Professional Documents

Culture Documents

Practice Problems, Governors: Semester IV, B. Tech., 2016-19

Uploaded by

viswas andrewsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practice Problems, Governors: Semester IV, B. Tech., 2016-19

Uploaded by

viswas andrewsCopyright:

Available Formats

Practice problems, Governors: Semester IV, B. Tech.

, 2016-19

Instructor: Dr. B Pattabhi Ramaiah

School of Mechanical Sciences,

Indian Institute of Technology Bhubaneswar, India

Instructions:

Solve all the problems.

1. A Hartnell governor with a central sleeve spring and two right-angled bell crank levers operates in the

speed range of 290 RPM and 310 RPM, for a sleeve lift of 15 mm. Length of the sleeve arms and the

ball arms are 80 mm and 120 mm respectively. The bell crank levers are pivoted at 120 mm from the

governor axis and mass of each ball is 2.5 kg. The ball arms are parallel to the governor axis at the lowest

equilibrium speed. Determine : (i) loads on the spring at the lowest and the highest equilibrium speeds,

and (ii) stiffness of the spring. Neglect the obliquity effects of the arms and the moment due to weight of

the balls.

2. In a spring loaded governor of the Hartnell type, the mass of each ball is 5 kg and the lift of the sleeve

is 50 mm. The speed at which the governor begins to float is 240 RPM, and at this speed the radius of

the ball path is 110 mm. The mean working speed of the governor is 20 times the range of speed when

friction is neglected. The lengths of ball and roller arm of the bell crank lever are 120 mm and 100 mm,

respectively and the distance between the centre of pivot of bell crank lever and axis of governor spindle

is 140 mm. (i) Determine the initial compression of the spring taking into account the obliquity of arms.

(ii) If friction is equivalent to a force of 30 N at the sleeve, find the total alteration in speed before the

sleeve begins to move from mid-position.

3. In a spring-controlled governor of the Hartung type, the length of the ball and sleeve arms are 80 mm

and 120 mm respectively. The total travel of the sleeve is 25 mm. In the mid position, each spring is

compressed by 50 mm and the radius of rotation of the mass centres is 140 mm. Each ball has a mass of 4

kg and the spring has a stiffness of 10 kN/m of compression. The equivalent mass of the governor gear

at the sleeve is 16 kg. Neglecting the moment due to the revolving masses when the arms are inclined,

determine the ratio of the range of speed to the mean speed of the governor. Find, also, the speed in the

mid-position.

4. Consider a governor of Wilson-Hartnell type, where the mass of each ball is 5 kg. The length of the all

arm and sleeve arm of each bell-crank lever is 100 mm and 80 mm, respectively. The stiffness of each of

the two springs attached directly to the balls is 0.4 N/mm. The lever for the auxiliary spring is pivoted

at its midpoint. When the radius of rotation is 100 mm, the equilibrium speed is 200 RPM. If the sleeve

is lifted by 8 mm for an increase of speed of 6%, find the required stiffness of the auxiliary spring.

5. A gramophone is driven by a Pickering governor. The mass of each disc attached to the centre of a leaf

spring is 20 g. Each spring is 5 mm wide and 0.125 mm thick. The effective length of each spring is 40

mm. The distance from the spindle axis to the centre of gravity of the mass when the governor is at rest

is 10 mm. Find the speed of the turntable when the sleeve has risen 0.8 mm and the ratio of the governor

speed to the turntable speed is 10.5, considering E = 210 kN/mm2 .

Theory of Machines II (ME2L005) April 6, 2018

You might also like

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsFrom EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Numerical Sheet 3Document2 pagesNumerical Sheet 3Nishant MayekarNo ratings yet

- GovernorsDocument3 pagesGovernorsDhinakaran VeemanNo ratings yet

- E-Tivity 4.1 Tutorials On GovernorsDocument1 pageE-Tivity 4.1 Tutorials On GovernorsMugisha OlivierNo ratings yet

- Governor ProblemsDocument8 pagesGovernor Problemsmane prathameshNo ratings yet

- Questions On GovernorDocument4 pagesQuestions On GovernorVinAyNo ratings yet

- DOM T2 Question BankDocument6 pagesDOM T2 Question BankAyush KothariNo ratings yet

- QB For Mid-IiDocument3 pagesQB For Mid-Iihod mechNo ratings yet

- Assignment Questions Dom Me 5004Document5 pagesAssignment Questions Dom Me 5004sharmasweeta927No ratings yet

- DOM AssignmentDocument2 pagesDOM AssignmentBharath NNo ratings yet

- Governor ProblemsDocument3 pagesGovernor ProblemsPappuRamaSubramaniamNo ratings yet

- Part B & Part C Questions - Unit WiseDocument3 pagesPart B & Part C Questions - Unit WiseShobiNo ratings yet

- DOM QuestionsDocument14 pagesDOM QuestionsManda Ramesh BabuNo ratings yet

- Dom TutorialDocument7 pagesDom TutorialsrishashankNo ratings yet

- Sheet #2Document1 pageSheet #2Sports GloballyNo ratings yet

- DOM2Document7 pagesDOM2ds_shivaNo ratings yet

- DOM PortantDocument6 pagesDOM PortantkannanNo ratings yet

- DSMV Assignment IDocument2 pagesDSMV Assignment IRajakumar SaiNo ratings yet

- DOM Unit 4 & 5 QBDocument6 pagesDOM Unit 4 & 5 QBRayleighNo ratings yet

- 02 Governors PPT v2Document46 pages02 Governors PPT v2Shashank JaiswalNo ratings yet

- Our Official Android App - REJINPAUL NETWORK FromDocument3 pagesOur Official Android App - REJINPAUL NETWORK FromAjay KumarNo ratings yet

- Anna University Exams Nov / Dec 2019 - Regulation 2017 Unit I-V 1Document5 pagesAnna University Exams Nov / Dec 2019 - Regulation 2017 Unit I-V 1Sai KrishnaNo ratings yet

- Previous Questions DomDocument5 pagesPrevious Questions DomSafeer MNo ratings yet

- Dom Unit I Imp QuestionsDocument1 pageDom Unit I Imp QuestionsSree MurthyNo ratings yet

- Mechanism MechanicsDocument5 pagesMechanism MechanicsEzmel KazimNo ratings yet

- 2mid Imp Questions ModelsDocument4 pages2mid Imp Questions ModelsSrimanthula SrikanthNo ratings yet

- Dom Assign MentDocument2 pagesDom Assign Mentjamunaa830% (2)

- Me 8594 Dynamics of Machines: Unit - 5 GovernorsDocument45 pagesMe 8594 Dynamics of Machines: Unit - 5 GovernorsHemaNo ratings yet

- Machine DesignTthDocument2 pagesMachine DesignTthMarc Graham NacuaNo ratings yet

- Dynamics of MachineryDocument2 pagesDynamics of MachineryArun ManoNo ratings yet

- Thermal Important QuestionsDocument2 pagesThermal Important QuestionschshsksbNo ratings yet

- DOM Model QuestionDocument2 pagesDOM Model QuestionSenthilkumar SubbiahNo ratings yet

- Find The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inDocument4 pagesFind The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inGeoffrey GolbequeNo ratings yet

- Tutorial 4 (Governors) - 1Document1 pageTutorial 4 (Governors) - 1Suhas AdusumilliNo ratings yet

- Elemen MesinDocument23 pagesElemen MesinMonika NikaNo ratings yet

- 9A03502 Dynamics of MachineryDocument4 pages9A03502 Dynamics of MachinerysivabharathamurthyNo ratings yet

- rr320304 Dynamics of MachinesDocument8 pagesrr320304 Dynamics of MachinesSRINIVASA RAO GANTANo ratings yet

- Design of ShaftDocument2 pagesDesign of Shaftgourab190% (1)

- Tom-Assignment 3Document2 pagesTom-Assignment 3jamunaa83No ratings yet

- AssignmentDocument1 pageAssignmentVikäs SíñghNo ratings yet

- The Crank and Connecting Rod of A Steam Engine Are 0Document7 pagesThe Crank and Connecting Rod of A Steam Engine Are 0ANBU RAJ ANo ratings yet

- Dom 16 MarksDocument2 pagesDom 16 MarksKarthikn AltocNo ratings yet

- Unit I - Shafts: Single ElementDocument7 pagesUnit I - Shafts: Single Elementchelam101100% (1)

- Governors PPT - 1Document24 pagesGovernors PPT - 1Bhukya Reethvik RathodNo ratings yet

- Tom-Assignment 2Document2 pagesTom-Assignment 2jamunaa83No ratings yet

- Tutorial DOM 2015 1Document3 pagesTutorial DOM 2015 1ismail oganlaNo ratings yet

- Machine Theory NumericalsDocument5 pagesMachine Theory NumericalsSaad FarooqNo ratings yet

- MTM Question BankDocument19 pagesMTM Question BankankiosaNo ratings yet

- D04FA48908744891B70ED91613E5E5ABDocument4 pagesD04FA48908744891B70ED91613E5E5AByashvantNo ratings yet

- Important Questions DomDocument6 pagesImportant Questions DomSanthosh RasaNo ratings yet

- Damping ExerciseDocument5 pagesDamping ExerciseArif NecNo ratings yet

- ME2352-DTS Question BankDocument8 pagesME2352-DTS Question BankNaresh015No ratings yet

- Anna University Madras Institute of Technology: 718 R.P.M N 843 R.P.M)Document4 pagesAnna University Madras Institute of Technology: 718 R.P.M N 843 R.P.M)veeyeskay_2006No ratings yet

- Automotive Chassis DesignDocument4 pagesAutomotive Chassis DesigndressfeetNo ratings yet

- Home Assignment ProblemsDocument2 pagesHome Assignment ProblemsAneesh KumarNo ratings yet

- 19ME5603 DOM Unit I QuestionsDocument3 pages19ME5603 DOM Unit I QuestionsRobinston Jeyasingh KNo ratings yet

- 19ME5603 DOM Unit II QuestionsDocument3 pages19ME5603 DOM Unit II QuestionsRobinston Jeyasingh KNo ratings yet

- Dynamics of Machines 4 Units New Question BankDocument4 pagesDynamics of Machines 4 Units New Question BankgbharathreddysNo ratings yet

- Ambo University Hachalu Hundessa Campus School of Mechanical and Industrial Engineering Machine Element II, Assignment 1Document2 pagesAmbo University Hachalu Hundessa Campus School of Mechanical and Industrial Engineering Machine Element II, Assignment 1chalaNo ratings yet

- Spin Top CycloneDocument2 pagesSpin Top CyclonegshdavidNo ratings yet

- Alpha Call Up ListDocument108 pagesAlpha Call Up ListRendi 911No ratings yet

- A Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowDocument19 pagesA Review of Heat Exchanger Tube Bundle Vibrations in Two-Phase Cross-FlowPeerasak ArunNo ratings yet

- Asme Sec Viii D1 Nma App y PDFDocument15 pagesAsme Sec Viii D1 Nma App y PDFADRIANNo ratings yet

- DIN Flange 2502-2503 PDFDocument2 pagesDIN Flange 2502-2503 PDFHeru Agus SetyawanNo ratings yet

- Drive Right Chapter 3 Basic Vehical ControlDocument23 pagesDrive Right Chapter 3 Basic Vehical Controlapi-279470525No ratings yet

- Analysis of Balsa Wood Bridge ModelsDocument28 pagesAnalysis of Balsa Wood Bridge ModelsHazem EmamNo ratings yet

- Tajima CordingDocument45 pagesTajima CordingWilsonGutierrezNo ratings yet

- Three-Phase Electric Motor: General Information FileDocument66 pagesThree-Phase Electric Motor: General Information FileJacob SánchezNo ratings yet

- Vk4105G Series: Gas Controls For Combined Valve and Ignition Modulating SystemDocument18 pagesVk4105G Series: Gas Controls For Combined Valve and Ignition Modulating Systemandrei7radu1159No ratings yet

- Optimization of Recirculating Laminar Air FlowDocument6 pagesOptimization of Recirculating Laminar Air FlowreiferNo ratings yet

- Torsion PendulumDocument20 pagesTorsion PendulumOmar ShamaylehNo ratings yet

- Service Parts List: Converter CL9672-18 4265618Document42 pagesService Parts List: Converter CL9672-18 4265618Chester Dalitso Mwanza100% (3)

- Major Project ReportDocument58 pagesMajor Project ReportHIMANSHU GANWANINo ratings yet

- Cilindri PDFDocument40 pagesCilindri PDFSlobodan SavicNo ratings yet

- Manitou MHT 10120 enDocument16 pagesManitou MHT 10120 enElardus EngelbrechtNo ratings yet

- Hyundai H380 TrucksDocument12 pagesHyundai H380 TrucksIrfan SaeedNo ratings yet

- Kunci Jawaban Basic Ac MaterialDocument5 pagesKunci Jawaban Basic Ac Materialdyan dyanNo ratings yet

- Fai Filtri Oil Filter Codes PDFDocument8 pagesFai Filtri Oil Filter Codes PDFSebastian GanciNo ratings yet

- DTC 17501 - P1093 - 004243Document1 pageDTC 17501 - P1093 - 004243JuanLopez64ChNo ratings yet

- Thermodynamics 2 & Fluid MechanicsDocument18 pagesThermodynamics 2 & Fluid MechanicsNicole Mae AllosadaNo ratings yet

- Plano Explosivo & Partes y Piezas Wmf-m160gbDocument18 pagesPlano Explosivo & Partes y Piezas Wmf-m160gbCatalina GonzalezNo ratings yet

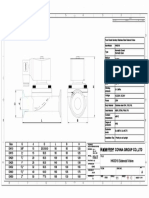

- COVNA HK0018 Series Sanitary Solenoid Valve SpecificationDocument1 pageCOVNA HK0018 Series Sanitary Solenoid Valve Specificationemosquerasaurus saurusNo ratings yet

- Banda Lido Datasheet - uni-OWLDocument2 pagesBanda Lido Datasheet - uni-OWLVilma sagresaNo ratings yet

- Uniform Rotary MotionDocument26 pagesUniform Rotary MotionMark RamosNo ratings yet

- N67 MNT F41: Air InductionDocument3 pagesN67 MNT F41: Air InductionHabineza RemyNo ratings yet

- Ece Lab Manual - MiteDocument44 pagesEce Lab Manual - MiteSubuddhi DamodarNo ratings yet

- Working As A Mechanical EngineerDocument13 pagesWorking As A Mechanical EngineerNikita PawarNo ratings yet

- A Polyhydron Group Company: Pilot Operated Check Valve Modular Construction Model: CIM10Document2 pagesA Polyhydron Group Company: Pilot Operated Check Valve Modular Construction Model: CIM10mdkhandaveNo ratings yet