Professional Documents

Culture Documents

Finite Element Simulative Analysis of Concrete Arch Dam Structure

Uploaded by

Mathy TuringOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Finite Element Simulative Analysis of Concrete Arch Dam Structure

Uploaded by

Mathy TuringCopyright:

Available Formats

2nd International Conference on Electronic & Mechanical Engineering and Information Technology (EMEIT-2012)

Finite Element Simulative Analysis of Concrete Arch Dam Structure

Dongyu Ji1,a, Weixing Chen2,b

1

Hunan Urban Construction College, Xiangtan, Hunan Province 411101, P.R. China

2

Survey, Design & Research Institute of Henan Petroleum Exploration Bureau (HPEB), SINOPEC,

Nanyang, Henan Province 473132, P.R. China

a

hnjdy@126.com, b1949cwx@163.com

Keywords: Concrete arch dam; Finite element method; Simulation analysis; Stress distribution.

Abstract. In this paper, finite element simulative analysis is proceeded for the concrete arch dam of

Tianshengqiao reservoir. Deducing variation law of the dam’s stress and displacement in construction

process and operational process. The analytic results are shown: concrete arch dam of Tianshengqiao

reservoir is reasonable structure, and every index meets the requirements for design.

Introduction

Tianshengqiao reservoir is located Laliu River, which is located Nandan county in the Guangxi

zhuang autonomous region. The main function of reservoir is irrigation, and it is a comprehensive

utilization water conservancy and hydropower engineering. The main buildings include concrete

arch dam, left bank gravity pier, shore spillway, penstock, power station and underport, etc. Total

reservoir storage capacity is 402 million m3, reservoir’s normal storage level is 24 m, design level is

28.1 m, flood level is 30.3 m. The dam is concrete single arch dam, maximum dam high is 31.6 m,

the arc length of dam crest is 43.44 m, thickness of dam crest is 1.2 m, thickness of dam bottom is

1.7 m, hickness-to-height ratio of arch dam’s section is 0.07. River valley of dam site is

ladder-shaped, gravity pier is set at the left bank, river valley is rectangular-shaped.

Calculation Model

Model Parameters. Concrete strength grade of Tianshengqiao reservoir concrete arch dam is

C15, elastic modulus E1=22 GPa[1], Poisson ratio μ1 =0.167, density γ 1 =24 kN/m3. The foundation of

dam is Qixia limestone of permian period, the limestone is medium thickness seam, lithology is

hard, it is basic complete. Rock stratum tends to upstream, karst of dam site is not the development,

the rock stratum is not leaking. Rock’s elastic modulus E2=12 GPa[2], Poisson ratio μ 2 =0.28.

Model Element. Concrete arch dam and bedrock structure model is divided by eight nodes

isoparametric block element. The element is often applied to three-dimensional model of entity

structure, it has plasticity, creep, expansion, stress rigidization, large deformation and large strain

characteristics. It has eight nodes, each node has three translational degree of freedoms[3].

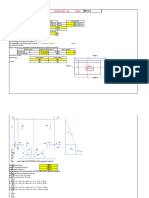

Model size. Calculation model simulation range is listed below, calculation model along the

river is 90 m, transverse of the river is 75 m, vertical direction is 76 m. The simulation range of

whole calculation model is 90 m×75 m×76 m. Element division of dam and bedrock is shown in

Fig.1.

Calculation Cases. Considering mechanical characteristics of dam structure in operating

process[4], researching three calculation cases as follows. Case 1, normal storage level and dam

weight, case 2, design level, tail water level and dam weight, case 3, flood level, tail water level and

dam weight.

Arch Dam Structure Analysis

Analysis Path. In order to analyzing concrete arch dam of Tianshengqiao reservoir, one analysis

path is defined, on the upstream face of crown cantilever, choosing one calculation point every 5 m

Published by Atlantis Press, Paris, France.

© the authors

0844

2nd International Conference on Electronic & Mechanical Engineering and Information Technology (EMEIT-2012)

from dam bottom to dam crest, there are seven calculation points totally, these points assembled

analysis path. Stress distribution of the path is provided in the paper.

Fig.1 Element division of dam and bedrock

Stress Analysis. In order to researching stress distribution law of crown cantilever, obtaining

circumferential and vertical stress values of analysis path under various cases, the stress values of

crown cantilever under various cases are listed in the table 1.

Table 1. Calculation point’s circumferential and vertical stress values on the dam’s analysis path

under various cases(MPa)

Calculation Point 1 2 3 4 5 6 7

Circumferential

0.386 -0.418 -1.513 -1.229 -0.425 -0.070 0.034

Case 1 stress

Vertical stress 1.871 0.522 -0.861 -0.405 0.117 0.116 0.001

Circumferential

0.455 -0.095 -1.821 -1.862 -1.057 -0.377 0.067

Case 2 stress

Vertical stress 1.850 1.089 -0.981 -0.583 -0.092 0.056 0.001

Circumferential

0.559 -0.513 -2.219 -2.226 -1.452 -0.736 -0.137

Case 3 stress

Vertical stress 2.666 0.969 -0.138 -0.098 -0.058 -0.020 0.005

We can see from table 1, under various cases, circumferential stress of crown cantilever’s

upstream face is mainly compressive stress. But vertical stress is mainly tensile stress, tensile stress

value is larger especially in the junction of dam bottom and bedrock, this is mainly because the

junction appears stress concentration phenomenon. These larger stress values can be reduced by the

finite element equivalent stress method[5].

We obtain concrete arch dam’s contour maps of first principal stress and circumferential stress

under various cases, contour maps are shown from Fig.2 to Fig.7.

We can see from Fig.2, Fig.4 and Fig.6, arch dam’s contour map of first principal stress is similar

under various cases, maximum principal tensile stress appears the junction of dam bottom and

bedrock. And first principal stress values increase with water pressure increases, distribution range

of principal tensile stress values also gradually increases. In the Fig.3, Fig.5 and Fig.7,

circumferential stress of arch dam is mainly compressive stress, and stress distribution is more

complex, near the arch dam’s bottom appears tensile stress, but tensile stress values are smaller.

Published by Atlantis Press, Paris, France.

© the authors

0845

2nd International Conference on Electronic & Mechanical Engineering and Information Technology (EMEIT-2012)

ANSYS 10.0

NODAL SOLUTION NODAL SOLUTION

BBB BB B B B BB B BB STEP=1 G

FE GG G G H H G G GG FG

B B G G

F G H G G

F STEP=1

B B B B G G H G

B B B B SUB =1 F F G G FG F SUB =1

B B F GF G F

F G

B B TIME=1 GF F GG G TIME=1

B B G G G G F F

BB S1 (AVG) F F GF G G SY (AVG)

F

BB TOP F F F F F F F TOP

B F F F F

BBB B B B B B B BB B DMX =.001968 E E

E E E E F RSYS=15

B BB FE E E E E E

B BB SMN =-306738 D D E EE DMX =.001968

B B B DE D D D D D D D D E FG

B SMX =.208E+07 D

C

B EFC D C C D

C CC C D C C DC CE SMN =-.182E+07

C C A =-174324 D C C B D

CB B

B C C C C C C C C C C F ED C B B G

F

E SMX =698701

G BB C B B B C A H

D B =90506 A =-.168E+07

D D D D D B BCB E B D BADEFGH

D

D C C =355336 B AA A MN B =-.140E+07

C C GC

F CD B C D DCC BC

D D D =620165 D E B C B C C =-.112E+07

B A E

B BC

CB D D D C G EDC E

F C B B C H

G

F

D D E =884995 C C C D BD B B C D D =-839361

D C B B C B C D DD D C C B

DEFGH

CC D C B C B

B B B B BBCB F =.115E+07 E E E E E E D C

E =-559713

BB D

D

B

E C B B C C GF E D D D D E D DDCDC

B F E E EF EEEEF E

B FB

CCCE EF HGE B D

I C C A A B B CBBB C

C BB

E

DFGH

G =.141E+07 FF FGF FG F GCHG E E

EE EEE F =-280066

F

D

D CC B C B

D DE EF F F F E EE

F F

F FE

E E D FHI MX

F

F

G

C C CB C C CC B H =.168E+07 FG

D F EGH

F G =-418.234

BC D D B D EG F F F F F F E FH

B DB

C E

D

EBF B E

F E F

G

E F E D DB C

B I =.194E+07 E

H

F G G G H =279229

G F F H G G G

CD BFBC F D G

GH A

E C B

H A

F G

CD

H

I

IBMXMN

H EAFD

C AH

I

GDBIH

AB G E D

E FCHGD E CEBBBCB F

G G H G H F HF HGF FH H G GH GH G GG G I =558877

Fig.2 Arch dam’s contour map of first Fig.3 Arch dam’s contour map of

principal stress under case 1(Pa) circumferential stress under case 1(Pa)

NODAL SOLUTION

BB B BB B B C C BC

NODAL SOLUTION

C BBBB B BB STEP=1 DGFGG FG HGG H H H

B B B B B B B

B EE G HF

H I II HI HHH H G HG GGF EG F STEP=1

B B B

B

SUB =1 G F HG H

H H HF F G

GF SUB =1

B B F G GH G GG G

TIME=1 F G GF

B B

F G G G G F G FF TIME=1

B S1 (AVG) G F G F

B B B FF F F FF F F SY (AVG)

F

F FF E F F F F F

B B B TOP E F

E

F

E E E E E EE EDD F TOP

B B B DMX =.002597 E E E E E E

EDEED D D DE D D FG E RSYS=15

B B B B B B B SMN =-282353 D D D D D E

C B C GF DC C C D C C C G DMX =.002597

CB B SMX =.231E+07 C C D BD

C

D

E

GB B C

F C DB CD CF SMN =-.239E+07

C CC CC A =-138102 B B CB B AE

C BC E B B B C SMX =649867

C D D D D D D D D D B =150399 C CD D BA FG H

D

BC B CB D B AA MNA A =-.222E+07

B D D C C =438901 HGFED C D C A CDB GHE

EI B =-.189E+07

CB B CD

AA E D A D E

A

E E E E EA B D =727402 HB B B B

D

G

F C B C B

E DC CI F

A E

D D A

A BC C DC E DBD C C CB B B B CB F G

E

E

D C =-.155E+07

C E E =.102E+07 E C C C C H

C C B C B C C C D B DC CB E D F D D D D CE D =-.121E+07

B C

D DE B D

C

B D C B C

B B B BDB C F =.130E+07 HGDF E F E D D D D D F EDC

EC

B CCD

B E B F F F E E E E E E FGHEF E =-871870

C F

B A C G =.159E+07 F F F F F F F D

B EFC B EHCG

DG F MX

B I

H G ED A A E

A E MN AA B B DBD BCDBEF G G G F F F

G G F GG G G GFF F F =-533707

BFD

D

C E

C C C C C C C C CD

H =.188E+07 GG H G H FEFF

HFH G GG

GGG G GG G IMX

G

B C

D D

C B

D D D D D D C B FH G GG G GG H G =-195543

B G H

BB

CD FF

E F E E E

E

F E E E EB C I =.217E+07

HG H H G H =142621

G H

BC ECDF C

B

E

D G C

E

D

C EA C

D HA

BH B

G

F

E

D G

F

G

CA H AH

G

GBA C

F G F FD EB

F B

B DB C B G H H GH H

H HH H H H H H I =480785

Fig.4 Arch dam’s contour map of first Fig.5 Arch dam’s contour map of

principal stress under case 2(Pa)

ANSYS 10.0

circumferential stress under case 2(Pa)

NODAL SOLUTION NODAL SOLUTION

BB BB BB B B BB B B ED FG F

F G GF G H H

G G HG H

H G G F

G G

F GF FEEDF STEP=1

BB B STEP=1 F G F E F

B B

B F EF G

E G

F GGF F GF F

G F G G SUB =1

B SUB =1 F F E FF G F E F F

B B E E F F F E TIME=1

B TIME=1 F EE E FE EF E EF

B BB E E E SY (AVG)

B B B S1 (AVG) E E E E DD

D E E F TOP

B B B TOP F D E E E E

D D D DE

B D D

B DMX =.003232 E D D D D D

E RSYS=15

C CD D CD C G

D

E

F D D C C D DCBBBG F DMX =.003232

B B B B B B B B B B B BC

B SMN =-402559 D C D C C C D

C FE SMN =-.290E+07

B SMX =.294E+07 BDB B BB C BB C B D B

A

D FE

C

C A =-217129 E

D

GC CCD B AE HG SMX =914744

C C C C C C C B C D D

B =153729 GF C B CB BD GH

F A =-.268E+07

CB B C D C BCB MN

D D D D D D D DD C =524588 B B B B C D CAD FE B =-.226E+07

B C F

D ED C

E B C

C C CA C =-.184E+07

D

D D D B C D =895446 GC CD C D C

BD EB D ED H

G

C B D C C D C E C C B

C D =-.141E+07

D E =.127E+07 D

C

BB D DBC D D

C

B C

B B B B B C BCB E E EE

GF E E

E

D D D D D CCGH F

E =-990636

BB C

C

B C

B CC C C F =.164E+07 F EF F EE E E E

E EF E E E F

E

CD E BF C B FG G F FG F F =-567218

BC E B FC D CG

EF

GI

HG D C D D A

D

D

C A

D AA CA A A ACDA D B C CCB B C

B

C BGH G =.201E+07 GE E

HD G FF F FF F F FF F G FFFEF EF FFGGHI

MX

B

D

ED B B DCEFD B FF F F G =-143800

C B C C C B C B H =.238E+07 E

F

G G G G G GF F F H

C B B D E C DC C C H G G G G F G H H =279618

B E E

F F G E

F G EE B DB B I =.275E+07 F F G G

E F H H G

C

B DE C

F

BFC B E

G

GHA C H B

A F G

E I

H

DMX

H

I

D

MN

C EF

DB H

I

GB

D IHC FGF

B

FHG

E D C B BCB GH H G H H G G H G H H HGHG G I =703035

Fig.6 Arch dam’s contour map of first Fig.7 Arch dam’s contour map of

principal stress under case 3(Pa) circumferential stress under case 3(Pa)

Displacement Analysis. Through displacement analysis of Tianshengqiao reservoir concrete

arch dam, getting radial displacement of crown cantilever’s calculation points under various cases,

the radial displacement values of crown cantilever under various cases are listed in the table 2,

contour maps of displacement under various cases are shown from Fig.8 to Fig.9.

Table 2. Calculation point’s radial displacement values on the analysis path of arch dam’s crown

cantilever under various cases(mm)

Calculation Point 1 2 3 4 5 6 7

Case 1 0.160 0.766 1.785 1.638 0.869 0.443 0.306

Case 2 0.057 0.579 2.177 2.446 1.734 1.049 0.640

Case 3 0.222 1.087 2.774 3.055 2.383 1.673 1.159

Published by Atlantis Press, Paris, France.

© the authors

0846

2nd International Conference on Electronic & Mechanical Engineering and Information Technology (EMEIT-2012)

NODAL SOLUTION NODAL SOLUTION

I G F

GH F

G GHGF G

H H

G G

H F GH F HG STEP=1

I I MX I H G GGG HH

G HH

I III STEP=1 G F F

I I H G FF F F H SUB =1

H G FF G H SUB =1 H

H G F F F G G H H

F F H

TIME=1

H G

G F F

E E E F GG TIME=1 I F F G

HH

GG F E

E E

E G HHH UX

G H FI I UZ

HH F E F H G

FF E D D DD E FFFF G F

I I

TOP

H F D D F G TOP E F F

I

F F EE D D C D GG RSYS=15

C CC EE RSYS=15 F H I H

H C H

E DD C C D F G E I I DMX =.002597

G GF C B B B B B E FH DMX =.002597 E H F F G

C C C G HH SMN =-.464E-03

H F

FE BB BB G SMN =-.002595 E H

H F

G A A B C E FG EFG G G

SMX =.101E-03

B AA A CD SMX =.455E-03 F F G G

H E ED D C B B A AA B B D CD H F G G G G G F G

F A =-.433E-03

MN A =-.002425 F F F F G F F GF F F G

FG C H F G E E G F F F B =-.370E-03

C B AA B =-.002086 F E G E E E

GH F A A A C D EFGE FG G D D

H D

B BB B C =-.001747 F GD D HC C C I I IC

D E C =-.307E-03

H E ED DD C C B B B B C H F B I I C HD F

C C C C C DD E D =-.001409 G I B B BMX I H G F

D =-.244E-03

F E D C C F D CH I

A

GG

F E D D D D D DD D F H E =-.00107 A A

I

A A E =-.181E-03

G

H G GG F F

E E E E E E E F FG EG B H H A B H B H H B H H HB H HC

IB C G F F =-.119E-03

H G GG G F F F F F F G HH F =-.731E-03 F FE E C E C

DFE

EC B

G

GB

G A

G HMNB BABHA C B BHCHC DDE

E EF G

G GG G H D G GF G =-.557E-04

GG GG H H

G =-.392E-03 D FC BG AH H

ED C B G G F G F H =.716E-05

H H =-.532E-04 F G G G

H H H H EDD C F FB F C D F D E FF F I =.700E-04

H H HHH HH H I =.286E-03 E

D E EC DED E EE FFG

Fig.8 Arch dam’s contour map of radial Fig.9 Arch dam’s contour map of vertical

displacement under case 2(Pa) displacement under case 2(Pa)

We can see from table 2, Fig.8 and Fig.9, calculation point’s radial displacement values of arch

dam’s crown cantilever obviously increase with water pressure increases. But maximum radial

displacement appears the middle of crown cantilever, displacement values of crown cantilever’s top

and bottom are smaller. Arch dam’s radial displacement values are more larger than vertical

displacement values, maximum vertical displacement appears crown cantilever’s top.

Conclusion

From the above, Tianshengqiao reservoir adopts concrete arch dam is economic and reasonable.

The arch dam’s circumferential stress is basically compressive stress, and arch dam’s first principal

stress values are smaller, stress values can meet strength requirements, the arch dam structure is safe

and reliable.

References

[1] SL191-2008: Design Code for Hydraulic Concrete Structures(China Water Conservancy and

Hydropower Press, China 2008)(in Chinese)

[2] M.R. Shen, J.F. Chen: Rock Mechanics(Tongji University Press, China 2006)(in Chinese)

[3] X.CH. Wang, M. Shao: Finite Element Method Basic Principle and Numerical Method(Tsinghua

University Press, China 1997)(in Chinese)

[4] SL282-2003: Design Code for Concrete Arch Dam(China Water Conservancy and Hydropower

Press, China 2003)(in Chinese)

[5] B.F. Zhu, J.ZH. Gao, Z.Y. Chen, Y.SH Li: Arch Dam Design and Research(China Water

Conservancy and Hydropower Press, China 2002)(in Chinese)

Published by Atlantis Press, Paris, France.

© the authors

0847

You might also like

- Workbook to Accompany Physics for Students of Science and EngineeringFrom EverandWorkbook to Accompany Physics for Students of Science and EngineeringNo ratings yet

- Slope Stability Analysis Based On AASHTO 17th & 2018 IBC: Project: Client: Design By: Job No.: Date: Review byDocument1 pageSlope Stability Analysis Based On AASHTO 17th & 2018 IBC: Project: Client: Design By: Job No.: Date: Review byjorge01No ratings yet

- Análisis de Estabilidad de TaludesDocument4 pagesAnálisis de Estabilidad de TaludesJosue Acosta EspinozaNo ratings yet

- Force Calculation Applications in Pipenet: F Tag F Tag FDocument10 pagesForce Calculation Applications in Pipenet: F Tag F Tag FPasquale CutriNo ratings yet

- Bunker Design With Horizontal StiffenersDocument38 pagesBunker Design With Horizontal StiffenersChetan SukteNo ratings yet

- Porting Analysis Directed To Shotguns: 1 The Flow Through PortsDocument13 pagesPorting Analysis Directed To Shotguns: 1 The Flow Through PortsjwfosteNo ratings yet

- Slope StabilityDocument1 pageSlope StabilityAbdullah Al MamunNo ratings yet

- CSR For Bulk CarrierDocument3 pagesCSR For Bulk Carrierdzaky bestariNo ratings yet

- Pad FootingDocument11 pagesPad FootingAinie ButtNo ratings yet

- Pressure Balancing Techniques To Control Spontaneous CombustionDocument26 pagesPressure Balancing Techniques To Control Spontaneous CombustionpablomilanezNo ratings yet

- Three-Dimensional Finite Element Analysis For Concrete Arch Dam of Tianshengqiao ReservoirDocument4 pagesThree-Dimensional Finite Element Analysis For Concrete Arch Dam of Tianshengqiao ReservoirMathy TuringNo ratings yet

- Quiz 22-23 Sem1Document6 pagesQuiz 22-23 Sem1Dheemant RastogiNo ratings yet

- C.2 Beggs and Brill Method Procedure For Segmenting by Pressure IncrementsDocument10 pagesC.2 Beggs and Brill Method Procedure For Segmenting by Pressure Incrementsسحر سلامتیانNo ratings yet

- Face Stability Paper AnagnostouDocument9 pagesFace Stability Paper Anagnostoudevang_gajeraNo ratings yet

- G2 - Hydrostatic Pressure & ForcesDocument18 pagesG2 - Hydrostatic Pressure & ForcesAnnisa ShabrinaNo ratings yet

- Andrew KC Chan (2003) - Observations From Excavations - A ReflectionDocument19 pagesAndrew KC Chan (2003) - Observations From Excavations - A ReflectionMan Ho LamNo ratings yet

- GEOTECH2Document10 pagesGEOTECH2Kurt Juden Abrio PardoNo ratings yet

- Bouncing of The Diesel Injector Needle at The Closing StageDocument10 pagesBouncing of The Diesel Injector Needle at The Closing StageShahfin Ahmed IftiNo ratings yet

- Andrew Chan Reference Paper For E' ValueDocument19 pagesAndrew Chan Reference Paper For E' Valueoken TNo ratings yet

- 2D Linear Static Analysis of Truss Structures-Part 01Document5 pages2D Linear Static Analysis of Truss Structures-Part 01c.sahasakNo ratings yet

- Lecture30 PDFDocument23 pagesLecture30 PDFSrinivas KumarNo ratings yet

- FluidMechanics TD Chaps 01-05Document14 pagesFluidMechanics TD Chaps 01-05Mamoudou Bah DialloNo ratings yet

- P-Y Curves For Single Piles in Fine Soils From The Prebored Pressuremeter - A New ApproachDocument7 pagesP-Y Curves For Single Piles in Fine Soils From The Prebored Pressuremeter - A New ApproachSantiago OsorioNo ratings yet

- Review Module 35 - Hydraulics 1 - Part 2Document1 pageReview Module 35 - Hydraulics 1 - Part 2Mina, KhristineNo ratings yet

- 4th Sem Hydraulics Civil Answer Paper Winter 2014Document15 pages4th Sem Hydraulics Civil Answer Paper Winter 2014Harsh PuseNo ratings yet

- Review Pneumatics HydraulicsDocument200 pagesReview Pneumatics Hydraulicshoan thanhNo ratings yet

- Lesson 07-Chapter 7 Approach Roadway DeformationsDocument117 pagesLesson 07-Chapter 7 Approach Roadway DeformationsYasser AlghrafyNo ratings yet

- Exp 1 FluidDocument15 pagesExp 1 FluidMaling KontolNo ratings yet

- Engineering Fluid Mechanics: EFO2a-HYDROSTATICS (10 Points) Jun 9 2020 Surname: Name: GroupDocument4 pagesEngineering Fluid Mechanics: EFO2a-HYDROSTATICS (10 Points) Jun 9 2020 Surname: Name: GroupDiego MartinNo ratings yet

- 1969 - Fessler - NotchesDocument10 pages1969 - Fessler - NotchesChiara GastaldiNo ratings yet

- Li 2012 IOP Conf. Ser. Earth Environ. Sci. 15 032018Document9 pagesLi 2012 IOP Conf. Ser. Earth Environ. Sci. 15 032018mohanNo ratings yet

- Stability Analysis of Embankment On Soft GroundDocument22 pagesStability Analysis of Embankment On Soft Groundועדת איכות הסביבה חייםNo ratings yet

- Exp1 - Fluid Friction New DMCFDocument6 pagesExp1 - Fluid Friction New DMCFSri Haaran RameshNo ratings yet

- Flow MeasurementDocument15 pagesFlow MeasurementPhongNo ratings yet

- HS1 Chapter 2 Part 2Document5 pagesHS1 Chapter 2 Part 2hanoseNo ratings yet

- HS1 Chapter 2 Part 2Document5 pagesHS1 Chapter 2 Part 2hanoseNo ratings yet

- Assignment 1 - Fluid StaticsDocument3 pagesAssignment 1 - Fluid StaticsaarijNo ratings yet

- The Design Is AdequateDocument3 pagesThe Design Is Adequatejorge01No ratings yet

- Chapter 5 Solid and FluidDocument50 pagesChapter 5 Solid and FluidJerome FizzowNo ratings yet

- Stress and Deflection Analysis of Belleville Spring PDFDocument6 pagesStress and Deflection Analysis of Belleville Spring PDFDeepak BhopeNo ratings yet

- Fiitjee: JEE (Mains)Document12 pagesFiitjee: JEE (Mains)Mrityunjay GuptaNo ratings yet

- Limit Analysis Pore PressureDocument57 pagesLimit Analysis Pore PressureM TaufikNo ratings yet

- November 2022 (v3) QPDocument20 pagesNovember 2022 (v3) QPElizabeth HariyantoNo ratings yet

- Exam and Solutions 2004-2013 TPG4205Document21 pagesExam and Solutions 2004-2013 TPG4205Hoan HoanNo ratings yet

- f M π /4) d S D /2) t P (D/2) : Southern Region Houston, TexasDocument4 pagesf M π /4) d S D /2) t P (D/2) : Southern Region Houston, Texasmohamed amine AtiaNo ratings yet

- Calculation of Lateral Loads On Sump Walls Distribution of Earth Pressure On Sump WallDocument19 pagesCalculation of Lateral Loads On Sump Walls Distribution of Earth Pressure On Sump WallHARSHARANNo ratings yet

- Shirlaw TUCSS2011 FacepressurecalculationsDocument31 pagesShirlaw TUCSS2011 Facepressurecalculationsmayank dixitNo ratings yet

- Lab1 Fluid ManualDocument10 pagesLab1 Fluid Manualjin76No ratings yet

- Author's Accepted Manuscript: International Journal of Mechanical SciencesDocument26 pagesAuthor's Accepted Manuscript: International Journal of Mechanical SciencesKris SmaczekNo ratings yet

- EAH 221-Aug 06th2009Document7 pagesEAH 221-Aug 06th2009imaniNo ratings yet

- AbstractDocument9 pagesAbstractrebafilweNo ratings yet

- Experiment: Expected Duration: Objective:: Higher Diploma in Civil Engineering Fluid MechanicsDocument4 pagesExperiment: Expected Duration: Objective:: Higher Diploma in Civil Engineering Fluid Mechanics阿樂No ratings yet

- Quite Hydraulic Actuation Bellows Design Considerations: Laser Interferometer Gravitational Wave Observatory - LIGODocument11 pagesQuite Hydraulic Actuation Bellows Design Considerations: Laser Interferometer Gravitational Wave Observatory - LIGONayri AkbuğaNo ratings yet

- Lecture 4 - HydrostaticForcesOnSurfaces PDFDocument13 pagesLecture 4 - HydrostaticForcesOnSurfaces PDFAmr fNo ratings yet

- Hopper DesigningDocument34 pagesHopper DesigningZaeem Uddin Ali100% (2)

- 19 Thincylinderr2Document14 pages19 Thincylinderr2IrsyadNo ratings yet

- Quiz 23S1Document6 pagesQuiz 23S1Dheemant RastogiNo ratings yet

- EW70 Draft - Ver 004Document78 pagesEW70 Draft - Ver 004Radoslav PenevNo ratings yet

- JEEM Mock Test 1-06-12 19Document13 pagesJEEM Mock Test 1-06-12 19ShobnamNo ratings yet

- Learning Autodesk Revit Structure 2010Document450 pagesLearning Autodesk Revit Structure 2010Fernando FrançaNo ratings yet

- Three-Dimensional Finite Element Analysis For Concrete Arch Dam of Tianshengqiao ReservoirDocument4 pagesThree-Dimensional Finite Element Analysis For Concrete Arch Dam of Tianshengqiao ReservoirMathy TuringNo ratings yet

- Guideline For FE Analyses of Concrete Dams: ICOLD 2017 PragueDocument17 pagesGuideline For FE Analyses of Concrete Dams: ICOLD 2017 PragueMathy TuringNo ratings yet

- 45StructuralDesignOptimization StatusandDirectionDocument28 pages45StructuralDesignOptimization StatusandDirectionMathy TuringNo ratings yet

- Guideline For FE Analyses of Concrete Dams: ICOLD 2017 PragueDocument17 pagesGuideline For FE Analyses of Concrete Dams: ICOLD 2017 PragueMathy TuringNo ratings yet

- 01 Overview 2Document39 pages01 Overview 2Abdullah Al Bari TusharNo ratings yet

- Frbiblio PDFDocument16 pagesFrbiblio PDFreolox100% (1)

- Do You Agree or Disagree With The Following StatementDocument2 pagesDo You Agree or Disagree With The Following StatementVũ Ngọc Minh ThuNo ratings yet

- English HL P1 Nov 2019Document12 pagesEnglish HL P1 Nov 2019Khathutshelo KharivheNo ratings yet

- Post Cold WarDocument70 pagesPost Cold WarZainab WaqarNo ratings yet

- CRM Final22222222222Document26 pagesCRM Final22222222222Manraj SinghNo ratings yet

- Jurnal Perdata K 1Document3 pagesJurnal Perdata K 1Edi nur HandokoNo ratings yet

- Delegated Legislation in India: Submitted ToDocument15 pagesDelegated Legislation in India: Submitted ToRuqaiyaNo ratings yet

- Lower Gastrointestinal BleedingDocument1 pageLower Gastrointestinal Bleedingmango91286No ratings yet

- Iluminadores y DipolosDocument9 pagesIluminadores y DipolosRamonNo ratings yet

- Living Greyhawk - Greyhawk Grumbler #1 Coldeven 598 n1Document2 pagesLiving Greyhawk - Greyhawk Grumbler #1 Coldeven 598 n1Magus da RodaNo ratings yet

- Activity-Based Management (ABM) Is A Systemwide, Integrated Approach That FocusesDocument4 pagesActivity-Based Management (ABM) Is A Systemwide, Integrated Approach That FocusestogarikalNo ratings yet

- Hellwalker: "What Terrors Do You Think I Have Not Already Seen?"Document2 pagesHellwalker: "What Terrors Do You Think I Have Not Already Seen?"mpotatoNo ratings yet

- Book Review On PandeymoniumDocument2 pagesBook Review On PandeymoniumJanhavi ThakkerNo ratings yet

- Information: Republic of The Philippines Regional Trial Court 8 Judicial Region Branch VIDocument2 pagesInformation: Republic of The Philippines Regional Trial Court 8 Judicial Region Branch VIlossesaboundNo ratings yet

- Advanced Financial Accounting and Reporting Accounting For PartnershipDocument6 pagesAdvanced Financial Accounting and Reporting Accounting For PartnershipMaria BeatriceNo ratings yet

- Approach To A Case of ScoliosisDocument54 pagesApproach To A Case of ScoliosisJocuri KosoNo ratings yet

- Pharmaniaga Paracetamol Tablet: What Is in This LeafletDocument2 pagesPharmaniaga Paracetamol Tablet: What Is in This LeafletWei HangNo ratings yet

- User Manual For Inquisit's Attentional Network TaskDocument5 pagesUser Manual For Inquisit's Attentional Network TaskPiyush ParimooNo ratings yet

- Demand and SupplyDocument61 pagesDemand and SupplyGirish PremchandranNo ratings yet

- Lifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMDocument2 pagesLifeline® Specialty: Fire Resistant QFCI Cable: Fire Resistant, Flame Retardant Halogen-Free Loose Tube - QFCI/O/RM-JMkevinwz1989No ratings yet

- Walt Whitman Video Worksheet. CompletedDocument1 pageWalt Whitman Video Worksheet. CompletedelizabethannelangehennigNo ratings yet

- Group 2 Lesson 2 DramaDocument38 pagesGroup 2 Lesson 2 DramaMar ClarkNo ratings yet

- 5g-core-guide-building-a-new-world Переход от лте к 5г английскийDocument13 pages5g-core-guide-building-a-new-world Переход от лте к 5г английскийmashaNo ratings yet

- Quiz 07Document15 pagesQuiz 07Ije Love100% (1)

- ACSRDocument3 pagesACSRWeber HahnNo ratings yet

- Panlilio vs. Regional Trial Court, Branch 51, City of ManilaDocument10 pagesPanlilio vs. Regional Trial Court, Branch 51, City of ManilaMaria Nicole VaneeteeNo ratings yet

- MGT 601-Smes Management MCQ For Final Term Preparation: ProductionDocument80 pagesMGT 601-Smes Management MCQ For Final Term Preparation: ProductionSajidmehsudNo ratings yet

- Land Building and MachineryDocument26 pagesLand Building and MachineryNathalie Getino100% (1)

- FAMILYDocument3 pagesFAMILYJenecel ZanoriaNo ratings yet

- Pigeon Racing PigeonDocument7 pagesPigeon Racing Pigeonsundarhicet83No ratings yet