Professional Documents

Culture Documents

Chrome Blue OTRF

Uploaded by

Harsh KushwahaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chrome Blue OTRF

Uploaded by

Harsh KushwahaCopyright:

Available Formats

Gap Inc.

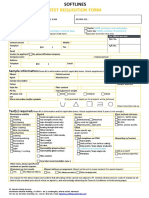

Standard Softlines Test Request Form Test Service Requested- Priority

Date Submitted Sourcing Office Form ID Version

2019-04-26 15:29 (GMT + 08:00) GIS India 577661-SO004-20 1

Gap Inc. Brand For Laboratory Use

Gap

Division Department

Testing lab Intertek / India-Gurgaon

Country of Canada, China, Europe & EU Regional Inventory, Japan, US

SHIP LOGIN DUE

Sale Franchise Market: Thailand,Indonesia,UAE,Panama,Egypt,Greece

Gap Inc. TRIPTI VARMA / SUMEET GIS Category

Wovens Laboratory No.:

Contact SHARMA Management

Re-Test

Previous Test Report No. Specify Test Failures

DELT19023334-R1 Dimensional Stability to home laundering and dry-cleaning

Intended Age

Adults ADULT - Women Kids Baby & Toddler

Submitter

Vendor 305599: PEARL GLOBAL INDUSTRIES LIMITED

Factory

Mill or Yarn Supplier 1022818: RMP

Trim Supplier

Sample to be Tested Details

Style No. / Fabric RD No. / Master Style No. / Mill

Sample Type Color

Trim RD No. Fabric ID / Trim Article No.

Garment 468783 CHROME BLUE

Partial Test Report No.

Country Of Origin INDIA

Description HALTER DRESS

End Use of Garment Dress Is this a VMI style? No

Season 2019 Summer Date Code

Fiber Content

Is the finished product an apparel set (2 or more items sold as one)? No

Overall Content Disclosure

Rayon: 100%

Requester has checked to certify that fabric is 100% single fiber. Lab will not verify as part of package test. Certifier is responsible for legal compliance.

Submitted Care Instructions

Shell100%Rayon/Viscose,Lining100%Polyester-Machine wash cold,Gentle cycle,wash and dry with like colors,Only non chlorine bleach when needed,line

dry,reshape while damp Warm iron,dry clean.

Test Package

Testing Status Production Product Stage Garment

Product Category Woven Test Protocols PERFORMANCE ONLY

Test Packages Individual Tests (Performance)

Special Claims

Individual Tests (PSR)

Test Item Description

Form Version: 1.0 Page 1 of 4 577661-SO004-20(1)

Gap Inc. Standard Softlines Test Request Form Test Service Requested- Priority

Individual Tests (Performance)

Test Item Description

Dimensional Stability DC

Dimensional Stability HL

Product Safety & Regulations (PSR)

Party Responsible for CPSC Certification* #1

CPSC Sampling Protocol-Additional Testing Above Gap Inc. Minimum #2

CPSC Tests Total No. of Tests Requested

General Wearing Apparel Flammability

Is Finished Product style subject to Gap Inc. General Wearing Apparel

Flammability Testing under 16 CFR 1610?

Flammability PO Information

PO No. PO Quantity

Children's Sleepwear

Type of Sampling Plan

Sleepwear Tests

Type of Testing Requested

Phthalates (Non-CPSC Testing)

Request for automatic single component testing after composite testing failure in basic test package

Is Product in Final Packaging?

Report Traceability

Fabric Stage Test Reports

Fabric Description Fabric Article No. Fabric Stage Report No. Eligible Tests

RAYON CREPE RD#230019

Trim Stage Test Reports

Trim Component

Trim Article No. Trim Stage Report No. Eligible Tests

Short Description

Development Stage Test Reports

Item Description RD or Style No. Development Report No.

Product Details

Fabric Details

Thread Count - Thread Count -

Fabric Construction Crepe 82 62

Ends/Inch Picks/Inch

Yarn Size 30s + 30's

Stretch and Recovery Mill Spec Claim

Elongation at load (warp) Elongation at load (weft) Modulus @25% (warp)

0 0 0

ASTM 3107 (modified) ASTM 3107 (modified) S1064

Modulus @25% (weft) Elongation at load (warp) Modulus @10% (warp)

0 0 0

S1064 S1034 S1034

Modulus @20% (warp) Modulus @30% (warp) Modulus @40% (warp)

0 0 0

S1034 S1034 S1034

Elongation at load (weft) Modulus @10% (weft) Modulus @20% (weft)

0 0 0

S1034 S1034 S1034

Form Version: 1.0 Page 2 of 4 577661-SO004-20(1)

Gap Inc. Standard Softlines Test Request Form Test Service Requested- Priority

Modulus @30% (weft) Modulus @40% (weft)

0 0

S1034 S1034

Fabric Weight

Unit g / sq. m Before Wash 135 After Wash 143

Before Coating After Coating

Others

Net Fill Weight (Down /

Product Differentiation Seasonal

Feather Only)

Product Characteristics (as per SLM)

Woven (Rigid Fabric,

Washed Fabric GD - Garment Dyed No GW - Garment Wash Yes

Washed Fabric)

SW - Stone Wash No EW - Enzyme Wash No D - Sanding, Destruction No

P - Prints No TD - Top Dyed No YD - Yarn Dyed No

SD - Special Dye No Sulphur No Indigo No

Coated No Peach Finish No Prepared for dye (PFD) No

Trim Details

Dye Button No

Functional Trim No

Color Block (Textile or Trim used in Color-Blocked Products) No

EXPEDITED Attachment Strength Test - MAH Trim Supplier

EXPEDITED Attachment Strength Test - MAH Trim Type

EXPEDITED Attachment Strength Test - MAH Trim Component ID

EXPEDITED Attachment Strength Test - MAH Machine Model #

EXPEDITED Attachment Strength Test - Machine Pinch Setting Tolerance

EXPEDITED Attachment Strength Test - Finished Product First Ship Date

EXPEDITED Attachment Strength Test - Finished Product PO Number/s

Special Test Instructions

Dimensional Stability to home laundering 5Pcs, Dimensional Stability to Dry-cleaning 1Pcs, GIS Counter 1Pc.

Submitter & Billing Details

Submitted Sample Qty 7 Return Destroyed Samples? No

Send Billing Information To

Invoice test request submitter Yes Confirmation received from Gap Inc. ?

Company Pearl Global Industries Ltd

Contact Name Ramanuj Kalita, Arpan Kalra, Harsh Kushwaha

Address Plot-73,Phase-1,Udyog Vihar, Gurgaon-Haryana, 122016

Phone / Fax +91-124-4871155, 4871151

E-mail ramanuj.kalita@pearlglobal.com,arpan.kalra@pearlglobal.com,harsh.kushwaha@pearlglobal.com

Submitted Sample From

Submitter Is Vendor

Company Pearl Global Industries Ltd

Contact Name Ramanuj Kalita, Arpan Kalra, Harsh Kushwaha

Address Plot-73,Phase-1,Udyog Vihar, Gurgaon-Haryana, 122016

Phone / Fax +91-124-4871155, 4871151

E-mail ramanuj.kalita@pearlglobal.com,arpan.kalra@pearlglobal.com,harsh.kushwaha@pearlglobal.com

Remark

#1 Submitters are 100% responsible for selecting the correct party responsible for CPSC Certification. Submitters should contact GIS Vendor

Form Version: 1.0 Page 3 of 4 577661-SO004-20(1)

Gap Inc. Standard Softlines Test Request Form Test Service Requested- Priority

Management if they are unsure about the responsible party.

#2 Submitter is responsible for selecting representative samples and conduct a sufficient number of test to demonstrate the ongoing compliance

of the entire production lot, including any variability that might affect the product’s ability to comply with applicable safety rule(s).

When the Submitter determines the number of tests needed to demonstrate ongoing compliance to a high degree of assurance is greater than

the established Gap Inc. minimums, the submitter may request additional testing by completing the fields below.

Form Version: 1.0 Page 4 of 4 577661-SO004-20(1)

You might also like

- Shake and Bake One Pot MethamphetamineexperimentDocument4 pagesShake and Bake One Pot MethamphetamineexperimentCep Oboz Cc'settand Nalaktack0% (1)

- Coupling Inspection SOP GSE FinalDocument11 pagesCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- Sample PPAP Level-3Document36 pagesSample PPAP Level-3Mr. Mafia BhargavNo ratings yet

- 8D For Big ID DepthDocument18 pages8D For Big ID DepthKuldeep SinghNo ratings yet

- Salt Spray Test Report - SampleDocument8 pagesSalt Spray Test Report - SamplearvindNo ratings yet

- 4-Storey Commercial Bldg. by Staadpro Using UBC & American CodeDocument35 pages4-Storey Commercial Bldg. by Staadpro Using UBC & American CodeBilal Ahmed Barbhuiya50% (2)

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionFrom EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionRating: 5 out of 5 stars5/5 (3)

- Drilling String InspectionDocument7 pagesDrilling String Inspectionrais ridha100% (2)

- Fuel Types and Firing SystemsDocument80 pagesFuel Types and Firing SystemsIrshad HussainNo ratings yet

- Plating Process Audit Checksheet 9332E-XDocument3 pagesPlating Process Audit Checksheet 9332E-Xabhionlyster63% (8)

- Quality Control PlanDocument1 pageQuality Control PlanScha Affin100% (1)

- IRC-SP-100-2014 Cold MixDocument7 pagesIRC-SP-100-2014 Cold MixVikas ThakarNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)RupKamalKutum100% (3)

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)RupKamalKutum100% (3)

- Final Exam PracticeDocument17 pagesFinal Exam PracticeKayla Dollente100% (1)

- 2.audit Report BRCDocument34 pages2.audit Report BRCCôn LuânNo ratings yet

- Amorphous MaterialsDocument12 pagesAmorphous MaterialsdevendrakphyNo ratings yet

- Ruby Wine OtrfDocument4 pagesRuby Wine OtrfHarsh KushwahaNo ratings yet

- Test Requisition Form: SoftlinesDocument4 pagesTest Requisition Form: SoftlinesArslan HaiderNo ratings yet

- Softlines General TRF (Indonesia) 2022 - UnlockedDocument5 pagesSoftlines General TRF (Indonesia) 2022 - UnlockedVimalNo ratings yet

- Apparel Factory Audit Report Blank v3.3Document25 pagesApparel Factory Audit Report Blank v3.3Minal HadiNo ratings yet

- GPT and FPT - 10Document2 pagesGPT and FPT - 10satex100% (1)

- Paradise Pink (Add) 8222) 307-0012Document14 pagesParadise Pink (Add) 8222) 307-0012pista0629No ratings yet

- Test ReportDocument8 pagesTest ReportNishantNo ratings yet

- FTR Kal2 2017 03607, Black F.terryDocument4 pagesFTR Kal2 2017 03607, Black F.terrySaifur RahmanNo ratings yet

- Protocol 00141 ADocument10 pagesProtocol 00141 AMuralidaran Kulanthiyappan100% (1)

- 3669B Marked Protocol CNMR-HL-PTCL-03000-US-UPHOLSTERY FABRICS INDOOR OUTDOOR-V44Document4 pages3669B Marked Protocol CNMR-HL-PTCL-03000-US-UPHOLSTERY FABRICS INDOOR OUTDOOR-V44Storm RainNo ratings yet

- KD GOWN PPPE 45gsm AAMI Level 2 Physical Test EUROFINSDocument12 pagesKD GOWN PPPE 45gsm AAMI Level 2 Physical Test EUROFINSTom GewinnNo ratings yet

- Report No.: MAN:HL:1348003357 DATE: 21 April, 2022: JOE No.:2248801377 4919047 Control No.:1348504335Document9 pagesReport No.: MAN:HL:1348003357 DATE: 21 April, 2022: JOE No.:2248801377 4919047 Control No.:1348504335sumanNo ratings yet

- Chemical and Construction Input Industry Development Institute /C.C.I.I.D.IDocument6 pagesChemical and Construction Input Industry Development Institute /C.C.I.I.D.IEyob HaylemariamNo ratings yet

- Textile Testing International Total Testing Solutions Inc.: Vendor InformationDocument4 pagesTextile Testing International Total Testing Solutions Inc.: Vendor InformationJawad IqbalNo ratings yet

- CAI, IS0 15874 - Polypropylene Pipes & FittingsDocument2 pagesCAI, IS0 15874 - Polypropylene Pipes & FittingsAttef BedaweNo ratings yet

- Solicitare Raport IntertekDocument5 pagesSolicitare Raport IntertekNicoletaNo ratings yet

- 羽林GB32610英文检测报告Document5 pages羽林GB32610英文检测报告A ANo ratings yet

- 羽林GB32610英文检测报告Document5 pages羽林GB32610英文检测报告A ANo ratings yet

- 8D For ID Over sizeTECUMSEHDocument4 pages8D For ID Over sizeTECUMSEHKuldeep SinghNo ratings yet

- Chemical and Construction Input Industry Development Institute /C.C.I.I.D.IDocument5 pagesChemical and Construction Input Industry Development Institute /C.C.I.I.D.IEyob HaylemariamNo ratings yet

- GeM Bidding 3411046Document6 pagesGeM Bidding 3411046Irshad AhmedNo ratings yet

- Target Corporation: Report Number: (8221) 098-0360 REVISEDDocument10 pagesTarget Corporation: Report Number: (8221) 098-0360 REVISEDMehedi HasanNo ratings yet

- Xone 500GT Dot PDFDocument5 pagesXone 500GT Dot PDFFlor Viviana CASTAÑO VELANDIANo ratings yet

- Steel Toe Cap 459 CertificateDocument3 pagesSteel Toe Cap 459 CertificatelufvijpharmaNo ratings yet

- Vineyard Vines - SGS Test Request Form - 7 Feb 2023Document4 pagesVineyard Vines - SGS Test Request Form - 7 Feb 2023Keith ChenNo ratings yet

- Pass-Zudio Mens Printed - Lt. Blue (Passion) - Next Fashion Apparels - SBM 42478Document3 pagesPass-Zudio Mens Printed - Lt. Blue (Passion) - Next Fashion Apparels - SBM 42478SHIVANAND HIRAVANNAVARNo ratings yet

- AI - Inspection Report - BagsDocument37 pagesAI - Inspection Report - Bagssiva6751No ratings yet

- Supplier Re-Evaluation Form - LatestDocument5 pagesSupplier Re-Evaluation Form - LatestR.BALASUBRAMANINo ratings yet

- Wool Spuns Private Limited:Ref. No. PSPL/102018/66391Document2 pagesWool Spuns Private Limited:Ref. No. PSPL/102018/66391arun yadavNo ratings yet

- THD-27L-7-003-UCM Solar Light-UL-V4 2015-11-23Document24 pagesTHD-27L-7-003-UCM Solar Light-UL-V4 2015-11-23jim kangNo ratings yet

- (IQC) LG (67) - G3-1214 - Grille Assembly Discharge - Detailed Inspection ProcedureDocument15 pages(IQC) LG (67) - G3-1214 - Grille Assembly Discharge - Detailed Inspection ProcedureAnonymous Lta32Ta9No ratings yet

- Tommy Hilfiger, 831H 14C, WHITEDocument2 pagesTommy Hilfiger, 831H 14C, WHITEOnnoSaikatNo ratings yet

- Quality Assurance Plan For Inert Ceramic Ball (Al2O3:90%)Document3 pagesQuality Assurance Plan For Inert Ceramic Ball (Al2O3:90%)Satyanneshi ERNo ratings yet

- Material Testing RequirementsDocument23 pagesMaterial Testing RequirementsbinhNo ratings yet

- GeM Bidding 2700858Document6 pagesGeM Bidding 2700858Harshit GautamNo ratings yet

- TESTING REPORT-Mask EarloopDocument4 pagesTESTING REPORT-Mask EarloopMamdouhNo ratings yet

- THD-P-001-1A1B V3 For General ProductDocument12 pagesTHD-P-001-1A1B V3 For General Productjim kangNo ratings yet

- Page 1 of 1: Control PlanDocument1 pagePage 1 of 1: Control PlannormalNo ratings yet

- Cert. Conformitate PROOFOT CLUB 50mmDocument19 pagesCert. Conformitate PROOFOT CLUB 50mmAnNe MaRieNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- GeM Bidding 4045892Document5 pagesGeM Bidding 4045892Kartik RajputNo ratings yet

- COSMOTHENE® F108-5 - The Polyolefin Company (Singapore)Document3 pagesCOSMOTHENE® F108-5 - The Polyolefin Company (Singapore)Eko Sabtian0% (1)

- Performance Standards Filled Bedding Textiles 2015 17Document10 pagesPerformance Standards Filled Bedding Textiles 2015 17Tahir NizamNo ratings yet

- Test Glo-Qc-Tm-0744Document6 pagesTest Glo-Qc-Tm-0744rx bafnaNo ratings yet

- PQ MULTI MILL LAB MODEL - SunriseDocument11 pagesPQ MULTI MILL LAB MODEL - SunriseRavii CurtisNo ratings yet

- 2) Test Glo-Qc-Tm-0744Document6 pages2) Test Glo-Qc-Tm-0744Toe PaingNo ratings yet

- MS-DD-3000-HSE-FRM-0126 - Submersible Pump Inspection ChecklistDocument1 pageMS-DD-3000-HSE-FRM-0126 - Submersible Pump Inspection ChecklistlukmanNo ratings yet

- The Art of Unit Testing, Third Edition: with examples in JavaScriptFrom EverandThe Art of Unit Testing, Third Edition: with examples in JavaScriptNo ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- Chrome Blue OTRFDocument4 pagesChrome Blue OTRFHarsh KushwahaNo ratings yet

- On, W Dresses & Outerwear, 343365, Black Floral, HR Test, Ho16, FailDocument10 pagesOn, W Dresses & Outerwear, 343365, Black Floral, HR Test, Ho16, FailHarsh KushwahaNo ratings yet

- SS Round SLV Pintuck Shirt 000479447 PDFDocument7 pagesSS Round SLV Pintuck Shirt 000479447 PDFHarsh KushwahaNo ratings yet

- SS Round SLV Pintuck Shirt 000479447 PDFDocument7 pagesSS Round SLV Pintuck Shirt 000479447 PDFHarsh KushwahaNo ratings yet

- Literature - Leading Technology Elements - Gas Depth - PEACH Gas Filters & Filter Separators - EL-PCHG-SL-01Document4 pagesLiterature - Leading Technology Elements - Gas Depth - PEACH Gas Filters & Filter Separators - EL-PCHG-SL-01Erlisa YustiantiNo ratings yet

- RX022Document356 pagesRX022ElZeroMJNo ratings yet

- SEJ BoardDocument2 pagesSEJ BoardShodhan M AminNo ratings yet

- Experiment 11 - Types of Chemical ReactionsDocument7 pagesExperiment 11 - Types of Chemical ReactionsUpekkha Phm100% (1)

- Heating Torch: The "Hot One" From HarrisDocument2 pagesHeating Torch: The "Hot One" From HarrisedsngarNo ratings yet

- Chapter 8Document117 pagesChapter 8subham kumarNo ratings yet

- Is549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysDocument4 pagesIs549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysSandro MendesNo ratings yet

- Forging Applications: Uddeholm Tool Steels ForDocument24 pagesForging Applications: Uddeholm Tool Steels ForMin HanNo ratings yet

- Excel First Review and Training Center, Inc.: Cebu: Davao: Manila: BaguioDocument3 pagesExcel First Review and Training Center, Inc.: Cebu: Davao: Manila: BaguioJohn Anthony YumulNo ratings yet

- Concrete Testing: Non-DestructiveDocument46 pagesConcrete Testing: Non-DestructivekevalNo ratings yet

- Design Calculations (Singly-Reinforced Beam Design)Document4 pagesDesign Calculations (Singly-Reinforced Beam Design)John Kevin CruzNo ratings yet

- Design Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Document20 pagesDesign Analysis and Comparison Between The Conventional Materialswith Composite Material of The Leaf Springs Fmoa 1000127Anonymous oTrMzaNo ratings yet

- Cicli Corsa - Racing Bikes: Listino Prezzi - Price ListDocument6 pagesCicli Corsa - Racing Bikes: Listino Prezzi - Price ListcarbonabikesNo ratings yet

- Plastic Fiber Optic Assembly Model PBT26U PBT26U: .02" Diameter Bifurcated Fiber With Threaded Sensing EndDocument2 pagesPlastic Fiber Optic Assembly Model PBT26U PBT26U: .02" Diameter Bifurcated Fiber With Threaded Sensing Endtranphuongxd369No ratings yet

- SL Somos WaterClear Ultra Material Specifications PDFDocument2 pagesSL Somos WaterClear Ultra Material Specifications PDFTushar Prakash ChaudhariNo ratings yet

- Fischer Fixing Catalogue - 2021Document332 pagesFischer Fixing Catalogue - 2021rashid isaarNo ratings yet

- Chapter 5 - GasesDocument72 pagesChapter 5 - GasesAmbar WatiNo ratings yet

- Project Proposal: To Study Expansive Behavior of D. I. Khan Soil and Its TreatmentDocument8 pagesProject Proposal: To Study Expansive Behavior of D. I. Khan Soil and Its TreatmentNoman KhanNo ratings yet

- BALURAN Molecular CompoundsDocument15 pagesBALURAN Molecular CompoundsTito V. Bautista Jr.No ratings yet

- Zoznam NoriemDocument4 pagesZoznam NoriemPeter TvardzíkNo ratings yet

- New Pump Connection Scheme (Anudan Yojna)Document15 pagesNew Pump Connection Scheme (Anudan Yojna)souvikbesu89No ratings yet

- Unit - 3 Bituminous Mixes: Mechanical Properties, Dense and Open Textured MixesDocument21 pagesUnit - 3 Bituminous Mixes: Mechanical Properties, Dense and Open Textured Mixessyed awais50% (2)

- GMW14668 - Minimum Performance Requirements For Decorative Chromium Plated PlasticsDocument20 pagesGMW14668 - Minimum Performance Requirements For Decorative Chromium Plated Plastics廖健翔No ratings yet

- Solid Waste Management Opportunities Challenges GujaratDocument14 pagesSolid Waste Management Opportunities Challenges GujaratRahul Kumar AwadeNo ratings yet