Professional Documents

Culture Documents

Boehler Metal Cored Wires

Uploaded by

rusf123Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boehler Metal Cored Wires

Uploaded by

rusf123Copyright:

Available Formats

Lasting Connections

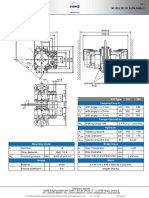

PARAMETER GUIDE FOR

ALL-POSITIONAL METAL CORED WIRES

ø 1.0 mm / .039 Inch

Wire feed speed Arc voltage Welding current Arc mode Chart valid for:

(m/min.) (inch/min.) (V) (A)

3 118 15-15.5 80-90 Short arc BÖHLER HL 46 T-MC

BÖHLER HL 51 L-MC

4 157 16-17 110-120 Short arc BÖHLER HL 51 T-MC

BÖHLER HL 53 T-MC

5 197 18-18.5 130-140 Globular arc BÖHLER DMO T-MC

BÖHLER DCMS T-MC

6 236 22-23 150-160 Globular arc

BÖHLER HL 60 Pipe T-MC

7 276 24-24.5 170-180 Spray arc BÖHLER X70 L-MC

BÖHLER alform® 700 L-MC

8 315 25-26 190-200 Spray arc BÖHLER alform 900 L-MC

BÖHLER alform 960 L-MC

9 354 26-27 210-220 Spray arc BÖHLER X90 L-MC

BÖHLER X96 L-MC

10 394 27-28 230-240 Spray arc

Polarity: DC+ Stickout: 15 mm/0.6“ Shielding gas: M21

Welding parameters Ø 1.0 mm / .039 Inch

Welding parameters Ø 1.0 mm

30

How to use:

230-240 A

210-220 A »» Welding parameters are valid for the

190-200 A recommended polarity, stickout length

25 170-180 A

and shielding gas.

150-160 A

»» First set wire feed speed and voltage

130-140 A

according to the diagram, then fine-

20

tune according to the table.

110-120 A

»» Variations in stickout length will

Voltage [ V ]

80-90 A

change the welding current.

15

»» Values shown on welding machine dis-

plays may be higher than the actual

arc voltage due to the voltage drop in

063/2018/EN/GL

10

welding cables.

»» Add 1.5-2V arc voltage for C1.

5

0

3 4 5 6 7 8 9 10

Wire feed speed [mt /min]

voestalpine Böhler Welding

www.voestalpine.com/welding

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- BS2400.402HT243 90KW - 400VDocument7 pagesBS2400.402HT243 90KW - 400VorhanNo ratings yet

- VSQ-CC-30 052111XYZ Sequence Direct Acting Poppet Type CompensatedDocument2 pagesVSQ-CC-30 052111XYZ Sequence Direct Acting Poppet Type CompensatedCarlos Andrés CuelloNo ratings yet

- K CS KLRC125 - 1st - 3 21Document4 pagesK CS KLRC125 - 1st - 3 21macaco logoNo ratings yet

- PlasmaDocument37 pagesPlasmaJuniorNo ratings yet

- Fire pump head calculation for Lulu Mall Lucknow projectDocument1 pageFire pump head calculation for Lulu Mall Lucknow projectJaleel Desionics100% (1)

- Screw Compressor ASY (R-134) Series PDFDocument52 pagesScrew Compressor ASY (R-134) Series PDFNajam2450% (2)

- OFC-VILLA 2015 General CatalogueDocument256 pagesOFC-VILLA 2015 General CatalogueМихаилNo ratings yet

- 11.8a Ghibson GB015Document2 pages11.8a Ghibson GB015Shah Rizal AbidNo ratings yet

- ACI318-08 FlexureDocument4 pagesACI318-08 Flexureazamislam726537No ratings yet

- CPDAS343Document2 pagesCPDAS343ali.mamuti.36No ratings yet

- 084519xyz Re18307-49Document2 pages084519xyz Re18307-49NABEILNo ratings yet

- Hyva Gear Pumps: External Gear Type - Brite SeriesDocument2 pagesHyva Gear Pumps: External Gear Type - Brite SeriesdenykNo ratings yet

- Halton DamperDocument8 pagesHalton Dampermarcel cocanNo ratings yet

- Omega/Omega V: Axially Split Volute Casing PumpsDocument56 pagesOmega/Omega V: Axially Split Volute Casing Pumpsmohammad ziad khatibNo ratings yet

- Force Ksb-Omega-Pump Sarcina Pe Flanse PDFDocument19 pagesForce Ksb-Omega-Pump Sarcina Pe Flanse PDFRusu DimaNo ratings yet

- Catalog PDFDocument72 pagesCatalog PDFVIVEK UPADHYAYNo ratings yet

- Ksb-Omega-Pump Sarcina Pe Flanse PDFDocument56 pagesKsb-Omega-Pump Sarcina Pe Flanse PDFRusu DimaNo ratings yet

- RPH RO - Tech. ManualDocument16 pagesRPH RO - Tech. ManualEdgar CalatayudNo ratings yet

- ArchDocument4 pagesArchCarlos Torres OliverosNo ratings yet

- Yuken Hydraulic CylinderDocument11 pagesYuken Hydraulic CylinderDk PanigrahiNo ratings yet

- 2 3 10 01-GB PDFDocument2 pages2 3 10 01-GB PDFbeu catalinNo ratings yet

- 3-Way Control Valve Type M3FA: PN 10, DN 80 - 300 MM, Except DN 200/175 and 200 MM - PN 16 0-2.3.10.01-A Page 1 of 2Document2 pages3-Way Control Valve Type M3FA: PN 10, DN 80 - 300 MM, Except DN 200/175 and 200 MM - PN 16 0-2.3.10.01-A Page 1 of 2beu catalinNo ratings yet

- Single Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - ZDocument2 pagesSingle Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - Znemi90No ratings yet

- Calliper Brake SHI 251 & 252Document19 pagesCalliper Brake SHI 251 & 252Shaiju NarayananNo ratings yet

- Bye Pass Rotameter: Eureka Industrial Equipments Pvt. LTDDocument2 pagesBye Pass Rotameter: Eureka Industrial Equipments Pvt. LTDArunasis KarmakarNo ratings yet

- DL22N 22Document1 pageDL22N 22embasianNo ratings yet

- BF109 GUIDEDocument50 pagesBF109 GUIDEPro FlexNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Htk12Aa KAPPA LBP Compressor Top Efficiency R600a 220-240V 50HzDocument2 pagesHtk12Aa KAPPA LBP Compressor Top Efficiency R600a 220-240V 50HzTunaNo ratings yet

- Reciprocating Process Gas CompressorsDocument2 pagesReciprocating Process Gas CompressorsedosviracNo ratings yet

- Fire Damper WH25: DimensionsDocument11 pagesFire Damper WH25: DimensionsAncuta CosmanNo ratings yet

- Thermodynamic steam trap performance and specificationsDocument2 pagesThermodynamic steam trap performance and specificationshamid vahedil larijaniNo ratings yet

- Bill of MAterialsDocument2 pagesBill of MAterialsKaori Miyazono (Kobe)No ratings yet

- Fire Sprinkler Product BrochureDocument8 pagesFire Sprinkler Product Brochurecvolkan1No ratings yet

- كتالوج الشيلراتDocument54 pagesكتالوج الشيلراتFathy RakhaNo ratings yet

- FuzibileDocument52 pagesFuzibileBogdan OrşanNo ratings yet

- 200Document1 page200ChristianGuerreroNo ratings yet

- Catalog Tehnic wh25Document2 pagesCatalog Tehnic wh25DANNo ratings yet

- RKP Product info new gear pump en-2006-03Document9 pagesRKP Product info new gear pump en-2006-03Arko RoosNo ratings yet

- 7.2.F-T1-B0-02 DWGDocument1 page7.2.F-T1-B0-02 DWGKyi LwinNo ratings yet

- Double Check Valve DC: Technical DataDocument2 pagesDouble Check Valve DC: Technical DataAthanasoulis KostasNo ratings yet

- Service: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)Document1 pageService: Non Corrosive Hydrocarbons - Glycol - Blow Down - Vents - Drains (T 120°C)AliZenatiNo ratings yet

- Tabla Americana de Avances de Accesorios... RAUL SUAREZDocument9 pagesTabla Americana de Avances de Accesorios... RAUL SUAREZJulio Enrique Oliver CuelloNo ratings yet

- Ranger 10000Document2 pagesRanger 10000carlos790510No ratings yet

- Operating ranges and specifications for MMI 50 centrifugal pumpsDocument8 pagesOperating ranges and specifications for MMI 50 centrifugal pumpsTaimoorNo ratings yet

- Centrifugal Pumps Guide for 2CDX Series PumpsDocument13 pagesCentrifugal Pumps Guide for 2CDX Series PumpsDirector Tecnico y Operaciones Baying SASNo ratings yet

- Proline Maxi: Electrical Submersible Drainage Pump 60 HZDocument1 pageProline Maxi: Electrical Submersible Drainage Pump 60 HZRobert ArticaNo ratings yet

- Material Data Sheet for 52CrMoV4 Spring SteelDocument3 pagesMaterial Data Sheet for 52CrMoV4 Spring SteelMartin HristovNo ratings yet

- Material Data Sheet for 52CrMoV4 Spring SteelDocument3 pagesMaterial Data Sheet for 52CrMoV4 Spring SteelMartin HristovNo ratings yet

- Application Deep Well Turbine Pumps: Product Introduction 2361.1x/01-10G3Document4 pagesApplication Deep Well Turbine Pumps: Product Introduction 2361.1x/01-10G3FawadNo ratings yet

- Condensing Unit Vertical Discharge 60 HZ R410A: 36KBTU Model Has A Different GrillDocument1 pageCondensing Unit Vertical Discharge 60 HZ R410A: 36KBTU Model Has A Different GrilljuanNo ratings yet

- 52crmov4: Steel GradeDocument3 pages52crmov4: Steel GradeemregnesNo ratings yet

- High Velocity Water Spray Nozzle: Models Hv-As & Hv-BsDocument6 pagesHigh Velocity Water Spray Nozzle: Models Hv-As & Hv-BsVipin SomasekharanNo ratings yet

- Chuck Guide Il 2 Cliffs of Dover Bf110 PDFDocument64 pagesChuck Guide Il 2 Cliffs of Dover Bf110 PDFPaolo FontanazziNo ratings yet

- Chuck Guide Il 2 Cliffs of Dover He111Document91 pagesChuck Guide Il 2 Cliffs of Dover He111sandyNo ratings yet

- Air Condition GB5BMDocument8 pagesAir Condition GB5BMOFNo ratings yet

- Standard Specificatio for Pipe, Valves & Fitttings "BA1Document4 pagesStandard Specificatio for Pipe, Valves & Fitttings "BA1Jhonny Chugá MejíaNo ratings yet

- Transformer Plinth For 2.1MWDocument1 pageTransformer Plinth For 2.1MWSarin100% (2)

- Taw000017g 1Document1 pageTaw000017g 1rusf123No ratings yet

- VAUTID ASW 143 Engl 041016Document1 pageVAUTID ASW 143 Engl 041016rusf123No ratings yet

- 348410575GBDocument1 page348410575GBrusf123No ratings yet

- High-Temp Stainless ElectrodeDocument1 pageHigh-Temp Stainless Electroderusf123No ratings yet

- Utp A Dur 250Document1 pageUtp A Dur 250rusf123No ratings yet

- ABRASION RESISTANT MILD STEEL PLATE DURETAL 45Document2 pagesABRASION RESISTANT MILD STEEL PLATE DURETAL 45rusf123No ratings yet

- Doc 01 RO 20181023132955Document2 pagesDoc 01 RO 20181023132955rusf123No ratings yet

- T - Thermanit ATS 4 - Ss - en - 5Document1 pageT - Thermanit ATS 4 - Ss - en - 5rusf123No ratings yet

- VAUTID ASW 143 Engl 041016Document1 pageVAUTID ASW 143 Engl 041016rusf123No ratings yet

- Tipuri de UmpluturiDocument1 pageTipuri de Umpluturirusf123No ratings yet

- High Strength Steel Welding Wire for Cr-Ni-Mo AlloysDocument1 pageHigh Strength Steel Welding Wire for Cr-Ni-Mo Alloysrusf123No ratings yet

- Agillo Article Number: 3411320 Identify Number: 11017: Cordless ScytheDocument7 pagesAgillo Article Number: 3411320 Identify Number: 11017: Cordless Scytherusf123No ratings yet

- Voabulary Term DefinitionDocument3 pagesVoabulary Term Definitionrusf123No ratings yet

- Manual Cdi 3102Document56 pagesManual Cdi 3102rusf123No ratings yet

- Verification Statement: Air Liquide Welding France SAF-FRO BrandDocument2 pagesVerification Statement: Air Liquide Welding France SAF-FRO Brandrusf123No ratings yet

- Mode of Metal Transfer-Gas Metal Arc Wel PDFDocument5 pagesMode of Metal Transfer-Gas Metal Arc Wel PDFRamesh RNo ratings yet

- Type Approval Certificate: Lincoln Electric Europe B.VDocument1 pageType Approval Certificate: Lincoln Electric Europe B.Vrusf123No ratings yet

- ASME and AWS Welding Codes and Standards GuideDocument14 pagesASME and AWS Welding Codes and Standards Guiderusf123100% (1)

- Type Approval Certificate: Esab AbDocument1 pageType Approval Certificate: Esab Abrusf123No ratings yet

- Astrup+MDS+1 4418+QT900+v1,4Document1 pageAstrup+MDS+1 4418+QT900+v1,4rusf123No ratings yet

- European Welding New-StandardsDocument39 pagesEuropean Welding New-StandardsJOECOOL67100% (3)

- Ab87118 20CRDocument3 pagesAb87118 20CRrusf123No ratings yet

- Tabel Euronormen ENG PDFDocument1 pageTabel Euronormen ENG PDFFadzil NorNo ratings yet

- Ab87118 1CRDocument3 pagesAb87118 1CRrusf123No ratings yet

- TIPS On CUTTINGDocument8 pagesTIPS On CUTTINGrusf123No ratings yet

- 2016 Torch and Consumables Catalog: For Mechanized Plasma SystemsDocument52 pages2016 Torch and Consumables Catalog: For Mechanized Plasma Systemsrusf123No ratings yet

- Test For Welder QualificationsDocument1 pageTest For Welder Qualificationsrusf123No ratings yet

- BW DS-ParameterChart All-Positional Metal Cored W 1.2mm en PreviewDocument1 pageBW DS-ParameterChart All-Positional Metal Cored W 1.2mm en Previewrusf123No ratings yet

- 087 2017 en GL Sales Brief WebDocument2 pages087 2017 en GL Sales Brief Webrusf123No ratings yet

- Simply Put - ENT EAR LECTURE NOTESDocument48 pagesSimply Put - ENT EAR LECTURE NOTESCedric KyekyeNo ratings yet

- Difference Between Text and Discourse: The Agent FactorDocument4 pagesDifference Between Text and Discourse: The Agent FactorBenjamin Paner100% (1)

- House Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Document4 pagesHouse Rules For Jforce: Penalties (First Offence/Minor Offense) Penalties (First Offence/Major Offence)Raphael Eyitayor TyNo ratings yet

- UTP3-SW04-TP60 Datasheet VER2.0Document2 pagesUTP3-SW04-TP60 Datasheet VER2.0Ricardo TitoNo ratings yet

- Kami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Document3 pagesKami Export - BuildingtheTranscontinentalRailroadWEBQUESTUsesQRCodes-1Anna HattenNo ratings yet

- Game Rules PDFDocument12 pagesGame Rules PDFEric WaddellNo ratings yet

- AATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsDocument3 pagesAATCC 100-2004 Assesment of Antibacterial Dinishes On Textile MaterialsAdrian CNo ratings yet

- Mazda Fn4A-El 4 Speed Ford 4F27E 4 Speed Fnr5 5 SpeedDocument5 pagesMazda Fn4A-El 4 Speed Ford 4F27E 4 Speed Fnr5 5 SpeedAnderson LodiNo ratings yet

- Polytechnic University Management Services ExamDocument16 pagesPolytechnic University Management Services ExamBeverlene BatiNo ratings yet

- 50 Years of Teaching PianoDocument122 pages50 Years of Teaching PianoMyklan100% (35)

- 2023-Physics-Informed Radial Basis Network (PIRBN) A LocalDocument41 pages2023-Physics-Informed Radial Basis Network (PIRBN) A LocalmaycvcNo ratings yet

- Passenger E-Ticket: Booking DetailsDocument1 pagePassenger E-Ticket: Booking Detailsvarun.agarwalNo ratings yet

- Marshal HMA Mixture Design ExampleDocument2 pagesMarshal HMA Mixture Design ExampleTewodros TadesseNo ratings yet

- GLF550 Normal ChecklistDocument5 pagesGLF550 Normal ChecklistPetar RadovićNo ratings yet

- KSEB Liable to Pay Compensation for Son's Electrocution: Kerala HC CaseDocument18 pagesKSEB Liable to Pay Compensation for Son's Electrocution: Kerala HC CaseAkhila.ENo ratings yet

- Accomplishment Report 2021-2022Document45 pagesAccomplishment Report 2021-2022Emmanuel Ivan GarganeraNo ratings yet

- Catalogoclevite PDFDocument6 pagesCatalogoclevite PDFDomingo YañezNo ratings yet

- TDS Sibelite M3000 M4000 M6000 PDFDocument2 pagesTDS Sibelite M3000 M4000 M6000 PDFLe PhongNo ratings yet

- GROSS DOMESTIC PRODUCT STATISTICS (Report) - Powerpoint PresentationDocument37 pagesGROSS DOMESTIC PRODUCT STATISTICS (Report) - Powerpoint PresentationCyryhl GutlayNo ratings yet

- Important Instructions To Examiners:: Calculate The Number of Address Lines Required To Access 16 KB ROMDocument17 pagesImportant Instructions To Examiners:: Calculate The Number of Address Lines Required To Access 16 KB ROMC052 Diksha PawarNo ratings yet

- Case 5Document1 pageCase 5Czan ShakyaNo ratings yet

- Briana SmithDocument3 pagesBriana SmithAbdul Rafay Ali KhanNo ratings yet

- Additional Help With OSCOLA Style GuidelinesDocument26 pagesAdditional Help With OSCOLA Style GuidelinesThabooNo ratings yet

- ServiceDocument47 pagesServiceMarko KoširNo ratings yet

- MODULE+4+ +Continuous+Probability+Distributions+2022+Document41 pagesMODULE+4+ +Continuous+Probability+Distributions+2022+Hemis ResdNo ratings yet

- Resume of Deliagonzalez34 - 1Document2 pagesResume of Deliagonzalez34 - 1api-24443855No ratings yet

- NLL - Elementary - Coursebook 2019 PDFDocument24 pagesNLL - Elementary - Coursebook 2019 PDFgilmolto100% (1)

- Rishte ki baat SMS messages collectionDocument108 pagesRishte ki baat SMS messages collectionTushar AggarwalNo ratings yet

- Ir35 For Freelancers by YunojunoDocument17 pagesIr35 For Freelancers by YunojunoOlaf RazzoliNo ratings yet

- DIN Flange Dimensions PDFDocument1 pageDIN Flange Dimensions PDFrasel.sheikh5000158No ratings yet