Professional Documents

Culture Documents

Project Profile On R.C.C

Uploaded by

saubhik goswamiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Profile On R.C.C

Uploaded by

saubhik goswamiCopyright:

Available Formats

"KVIC- REGP-(Gramodyog Rojgar Yojana)"

Project Profile on R.C.C. Spun Pipe

Introduction :

Reinforced cement concrete spun pipes upto 1000 mm dia are exclusively reserved for manufacture in

the SSI sector. These pipes are widely used for water drainage,sewerage, culverts and irrigation. RCC

pipes are classified as pressure and non pressure pipes viz. NP1, NP2, NP3, P1, P2, P3 for use in

specific conditions. These pipes are made from cement, coarse and fine aggregate, sand, mild steel and

HT rods and bars.

Process of Manufacture:The reinforced cage is first prepared on the cage-winding machine by hand

process. The cage is then placed inside the pipe mould which is then hoisted up and mounted horizontally

on the turn unions. It is rotated by driving shaft withvariable speed arrangement, the rotation is kept slow

in the beginning and then the speed is increased. The concrete mixture for the RCC spun pipe is

prepared in porportion of 1:2:5:2:5 of cement stone, metal and sand respectively. The cement concrete is

fed into the moulds during rotation which spreads inside evenly. The time required for completion of this

operation depends upon the diameter and class of the pipe. The pipes are kept in the mould for 24 hours.

1 Name of the Product : R.C.C. Spun Pipe

2 Project Cost :

a Capital Expenditure

Land : Own

Workshed in sq.Mts 205 240 Rs. 48,000.00

Equipment : Rs. 1,211,000.00

Pipe moulding machine-1, Gauge winding machine-2,Concrete mixer-

1,Collar winding drum with stand-2, Gantry with pull-push trolley-

1,Testing equipments-LS,Collar moulds complete with end rings-

40,Pipe moulds 100 mm to 600 mm-40

Total Capital Expenditure Rs. 1,259,000.00

b Working Capital Rs. 550,000.00

TOTAL PROJECT COST : Rs. 1,809,000.00

3 Estimated Annual Production Capacity: (Rs. in 000)

Sr.No. Particulars Capacity in Running mts. Rate Total Value

1 R.C.C. Spun Pipe 200000.00 3459.26

TOTAL 200000.00 0.00 3459.26

4 Raw Material : Rs. 2,064,000.00

5 Labels and Packing Material : Rs. 200,500.00

6 Wages (3-Skilled & 4-Unskilled) : Rs. 567,000.00

7 Salaries Manager 1 Rs.

: 120,000.00

PAGE ( 2 )

8 Administrative Expenses : Rs. 144,000.00

9 Overheads : Rs. 80,000.00

10 Miscellaneous Expenses : Rs. 36,000.00

11 Depreciation : Rs. 123,500.00

12 Insurance : Rs. 12,590.00

13 Interest (As per the PLR)

a. C.E.Loan : Rs. 163,670.00

b. W.C.Loan : Rs. 71,500.00

Total Interest Rs. 235,170.00

14 Working Capital Requirement :

Fixed Cost Rs. 476,260.00

Variable Cost Rs. 2,983,000.00

Requirement of WC per Cycle Rs. 576,543.00

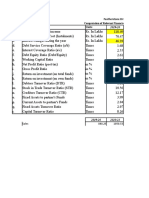

15 Cost Analysis

Sr.No. Particulars Capacity Utilization(Rs in '000)

100% 60% 70% 80%

1 Fixed Cost 476.26 285.76 333.38 381.01

2 Variable Cost 2983.00 1789.80 2088.10 2386.40

3 Cost of Production 3459.26 2075.56 2421.48 2469.11

4 Projected Sales 4240.00 2544.00 2968.00 3392.00

5 Gross Surplus 780.74 468.44 546.52 624.59

6 Expected Net Surplus 657.00 345.00 423.00 501.00

Note : 1. All figures mentioned above are only indicative.

2. If the investment on Building is replaced by Rental then

a. Total Cost of Project will be reduced.

b. Profitability will be increased.

c. Interest on C.E.will be reduced.

You might also like

- Cashew Nut ProcessingDocument8 pagesCashew Nut ProcessingSunil ParikhNo ratings yet

- Conoco's "Green" Oil Strategy: Group-6Document7 pagesConoco's "Green" Oil Strategy: Group-6Rohit DeshpandeNo ratings yet

- Chomsky On AnarchismDocument7 pagesChomsky On AnarchismPedro SilvaNo ratings yet

- Silo - Tips Quality Manual Iso 90012000Document19 pagesSilo - Tips Quality Manual Iso 90012000Mariel GentilesNo ratings yet

- 20,000 LPD Milk Processing Plant with Supply ChainDocument6 pages20,000 LPD Milk Processing Plant with Supply ChainAmit PrajapatiNo ratings yet

- Tesda Perpetual and Periodic Inventory SystemsDocument6 pagesTesda Perpetual and Periodic Inventory Systemsnelia d. onteNo ratings yet

- Bakery BreaddprDocument20 pagesBakery Breaddprsharma_761816814No ratings yet

- Project Report NoddleDocument26 pagesProject Report NoddleKumar DiwakarNo ratings yet

- Dairy InfoDocument16 pagesDairy InforakeshNo ratings yet

- Advanced Corporate Finance Group Assignment PDFDocument8 pagesAdvanced Corporate Finance Group Assignment PDFaddisie temesgenNo ratings yet

- SIMPLE INTEREST AND DISCOUNT WORD PROBLEMS SOLVEDDocument3 pagesSIMPLE INTEREST AND DISCOUNT WORD PROBLEMS SOLVEDkris salacNo ratings yet

- Activity Based CostingDocument13 pagesActivity Based CostingSudeep D'SouzaNo ratings yet

- Gourmet Baker's Supply Chain AnalysisDocument29 pagesGourmet Baker's Supply Chain AnalysisHaroon Fareed100% (1)

- Free Lobbying Firm Business PlanDocument10 pagesFree Lobbying Firm Business PlanEdited By MENo ratings yet

- Key Performance Indicators For Sustainable ManufacDocument6 pagesKey Performance Indicators For Sustainable ManufacShimondiNo ratings yet

- Pakistan: Form Cp-02 Water and Power Development Authority Abridged Conditions of SupplyDocument8 pagesPakistan: Form Cp-02 Water and Power Development Authority Abridged Conditions of Supplyیاسین اختر اعوانNo ratings yet

- Group Assignment SMDocument13 pagesGroup Assignment SMSania Zaheer QureshiNo ratings yet

- Potato FlakesDocument9 pagesPotato FlakesDavis J MenacheryNo ratings yet

- Rice Milling Unit Project ReportDocument19 pagesRice Milling Unit Project ReportHarpy happyNo ratings yet

- Egg Processing Guide BookDocument31 pagesEgg Processing Guide BookClaudia Melissa Orlandini MendozaNo ratings yet

- Indian Leather IndustryDocument10 pagesIndian Leather IndustryMohammed BilalNo ratings yet

- Gypsum Board AADocument26 pagesGypsum Board AAJohn100% (1)

- Tender Document Green House Construction - CompleteDocument59 pagesTender Document Green House Construction - CompleteAlejandroNo ratings yet

- Quality Managementpracticein EthiopiaDocument12 pagesQuality Managementpracticein Ethiopiaandu asfaw100% (1)

- Case Study: Magnolia Fresh Chicken: SWOT AnalysisDocument5 pagesCase Study: Magnolia Fresh Chicken: SWOT AnalysisAnnamaAnnamaNo ratings yet

- Sample Asset Valuation ReportDocument27 pagesSample Asset Valuation ReportAhisjNo ratings yet

- Maize QC Trainig GuidelineDocument84 pagesMaize QC Trainig GuidelineMelikteNo ratings yet

- Environmental Assessment and Risk Screening For Rural Water Supply: Guidance Note Developed For The SWIFT ConsortiumDocument56 pagesEnvironmental Assessment and Risk Screening For Rural Water Supply: Guidance Note Developed For The SWIFT ConsortiumOxfamNo ratings yet

- Rubco Huat Woods Pvt. LTDDocument22 pagesRubco Huat Woods Pvt. LTDShamseer Ummalil100% (1)

- Dimma HoneyASDocument50 pagesDimma HoneyASAnonymous h2hxB1No ratings yet

- A Study On Evaluation of Customer Centricity at Value Format Reliance Fresh Stores DelhiDocument39 pagesA Study On Evaluation of Customer Centricity at Value Format Reliance Fresh Stores DelhiBirjesh KumarNo ratings yet

- Business Policy Group AssignmentDocument21 pagesBusiness Policy Group AssignmentBamlak HailuNo ratings yet

- Faecal Sludge Treatment Plant (FSTP), Leh, Ladakh: School of Planning and Architecture, BhopalDocument7 pagesFaecal Sludge Treatment Plant (FSTP), Leh, Ladakh: School of Planning and Architecture, BhopalShaun George100% (1)

- Abaca - A Study of Reproducible Fibre Characterization and A Critical Evaluation of Existing Grading Systems PDFDocument12 pagesAbaca - A Study of Reproducible Fibre Characterization and A Critical Evaluation of Existing Grading Systems PDFlintianananNo ratings yet

- Detailed Project Report Bread Making Unit Under Pmfme SchemeDocument26 pagesDetailed Project Report Bread Making Unit Under Pmfme SchemeMohammed hassenNo ratings yet

- Export BUSINESS PLAN-Sena FinalDocument26 pagesExport BUSINESS PLAN-Sena FinalAbel Getachew100% (1)

- McdonaldDocument10 pagesMcdonaldNaveen Disc JokeyNo ratings yet

- PVC Project Report PDFDocument21 pagesPVC Project Report PDFifiokNo ratings yet

- Parmetol A 26 ZTM P Ic e enDocument2 pagesParmetol A 26 ZTM P Ic e enalthea badayosNo ratings yet

- Nestle Pakistan Ltd Mission StatementDocument8 pagesNestle Pakistan Ltd Mission StatementHassan JavedNo ratings yet

- Project Report On Vermi Compost PDFDocument2 pagesProject Report On Vermi Compost PDFsrisairamcomputersNo ratings yet

- Market Report On RiceDocument24 pagesMarket Report On RiceSyam SundharNo ratings yet

- PROCESS COSTING EXPLAINEDDocument31 pagesPROCESS COSTING EXPLAINEDJyoti SinghNo ratings yet

- Project Blue Nile Industry and Financial OverviewDocument9 pagesProject Blue Nile Industry and Financial OverviewKristin BryanNo ratings yet

- Project ReportDocument19 pagesProject ReportamarjainNo ratings yet

- Jowar FlakesDocument8 pagesJowar FlakesAmit JainNo ratings yet

- PET Bottles ManufacturingDocument7 pagesPET Bottles ManufacturingUmesh Kumar Sharma Ramamoorthi100% (1)

- Overview of India S Bathroom Kitchen IndustryDocument16 pagesOverview of India S Bathroom Kitchen IndustryVishal Rajaram JoshiNo ratings yet

- 1 PDFDocument8 pages1 PDFNealNo ratings yet

- QMSDocument30 pagesQMSTatiana RiloNo ratings yet

- Full ProjectDocument58 pagesFull ProjectKing KrishNo ratings yet

- Feasibility Study ON Animal Fattening AND Animal Feed ProductionDocument59 pagesFeasibility Study ON Animal Fattening AND Animal Feed ProductionYonas MelakuNo ratings yet

- Raw Materials For Socks Making BusinessDocument7 pagesRaw Materials For Socks Making BusinessNajiya shakiraNo ratings yet

- Regional Bulk Water Supply Programme CriteriaDocument36 pagesRegional Bulk Water Supply Programme CriteriaTrevor T ParazivaNo ratings yet

- Business Plan Nepal Breweries Private LimitedDocument71 pagesBusiness Plan Nepal Breweries Private Limitedsubash shresthaNo ratings yet

- Customs Clearing Agents RegulationDocument5 pagesCustoms Clearing Agents RegulationTSEDEKENo ratings yet

- Community Based Environmental Protection Initiative ProjectDocument5 pagesCommunity Based Environmental Protection Initiative ProjectAnonymous Qq28iAIdlNo ratings yet

- Strategic Planning, Marketing Strategy & Vodafone Case StudyDocument16 pagesStrategic Planning, Marketing Strategy & Vodafone Case Studyyuvraj9898No ratings yet

- ADDONCARDSFORCOMPUTERDocument2 pagesADDONCARDSFORCOMPUTERAR MOHANRAJNo ratings yet

- Project Profile On Exhaust FansDocument2 pagesProject Profile On Exhaust FansPhilip KotlerNo ratings yet

- Project Profile On Drawing BoardsDocument2 pagesProject Profile On Drawing BoardsAR MOHANRAJNo ratings yet

- Project Profile On WindDocument3 pagesProject Profile On WindSangzuala HlondoNo ratings yet

- Project Profile On Wheel BarrowsDocument2 pagesProject Profile On Wheel BarrowsLaxman SinghNo ratings yet

- Sattu Manufacturing Project ProfileDocument2 pagesSattu Manufacturing Project ProfileKunal SinhaNo ratings yet

- Budget (MAA SHAKTI)Document47 pagesBudget (MAA SHAKTI)saubhik goswamiNo ratings yet

- New Project Report RM AQUADocument33 pagesNew Project Report RM AQUAsaubhik goswamiNo ratings yet

- Pylorisis ProjectDocument32 pagesPylorisis Projectsaubhik goswamiNo ratings yet

- (Projections) Prime INDIADocument28 pages(Projections) Prime INDIAsaubhik goswamiNo ratings yet

- Featherstone Dry Mix Pvt. Ltd. Serial Particulars Units: Sales 848.25 1050.53Document39 pagesFeatherstone Dry Mix Pvt. Ltd. Serial Particulars Units: Sales 848.25 1050.53saubhik goswamiNo ratings yet

- (Main) Future LeatherDocument49 pages(Main) Future Leathersaubhik goswamiNo ratings yet

- Feather StoneDocument22 pagesFeather Stonesaubhik goswamiNo ratings yet

- Feather StoneDocument22 pagesFeather Stonesaubhik goswamiNo ratings yet

- RMC Business Proposal For Kolkata RMC Business - An OverviewDocument1 pageRMC Business Proposal For Kolkata RMC Business - An Overviewsaubhik goswamiNo ratings yet

- (Projections) Prime INDIADocument28 pages(Projections) Prime INDIAsaubhik goswamiNo ratings yet

- Non-Autoclaved Aerated Concrete (NAAC) Blocks: An Alternative Building Construction MaterialDocument5 pagesNon-Autoclaved Aerated Concrete (NAAC) Blocks: An Alternative Building Construction MaterialIJRASETPublicationsNo ratings yet

- Write Up On NAACBDocument38 pagesWrite Up On NAACBsaubhik goswamiNo ratings yet

- Income Statement Template For WebsiteDocument5 pagesIncome Statement Template For WebsiteKelly CantuNo ratings yet

- Chad Humphrey ResumeDocument2 pagesChad Humphrey ResumeSeattleChadNo ratings yet

- 26 Structured RepoDocument4 pages26 Structured RepoJasvinder JosenNo ratings yet

- 6 ACCT 2A&B C. OperationDocument10 pages6 ACCT 2A&B C. OperationShannon Mojica100% (1)

- An Appraisal of The Philosophy of Nigerian Education For Sustainable Livelihood in Nigeria (2008 - 2012) .Document6 pagesAn Appraisal of The Philosophy of Nigerian Education For Sustainable Livelihood in Nigeria (2008 - 2012) .Alexander Decker100% (1)

- Tender Document CONCORDocument109 pagesTender Document CONCORgiri_placid100% (1)

- President's Report by Roberta HoeyDocument5 pagesPresident's Report by Roberta HoeyAltrusa International of Montrose CONo ratings yet

- GMG AirlineDocument15 pagesGMG AirlineabusufiansNo ratings yet

- SAARC - Successes and Challenges PDFDocument6 pagesSAARC - Successes and Challenges PDFalam amarNo ratings yet

- Kheda Satyagraha - 3291404Document27 pagesKheda Satyagraha - 3291404Bhaskar AmasaNo ratings yet

- Product Data Mtu Kinetic PowerPackDocument9 pagesProduct Data Mtu Kinetic PowerPackEhab AllazyNo ratings yet

- Vertical Public InfrastructureDocument3 pagesVertical Public Infrastructuresachink20100% (1)

- Chevron Attestation PDFDocument2 pagesChevron Attestation PDFedgarmerchanNo ratings yet

- Lavanya Industries Tool Manufacturing Facility ProfileDocument11 pagesLavanya Industries Tool Manufacturing Facility ProfilepmlmkpNo ratings yet

- Peraturan Presiden Nomor 16 Tahun 2018 - 1001 - 1Document174 pagesPeraturan Presiden Nomor 16 Tahun 2018 - 1001 - 1Bambang ParikesitNo ratings yet

- ISO 14001 Certification Woodward ControlsDocument3 pagesISO 14001 Certification Woodward ControlsErick MoraNo ratings yet

- 2BBC One Lotto2Document4 pages2BBC One Lotto2Krishna PriyaNo ratings yet

- Company Scrip Code: 533033Document17 pagesCompany Scrip Code: 533033Lazy SoldierNo ratings yet

- Finance Manager Reporting Planning in Los Angeles, CA ResumeDocument2 pagesFinance Manager Reporting Planning in Los Angeles, CA ResumeRCTBLPONo ratings yet

- Civpro Cases FinalsDocument4 pagesCivpro Cases FinalsMc DalayapNo ratings yet

- Robot Book of KukaDocument28 pagesRobot Book of KukaSumit MahajanNo ratings yet

- Train Law Excise Tax 1Document29 pagesTrain Law Excise Tax 1Assuy AsufraNo ratings yet

- INFORME FINALlllllllllllllllllllDocument133 pagesINFORME FINALlllllllllllllllllllAnonymous Rr3py6jdCpNo ratings yet

- EPRescober - Topic - 4PL and 5PL - LogisticsDocument6 pagesEPRescober - Topic - 4PL and 5PL - LogisticsELben RescoberNo ratings yet

- López Quispe Alejandro MagnoDocument91 pagesLópez Quispe Alejandro MagnoAssasin WildNo ratings yet

- MTNL Mumbai PlansDocument3 pagesMTNL Mumbai PlansTravel HelpdeskNo ratings yet

- SIP Project Presentation Brand Promotion of Moolchand Medcity Through Value Added Service (VAS) Program and Medical Camp Nitin SharmaDocument17 pagesSIP Project Presentation Brand Promotion of Moolchand Medcity Through Value Added Service (VAS) Program and Medical Camp Nitin SharmaNitin SharmaNo ratings yet