Professional Documents

Culture Documents

Wireless Sensors For Harsh Coal Plants

Uploaded by

Anu ParthaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wireless Sensors For Harsh Coal Plants

Uploaded by

Anu ParthaCopyright:

Available Formats

TECHNOLOGY MATURATION OF WIRELESS HARSH-

ENVIRONMENT SENSORS FOR IMPROVED CONDITION-BASED

MONITORING OF COAL-FIRED POWER GENERATION

Motivation Project Structure & Implementation

M. Pereira da R. J. Cunha1, 2,

G. A. Lad1, 2, Harkay 2, Maskay1, 2

1University of Maine, Orono, Maine, U.S.A

COAL: U.S. Energy Information Administration (EIA) Project Tasks:

2Environetix Technologies Corporation, Orono, Maine, U.S.A. TASK 1 – Project Management & Planning

U.S.A 21% of the world’s proven recoverable

reserves of coal (255.8 billion short tons) TASK 2 – Technology Transition & Adaptation: High

Temperature Wireless SAW Sensor Technology in

This is only 6.5% of the potential total coal resources Surface Acoustic Wave (SAW) Technology UMaine/Environetix Previous Experience Harsh Coal-fired Power Plant Environments

HUGE SOURCE OF ENERGY FOR THIS COUNTRY! TASK 3 – Implementation and Testing of Mature

Class of Micromechanical Systems (MEMS) Collaboration with Penobscot Energy Recovery Company Prototype Wireless Sensor System within Power Plants

Electronic platform: electrical signal translated into (PERC) Power Plant in Orrington, ME TASK 4 – Protective Coatings and Piezoelectric Thin

Films for Improved Sensor Packaging & Performance

microwave acoustics using a piezoelectric substrate PERC Municipal Solid Waste (MSW) Power Plant

TASK 5 – Development of Prototype SAW-based Strain

Delay line and resonators: typical SAW structures used for Goal Implement a Wireless Temperature Monitoring Sensor

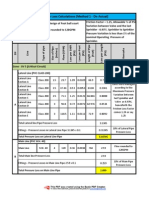

sensor applications System(s) at the MSW power plant Milestone Planned Completion Milestone Title

Interdigitated transducers (IDTs) used for wave generation; M1 1st quarter of Year 1 Kick-off Meeting with DOE / NETL Program Officer

reflector electrodes used for acoustic wave energy trapping Definition of Target Locations to Install Prototype

M2 4th quarter of Year 1

Wireless HE SAW Sensor System

output W acoustic

interdigital absorber M3 1st quarter of Year 2 Wireless Communication Planning and Testing

June 2017 Monthly Energy Review, U.S. Energy Information Administration transducer

Fabrication of Prototype Wireless HE SAW Sensor

(EIA), DOE/EIA-0035(2017/6)

M4 3rd quarter of Year 2

piezoelectric

System

Coal usage diminishing since the mid-2000s : input

material

Installation of Specific Prototype Sensor System in

interdigital

SAW

M5 4th quarter of Year 2

Coal-fired Variable Operations and Maintenance transducer z x Identified Power Plant Locations

d

Testing of Specific Prototype Sensor System in

(VOM) consistently HIGHER than Natural Gas

acoustic

absorber

y

M6 1st quarter of Year 3

Identified Power Plant Locations

Refinement of Sensor System Performance and

Emissions M7 4th quarter of Year 3

Additional Testing

Busbars

High Coal availability in the U.S. calls for: http://www.rfwireless-world.com

Identification of the Best Thin Film Dielectric

M8 1st quarter of Year 3 Coatings for Packaging of Sensor in Harsh-

New Advanced Technologies for use in harsh Typical operating features: Environment

environments vp 3.103 m/s << c= 3.108 m/s (5 order of mag. size ) Power plant conditions: Identification of the Best Piezoelectric Materials for

M9 2nd quarter of Year 3 Enhanced Sensor Manufacturability and Integration

Advanced Sensors for Condition Based Frequency range: 50 MHz to a few GHz (range Temps 900°C (1650°F) with Sensor Antenna

Maintenance (CBM) determined by size & lithography) Highly erosive/corrosive exhaust gases M10 2nd quarter of Year 3

Field Testing of Wireless Temperature Sensor Arrays

in Selected Power Plant Locations

Advanced Sensors: Respective (vp = . F) from 60µm to 1.5µm ¾” Schedule 40 Hastelloy

thermocouple tube after ~6 mo M11 2nd quarter of Year 3 Demonstration of Strain Sensor

Operating Maintenance minimum feature size /4 ~ 15µm to 0.4µm

Emissions

Cost Cost Low cost in high volume production Wireless HE/HT Sensor Array tested at Economizer M12 4th quarter of Year 3

Final Demonstrations in Coal-fired Power Plants and

Final Project Reporting Preparation to DOE / NETL

Reproducible manufacturing based on semiconductor Example of wireless temperature

fabrication capabilities

monitoring over 5 weeks Current Activity Status:

Goals and Objectives Kick-off meeting DOE on February 22, 2018

Environetix subcontract executed on March 21, 2018

GOALS Contact & Coordination with Duke Energy / PERC/

SAW Sensors in Harsh Environments Other Coal-based Power Plants

Usage of Harsh-Environment (HE) High-Temperature

Hiring staff for project support at UMaine

(HT) Wireless Surface Acoustic Wave (SAW) Sensor

Technology to: Engaging Grad and Undergrad students

Reliable maintenance through CBM of critical

coal-based power plant equipment

Conclusions

Wireless SAW sensor tests in

monopole

Cost-effective efficiency of power plant 6 dipoles + interrogating

power plant harsh environment

operations SAW technology can be used to measure a variety of sensor carried out over 2 years Project initiated within the past 2 months.

SAW Sensors antenna

parameters: temperature, pressure, torque, strain, gas Presented Project Background: Motivation, Goals, &

Power Plant Safety Wireless HE/HT Sensor Array tested in Boiler

Small sensor footprint 300 MHz Objectives

HE/HT Wireless SAW Sensor Technology SAW Sensor PERC Indicated the need for: Provided SAW Technological Overview and HE/HT

Readiness Level (TRL) via test & implementation Robust and stable over long-term

Placement of sensor array on Boiler tubes for CBM SAW Sensor Background

Varying detection mechanisms: mass

Locate blockage optimally aim steam/soot blowers UMaine/Environetix are under current discussions with

OBJECTIVES loading, absorption, stress, changes in film

coal power plant collaborators to be selected as test bed

thickness or material properties

HE/HT Wireless Surface Acoustic Wave (SAW) for technology demonstration and advancement

Temperature Sensors CBM in Coal Power Plants Existence of substrates for high temperature applications, Described Project Structure & Implementation

such as the langasite (LGS)

Improvement in the packaging of SAW temperature Tasks & Milestones

sensors & antennas LGS : 1470°C Melting point Current Activity Status

Advancement in piezoelectric films and strain sensors Advantages of SAW Sensors:

Wireless, battery-free, robust, passive operational

Wireless communication protocols & signal

capability leading to reduced installation &

processing refinements

maintenance cost DOE / NETL Project DE-FE0031550

Technology validation and transition to coal-based Program DE-FOA-0001728:

power plants Complexity Reliability Size Advanced Combustion Systems (ACS): Existing Plant

Improvements and Transformational Technologies

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Ford Everes PDFDocument584 pagesFord Everes PDFTiến Hồ100% (6)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Friction Loss Calculations of Irrigation Design A Foot Ball CourtDocument13 pagesFriction Loss Calculations of Irrigation Design A Foot Ball Courtmathewmanjooran100% (2)

- Turbine Clearance ControlDocument135 pagesTurbine Clearance ControlAnu Partha100% (1)

- Wireman, Terry - Training Programs For Maintenance Organizations - Maintenance Strategy Series (2013, Reliabilityweb Com)Document221 pagesWireman, Terry - Training Programs For Maintenance Organizations - Maintenance Strategy Series (2013, Reliabilityweb Com)Faiza TariqNo ratings yet

- Fire Hydrant System Design Installation Commisioning and TestingDocument5 pagesFire Hydrant System Design Installation Commisioning and Testingjaianit89No ratings yet

- Commercial Office Space - Cyber CityDocument8 pagesCommercial Office Space - Cyber CityankurNo ratings yet

- Brige Lauching Cap 1 PDFDocument16 pagesBrige Lauching Cap 1 PDFAnonymous VkzquW39No ratings yet

- The SGT-8000H After 2 Years of Commercial OperationDocument17 pagesThe SGT-8000H After 2 Years of Commercial OperationAnu ParthaNo ratings yet

- KM Adhikarya - TBK KomplitDocument15 pagesKM Adhikarya - TBK KomplitHelloMotion AcademyNo ratings yet

- CMC Vanes PDFDocument108 pagesCMC Vanes PDFAnu ParthaNo ratings yet

- Practical Techniques For Modeling Gas Turbine Engine PerformanceDocument26 pagesPractical Techniques For Modeling Gas Turbine Engine PerformanceAnu ParthaNo ratings yet

- Introduction To DOE's New Energy Assessment Tool Suite MEASUR - Slides PDFDocument16 pagesIntroduction To DOE's New Energy Assessment Tool Suite MEASUR - Slides PDFAnu ParthaNo ratings yet

- Sequential Combustion ModelingDocument24 pagesSequential Combustion ModelingAnu ParthaNo ratings yet

- BG 16 1657 2019 PDFDocument15 pagesBG 16 1657 2019 PDFAnu ParthaNo ratings yet

- Gas Turbine Power Plant Performance Evaluation Under Key FailuresDocument16 pagesGas Turbine Power Plant Performance Evaluation Under Key FailuresAnu ParthaNo ratings yet

- An Experimental Prototype of Micro Hydro Power GenerationDocument5 pagesAn Experimental Prototype of Micro Hydro Power GenerationAnu ParthaNo ratings yet

- Ecp18154010 PDFDocument10 pagesEcp18154010 PDFAnu ParthaNo ratings yet

- Onshore Reliability, Availability & Maintainability (Ram) StudiesDocument1 pageOnshore Reliability, Availability & Maintainability (Ram) StudiesAnu ParthaNo ratings yet

- 9 0 Development and OperatingDocument12 pages9 0 Development and OperatingAnu Partha100% (1)

- Comprehensive Property Protection Plan: Boiler and Machinery/Equipment Breakdown Program Policy GuideDocument6 pagesComprehensive Property Protection Plan: Boiler and Machinery/Equipment Breakdown Program Policy GuideAnu ParthaNo ratings yet

- Guide To Open Electricity Market: Panduan Bagi Pasaran Terbuka Unt Uk Bekalan ElektrikDocument28 pagesGuide To Open Electricity Market: Panduan Bagi Pasaran Terbuka Unt Uk Bekalan ElektrikAnu ParthaNo ratings yet

- Property Risk Assessment For Combined Cycle Power PlantsDocument39 pagesProperty Risk Assessment For Combined Cycle Power PlantsAnu ParthaNo ratings yet

- Tubine Meter GTX GTS GT Literature PDFDocument12 pagesTubine Meter GTX GTS GT Literature PDFAnu ParthaNo ratings yet

- Latcovich PDFDocument9 pagesLatcovich PDFAnu ParthaNo ratings yet

- This Chapter Should Be Cited As: Infrastructure in East Asia Through Power Grid Interconnection. ERIA Research ProjectDocument53 pagesThis Chapter Should Be Cited As: Infrastructure in East Asia Through Power Grid Interconnection. ERIA Research ProjectAnu ParthaNo ratings yet

- Applied Hydrology LabDocument6 pagesApplied Hydrology Labshehbaz3gNo ratings yet

- Stanley 46 InstructionsDocument2 pagesStanley 46 Instructionsj_abendstern4688No ratings yet

- Kroo Subsonic WingDocument8 pagesKroo Subsonic WingRod ManserNo ratings yet

- Pic Attack1Document13 pagesPic Attack1celiaescaNo ratings yet

- FTB - Fire Alarm Boq Take Off - 10-08-2022Document4 pagesFTB - Fire Alarm Boq Take Off - 10-08-2022Thai ChheanghourtNo ratings yet

- ASSAM - Uniform Zoning Regulation 2000Document35 pagesASSAM - Uniform Zoning Regulation 2000rajatesh1No ratings yet

- Case Adhesives BrochureDocument6 pagesCase Adhesives BrochureChanakyaNo ratings yet

- Remote Log-In, Electronic Mail and File Transfer: Solutions To Odd-Numbered Review Questions and ExercisesDocument2 pagesRemote Log-In, Electronic Mail and File Transfer: Solutions To Odd-Numbered Review Questions and ExercisesAnurag UpadhyayNo ratings yet

- Column Marking For G+4 Hostel Building: All Dimensions Are in MeterDocument1 pageColumn Marking For G+4 Hostel Building: All Dimensions Are in Metergowtham gowdaNo ratings yet

- Codex 2017 enDocument713 pagesCodex 2017 enJIgnacio123No ratings yet

- Transportation ChecklistDocument1 pageTransportation ChecklistHolly Smith100% (1)

- Green Pin Shackles - Certificates Overview and Specifications - 0Document1 pageGreen Pin Shackles - Certificates Overview and Specifications - 0Eduardo SolanoNo ratings yet

- 180 W PC Main SFX Supply - PHPDocument2 pages180 W PC Main SFX Supply - PHPCici Icic100% (1)

- CH 4Document34 pagesCH 4saadkhalisNo ratings yet

- 2 TensionDocument28 pages2 TensionRICKY IVANNo ratings yet

- DMPCDocument49 pagesDMPCiprassandyNo ratings yet

- SWOT Analysis of Viyellatex Spinning LimitedDocument81 pagesSWOT Analysis of Viyellatex Spinning LimitedHossain RanaNo ratings yet

- Shell Spirax S6 Txme: Performance, Features & BenefitsDocument2 pagesShell Spirax S6 Txme: Performance, Features & BenefitsAbdelhadi HoussinNo ratings yet

- This Study Resource Was: Laboratory Exercise 2 Preparation of Disturbed Soil Sample For Test ObjectiveDocument3 pagesThis Study Resource Was: Laboratory Exercise 2 Preparation of Disturbed Soil Sample For Test ObjectiveBienvenida Ycoy MontenegroNo ratings yet

- Phychem Expt #2Document7 pagesPhychem Expt #2Candace AguilarNo ratings yet

- 14HDocument2 pages14HWiliam Vega Farias100% (2)

- Guide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1Document51 pagesGuide To The Systems Engineering Body of Knowledge (Sebok), Version 1.1António FerreiraNo ratings yet

- Instruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 ADocument32 pagesInstruction Manual: Oil-Lubricated Rotary Vane Vacuum Pumps RA 0750 AYunisNo ratings yet