Professional Documents

Culture Documents

Final - Gas Distribution Systems PDF

Uploaded by

RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final - Gas Distribution Systems PDF

Uploaded by

RajCopyright:

Available Formats

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

Environmental, Health, and Safety Guidelines

for Gas Distribution Systems

Introduction specific variables, such as host country context, assimilative

capacity of the environment, and other project factors, are

The Environmental, Health, and Safety (EHS) Guidelines are taken into account. The applicability of specific technical

technical reference documents with general and industry- recommendations should be based on the professional opinion

specific examples of Good International Industry Practice of qualified and experienced persons. When host country

(GIIP) 1. When one or more members of the World Bank Group regulations differ from the levels and measures presented in

are involved in a project, these EHS Guidelines are applied as the EHS Guidelines, projects are expected to achieve

required by their respective policies and standards. These whichever is more stringent. If less stringent levels or measures

industry sector EHS guidelines are designed to be used than those provided in these EHS Guidelines are appropriate,

together with the General EHS Guidelines document, which in view of specific project circumstances, a full and detailed

provides guidance to users on common EHS issues potentially justification for any proposed alternatives is needed as part of

applicable to all industry sectors. For complex projects, use of the site-specific environmental assessment. This justification

multiple industry-sector guidelines may be necessary. A should demonstrate that the choice for any alternate

complete list of industry-sector guidelines can be found at: performance levels is protective of human health and the

www.ifc.org/ifcext/enviro.nsf/Content/EnvironmentalGuidelines environment. .

The EHS Guidelines contain the performance levels and

measures that are generally considered to be achievable in new

Applicability

facilities by existing technology at reasonable costs. Application The EHS Guidelines for Gas Distribution Systems include

of the EHS Guidelines to existing facilities may involve the information relevant to the distribution of low pressure natural

establishment of site-specific targets, with an appropriate gas from the city gate to residential, commercial, and industrial

timetable for achieving them. users. Annex A provides a summary of industry sector activities.

The applicability of the EHS Guidelines should be tailored to This document is organized according to the following sections:

the hazards and risks established for each project on the basis

Section 1.0 — Industry-Specific Impacts and Management

of the results of an environmental assessment in which site-

Section 2.0 — Performance Indicators and Monitoring

Section 3.0 — References

Annex A — General Description of Industry Activities

1 Defined as the exercise of professional skill, diligence, prudence and foresight

that would be reasonably expected from skilled and experienced professionals

engaged in the same type of undertaking under the same or similar

circumstances globally. The circumstances that skilled and experienced

professionals may find when evaluating the range of pollution prevention and

control techniques available to a project may include, but are not limited to,

varying levels of environmental degradation and environmental assimilative

capacity as well as varying levels of financial and technical feasibility.

APRIL 30, 2007 1

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

1.0 Industry-Specific Impacts and • Habitat Alteration

Management • Air Emissions

This section provides a summary of EHS issues associated with

Habitat Alteration

gas distribution systems that occur during the construction and

Habitat alteration is only considered a relevant potential impact

operations phases, along with recommendations for their

during construction of gas distribution pipeline systems in newly

management. Recommendations for the management of EHS

developed rural or periurban areas. These impacts may be

issues common to most large industrial facilities during the

associated with excavation, trenching, pipe laying, backfilling,

decommissioning phase are provided in the General EHS

and the establishment of infrastructure such as regulating

Guidelines.

stations, which may create temporary or permanent terrestrial

habitat alteration depending on the characteristics of existing

1.1 Environment vegetation and topographic features along the proposed right of

way. The potential for impacts depends on the level of existing

Distribution pipeline construction impacts greatly depend on the

development, and will likely be less of an issue in urbanized

location of proposed pipeline installation. In already developed

areas or along existing utility rights-of-way corridors.

urban areas, environmental impacts are considerably different

than in suburban or mixed use areas. Common impacts may Depending on the level of existing urbanization in the proposed

include noise and vibration caused by the operation of earth project area, examples of habitat alteration from these activities

moving and excavation equipment, and materials transport and may include landscape fragmentation; loss of wildlife habitat,

delivery; dust emissions generated by a combination of on-site including for nesting; and establishment of non-native invasive

excavation and movement of earth materials, contact of plant species. In addition, construction of distribution pipelines

construction machinery with bare soil, and exposure of bare soil crossing aquatic habitats that may disrupt watercourses and

and soil piles to wind; mobile emissions from exhaust of diesel wetlands, and require the removal of riparian vegetation.

engines for earth moving equipment; and hazardous materials Sediment and erosion from construction activities and storm

and waste handling, including oil spills associated with heavy water runoff may increase turbidity of surface watercourses.

equipment operation and fueling activities. In newly developed

areas, impacts may also include soil erosion resulting from To prevent and control impacts to terrestrial habitats, distribution

excavated areas prior to the reestablishment of vegetation. In pipeline rights-of-way and regulating stations should be sited to

urban areas, impacts may include noise, traffic interruption, avoid critical habitat through use of existing utility and transport

disposal of contaminated soil, and presence of archeological corridors, whenever possible. To prevent and control impacts to

artifacts. aquatic habitats, distribution pipeline rights-of-way should be

sited to avoid critical aquatic habitat such as watercourses,

Recommendations for prevention and control of construction wetlands, and riparian areas, as well as fish spawning habitat,

related impacts are addressed in the General EHS Guidelines. and critical fish over-wintering habitat, whenever possible. Use

of guided / directional drilling for distribution pipeline installation

Environmental issues that may occur during gas distribution

projects include the following:

APRIL 30, 2007 2

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

should be considered where feasible to reduce impacts to both polyethylene pipe6, which is not subject to corrosion, should

terrestrial and aquatic habitats. be considered as an alternative to ferrous metal pipeline

materials;

Air Emissions • Testing of pipelines and pipeline components for pressure

Gas distribution systems may generate gas leaks as a result of specifications and presence of leaks should be undertaken

normal operations, equipment venting for maintenance, and prior to commissioning. The system should be gas tight

aging.2 Gas leakage, principally consisting of methane (CH4), a when tested at a higher pressure than the normal maximum

greenhouse gas, may result from corrosion3 and degradation of operation gas pressure;

pipelines and related components over time and from fugitive • Leak and corrosion detection programs should be

emissions from pipelines and regulating stations. undertaken, including use of appropriate leak detection

assessment techniques and equipment.7 Maintenance

Recommended measures to prevent and control air emissions programs to repair and replace infrastructure should be

due to leaks include: undertaken as indicated by detection results. Typical urban

testing sites include atmospheres in confined spaces of

• Gas pipelines and pipeline components, in addition to

utility infrastructure (e.g. sewer and water system

general installation and pipe joining techniques such as

manholes), as well as at openings in pavement and on

welding, should meet international standards for structural

streets and walkways. Areas of gas infrastructure subject to

integrity and operational performance;4

forces from heavy load traffic or physical land shifts should

• Corrosion prevention of buried ferrous metal pipelines

also be periodically monitored for leaks and ruptures;

should be undertaken using coating or cathodic protection

• Comparisons of purchased and delivered gas amounts

techniques.5 For underground applications, the use of

should be periodically examined for discrepancies and

unaccounted for gas which may be an indicator of

excessive system leakage;

2 The methane emission from the gas distribution sector is 26 percent of the • Regulating stations and vaults, both above and below

total methane emissions in the US natural gas industry sector. United States

Environment Protection Agency (US EPA) (1999). ground, may contain equipment (e.g. safety valves, filters)

3

Steel and other ferrous metals used for gas pipelines may be subject to

corrosion, a reaction between external and internal surfaces of the pipe and its that may emit fugitive emissions of gas. Pipelines, valves,

surroundings in both below and above ground settings. Corrosion weakens the

structural integrity of the pipe and may lead to leakage. The characteristics of and other component infrastructure should be regularly

the physical environment of the pipeline including soil resistivity, moisture, and

presence of contaminants may encourage corrosive activity. US Department of maintained, and ventilation and gas detection / alarm

Transportation, Office of Pipeline Safety (2002). equipment installed in station buildings or vaults.

4 For example, US 49 CFR Part 192—Transportation of Natural Gas and Other

Gas by Pipeline: Minimum Federal Safety Standards subparts A to H, and

European (EN) Standards: EN 12007-1:2000: Gas Supply Systems. Pipelines

for maximum operating pressure up to and including 16 bar. General functional 6 An example of the performance specifications for polyethylene gas pipe is the

recommendations. ASTM D 2513 Standard Specification for Thermoplastic Gas Pressure Pipe,

5

Cathodic protection is a procedure by which an underground metallic pipe is Tubing, and Fittings or Standard EN 1555 Plastics Piping Systems.

protected against corrosion. There are two basic methods of cathodic protection: 7

Leaks are indicated by the presence of gas odor and hissing sounds.

use of galvanic anode and impressed current system s. Galvanic systems rely on Additional indicators may include changes in vegetation, insect activity, and the

a sacrificial metal, such as zinc, to protect the pipe. For impressed current presence of fungal growths surrounding pipelines and components. Examples of

systems, a direct current is impressed onto the pipe by means of a rectifier, and leak detection equipment include specialized soap solutions, in addition to

corrosion is reduced where sufficient current flows onto the pipe. Testing of the combustible gas indicators (CGI), flame ionization detectors (FI), and sonic

electrical current for cathodic protection should be undertaken regularly. US detectors that use sound levels to locate leaks. US Department of

Department of Transportation, Office of Pipeline Safety (2002). Transportation, Office of Pipeline Safety (2002).

APRIL 30, 2007 3

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

1.2 Occupational Health and Safety lines as part of installation, and updating as necessary on

an ongoing basis;

Occupational health and safety (OHS) issues in the construction

• Removal of sources of ignition prior to gas venting for

phase include potential exposures to dust, noise, physical strain,

maintenance and repair activities. Purging of gas from

and trenching excavation hazards. Recommendations for the

pipeline or pipe components prior to welding or cutting

management of construction phase hazards are addressed in

activities;

more detail in the General EHS Guidelines. Occupational

• Installation of gas lines and components using sufficient

health and safety hazards associated with the construction and

separation distance and appropriate pipe protection

operation of gas distribution systems may also include:

layering to minimize potential interference with other

• Occupational exposure to gas leaks and explosions underground infrastructure. Separation of plastic pipes from

sources of heat;

• Confined spaces

• Odorization of gas to facilitate detection of gas leakage;8

• Electrocution

• Training of gas utility workers in procedures for emergency

Additional recommendations for operational phase OHS issues preparedness and response involving appropriate public

also applicable to gas distribution activities are also addressed authorities, in addition to emergency shutdown and

in the General EHS Guidelines. pressure reduction in the pipeline system. Further

recommendations for emergency preparedness and

Occupational exposure to gas leaks and response are addressed in the General EHS Guidelines.

explosions

Excavation, construction, and repair of gas distribution systems Confined spaces

may result in accidental pipeline rupture or leakage and Accumulation of natural gas in a confined space is a potentially

consequent exposure of workers to harmful gases and an fatal condition. Entry by workers into confined spaces and the

explosive gas atmosphere. In addition, excavation by non-gas associated potential for accidents may vary among gas

utility personnel may result in accidental ruptures and exposure distribution project phases and facilities. Specific and unique

of untrained workers to explosion hazards. Recommended areas for confined space entry may include excavation trenches

techniques to prevent and control exposure to gases and during construction and regulating stations and vaults, both

explosive atmospheres caused by accidental gas line ruptures above and below ground, which may also contain equipment

and / or leaks include: (e.g. safety valves, filters) that may emit fugitive emissions of

gas and create a potential for oxygen deficient and explosive

• Training of employees and contractor personnel in safety

atmospheres. Gas distribution companies should develop and

procedures, together with provision of appropriate tools and

implement confined space entry procedures as described the

equipment;

General EHS Guidelines, and including the following:

• Identification and location of existing gas and other buried

utility infrastructure prior to excavation for installation or 8 A combustible gas in a distribution line must contain a natural odorant or be

repair of gas pipelines. Installation of visual marking of gas odorized so that at a concentration in air of one-fifth of the lower explosive limit,

the gas is readily detectable by a person with a normal sense of smell. See US

49 CFR Part 192.

APRIL 30, 2007 4

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

• Requiring work permits for all confined space entries; preparedness and response plan and communicate this plan to

• Installation of appropriate access controls for unauthorized the public as necessary.

personnel including signage to alert workers to the hazards

As part of the plan, gas system operators should implement a

of confined spaces;

telephone notification system to respond to reports of leaks or

• Use of ventilation and oxygen / explosive level detection

questions of general safety from the affected community and

and alarm equipment prior to access.

other interested parties. Operators should also provide a pipe

location service to assist outside contractors and the general

Electrocution

public to determine the location of gas infrastructure prior to

Excavation, construction, and repair of gas distribution systems

construction works proximate to gas pipelines.

may result in workers’ exposure to existing aboveground or

underground utilities, including aerial or buried electric Improper operation of natural gas fuelled appliances and

transmission lines. Identification and location of all relevant equipment may expose the user and the public to gas leakage

existing underground utilities should be undertaken prior to any and explosion hazards. Gas distribution system operators

construction and excavation activities. should make information available to customers (e.g. through

flyers and internet-based information) regarding the safe

operation of gas fueled appliances and equipment. This

1.3 Community Health and Safety

information should address issues of proper and safe use of

Community health and safety hazards associated with the gas-fired appliances, which in the case of residential use, may

construction and operation of gas distribution systems include include the following issues:

public exposure to gas leaks and explosions. Additional

recommendations for community health and safety issues • Proper location, installation, and maintenance of appliances

common to most industry sectors are addressed in the General and equipment such as natural gas fired heating units. For

EHS Guidelines. example, installation in areas with adequate ventilation to

ensure dispersion of residual carbon monoxide. Poor

combustion in a natural gas fired appliance or piece of

Public exposure to gas leaks and explosions

equipment may expose the user and the public to carbon

The presence of gas distribution systems within populated areas

monoxide exposure, especially in confined spaces;

may expose the public to hazards from gas leaks and

• Recognition of potential hazards or operating problems. For

explosions. Gas leakage may result from accidental rupture of

example, recognition of the hazards of poor ventilation or

pipelines during installation and repair or from contact during

identification of gas surges requiring action by the gas utility

excavation unrelated to the gas system. Gas utility operators

(identifiable when flame color in natural gas burning

should inform and advise affected communities, schools,

appliances is orange or yellow rather than blue), and how to

businesses / commercial facilities, and residents about the

respond to possible accumulation of gas vapors when odor

potential hazards presented by gas infrastructure. Gas

is detected with instructions on proper response

distribution system operators should establish an emergency

procedures. These procedures may include avoiding

APRIL 30, 2007 5

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

sources of ignition (e.g. electrical switches, lighters), Monitoring frequency should be sufficient to provide

ventilating area of gas accumulation, and calling the representative data for the parameter being monitored.

emergency contact number of the local gas utility from a Monitoring should be conducted by trained individuals following

safe location. monitoring and record-keeping procedures and using properly

calibrated and maintained equipment. Monitoring data should be

2.0 Performance Indicators and analyzed and reviewed at regular intervals and compared with

the operating standards so that any necessary corrective

Monitoring

actions can be taken. Additional guidance on applicable

2.1 Environment sampling and analytical methods for emissions and effluents is

provided in the General EHS Guidelines.

Emissions and Effluent Guidelines

2.2 Occupational Health and Safety

Although there are no significant point source emissions or

effluents for the gas distribution sector, fugitive emissions (from

Occupational Health and Safety Guidelines

city gate and regulating stations, underground piping, and third

Occupational health and safety performance should be

party damage) from gas distribution systems constitute a

evaluated against internationally published exposure guidelines,

significant portion of the overall atmospheric losses from the

of which examples include the Threshold Limit Value (TLV®)

natural gas transmission and distribution industry. Gas

occupational exposure guidelines and Biological Exposure

distribution system operators should conduct volume

Indices (BEIs®) published by American Conference of

reconciliation programs as an indicator of leakages by

Governmental Industrial Hygienists (ACGIH),10 the Pocket

comparing delivered gas amounts against sales to customers.9

Guide to Chemical Hazards published by the United States

Operators should also implement inspection and maintenance

National Institute for Occupational Health and Safety (NIOSH),11

programs to maintain and upgrade infrastructure and minimize

Permissible Exposure Limits (PELs) published by the

fugitive gas emissions.

Occupational Safety and Health Administration of the United

States (OSHA),12 Indicative Occupational Exposure Limit Values

Environmental Monitoring

published by European Union member states,13 or other similar

Environmental monitoring programs for this sector should be

sources.

implemented to address all activities that have been identified to

have potentially significant impacts on the environment, during

Accident and Fatality Rates

normal operations and upset conditions. Environmental

Projects should try to reduce the number of accidents among

monitoring activities should be based on direct or indirect

project workers (whether directly employed or subcontracted) to

indicators of emissions, effluents, and resource use applicable

to the particular project.

10 Available at: http://www.acgih.org/TLV/ and http://www.acgih.org/store/

11 Available at: http://www.cdc.gov/niosh/npg/

12 Available at:

9 Supervisory Control and Data Acquisition (SCADA) systems may be another http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDAR

useful means of monitoring system volume flows, especially in new system DS&p_id=9992

installations. 13 Available at: http://europe.osha.eu.int/good_practice/risks/ds/oel/

APRIL 30, 2007 6

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

a rate of zero, especially accidents that could result in lost work

time, different levels of disability, or even fatalities. Facility rates

may be benchmarked against the performance of facilities in this

sector in developed countries through consultation with

published sources (e.g. US Bureau of Labor Statistics and UK

Health and Safety Executive)14.

Occupational Health and Safety Monitoring

The working environment should be monitored for occupational

hazards relevant to the specific project. Monitoring should be

designed and implemented by accredited professionals15 as

part of an occupational health and safety monitoring program.

Facilities should also maintain a record of occupational

accidents and diseases and dangerous occurrences and

accidents. Additional guidance on occupational health and

safety monitoring programs is provided in the General EHS

Guidelines.

14 Available at: http://www.bls.gov/iif/ and

http://www.hse.gov.uk/statistics/index.htm

15 Accredited professionals may include Certified Industrial Hygienists,

Registered Occupational Hygienists, or Certified Safety Professionals or their

equivalent.

APRIL 30, 2007 7

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

3.0 References and Additional Sources

22nd World Gas Conference, June 2003, Tokyo Japan. Working committee 8

report: Environment, safety and health. Chairman Wayne Soper, Canada.

Available at www.igu.org/WGC2003/WGC_pdffiles/WOC_R_8.pdf

American Society for Testing and Materials (ASTM). 2006. D 2513-06a.

Standard Specification for Thermoplastic Gas Pressure Pipe, Tubing, and

Fittings. West Conshohocken, PA: ASTM.

European Commission. Directive 2003/87/EC of the European Parliament and of

the Council of 13 October 2003 establishing a scheme for greenhouse gas

emission allowance trading within the Community and amending Council

Directive 96/61/EC. Available at http://eur-

lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32003L0087:EN:HTML

European Environment Agency (EEA). 1994. The Corinair 94 Database. Data

for Air Emissions from Different Sources in Europe. European Topic Center Air

Emissions. Available at http://www.aeat.co.uk/netcen/corinair/94/

European Union (EU). 2000. European Standard (EN). 12007-1:2000 Gas

supply system - Pipelines for maximum operating pressure up to and including

16 bar - Part 1: General functional recommendations.

EU. 1999. EN 12569:1999. Industrial valves. Valves for chemical and

petrochemical process industry. Requirements and tests.

Intergovernmental Panel on Climate Change (IPCC). 1996. Revised 1996 IPCC

Guidelines for National Greenhouse Gas Inventories. Reference Manual

(Volume 3). United Nations Environment Programme (UNEP), Organisation for

Economic Co-operation and Development (OECD), International Energy Agency

(IEA), and IPCC. Available at http://www.ipcc-nggip.iges.or.jp/public/gl/invs6.htm

Harison, M. R., et al. 1996. Radian International LLC. Methane Emissions from

the Natural Gas Industry. Volume 1, Executive Summary. Prepared for the Gas

Research Institute (GRI) and US Environmental Protection Agency (US EPA).

Report GRI-94/0257 and EPA-600/R-96-080a GRI/EPA.

Paul Scherrer Institut (PSI). 2005. Comparative Assessment of Natural Gas

Accident Risks. Burgherr, P., and Hirschberg, S. Available at http://www.psi.ch

Swedish Gas Centre (SGC). 2000. Small Methane leakage from the Swedish

Natural Gas System, information letter SGC 026. Additional information

available at: http://www.sgc.se/uk/index.asp

United States (US) Department of Transportation. 2002. Office of Pipeline

Safety: Guidance Manual for Operators of Small Natural Gas Systems. Available

at: http://ops.dot.gov/regs/small_ng/SmallNaturalGas.htm

US Environment Protection Agency (US EPA). 2006. US Code of Federal

Regulations (CFR). 49 CFR Part 192—Transportation of Natural Gas and Other

Gas by Pipeline: Minimum Federal Safety Standards. Subparts A to H.

Washington, DC: US EPA. Available at: http://www.gpoaccess.gov/cfr/index.html

US EPA. 2003. Inventory of US Greenhouse Gas Emissions and Sinks: 1990-

2001. Washington, DC: US EPA. Available at

http://yosemite.epa.gov/OAR/globalwarming.nsf/

US EPA. 1999. 430-R-99-013. US Methane Emissions 1990-2020. Inventories,

Projections and Opportunities for Reductions. Washington, DC: US EPA.

APRIL 30, 2007 8

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

Annex A: General Description of Industry Activities

Gas distribution systems deliver natural gas to residential, The construction and installation of natural gas distribution

commercial, and industrial clients for use in appliances, heating pipeline systems involves planning and design for the right-of-

applications, and industrial process equipment. The distribution way, including use of existing utility corridors (e.g. co-location

system typically begins at the ‘city gate’ where natural gas from with sewer, water, telecommunication, and power systems)

high pressure transmission pipelines (typically at 50 to 70 bar16) where possible. Establishment of the right-of-way may involve

is depressurized, metered and odorized (to facilitate leak clearing of vegetation and grading of surfaces. Pipe is laid

detection). City gates are secure, above ground facilities, following trenching activities using a backhoe, and, where

typically less than 1 ha in area and containing equipment appropriate, the use of directional drilling to minimize land

belonging to both the transmission and distribution companies. disturbance. Guided drilling may be particularly useful when

Once metered and odorized, gas is fed into distribution mains crossing under roadways, waterways or wetland habitats.

and service lines for delivery of low pressure gas to end users Trenches are then backfilled and the right-of-way is restored

through underground, small diameter steel or plastic pipe using existing vegetation. Distribution pipes are typically of steel

systems. Pressure is further lowered, often in stages, for or plastic materials. Various coating and cathodic protection

delivery to the customer. techniques are employed to protect steel piping from corrosive

reactions, both above and below ground.

Gas supplied to distribution systems is normally referred to as

“pipeline quality natural gas”, which has been processed to Gas distribution systems typically involve the use of regulating

remove water vapor and other contaminants and has stations to adjust the pressure of gas throughout the distribution

predictable burning characteristics and heat content. Processed network. These installations are typically located above ground

natural gas typically contains 75 to 90+ percent methane, 3 to 4 and occupy approximately 20 m2 of land area. Regulating

percent nitrogen, and 2 percent carbon dioxide, but these stations are located after the ‘city gate’ and may operate in a

fractions may vary in different countries. In exceptional cases, sequential fashion to reduce gas pressure during distribution to

gas distribution systems may need to include additional end users. Final pressure adjustment is undertaken at the

processing if supplied gas is not of pipeline quality, such as gas individual residential customer (to about 0.1 bar), and at

produced locally from landfills, biomass, or manure. commercial, and industrial meters (to from 1 to 15 bar).

Gas distribution systems are often a mix of new construction Activities by the gas distribution system during operation and

and old infrastructure that may contain legacy issues such as maintenance include overall systems operation and monitoring

old gas meters that contain mercury, obsolete gas processing of infrastructure components, such as valves, regulating

facilities, and plants that were used for manufacture of synthetic stations, and pipes through flow meter data analysis and onsite

gas. Special attention should be paid to leak management when inspection. Operators regularly undertake inspections for gas

old and new infrastructure is combined or when the source of leaks, corrosion, and overall system integrity. Ongoing

gas is changed. connection of new subscribers within the distribution market is a

regular operational activity, and is typically undertaken while the

16 1 bar is approximately 1 atmosphere, or 14.5 lb/in 2. distribution pipes are pressurized, so as not to interrupt service

APRIL 30, 2007 9

Environmental, Health, and Safety Guidelines

GAS DISTRIBUTION SYSTEMS

WORLD BANK GROUP

to other customers. Repair activities involve all parts of the

distribution system and typical tasks include repair and

replacement of pipes and valves, in particular after accidental

damage due to excavation near pipeline infrastructure.

Gas distribution operators are also typically responsible for

training their employees, and ensuring that contractors are

trained, in the procedures and actions necessary for effective

emergency response to leaks, ruptures, and other incidents

caused by the operators themselves, third parties, or natural

hazards. Effective emergency response requires that gas

distribution operators integrate with local government and

municipal authorities, in addition to residential, commercial and

industrial partners to ensure coordinated actions in the event of

an emergency.

Decommissioning of distribution lines typically involves the

closure and securing of valves to impede flow of gas to the

customer and disconnection and sealing of the distribution mains

and service line piping after purging of residual gas. Above

ground structures such as regulating stations may be removed.

Below ground pipelines, vaults and other components may be

removed or left in place depending on site specific

considerations.

APRIL 30, 2007 10

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Air Sampling and Industrial HygieneDocument276 pagesAir Sampling and Industrial HygieneGenilson Almeida100% (1)

- Mass SpectrometryDocument15 pagesMass SpectrometryMeghan Norico Cristuta100% (1)

- Hydraulic Seal PDFDocument88 pagesHydraulic Seal PDFharoldNo ratings yet

- Repair and Rehabilitation of Reinforced ConcreteDocument15 pagesRepair and Rehabilitation of Reinforced ConcreteebinVettuchirayil100% (2)

- All About EthanolaminesDocument7 pagesAll About EthanolaminesVineeth Nair100% (1)

- FCC Wash Water SystemsDocument16 pagesFCC Wash Water SystemsBehnam RahzaniNo ratings yet

- Glucose Oxidase Effect On Dough Rheology and Bread QualityDocument8 pagesGlucose Oxidase Effect On Dough Rheology and Bread Qualitym_luchianNo ratings yet

- Lecture 5 - Industrial HygieneDocument50 pagesLecture 5 - Industrial HygieneDivyashini MohanNo ratings yet

- Top 1000Document21 pagesTop 1000Pradeep ChandarNo ratings yet

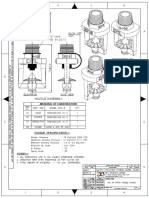

- Mvws NozzleDocument1 pageMvws NozzleRajNo ratings yet

- Jining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-02Document2 pagesJining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-02RajNo ratings yet

- Re Gadsg SDGEAGDocument1 pageRe Gadsg SDGEAGRajNo ratings yet

- Price. Bid: Ce For Pump S Sub.: Pri Pare and PartsDocument2 pagesPrice. Bid: Ce For Pump S Sub.: Pri Pare and PartsRajNo ratings yet

- Jining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-01Document2 pagesJining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-01RajNo ratings yet

- Chehab Nig. LTD.: ImmediatelyDocument1 pageChehab Nig. LTD.: ImmediatelyRajNo ratings yet

- 15nb Half CouplingDocument1 page15nb Half CouplingRajNo ratings yet

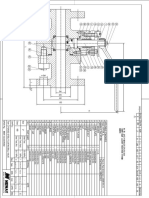

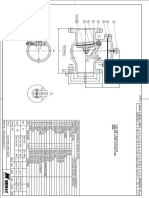

- Data Sheet for Double Headed Hydrant ValveDocument2 pagesData Sheet for Double Headed Hydrant ValveRajNo ratings yet

- Poe, N0, B-R La+nq/l U PT - Os: NOTES.Document1 pagePoe, N0, B-R La+nq/l U PT - Os: NOTES.RajNo ratings yet

- Special Tools: Erui International Electronic Commerce Co., LTDDocument7 pagesSpecial Tools: Erui International Electronic Commerce Co., LTDRajNo ratings yet

- Blessed Fred Construction EntDocument1 pageBlessed Fred Construction EntRajNo ratings yet

- Jining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-03Document1 pageJining Xunda Pipe Coating Materials Co.,Ltd: Test Report No. XD191014-03RajNo ratings yet

- Procurement Quotation for Chest Freezers, Chillers, Fans and Laundry EquipmentDocument1 pageProcurement Quotation for Chest Freezers, Chillers, Fans and Laundry EquipmentRajNo ratings yet

- Saturn Home Appliances: 271b Ajose Adeogun Street, Victoria IslandDocument1 pageSaturn Home Appliances: 271b Ajose Adeogun Street, Victoria IslandRajNo ratings yet

- Lubrication: Erui International Electronic Commerce Co., LTDDocument1 pageLubrication: Erui International Electronic Commerce Co., LTDRajNo ratings yet

- PW610 PWM BB3 PDFDocument6 pagesPW610 PWM BB3 PDFRajNo ratings yet

- ZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书Document17 pagesZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书RajNo ratings yet

- Product Certificate (Registered) : Standards Organisation of Nigeria Conformity Assessment ProgrammeDocument1 pageProduct Certificate (Registered) : Standards Organisation of Nigeria Conformity Assessment ProgrammeRajNo ratings yet

- 10 0.5G15N V3, C40 8 (-I,)Document1 page10 0.5G15N V3, C40 8 (-I,)RajNo ratings yet

- TUJW46U6UWEGTBFDocument1 pageTUJW46U6UWEGTBFRajNo ratings yet

- Zoomlion ZTC550V Truck Crane Technical SpecificationsDocument28 pagesZoomlion ZTC550V Truck Crane Technical SpecificationsRajNo ratings yet

- ZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书Document17 pagesZTC250H431 27CSzxFDGHAWERS4GSZDTQ78JHYY英文技术规格书RajNo ratings yet

- ZTC800V SPECIFICATIONSDocument27 pagesZTC800V SPECIFICATIONSRajNo ratings yet

- TUJW46U6UWEGTBFDocument1 pageTUJW46U6UWEGTBFRajNo ratings yet

- QWETWEFEWDocument1 pageQWETWEFEWRajNo ratings yet

- RWHRESFHGGRVDocument1 pageRWHRESFHGGRVRajNo ratings yet

- 10 0.5G15N V3, C40 8 (-I,)Document1 page10 0.5G15N V3, C40 8 (-I,)RajNo ratings yet

- 200 2BB6R V3 C40 3N662-Model PDFDocument1 page200 2BB6R V3 C40 3N662-Model PDFRajNo ratings yet

- 34T43ETFRWADocument1 page34T43ETFRWARajNo ratings yet

- 360 6S3R, C00 8 (-NRD3-VY1,) - ModelDocument1 page360 6S3R, C00 8 (-NRD3-VY1,) - ModelRajNo ratings yet

- MentholsDocument296 pagesMentholsrachelsantoso5259No ratings yet

- Sieve Analysis and Density Test For AggregatesDocument11 pagesSieve Analysis and Density Test For AggregatesgeorgeantoniosNo ratings yet

- EOSIN STAINING ALCOHOL SOLUTION MSDSDocument11 pagesEOSIN STAINING ALCOHOL SOLUTION MSDSfitrisya luckyNo ratings yet

- Kami Export - Physical and Chemical Changes WorksheetDocument2 pagesKami Export - Physical and Chemical Changes WorksheetTheo MillsNo ratings yet

- Iccesd 2020 PDFDocument12 pagesIccesd 2020 PDFzeekoNo ratings yet

- Peroxide Value Test ProcedureDocument2 pagesPeroxide Value Test ProcedureWynona BasilioNo ratings yet

- Deeper Neet DCT - ChemistryDocument8 pagesDeeper Neet DCT - Chemistryhbhaiya643No ratings yet

- Technical Data Sheet for Condenser On Load Tube Cleaning SystemDocument46 pagesTechnical Data Sheet for Condenser On Load Tube Cleaning SystemSupriyaRongNo ratings yet

- Equity Note - Active Fine Chemicals Ltd.Document3 pagesEquity Note - Active Fine Chemicals Ltd.Makame Mahmud DiptaNo ratings yet

- Be SyllabusDocument160 pagesBe Syllabusfiland880% (1)

- Class XI Chemistry Unit-8 Redox Reactions: TopicDocument60 pagesClass XI Chemistry Unit-8 Redox Reactions: TopicBaljit Singh100% (1)

- Orthovoltage Vs MegavoltageDocument7 pagesOrthovoltage Vs MegavoltageEmmanuel Cuevas MisNo ratings yet

- MC Electricity and MagnetismDocument7 pagesMC Electricity and MagnetismMelvin Garcia QuirosNo ratings yet

- Data Sheet For Nutraceuticals.Document13 pagesData Sheet For Nutraceuticals.ddeeppaakNo ratings yet

- BIO130 Sec2 - Lec1and2 - 1pptDocument38 pagesBIO130 Sec2 - Lec1and2 - 1pptlemonpartymanNo ratings yet

- EXP 7 - MaterialsDocument18 pagesEXP 7 - MaterialsLeslie CatindigNo ratings yet

- AEL02237 SDS - DISPERBYK-2200 - US - enDocument10 pagesAEL02237 SDS - DISPERBYK-2200 - US - enRıdvan SürmeliNo ratings yet

- Process Fluid Mechanics BTech 3rd Sem Mewar UniversityDocument3 pagesProcess Fluid Mechanics BTech 3rd Sem Mewar UniversityMahboob AlamNo ratings yet

- GroupIV WSDocument14 pagesGroupIV WSMaryam RaiNo ratings yet

- Christian Pfeiffer Maschinenfabrik GMBHDocument5 pagesChristian Pfeiffer Maschinenfabrik GMBHPeyman KhNo ratings yet

- CBSE Class-12 Chemistry Quick Revision Notes Chapter-03: ElectrochemistryDocument6 pagesCBSE Class-12 Chemistry Quick Revision Notes Chapter-03: ElectrochemistrySAKET TYAGI100% (1)