Professional Documents

Culture Documents

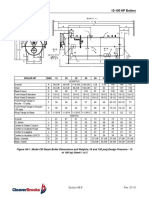

Model CB 15-100 HP Boilers

Uploaded by

sebaversaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model CB 15-100 HP Boilers

Uploaded by

sebaversaCopyright:

Available Formats

Model CB 15-100 HP Boilers

include two manual shut-off valves, solenoid valve, pressure regulator and

pressure gauge.

c. Oil Pump - An oil pump set with a capacity of approximately twice the

maximum burning rate shall be included.

A separate motor driven pump set shall be included shipped loose for

location favorable to the oil storage tank.

d. Oil Burner Piping - A fuel oil controller combining all of the fuel oil controls

into a single casing shall be provided. Oil pressure regulating devices, oil

metering controls, solenoid shutoff valves, high and low oil temperature

switches and necessary pressure and temperature gauges shall be included

in this packaged assembly mounted on the front door of the boiler. A fuel

strainer shall also be provided, mounted to the boiler. A single tip retractable

nozzle shall be used for the low pressure air atomizing burner. Flexible hoses

shall be provided to allow easy removal of the nozzle for inspection when it is

placed in the vice jaws located on the front door of the boiler.

The metering valve shall permit circulation of hot oil to the burner at all times.

The burner drawer oil piping and nozzle shall be purged of oil on each

shutdown.

For 70 through 100 hp, a low oil pressure switch shall be included in the oil

piping.

e. Low Pressure Air Atomizing

1) 50 through 100 hp. Separate air compressor module mounted on boiler

base rail with low atomizing air pressure switch.

f. Oil Preheat

The oil shall be preheated by a safety type water-to-water-to-oil preheating

system in conjunction with an electric preheater, each with thermostatic

control. Both heaters shall be mounted, piped, and wired on the boiler.

1) 50 through 100 hp. Electric preheater size shall be 5 kW.

7. Fuel Series 400 - No. 6 Oil or Gas Fired

a. Burner Type - The burner shall be integral with the front head of the boiler

and shall be a combination of the low pressure atomizing type for oil and high

radiant multi-port type for gas. The burner shall be approved for operation

with either CS12-48 Commercial No. 6 oil or natural gas.

b. Gas Pilot - The gas pilot shall be a premix type with automatic electric

ignition. An electronic detector shall monitor the pilot so that the primary oil

valve cannot open until pilot flame has been established. The pilot train shall

include two manual shut-off valves, solenoid valve, pressure regulator and

pressure gauge.

8. Oil Burner

a. Oil Pump - An oil pump set with a capacity of approximately twice the

maximum burning rate shall be included.

b. Oil Burner Piping - A fuel oil controller combining all of the fuel oil controls

into a single casing shall be provided. Oil pressure regulating devices, oil

metering controls, solenoid shutoff valves, high and low oil temperature

switches, and the necessary pressure and temperature gauges shall be

included in this packaged assembly mounted on the front door of the boiler.

A fuel strainer shall also be provided, mounted to the boiler. A single tip

retractable nozzle shall be used for the low pressure air atomizing burner.

Section A6-53 Rev. 07-10

Model CB 15-100 HP Boilers

Flexible hoses shall be provided to allow easy removal of the nozzle for

inspection when it is placed in the vice jaws located on the front door of the

boiler. The metering valve shall permit circulation of hot oil to the burner at all

times. The burner drawer oil piping and nozzle shall be purged of oil at each

shutdown.

For 70 through 100 hp, a low oil pressure switch shall be included in the oil

piping.

9. Low Pressure Air Atomizing

a. 50 through 100 hp. Separate air compressor module mounted on boiler base

rail with low atomizing air pressure switch.

10. Oil Preheat

The oil shall be preheated by a safety type water-to-water-to-oil preheating

system in conjunction with an electric preheater, each with thermostatic control.

Both heaters shall be mounted, piped, and wired on the boiler. Select one of the

following:

a. 50 through 100 hp. Electric preheater size shall be 5 kW.

11. Gas Burner

a. Gas Burner Piping - Gas burner piping on all units shall include pressure

regulator, primary gas shutoff valve, motor operated with proof of closure

switch and plugged leakage test connection. The main gas valve(s) shall be

wired to close automatically in the event of power failure, flame failure, low

water or any safety shutdown condition. A lubricating plug cock or butterfly

shutoff valve shall be provided as means for a tightness check of the primary

shutoff valve. An additional plug cock or butterfly valve shall be furnished at

entrance to gas train. Select one of the following:

1) 50 hp. Burner equipped as shown above.

2) 60 through 100 hp. High and low gas pressure switches shall be

provided.

3) Burner Turndown - Turndown shall be 4:1.

D. Boiler Flame Safeguard Controller and Control Panel

1. CB780E Flame Safeguard

2. 4.5.1.1 Boilers with CB780E Control - Each boiler shall be factory equipped with

flame safeguard controller providing technology and functions equal to the

Cleaver-Brooks Model CB780E.

Controller shall be computerized solid state having sequence and flame-on lights

and digital “first out” fault code indications of flame safeguard trip functions. It

shall include dynamic self-check logic. The controller shall have a fixed operating

sequence incapable of being manually altered. The sequence shall include start,

pre-purge, pilot and main fuel ignition run and post-purge cycles.

Controller shall be the non-recycle type for maximum safety that shall shutdown

the burner and indicate as a minimum the following trip functions: pilot and main

flame failure, high and low fire proving switch faults, running interlocks open,

false flame signal and fuel valve open (when proof of closure switch is furnished).

The controller shall have a run/test switch. It shall allow interruptions to sequence

just after pre- purge, during pilot ignition trial and run cycles for adjustments to

firing rate motor, damper linkages and pilot flame for minimum turndown tests.

Section A6-54 Rev. 07-10

Model CB 15-100 HP Boilers

3. Control Panel: The control panel shall be mounted on the front door of the boiler

in a location convenient to the operator. The hinged metal cabinet will have

NEMA 1A rating that includes a neoprene dust seal and a Yale cabinet key type

lock.

The panel shall contain the boiler flame safeguard controller, blower motor

starter, indicating lights and selector switches.

The panel shall have a removable sub-base for mounting the flame safeguard

controller, blower motor starter, and terminal blocks. For combination gas-oil and

heavy oil fired boilers the panel will contain the fuel selector and/or oil heater

selector switch.

The panel shall contain the following lights and switches:

a. Lights

• White - load demanded.

• White - fuel valve open.

• Red - low water.

• Red - flame failure.

b. Control Switches

• Burner On-Off.

• Manual-Automatic.

• Manual Firing Rate Control.

4. Oil, heat and moisture resistant wire shall be used and identified with circuit

numbers corresponding to the electrical wiring diagram.

5. All electrical equipment and wiring shall be in conformance with Underwriters

Laboratories requirements.

6. Boiler to be supplied with a control circuit transformer and fuse protection for the

control circuit.

7. Control Panel: The control panel shall be mounted on the front door of the boiler

in a location convenient to the operator. The hinged metal cabinet will have

NEMA 1A rating that includes a neoprene dust seal and a Yale cabinet key type

lock.

The panel shall contain the boiler flame safeguard controller, indicating lights and

selector switches.

Panel shall have a removable sub-base for mounting the flame safeguard

controller, and terminal blocks. For combination gas-oil and heavy oil fired boilers

the panel will contain the fuel selector and/or oil heater selector switch.

8. Oil, heat, and moisture resistant wire shall be used and identified with circuit

numbers corresponding to the electrical wiring diagram.

9. All electrical equipment and wiring shall be in conformance with Underwriters

Laboratories requirements.

10. Boiler to be supplied with a control circuit transformer and fuse protection for the

control circuit.

Section A6-55 Rev. 07-10

Model CB 15-100 HP Boilers

1.08 Efficiency Guarantee

The boiler manufacturer shall guarantee that, at the time of startup, the boiler will achieve

_____ fuel-to-steam efficiency at 100% firing rate when burning natural gas and _____

fuel-to-steam efficiency at 100% firing rate when burning oil (add efficiency guarantees at

25%,

50%, and 75% of rating, if required). If the boiler(s) fail to achieve the corresponding

guaranteed efficiency as published, the boiler manufacturer will rebate, to the ultimate

boiler owner, five thousand dollars ($5,000) for every full efficiency point (1.0%) that the

actual efficiency is below the guaranteed level.

The specified boiler efficiency is based on the following conditions.

A. Fuel specification used to determine boiler efficiency:

1. Natural Gas

Carbon, % (wt) = 69.98

Hydrogen, % (wt) = 22.31

Sulfur, % (wt) = 0.0

Heating value, Btu/lb = 21,830

2. No. 2 Oil

Carbon, % (wt) = 85.8

Hydrogen, % (wt) = 12.7

Sulfur, % (wt) = 0.2

Heating value, Btu/lb = 19,420

3. No. 6 Oil

Carbon, % (wt) = 86.6

Hydrogen, % (wt) = 10.9

Sulfur, % (wt) = 2.09

Heating value, Btu/lb = 18,830

B. Efficiencies are based on ambient air temperature of 80 °F, relative humidity of 30%,

and 15% excess air in the exhaust flue gas.

C. Efficiencies are based on manufacturer’s published radiation and convection losses.

(For Cleaver-Brooks radiation and convection losses, see Boiler Efficiency Facts

Guide, publication number CB-7767).

D. Any efficiency verification testing will be based on the stack loss method.

1.09 Warranty

A. All equipment is to be guaranteed against defects in materials and/or workmanship

for a period of 12 months from date of start-up or 18 months from date of shipment,

whichever comes first.

Section A6-56 Rev. 07-10

Model CB 15-100 HP Boilers

EXECUTION

2.01 Shop Tests

A. The packaged boiler must receive factory tests to check the construction, controls,

and operation of the unit. All tests may be witnessed by the purchaser, if desired.

B. Start-up Service

1. After boiler installation is completed, the manufacturer shall provide the services

of a field representative for starting the unit and training the operator at no

additional costs.

a. A factory approved and authorized start-up report shall be submitted to the

customer/user at the time of start-up.

Section A6-57 Rev. 07-10

You might also like

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBLE 100-800 HP BoilersDocument4 pagesModel CBLE 100-800 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- CBEX Elite 100-800 HPDocument4 pagesCBEX Elite 100-800 HPsebaversaNo ratings yet

- 60 PPM Nox Operation Natural Gas: CBEX Elite 100-800 HPDocument4 pages60 PPM Nox Operation Natural Gas: CBEX Elite 100-800 HPsebaversaNo ratings yet

- CBEX Elite 100-800 HPDocument4 pagesCBEX Elite 100-800 HPsebaversaNo ratings yet

- CBEX 350 To 800 HorsepowerDocument4 pagesCBEX 350 To 800 HorsepowersebaversaNo ratings yet

- Boiler SpecificationsDocument25 pagesBoiler Specificationspaul kioiNo ratings yet

- Series 500 Water SpecDocument5 pagesSeries 500 Water SpecChristhofer Arroyo ChacónNo ratings yet

- Series 4vt Steam SpecificationsDocument5 pagesSeries 4vt Steam Specificationsagusti24No ratings yet

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 pagesModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 pagesModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNo ratings yet

- Model 4WI 100 - 800 HP Boilers: WarrantyDocument4 pagesModel 4WI 100 - 800 HP Boilers: WarrantysebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: LightsDocument5 pagesModel CB 15-100 HP Boilers: LightssebaversaNo ratings yet

- Hurst Boiler & Welding Co., IncDocument4 pagesHurst Boiler & Welding Co., IncChristian Veliz CamargoNo ratings yet

- 2MW Turbine EnquiryDocument7 pages2MW Turbine EnquiryRamu MaddiNo ratings yet

- SECTION 15550 Hot Water Boilers Part 1 - General 1.1 Related DocumentsDocument13 pagesSECTION 15550 Hot Water Boilers Part 1 - General 1.1 Related DocumentsMunir RasheedNo ratings yet

- Tech Spec of Nitrogen InjectionDocument5 pagesTech Spec of Nitrogen InjectionJustin MyersNo ratings yet

- SPEC Model CB Steam Jan11Document12 pagesSPEC Model CB Steam Jan11Stanford BrownNo ratings yet

- Spec Modelcble Steam Mar4Document12 pagesSpec Modelcble Steam Mar4Jason PoloNo ratings yet

- Gas Detection SpecDocument4 pagesGas Detection Specinfo5922No ratings yet

- Section A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Document4 pagesSection A1 Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)sebaversa100% (1)

- Fire Protection and Suppression SystemDocument4 pagesFire Protection and Suppression Systemamrit90320No ratings yet

- Hurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDocument5 pagesHurst Boiler & Welding Company, Inc.: SERIES 500 STEAM BOILER (100-1500 HP, STEAM 15-300 Psig) Sample SpecificationsDaniel GonzalezNo ratings yet

- PplantDocument18 pagesPplantriyadhovicNo ratings yet

- DY DUPLEX SPECS 4-21-2010 Doc REV 3-1Document3 pagesDY DUPLEX SPECS 4-21-2010 Doc REV 3-1Josef MadronaNo ratings yet

- 9 IriDocument2 pages9 IriEnrique PauliniNo ratings yet

- Model Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Document12 pagesModel Cb-Le Steam Boiler Specifications (125-800 HP, STEAM 15-300 PSIG)Diogenes Rafael TorresNo ratings yet

- Eca Day Tank SpecDocument3 pagesEca Day Tank Specenlightened1718No ratings yet

- Engineer'S Specification Fuel Oil Day Tank 1.0 1.1Document4 pagesEngineer'S Specification Fuel Oil Day Tank 1.0 1.1Ladapo OladipupoNo ratings yet

- 43-4002 - Fuel Oil SupplyDocument4 pages43-4002 - Fuel Oil Supplydebu1985No ratings yet

- SPEC ModelCBR Steam Mar4Document10 pagesSPEC ModelCBR Steam Mar4Jason PoloNo ratings yet

- 1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance ParametersDocument8 pages1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance Parametersعامر شیخNo ratings yet

- Gs 18ms 1pdDocument11 pagesGs 18ms 1pdRitesh JhaNo ratings yet

- CB CBLE HW SpecsDocument11 pagesCB CBLE HW SpecsDiogenes Rafael TorresNo ratings yet

- CSI Spec EXN-SGO-07Document5 pagesCSI Spec EXN-SGO-07davidvranaNo ratings yet

- Burner Logic System PDFDocument5 pagesBurner Logic System PDFshiviitd02No ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Heavy Oil or Similar Firing Systems With Rotary Cup Atomizer BurnersDocument2 pagesHeavy Oil or Similar Firing Systems With Rotary Cup Atomizer Burners徐玉坤No ratings yet

- Section A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)Document4 pagesSection A1 Model Cb-Le Hot Water Specifications (125-800 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Tech Spec Guvnl-NffesDocument9 pagesTech Spec Guvnl-NffesShantanu DasNo ratings yet

- Scanboilerr TextDocument7 pagesScanboilerr TextAntonio AvilesNo ratings yet

- Diesel Pump Check ListDocument3 pagesDiesel Pump Check Listபிரபாகரன் மீண்டும் வருவான்No ratings yet

- Turn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsDocument18 pagesTurn Key Steam Boilers System Section 1 1.00 - GENERAL 1.01 Related DocumentsKarim Galal IsmailNo ratings yet

- Quinta Pro Range Suggested SchematicsDocument32 pagesQuinta Pro Range Suggested SchematicsAnonymous CRQ100100% (2)

- 28 Electro-Mechanical RegulatorsDocument2 pages28 Electro-Mechanical Regulatorsgenma2286No ratings yet

- APHDocument1 pageAPHsai987650No ratings yet

- Fluid Power & Tribology Section Refuelling Technology Division Bhabha Atomic Research Centre Trombay, Mumbai - 85Document28 pagesFluid Power & Tribology Section Refuelling Technology Division Bhabha Atomic Research Centre Trombay, Mumbai - 85rkp17No ratings yet

- Boiler Operation and Safety PrecautionDocument66 pagesBoiler Operation and Safety PrecautionSahil Mishra100% (1)

- Details Mentioned in DPR For BoilerDocument3 pagesDetails Mentioned in DPR For BoilershivendupadteNo ratings yet

- Chapter 13heating ControlsDocument30 pagesChapter 13heating ControlsGhada OrabiNo ratings yet

- Oil Circulation Tank 674 GB Register 7Document6 pagesOil Circulation Tank 674 GB Register 7hendraNo ratings yet

- AC-300 - Water Cooled Liquid ChillerDocument11 pagesAC-300 - Water Cooled Liquid Chillerjames_chan2178No ratings yet

- HPLP Bypass SystemDocument16 pagesHPLP Bypass SystemRakesh Kiran100% (1)

- Anhydrous Ammonia Vaporizer SystemDocument2 pagesAnhydrous Ammonia Vaporizer Systemavinash-mokashiNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Model CB 15-100 HP Boilers: LightsDocument5 pagesModel CB 15-100 HP Boilers: LightssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 pagesModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocument5 pagesModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- Research ArticleDocument9 pagesResearch ArticlesebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 pagesModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: Performance DataDocument4 pagesModel ICB 100-800 HP Boilers: Performance DatasebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizeDocument4 pagesModel ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizesebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- DT60-DT70S (50 HZ)Document3 pagesDT60-DT70S (50 HZ)Md ShNo ratings yet

- Benzene: Chemical Economics HandbookDocument3 pagesBenzene: Chemical Economics HandbookMaría VásquezNo ratings yet

- Fuel Leak DetectionDocument4 pagesFuel Leak Detectionocduran42004No ratings yet

- Linear Alkylbenzene (Lab) Manufacture: Andrea BozzanoDocument12 pagesLinear Alkylbenzene (Lab) Manufacture: Andrea BozzanoBharavi K SNo ratings yet

- Practice Problems Set1 WithAnswersDocument3 pagesPractice Problems Set1 WithAnswersMukul ChandraNo ratings yet

- Roper Serie 3600 PDFDocument2 pagesRoper Serie 3600 PDFantonioNo ratings yet

- Char-Broil 463439915 Assembly Manual, English, SpanishDocument48 pagesChar-Broil 463439915 Assembly Manual, English, SpanishAnonymous ijZ3W6JxT9No ratings yet

- PETE 323: Reservoir Models: EOR NotesDocument59 pagesPETE 323: Reservoir Models: EOR NotesJasmin Suko S.Pd.MMNo ratings yet

- Ingersoll Rand Air StarterDocument24 pagesIngersoll Rand Air Startermath62210No ratings yet

- UOP 163-10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitratDocument7 pagesUOP 163-10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitratBalas43100% (2)

- Demco Valves PDFDocument30 pagesDemco Valves PDFGhassan Ilias Alkiki100% (3)

- Brosur Lintech LNG ISO Tank & Other Pressure VesselDocument6 pagesBrosur Lintech LNG ISO Tank & Other Pressure VesselAndi NugrohoNo ratings yet

- F839-15 Standard Specification For Cautionary LabelingDocument3 pagesF839-15 Standard Specification For Cautionary LabelingAhmed AlzubaidiNo ratings yet

- Gulliver RGDF - TS0063UK00 PDFDocument16 pagesGulliver RGDF - TS0063UK00 PDFCarlos Castillo UrrunagaNo ratings yet

- Deepwater Horizon Blowout Preventer Failure Analysis PDFDocument83 pagesDeepwater Horizon Blowout Preventer Failure Analysis PDFHosamMohamed50% (2)

- Brayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsDocument15 pagesBrayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsmechturboNo ratings yet

- Gabungan Desulfurisasi Ta1Document75 pagesGabungan Desulfurisasi Ta1Rizki MuharomNo ratings yet

- Welder BrochureDocument2 pagesWelder Brochureanon-90168100% (2)

- Olp Gce Mech & Heat CT 5Document20 pagesOlp Gce Mech & Heat CT 5Shabbir H. KhanNo ratings yet

- QRA of LPG PlantDocument54 pagesQRA of LPG PlantAbdul RahmanNo ratings yet

- Charcoal Consumption Reduction Through AlternativesDocument29 pagesCharcoal Consumption Reduction Through AlternativesAhmedNo ratings yet

- Leak Test and VacuumDocument2 pagesLeak Test and VacuumLinh TruongNo ratings yet

- CDI 6 (Fire)Document12 pagesCDI 6 (Fire)Christopher PerazNo ratings yet

- Duri Crude Oil PropertiesDocument8 pagesDuri Crude Oil PropertiesBayu Ajip100% (1)

- Belzona 1391S: Instructions For UseDocument2 pagesBelzona 1391S: Instructions For UseimtiazNo ratings yet

- Dimensions: Guascor SFGLD 560 Lean Burn GensetDocument2 pagesDimensions: Guascor SFGLD 560 Lean Burn GensetTithy MoniNo ratings yet

- De Thi Thu Hai PhongDocument4 pagesDe Thi Thu Hai PhongHa NgoNo ratings yet

- Fire TriangleDocument45 pagesFire TriangleRosalina Caluscosin Gramay50% (10)

- InterlocksDocument26 pagesInterlocksFelipe SandovalNo ratings yet

- Blade 360 Sensor Posicion Rotativo SensovantDocument2 pagesBlade 360 Sensor Posicion Rotativo SensovantGianfranco JulcaNo ratings yet