Professional Documents

Culture Documents

List of Common Points 21.02.2018 (R2) PDF

Uploaded by

abdullah amanullahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

List of Common Points 21.02.2018 (R2) PDF

Uploaded by

abdullah amanullahCopyright:

Available Formats

Common Points agreed for all Bidders

Based on the discussion with various Bidders during the last week, the below mentioned

points shall supersede the requirement mentioned elsewhere in the Tender Document:

Mechanical & Process and General:

1) Bidder Scope shall start from OLBC (Over Land Belt Conveyor) from mines area to plant

premises. Equipment for feeding of Limestone on this OLBC conveyor shall be in Client

Scope. The feeding of limestone on OLBC may contain single or multiple feed points say

about 6 to 8. P&V system for tunnel (if required) is also in Client scope. Pollution Control

equipment for feed points shall be also under client scope. However, Pollution control

equipments for Transfer Towers shall be considered in Bidder Scope.

2) A Belt Magnetic Separator and metal detector with sand bag marker to be provided on the

OLBC Conveyor in the Mines area by the Bidders. Also belt weigher shall be considered

for measuring the instant and cumulative quantity of limestone

3) Max speed for OLBC (over land belt conveyor from mines to plant) shall be 1.6m/sec. Belt

for OLBC shall be of steel cord type. Downward inclination of OLBC shall not be more than

12 deg. Max size of feed material shall be 90 mm.

4) Un-obstructed Vehicle movement under the OLBC conveyor near the Transfer Tower

(near Diverter) has to be ensured. As far as possible, the OLBC conveyor to be kept along

the extreme end of the boundary of the quarry so that we have sufficient space for vehicle

movement and OLBC does not obstruct any vehicle movement in future. Bidder may

consider clear passage of 5 meter at 2 – 3 location under this conveyor for mines vehicle

movement in future.

5) Troughing angle of 35 deg may be used for all belt conveyors.

6) Only Provision of installation of an additional BRU for feeding the Limestone in Stacker to

be kept by Bidders. BRU for Limestone shall not be supplied now.

7) Dust Suppression System (Water Spray / Foam Spray) shall be considered for all

stockpiles throughout the stockpile length.

8) Dust suppression has to be provided for BRUs and other discharge chutes, if bag filter is

not able to achieve the guarantee emission.

9) An Electro-magnet with monorail and metal detector with sand bag marker to be provided

before the additive / coal / petcoke crusher. Metallic particle from Electro-magnet shall be

List of Common Points 21.02.2018 (R2) 1/11 Contract

Common Points agreed for all Bidders

removed by moving the magnet away from respective belt conveyor and then de-

magnetizing it. Metallic pieces detected by Metal Detector shall be manually removed

10) An Electro-magnet with monorail has to be considered on all the three Reclaimer Belt

Conveyor i.e. for Limestone, additives and coal / petcoke. Metallic particle from Electro-

magnet shall be removed by moving the magnet away from respective belt conveyor and

then de-magnetizing it.

11) Fly ash Silo and Bed Ash Silo, feeding of Flyash and Bed ash in their respective Silos, top

venting bag filters, Aeration System for Fly ash Silo and Bed Ash Silo, any conditioning

system and disposal system for Bedash and flyash shall be excluded from Bidders Scope.

These excluded items shall be supplied by CPP Supplier. Bidders to consider only the

extraction system for Bed Ash and Flyash for feeding the same in the Raw Mix, in

their scope.

Bidder to give both the options i.e. for locating the Flyash silo near proportioning hopper

for feeding on to Raw Mix feed belt as well as near the V-separator / VRM along with

complete extraction and feeding arrangement for flyash.

Bidder to note that the max particle size of bedash may be 10mm and bedash temperature

will be around 150 – 200 degC. Bedash Silo will be located near Proportioining Hoppers

Building only.

Steel Structure building for flyash and bed ash Silo will be also excluded from Bidder

Scope. The Bedash Silo building will be kept away from Raw Mill Proportioning Hopper

Building whereas Flyash silo wll be kept away from Raw Mill Proportioning Hopper

Building / Mill Building.

12) Bidders to provide the Raw Mix design for utilizing the Bed Ash and Flyash generated from

the CFBC Boiler.

13) Bidders to refer the Bed ash and Flyash analysis enclosed herewith for designing the Raw

Mix with utilization of Bed ash and Fly ash in the Raw Mix.

14) Raw Mill and Kiln Bag House and Cooler Bag House – shall have N+2 chambers (1

additional chamber for online maintenance and one additional chamber for offline

maintenance). Coal Mill Bag House – shall have only N chambers.

15) Max Bag Height of 6m is acceptable for process bag houses only.

List of Common Points 21.02.2018 (R2) 2/11 Contract

Common Points agreed for all Bidders

16) Kiln Feed Bin can be located outside the Blending Silo, as desired by some Bidders.

17) Coal / Petcoke Mill capacity shall be as follows:

a) Petcoke 19 TPH @ 2% R on 90micron with HGI 40.

b) Coal (Bidder to mention) TPH @ 12% on 90 micron with HGI 50. Minimum

capacity should be 25 TPH for Coal Grinding.

Performance curves shall be provided by the Bidders for different valves of HGI along

with their Bids.

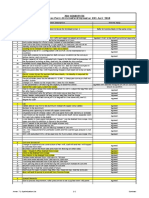

18) During discussion, there was confusion regarding the design capacities of various

equipments. Please note the followings for clarity:

Rated Remarks

DEPARTMENT / EQUIPMENT Capacity

Main Machinery

Belt Conveyor from Mines to Plant

2000 TPH

Premises

Limestone Stacker 2000 TPH

Limestone Re-claimer 750 TPH

Bulk Receiving Unit for Additives 400 TPH

Additives Crusher (Assuming 30% fines) 275 TPH

Additive Stacker 400 TPH

Additive Re-claimer 200 TPH

Bulk Receiving Unit for S. A. Coal /

200 TPH

Petcoke

Coal / Petcoke Stacker 400 TPH

Coal / Petcoke Re-claimer 100 TPH

Raw Mill (VRM) 275 TPH

Bag House for Raw Mill & Kiln

To Suit

(Pulse Jet type)

Kiln Feed 300 TPH

List of Common Points 21.02.2018 (R2) 3/11 Contract

Common Points agreed for all Bidders

Rated Remarks

DEPARTMENT / EQUIPMENT Capacity

__ TPH

(Coal)

Coal / Petcoke Mill (VRM)

19 TPH

(Petcoke)

Coal / Petcoke Conveying – Kiln Burner 11 TPH Consider

additional design

Coal / Petcoke Conveying – Pre-calciner

11 TPH margin of 15%

Burner

over and above

5-stage, single strand Pre-heater with in the rated

3000 TPD capacity.

line pre-calciner and low NOx burners

Rotary Kiln with three supports 3000 TPD

Grate

High efficiency Grate Cooler area > 80

m2

Bag House for Cooler To Suit

Clinker Transport to Clinker Silo top 250 TPH

2 x 300

Clinker Bulk Loading System

TPH

Clinker Bulk Loading System (Below Off 1 x 300

Spec. / Reject Clinker Silo) TPH

19) Shut-Off dampers for WHR System (Both PH and AQC Boiler) are now excluded from

Bidder’s Scope. Only control damper shall be provided in the pre-heater downcomer duct

by the Bidders.

20) Clinker Bulk Loading station shall be kept outside the Clinker Silo, with two nos. bulk

loading station, each having 2 no. bulk loading spouts, suitable to fill one open truck with

two loading spouts so that the two trucks can be loaded simultaneously. Deep Pan

Conveyors to be used for Clinker Silo Bulk Loading. Belt Conveyors not to be used for

Clinker Extraction. Considering daily dispatch of Clinker, 16hrs / day, the followings are to

be considered: Bin shall be with venting system and load cell.

• Capacity of Deep Pan Conveyors from Clinker Silo extraction to Bins = 350 TPH each.

• Capacity of Storage Bin for Bulk Loading = 250 MT each

List of Common Points 21.02.2018 (R2) 4/11 Contract

Common Points agreed for all Bidders

• Capacity of each Bulk Loading Spout = 300 TPH each

21) SNCR to be considered for achieving the guaranteed NOx emissions.

22) Provision shall be kept to feed the clinker from DPC of Unit-1 to Unit-II (Future) to their

respective Clinker Silos and vice versa.

23) HAG shall not to be considered and the same is removed from Scope of Bidders. Kiln Hot

gases shall be only used for initial start up of Raw Mill and Coal Mill.

24) Provision to be kept in the layout for installation of additional clinker stockpile in future.

25) Heat Balance Sheets to be provided by Bidders along with the Bids. Bidders to also

mention the amount of Waste Heat gases Available for WHRS from the pre-heater and

Cooler Mid Tap.

26) All Water Storage Tanks shall be constructed above ground.

27) R. O. Plant: The sizing of R. O. Plant should take care of the make-up water requirement

of Clinkerization Unit-1 (3000 TPD), Unit-2 (3000 TPD) and WHR & CPP. For WHRS and

CPP, the estimated make up water requirement is about 400 m3 / day. As per the cooling

water and process water requirement envisaged by each Bidder is concerned, the bidder

may re-size the R. O. Plant output capacity, if the 1000m3 / day specified in Tender

Document is inadequate.

28) R. O. Water generated from R. O. Plant shall be suitable for production of DM water for

CPP and WHRS Boilers.

29) Minimum Water Tank Capacities shall be considered as follows:

a) Raw Water Storage Tank (Double Chamber) – Around 2 day requirement of makeup

raw water. (Approx 3500 m3).

b) Dedicated Storage Tank for Fire Fighting – 250 m3. (Combined with Raw Water

Tank)

c) Storage Tank for R. O. Water – 500 m3.

d) Water Tank for Return Water from Cooling Tower – 500 m3.

30) Material of Construction for Fire Fighting Water Pipelines shall be Cast Iron (CI).

31) Material of construction for Raw Water Pipelines shall be UPVC / HDPE.

List of Common Points 21.02.2018 (R2) 5/11 Contract

Common Points agreed for all Bidders

32) Cranes / Monorail / Electric Hoist shall be provided for maintenance of all equipments.

Envisaged list of Electric Hoist / Cranes / Monorail is attached herewith as Annexure-A.

33) Hot Dust Bin / Kiln Feed Bin should not be located in the area on the 1st Floor of the pre-

heater.

34) Raw Material Grinding Rollers shall be Studded / Turbomax / Compound casting type.

35) Provision for Alternative Fuel feeding in Pre-heater to be considered by all Bidders.

36) Fire Tender is not required and not to be considered by Bidder in their Scope.

37) Ambulance requirement during the construction period shall be taken care by Bidders.

38) All nuisance bag filters (open to sky) to be provided with roof top shed.

39) DG set to be excluded from Bidder Scope. Only DG set requirement (emergency power

requirement) shall be mentioned by the Bidder in their proposal.

40) Pressurized Ventilation shall be considered for Compressor House.

41) Residual Moisture in Fine petcoke can be <1% instead of <0.5% mentioned earlier in

Tender Document.

42) Max Noise level mentioned as 50dB shall be measured at the Compound Wall.

43) Fluid coupling shall be provided for all auxiliary equipments > 37kW instead of 22kW

mentioned earlier in Tender Document (Clause 5.9 of Section-5).

44) In case of fluid coupling service factor shall be 1 on motor rating.

45) Belt Conveyors – 1 No. ZSS shall be provided at tail pulley only, instead of all pulleys

except drive pulley mentioned earlier in Tender Documents (Page -3 of Annexure-5A).

46) For small belt conveyors with motor rating < 9.3kW, geared motor can be considered.

47) Bucket Elevators:

a) Max speed for Chain Bucket Elevators (Single Bucket) – 1.4 to 1.7 m/sec

b) Max speed for Chain Bucket Elevators (Double Bucket) – 1.4 m/sec

c) Max Speed for Belt Bucket Elevators – 1.8 m/sec

48) Max pressure drop across process and nuisance bag filter shall be max 150 mmWG.

49) Capacity of the Passenger Lift for pre-heater shall be 1 MT.

List of Common Points 21.02.2018 (R2) 6/11 Contract

Common Points agreed for all Bidders

50) Circular Platform for chimney shall be provided at the area / level where instruments are

located, instead of every 10m. Kiln Exhaust Chimney shall be insulated where instruments

are located / wherever personnel movement is there from safety point of view.

51) Annexure – 7B of Tender Document: Kindly note the followings:

a) Refer S. No. 3: Digital Compression Testing Machine (Qty-1 No.) – Capacity shall be

revised to 500kN from earlier mentioned capacity of 250kN.

b) Refer S. No. 7: Flexure Testing Machine (Qty - 1 no.) – Not required now.

c) Refer S. No. 8: Mould for Flexural Prism, Steel, three compartments 40 x 40 x 160mm

with one spreader (Qty 1 set) – Not required now.

52) Minimum Capacity of Weigh Feeders to be considered as follows:

a) Limestone: 28.5 – 285 TPH

b) Shale: 6.5 – 65 TPH

c) Bauxite and Iron Ore : 1 – 10 TPH

53) Liners: Kindly note the followings for the Liners:

a) Arcoplate1600D shall be used for all Raw Material Chutes, all Raw Material

Proportioning Hoppers (Conical portion), Rejects Bins (Conical portion), Kiln Feed Bin

(Conical Portion), Raw Coal Hoppers (Conical Portion) and Coal discharge chutes.

Acroplate 8668 shall be used for conical portion of Hot Dust Bin, Off Spec Silo, Clinker

Bins and Clinker discharge chutes. Minimum thickness to be kept as 12mm.

b) For Fine Coal Handling bins SS410 (3.15mm thick) to improve flow-ability.

c) Liners for various equipment like Raw Mill / Roll Press, Process duct from separator to

Cyclones in Raw Mill Circuit, Coal Mill, Mill chute, Separators, Cyclones, Fans, B.E.

etc. shall be as per Bidder's standard.

54) Guarantee Capacity of Kiln for the PGT shall be demonstrated on the normal Kiln rpm and

not the Max kiln rpm. All Bidders to confirm the same in their Bids.

55) Except for Environmental Clearances shall be obtained by the Client, all other clearances

in Fujairah is to be taken by Bidders. This is to be confirmed by Bidders in their Bids.

List of Common Points 21.02.2018 (R2) 7/11 Contract

Common Points agreed for all Bidders

CIVIL:

1) Detailed Soil Investigation work will be under scope of the Bidder. Soil Investigation Report

enclosed in the Tender Document was only for reference. Actual design shall be based on

the Final Soil Investigation Report to be done by Bidders.

2) No grade slab to be provided inside Clinker silo.

3) Bidders to provide their QA / QC policy in line with the Tender.

4) Bidders to provide their HSE policy.

5) All construction drawings to be provided in soft copies with 1 hard copy (excluding copies

required for Civil contractor).

6) Land scaping work has been taken out from the scope of work of bidders.

7) Boundary wall and gate complex will be provided with drain along boundary wall only in

the region of mines.

8) Furniture & interior of non-plant building has been taken out of scope of work of Bidders.

9) All structural steel members will be painted with anti-rust paint after sand treatment.

10) All foundation will have polythene cover required at bottom of foundation.

11) All foundation will have Bituminous paint.

12) Non-plant buildings foundation will be provided with anti-termite treatment.

13) No cable trench in to be provided as either it is cable cellar or over head cable gallery.

14) It has been decided that cladding in form of louvers to be provided for the buildings to

protect equipments from rain and excessive heat. The louvers shall start at 1.5 m to 2.0 m

above the floor.

15) Non plant buildings: The tentative sketches are enclosed herewith for reference purpose

only.

List of Common Points 21.02.2018 (R2) 8/11 Contract

Common Points agreed for all Bidders

E&I:

1) Total connected load and maximum demand shall be furnished in line with the maximum

power guarantee being offered.

2) Cooler fans shall be 12 pulse type only using three winding transformer 11/0.4/0.4KV with

double busbar arrangement as shown in the tender drawing to reduce the harmonics

3) As per tender specifications, the following shall be followed

• Fixed speed motors – Below 250KW -380V, 250KW and above 11KV

• VFDs – Less than 400KW -380V,, 6 pulse, 400 to 800KW – 690V, 12 pulse, >800

KW – 11 KV, 36 pulse type

4) 1 more 11 KV feeder shall be added on the main 11 KV switch board for Lime stone belt

conveyors of 2 KM length and distribute to conveyor motors , bag filters, lighting and

welding loads using step down transformers to get 380V and then through a MCC feed all

LV loads.

5) Soft starter with bypass shall be considered for all 90 KW and above rating motors

irrespective of fluid couplings used for belt conveyors and bucket elevators etc.

6) 11 KV incoming cable of suitable length suitable for 2 no. 3000 tpd clinkerisation units

including the future plant, from CPP board shall be in your scope only.

7) All power cables shall be copper conductor only.

8) All lighting fittings shall be with LED lamps only.

9) In the makes of E&I equipment, only OEMs shall be considered and not system houses as

mentioned in your offer.

10) Emergency load list shall be furnished and required DG set capacity shall be furnished.

JSW propose to use the DG set of CPP and hence separate DG set for cement plant may

not be required. However, to include the power cable from DG set of CPP to your

emergency MCC.

11) 11 KV cables shall be 11 KV(UE) type as CPP generator neutral is earthed through

resistance. Also for 690V cables, 1.1 KV(UE) cable shall be considered

12) For earthing design, soil resistivity shall be measured at site and design accordingly

List of Common Points 21.02.2018 (R2) 9/11 Contract

Common Points agreed for all Bidders

13) For earthing and lightning protection, copper materials only shall be considered to meet

local regulations.

14) Power cable tray filling shall be limited to 60% only as per tender

15) Statutory approvals from FEWA etc for power system shall be included in your scope only

and Purchaser shall provide necessary help to the Supplier.

16) Construction power shall be by DG sets of Supplier only

17) No price implication for any changes in the tender document quantities as it is a EPC

contract and Supplier shall supply as per final requirement during detail engineering as

necessary for process control and to meet all local regulations

18) Distribution transformers shall have taps up to +/- 7.5% in place 5%

19) Distribution transformers shall have 30% margin as per tender specification.

20) Electric braking shall be considered for kiln, separator drives

21) Pull chord switches shall be with indication lamps for identification of operated switch.

22) Load break switches near the motors shall be considered to meet local regulations. Local

PB station may be combined with load break switch.

23) All safety items like rubber mats, sand buckets, safety charts, fire extinguishers, danger

notice boards etc for all substations, electrical rooms etc shall be included as it is EPC

contract.

24) CEMS panels for all main chimneys with measurements as per local regulations and

connected on line to the pollution board shall be considered.

25) Wireless communications for stacker and reclaimer considered shall be with necessary

licence approvals from local authorities, which shall be in bidder’s scope.

26) For field instruments, profibus type with local indicators as far as available shall be

included

27) P&V is not required as it will not work at site. However, P&V shall be considered for

compressor room

28) Air conditioning shall be through split type for smaller areas and package type for larger

areas. There shall be one no. spare split type or package type in every area so that spare

one can be used when any of them is down for maintenance.

List of Common Points 21.02.2018 (R2) 10/11 Contract

Common Points agreed for all Bidders

29) Control desks for CCR, local control rooms, engineering rooms along with executive chairs

(8 nos.) shall be included

30) Cable earthing trolley, bus earthing trolley and breaker handling trolley 1nos each shall be

supplied along with switchboard.

31) Starters for Damper actuators shall be provided in MCC only and not near damper

actuator

32) Second engineering station shall be mobile lap top with the same configuration as that of

engineering station.

33) MCC feeder list shall include 20% spares for each type of module.

34) Each IO rack shall have 20% wired IOs and space for adding 20% IOs in future

35) Licenses for all software used in control system and sub control system in original to be

included.

36) 16 /12 window 56” display for remote surveillance cameras shall also include 8 displays for

current process pages of the operating stations as per tender document

List of Common Points 21.02.2018 (R2) 11/11 Contract

You might also like

- Nonmetal Ducts - Guide Specification - Updated 6-2019Document17 pagesNonmetal Ducts - Guide Specification - Updated 6-2019abdullah amanullahNo ratings yet

- Aurora Fire PumpDocument8 pagesAurora Fire Pumpabdullah amanullahNo ratings yet

- Mohamed Anas.S: Job ObjectiveDocument3 pagesMohamed Anas.S: Job Objectiveabdullah amanullahNo ratings yet

- Sabb-Gray Water WsfuDocument22 pagesSabb-Gray Water Wsfuabdullah amanullahNo ratings yet

- CR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016Document5 pagesCR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016abdullah amanullahNo ratings yet

- New Indian Model School, Sharjah: Islamic Holidays' Assignment Primary SectionDocument1 pageNew Indian Model School, Sharjah: Islamic Holidays' Assignment Primary Sectionabdullah amanullahNo ratings yet

- Science Summer Break - Holiday Assignment 2019 - 20Document2 pagesScience Summer Break - Holiday Assignment 2019 - 20abdullah amanullahNo ratings yet

- L-4 Environment NotesDocument2 pagesL-4 Environment Notesabdullah amanullahNo ratings yet

- English Summer Break - Holiday Assignment 2019 - 20Document2 pagesEnglish Summer Break - Holiday Assignment 2019 - 20abdullah amanullahNo ratings yet

- Tamil (Second Language) Summer Break - Holiday Assignment 2019 - 20Document2 pagesTamil (Second Language) Summer Break - Holiday Assignment 2019 - 20abdullah amanullahNo ratings yet

- New Indian Model School, Sharjah: Holiday Homework Hindi - Grade 3Document3 pagesNew Indian Model School, Sharjah: Holiday Homework Hindi - Grade 3abdullah amanullahNo ratings yet

- 15730-DX Cooling Units Rev 01Document10 pages15730-DX Cooling Units Rev 01abdullah amanullahNo ratings yet

- Uae Social Studies Summer Break - Holiday Assignment 2019 - 20Document2 pagesUae Social Studies Summer Break - Holiday Assignment 2019 - 20abdullah amanullahNo ratings yet

- Revision SSTDocument2 pagesRevision SSTabdullah amanullahNo ratings yet

- PT2 Revision Worksheet EnglishDocument3 pagesPT2 Revision Worksheet Englishabdullah amanullahNo ratings yet

- Worksheet - WaterDocument2 pagesWorksheet - Waterabdullah amanullah100% (2)

- Sub Enrichment - Gr-3 - Our BodyDocument2 pagesSub Enrichment - Gr-3 - Our Bodyabdullah amanullahNo ratings yet

- Automatedmeterreadingtechnology PDFDocument5 pagesAutomatedmeterreadingtechnology PDFabdullah amanullahNo ratings yet

- AD R 004 Acoustic ReportDocument43 pagesAD R 004 Acoustic Reportabdullah amanullahNo ratings yet

- 0.list of Drawing - Lower LevelDocument1 page0.list of Drawing - Lower Levelabdullah amanullahNo ratings yet

- Technical Review Report: Applicant InformationDocument3 pagesTechnical Review Report: Applicant Informationabdullah amanullahNo ratings yet

- Annex 13 Exclusion ListDocument1 pageAnnex 13 Exclusion Listabdullah amanullahNo ratings yet

- A) Condition Unable To Understand Something: IV Match The MeaningsDocument2 pagesA) Condition Unable To Understand Something: IV Match The Meaningsabdullah amanullahNo ratings yet

- New Indian Model School, SharjahDocument2 pagesNew Indian Model School, Sharjahabdullah amanullahNo ratings yet

- Infrastructure Charges Notice CalculatorDocument1 pageInfrastructure Charges Notice Calculatorabdullah amanullahNo ratings yet

- Annex 11 List of Spare Parts For 2 Year OperationDocument16 pagesAnnex 11 List of Spare Parts For 2 Year Operationabdullah amanullahNo ratings yet

- 1 Extra External Piping Going To Each Lab MTR 250 100 25000.00 2 Extra Point For Kitchen MTR 50 20 1000Document5 pages1 Extra External Piping Going To Each Lab MTR 250 100 25000.00 2 Extra Point For Kitchen MTR 50 20 1000abdullah amanullahNo ratings yet

- 10.final Master Plan ParadipDocument128 pages10.final Master Plan Paradipabdullah amanullahNo ratings yet

- Deliverable SDocument2 pagesDeliverable Sabdullah amanullahNo ratings yet

- Annex 7.1 Optimization ListDocument5 pagesAnnex 7.1 Optimization Listabdullah amanullahNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rievtech Micro PLC Brochure PDFDocument37 pagesRievtech Micro PLC Brochure PDFjuan c. condori ch.No ratings yet

- EuroRig 350t BENTECDocument2 pagesEuroRig 350t BENTECEmanuel BreabanNo ratings yet

- Mitsubishi E700 Variable Frequency Drive (VFD) - BrochureDocument2 pagesMitsubishi E700 Variable Frequency Drive (VFD) - BrochureMROstop.comNo ratings yet

- Chapter 5 - Induction MotorDocument26 pagesChapter 5 - Induction MotorarifulNo ratings yet

- Electric Motors and Control Systems FRANK D. PETRUZELLADocument298 pagesElectric Motors and Control Systems FRANK D. PETRUZELLALc HiếuNo ratings yet

- MANUAL Vector VII Product Data Book - 8-15-09 FINALDocument38 pagesMANUAL Vector VII Product Data Book - 8-15-09 FINALOrlando MantillaNo ratings yet

- CD518 HV - HV SL - HV VFD - Sales Presentation - Rev1Document28 pagesCD518 HV - HV SL - HV VFD - Sales Presentation - Rev1Evanilson NogueiraNo ratings yet

- Protecting Submersible Motors From The Effects of PWM VoltageDocument6 pagesProtecting Submersible Motors From The Effects of PWM VoltagetareqNo ratings yet

- Revised Electrical Training Module Total 27 01Document102 pagesRevised Electrical Training Module Total 27 01aniket chaturvediNo ratings yet

- CV800 Series User Manual 16 Pages V1.5Document16 pagesCV800 Series User Manual 16 Pages V1.5Shafiqur RasulNo ratings yet

- Boq 4.3.14 .M FinalDocument16 pagesBoq 4.3.14 .M FinalSiam Hasan100% (1)

- W3 - Introduction To VFD AC DrivesDocument51 pagesW3 - Introduction To VFD AC DrivesBen RileyNo ratings yet

- Evapco O&M InstructionDocument52 pagesEvapco O&M InstructionYutt WattNo ratings yet

- Exploring Energy Auditing in Dairy IndustryDocument7 pagesExploring Energy Auditing in Dairy Industrymohit guptaNo ratings yet

- Partes Eléctricas de Emplayadora OrionDocument25 pagesPartes Eléctricas de Emplayadora OrionTony BravoNo ratings yet

- 5.0 - en-US - 2019-01 - TS - Flygt 3202Document60 pages5.0 - en-US - 2019-01 - TS - Flygt 3202FedeNo ratings yet

- Manual 166170Document37 pagesManual 166170Cristian Garcia100% (1)

- Project Documentation For Multilevel InvertersDocument89 pagesProject Documentation For Multilevel InvertersAnonymous hm7nSy1ebNo ratings yet

- GH Manual 2014Document24 pagesGH Manual 2014Krisvell ArmentaNo ratings yet

- CY62-40HP-4P-TCE-324T Datos MotorDocument8 pagesCY62-40HP-4P-TCE-324T Datos MotorraulNo ratings yet

- Index List - Material Requisition of Fire Water Pumps - IEIL OBSERVATION DT 06.04.19Document2 pagesIndex List - Material Requisition of Fire Water Pumps - IEIL OBSERVATION DT 06.04.19T Anees AHNo ratings yet

- DSP Controlled Inverter FedDocument16 pagesDSP Controlled Inverter FedARVINDNo ratings yet

- Challenges and Solutions of Protecting Variable Speed Drive Motors-NOTA TECNICADocument8 pagesChallenges and Solutions of Protecting Variable Speed Drive Motors-NOTA TECNICAEdgardo Kat ReyesNo ratings yet

- Electrical DrivesDocument4 pagesElectrical Drivesmanish_iitrNo ratings yet

- Hoyer Motors IE4 CatalogueDocument20 pagesHoyer Motors IE4 CatalogueGireeshNo ratings yet

- 5.0 en-US 2016-11 TS 3102 50Hz PDFDocument60 pages5.0 en-US 2016-11 TS 3102 50Hz PDFAlan CNo ratings yet

- Ijater 04 22 PDFDocument6 pagesIjater 04 22 PDFtamann2004No ratings yet

- Data Sheet 150 HP at 1800 RPM CTEDocument12 pagesData Sheet 150 HP at 1800 RPM CTEivan rodriguezNo ratings yet

- 9.all, More Electric Aircraft Engine & Airframe Systems Implementation, Bedek Aviation Group, Aircraft Programs Division, Israel Aerospace Industries, IsraelDocument48 pages9.all, More Electric Aircraft Engine & Airframe Systems Implementation, Bedek Aviation Group, Aircraft Programs Division, Israel Aerospace Industries, Israelfinock100% (1)