect Bar #S3 (2xI1cm)

70% Relative Humidity

0 0.01 0.02 0.03 0.04

0 0.01 0.02 0.03 0.04 0.05

Lacunarity

Lacunarity

Fig. 12 Fractal analysis of S1 model

at different defect sizes Fig. 17 Fractal analysis of S3 model

at different humidity

Fractal Analysis at Different Defect Sizes

CONCLUSION

2.4

2235

223

2.2

* PerfectBar#S2

* Defect Bar# S2 (2xlO

cm1 )

The test results show that the lower relative humidity,

2.15

2.1 4

Defect Bar # S2 (2x20 cm)

X Defect Bar # S2 (2x30cm)

the higher partial discharge activity, so we can

2.05

conclude that partial discharge phenomenon is

0 0.01 0.02

Lacunarity

0.03 0.04 0.05

influenced by the humidity. In addition, it was

confirmed that the change of skewness and kurtosis at

low relative humidity can be directly correlated with

Fig. 13 Fractal analysis of S2 model the insulation degradation, but at high relative

at different defect sizes humidity the correlation could not be shown. However,

the fractal analysis is the best effective tool used to

Fractal Analysis at Different Defect Sizes assess the condition of insulation since it shows a good

224 correlation at both low and high relative humidity.

2.3 x 4O* Perfect Bar #S3

2=253 - Defect Bar #S3(2x5cm')

2.2 - Defect Bar #S3(2x7.5cm') REFERENCES

a215 X DefectBar #S3(2xlOcm1

)

2.05 - Defect Bar #S3(2xl5cm')

2

0 0.01 0.02 0.03 0.04 0.05

[1] E. Gulski., F.H. Kreuger, "Computer-aided

Lacunarity recognition of Discharge Sources," IEEE Transactions

on Electrical Insulation, Vol. 27 No 1, pp.82-92

February 1992.

Fig. 14 Fractal analysis of S3 model [2] A. Krivada, "Automated Recognition of Partial

at different defect sizes

discharges," IEEE Transactions on Electrical

Insulation, Vol. 2 No 5, pp.796-821, October 1995.

Sk+ vs. Sk- Plot of Hqn at 40%, 60% and 70% Relative Humidity

[3] Yue Bo., Li Jian., Cheng Yonghong., Hengkun

2 Xie, "Study on the Multi-Stress Aging of Stator

1.5

* * DefectBar #S3 (2x 1cm')

40% Relative Humidity Insulation Based on Fingerprint Parameters," Proc. Of

Sk- * Defect Bar #S3 (2xI

60% Relative Humidity

1cm') 2001 International Symposium Electrical Insulating

0.5 * Defect Bar #S3 (2xI1cm')

70% Relative Humidity Materials (ISEIM 2001), pp. 729-732, 19-22 Nov.

0 0.5 1 1.5 2

2001.

Sk+ [4] Satish., L. and Zaengl, W.S. "Can Fractal be used

for Recognizing 3-D Partial Discharge Patterns?,"

Fig. 15 Sk plot of S3 model at different humidity IEEE Transaction of Dielectrics and Electrical

Insulation, Vol. 2, pp. 352-359, 1995.

1-4244-0189-5/06/$20.00 ©2006 IEEE. 60

You might also like

- H N Nagamani - 2017 - On-Line Diagnostic Technique For Monitoring Partial Discharges in Capacitor BanksDocument4 pagesH N Nagamani - 2017 - On-Line Diagnostic Technique For Monitoring Partial Discharges in Capacitor BanksdennyyusufNo ratings yet

- Marketing 3.0 SummaryDocument22 pagesMarketing 3.0 SummarydennyyusufNo ratings yet

- SF - An Excellent Insulating and Quenching Gas: Substantial Properties at A GlanceDocument16 pagesSF - An Excellent Insulating and Quenching Gas: Substantial Properties at A GlancedennyyusufNo ratings yet

- Omni FTIR - PS - ENDocument2 pagesOmni FTIR - PS - ENdennyyusufNo ratings yet

- GTD Summary PDFDocument26 pagesGTD Summary PDFdennyyusuf100% (1)

- Timeline - To Do ListDocument3 pagesTimeline - To Do ListdennyyusufNo ratings yet

- Article Siemens - Vacuum Vs SF6 TechTopics No. 03Document2 pagesArticle Siemens - Vacuum Vs SF6 TechTopics No. 03dennyyusufNo ratings yet

- Martin2010 PDFDocument4 pagesMartin2010 PDFdennyyusufNo ratings yet

- Tensor II Brochure enDocument7 pagesTensor II Brochure endennyyusufNo ratings yet

- Measuring System For Laboratory Analysis of Decomposition Products in SF6 Gas Model GFTIR-10 PDFDocument2 pagesMeasuring System For Laboratory Analysis of Decomposition Products in SF6 Gas Model GFTIR-10 PDFdennyyusufNo ratings yet

- Guidance - Process Connection Per en 837 by WikaDocument4 pagesGuidance - Process Connection Per en 837 by WikadennyyusufNo ratings yet

- IC Equipment CNDocument6 pagesIC Equipment CNdennyyusufNo ratings yet

- Template Entry Level FunctionalDocument2 pagesTemplate Entry Level FunctionaldennyyusufNo ratings yet

- Charity Proposal TemplateDocument8 pagesCharity Proposal Templatedennyyusuf100% (1)

- SF 6Document16 pagesSF 6dennyyusuf100% (1)

- Date Company Contact: SalespersonDocument36 pagesDate Company Contact: SalespersondennyyusufNo ratings yet

- Make Your Settings Only Into White Boxes Corresponding To Desired Standard Curve!Document4 pagesMake Your Settings Only Into White Boxes Corresponding To Desired Standard Curve!dennyyusufNo ratings yet

- Fundraising Event ProposalDocument5 pagesFundraising Event ProposaldennyyusufNo ratings yet

- DS SP6014 GB 51924Document6 pagesDS SP6014 GB 51924dennyyusufNo ratings yet

- Source: Micom P14X P141, P142, P143, P144 & P145 Feeder Management Relay Technical Manual-P14Xen Mde6+Gf7Document3 pagesSource: Micom P14X P141, P142, P143, P144 & P145 Feeder Management Relay Technical Manual-P14Xen Mde6+Gf7dennyyusufNo ratings yet

- Logic Timer From MiCOM P14x P141, P142, P143, P144 & P145 Feeder Management Relay Technical Manual-P14xEN MDe6+Gf7Document2 pagesLogic Timer From MiCOM P14x P141, P142, P143, P144 & P145 Feeder Management Relay Technical Manual-P14xEN MDe6+Gf7dennyyusufNo ratings yet

- Logic Gates From MiCOM P14x P141, P142, P143, P144 & P145 Feeder Management Relay Technical Manual-P14xEN MDe6+Gf7Document1 pageLogic Gates From MiCOM P14x P141, P142, P143, P144 & P145 Feeder Management Relay Technical Manual-P14xEN MDe6+Gf7dennyyusufNo ratings yet

- Commissioning and Maintenance MiCOM P125 P126 & P127-P12yEN CMC22Document26 pagesCommissioning and Maintenance MiCOM P125 P126 & P127-P12yEN CMC22dennyyusufNo ratings yet

- Per-Unit Problems & HW5-SolutionsDocument9 pagesPer-Unit Problems & HW5-SolutionsdennyyusufNo ratings yet

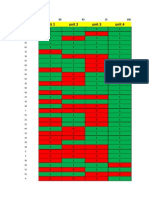

- Unit 1 Unit 2 Unit 3 Unit 4: Kapasitas MaksDocument8 pagesUnit 1 Unit 2 Unit 3 Unit 4: Kapasitas MaksdennyyusufNo ratings yet

- September 2014: Monda y Tuesda y Wednesda y Thursda y Frida y Saturda y Sunda yDocument1 pageSeptember 2014: Monda y Tuesda y Wednesda y Thursda y Frida y Saturda y Sunda ydennyyusufNo ratings yet

- 2013 Merged A5 Annual PlannerDocument1 page2013 Merged A5 Annual PlannerdennyyusufNo ratings yet

- InstructionDocument1 pageInstructiondennyyusufNo ratings yet

- Single Phase InverterDocument17 pagesSingle Phase InverterdennyyusufNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Topic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1Document49 pagesTopic 6 ESD & EMI Considerations Electrostatic Sensitive Devices (M4.2, 5.12 &5.14) - 1BeaglelalahahaNo ratings yet

- Final Reporting GuidelinesDocument183 pagesFinal Reporting GuidelinesAkhmad NuzulNo ratings yet

- Turbin 1Document27 pagesTurbin 1Durjoy Chakraborty100% (1)

- BPSK SimulinkDocument13 pagesBPSK SimulinkpootommyNo ratings yet

- D 2510 - 94 R98Document3 pagesD 2510 - 94 R98David Cazorla100% (1)

- Measurement Advisory Committee Summary - Attachment 3Document70 pagesMeasurement Advisory Committee Summary - Attachment 3MauricioICQNo ratings yet

- EMOC 208 Installation of VITT For N2 Cylinder FillingDocument12 pagesEMOC 208 Installation of VITT For N2 Cylinder Fillingtejcd1234No ratings yet

- Acceleration GrpahDocument14 pagesAcceleration GrpahRAFAEL TORRESNo ratings yet

- Schneider EngineeringDocument1 pageSchneider EngineeringT.J. MayesNo ratings yet

- JDE ApplicationDocument642 pagesJDE ApplicationAnonymous cputyzNo ratings yet

- Jacky Smith Resume Project ManagerDocument1 pageJacky Smith Resume Project ManagerGrey GrayNo ratings yet

- RequirementsDocument18 pagesRequirementsmpedraza-1No ratings yet

- Asgmnt HECRASDocument7 pagesAsgmnt HECRASShahruzi MahadzirNo ratings yet

- Piping Handbook - Hydrocarbon Processing - 1968Document140 pagesPiping Handbook - Hydrocarbon Processing - 1968VS271294% (16)

- Structured ProgrammingDocument31 pagesStructured ProgrammingkakaboomNo ratings yet

- AHRLACDocument18 pagesAHRLACVictor Pileggi100% (1)

- Tharmal Analysis BasicsDocument56 pagesTharmal Analysis BasicsNetoNo ratings yet

- ZF CAT EBook Oil-Filters-Construction-Agricultural-Machinery-Transmissions 50114 201806 V02 IN PDFDocument142 pagesZF CAT EBook Oil-Filters-Construction-Agricultural-Machinery-Transmissions 50114 201806 V02 IN PDFdeisy ortegaNo ratings yet

- CLS 747 200Document158 pagesCLS 747 200Rodrigo Adam100% (8)

- Mechanical Workshop Practice ReportDocument6 pagesMechanical Workshop Practice ReportMuhd AkmalNo ratings yet

- BurnerDocument4 pagesBurnerAhmed Mohamed KhalilNo ratings yet

- 06-901 Keyed Input SwitchesDocument4 pages06-901 Keyed Input Switchesmajed al.madhajiNo ratings yet

- TD Quintolubric 888 68Document2 pagesTD Quintolubric 888 68Haitham YoussefNo ratings yet

- Wireless Intelligent Network (WIN)Document24 pagesWireless Intelligent Network (WIN)Nakul Gawande100% (1)

- BM 81004 MuvDocument52 pagesBM 81004 MuvHamza Abbasi AbbasiNo ratings yet

- ITIL Quick ReferenceDocument3 pagesITIL Quick ReferenceKalyaan KrushnaNo ratings yet

- SMP Gateway SoftPLC Reference ManualDocument47 pagesSMP Gateway SoftPLC Reference Manualswalker948100% (1)

- Mauser 98K - Model 48 Rifle ManualDocument20 pagesMauser 98K - Model 48 Rifle ManualMeor Amri96% (28)

- Huawei: Quidway Full Series Ethernet Routing SwitchesDocument90 pagesHuawei: Quidway Full Series Ethernet Routing SwitchesWalter Aguiar0% (1)