Professional Documents

Culture Documents

Hydratight Morgrip Swivel Ring Flyer

Uploaded by

Senthil Kumar0 ratings0% found this document useful (0 votes)

9 views6 pagesflyer

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentflyer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views6 pagesHydratight Morgrip Swivel Ring Flyer

Uploaded by

Senthil Kumarflyer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

IDC 624,042.2:624,954: 351.785: 003.62

Lastannahmen fir Bauten; Lasten in Silozellen

3.1 Influence quantities

3.1.1 Bulk material properties -

3.1.2 Shape and size of bin cross section

3.1.3 Coefficients of wall friction

3.2 Filling pressures

33 Discharging pressures. .

33.1 General. . 5

332 Uniform pressures.

33.3 Non-uniform pressures

WUWEEEENNN WN

1. Field of application

1.1 General

‘This standard specified methods of determining pres-

sures/loads, predominantly static, produced by the silo

fill and acting on the silo structure.

It does not cover pressures/loads due to dust explosions,

the handling of bulk materials liable to cause such explo-

sions being subject to separate specification.

1.2 Silo bins

‘This standard applies to silo bins with vertical walls and

hoppers or shallow bottoms where the greatest height of

the silo fil, k, is not less than 0,8 times the diameter, d,

of the largest theoretical circle inscribed in the bin. The

standard also applies to silos where h/d is less than 0,8

provided that more than half of the silo fil is located

in the hopper and that the angle of inclination of the

hopper wall is not less than 20

‘This standard applies only where the ratio of vertical

filling pressure to density of the silo fill, Py y, does not

exceed 25 m.

‘This standard does not apply to silo bins of annular cross

section (bins fitted one inside the other) nor does it

DEUTSCHE NORM

Design loads for buildings

Loads in silo bins

In keeping with current practice in standerds published by the International Organization for Standardization /SO).

‘a comma has been used throughout as the decimal marker.

Contents

awe Pooe

1 Field of application 13.4 Pressures acting on bin bottom .4

1.1 General 135 Hopper loads . 4

1.2 Silo bins - 1 38.1 General 4

123 Silo fills 14 352 Hopper filing pressures «=. 4

1.4 Flow patterns 1 1 38.3 Hopper overfill pressures «2... 4

155 Silo operation - 11 3.6 Switch pressures : 4

3.7 Pressures due to injection of compressed air... 5

ee 3.7.1 Injection of ar For drying granular bulk

3 Loads due to bulk mater material . 5

DIN

1055

Part

Supersedes November 1964 edition,

3.7.2 Continuous injection of air as an aid to unload

jing powdery bulk material .

3.7.3 Injection of air for homogenizing powdery bulk

material

2.8 Pressures due to rapid filling and unloading

4 Pressures due to silage

5 Buckling and bulging loads .

6 Temperature effects

‘apply for an increase in pressure due to local changes in

the cross section, to internal fittings or discharge aids.

13 Silo fills

For the purposes of this standard, silo fills include bulk

materials and silage, the granular and powdery sub

stances listed in table 1 being regarded as bulk materials.

‘This standard does not apply to highly cohesive silo fills

such as certain types of forage and coarse meal or 10

bulk materiais liable to swel

1.4. Flow patterns

‘The flow patterns to which this standard is applicable

are funnel flow and mass flow, funnel flow being under-

stood to be flow with temporarily stagnant zones during

discharging and mass flow, flow where the whole bulk

‘material is steadily moving during discharging.

1.5 Silo operation

‘The operational conditions on which the structural

design is to be based shall be agreed by the planning

‘engineer and the user®

Continued on pages 2 to 6

DIN 1055 Part 6 Engl. Price group 5

May 1987 7

Page 2 DIN 1055 Part 6

‘Quantities and symbols

A Effective surface

Height of parallel section

Height

t

wore ese

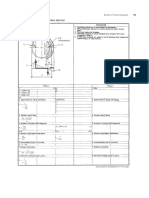

Figure 1. Diagrammatic representation of a silo bin, with notation

3 Loads due to bulk material

3.1. Influence quantities

3.1.1 Bulk matarial properties

Dimensions

diameter of largest theoretical inscribed circle

radius of largest theoretical inscribed circle

cross-sectional area of parallel section

internal perimeter

eccentricity of discharge

wall thickness

depth from effective surface level to point in question

local depth of overfill

maximum depth of silo fill

angle of inclination of hopper wall

Pressures

horizontal pressure

vertical pressure

pressure normal to inclined hopper wall

wall friction pressure

vertical pressure on bin bottom

inlet aie pressure

Subscripts associated with pressures/loads:

filling

discharging

‘Other quantities, coefficients and factors

density of silo fil

pressure ratio Py /Py

coefficient of wall friction (D/P)

angle of slope

‘material coefficient

“thle 1 gives parameters and coetficients relevant for granular and powdery bulk materials, which are to be used in the

4sign calculation, For the sake of simplicity, they may be assumed to be constant over depth z

sable 1, Coefficients for bulk materials

Bulk mat Density, y, | Pressure Coetficients of wall frietion Materil

inkN/m’ | “ratio, coefficient,

a wl ow Hs Be

35 060 380 | a0 05 14 os

a0 060 280 240 026 a)

Barley 80 088 O50 038 026 1 os

Flour 70 040 050 036 025 1 06

Sugar 95 60 | 055 250 086 12 oa

[Crushed quartasand| 160 050 080 250 O40 ta Oa

Rawr couse aporeane] 180 060 080 O50 oa 18 Oa

Limestone powder_| 730 068 056 050 O40 12, 05

(Cement clinker | 180 050 080 O85 04s 12, a7

fement 160 | 088 050 OAs 280 12, 05

iuminia 120 088 050 os 240 12 05

[Fhomas phosshows_| 220 065 055 a0 040 3B a0

CG

3.1.2 Shape and size of bin cross section

‘The shape and size of the bin cross section is introduced.

into the calculation as the ratio A/ss,

For rectangular bins, A/u shall be taken 3s B/2, with b as,

in figure 2, and for star-shaped bins, a: d/4, with d as in

figure 3.

Figure 2. Rectangular bin (plan view)

Figure 3, Star-shaped bin (plan view)

3.13 Coefficients of wall friction

‘As a function of the surface in contact with the bulk:

materials, a distinction is made between three coeffi

cients of wall friction (see table 1):

11 for rough walls, where friction mainly occurs in the

body of the bulk material (e.g. in the case of hori-

zontally stressed corrugated or folded sheet walls);

‘Ha, for walls of medium smoothness (e.g. walls made of

concrete, plaster, wood, sheet steel with rivets and

bolts);

s_ for smooth walls (e.g. walls made of welded or

rebated sheet steel or aluminium walls, plastic walls

and coated walls).

‘Any smoothing of walls by grease, wax or oil from

‘organic bulk materials has been allowed for in table 1.

3.2 Filling pressures

‘The following pressures shall be taken into considera-

tion when filling the silo bin:

wall fiction pressures, pugte) = 2A. 2) (0

horizontal pressures, pute) = 2A. ey 2;

vertical pressures, py(z) = = a oz) (3).

ia

In equations (1) to (3), the quotient gives the pressure at

nnonspecified depth of the silo fill and

4)

6

allows for the increase in pressure as the depth of the silo

fill increases.

‘The cumulative wall friction for 2 is given by:

A

putt) = 2S. 2-29-02

DIN 1055 Part 6 Page 3

33. Discharging pressures

3.3.1 General

During the emptying process, uniform pressures as in

subclause 3.3.2 and uniform pressures as in subclause

3.3.3 shall be assumed to act in the silo bin, However,

if a slo is specifically designed for mass flow, non-

uniform pressures as in subclause 3.3.3 need not be

considered, whilst pressure peaks as in subclause 3.6

shall be allowed for.

3.3.2 Uniform pressures

‘The following uniform pressures may be assumed:

wal fiction pressures, we = 1.1 Pat i”;

horizontal pressures, he = €h Pat @);

vertical pressures, Pye < py (9)

‘The factor 1,1 shall also apply for the cumulative wall

friction pressure, Pye: ex shall be taken from table 1. In

the case of silo bins with h/d greater than 5,0 -1., both

factors shall be used in the calculation at their true value;

for slo bins with hid less than 2,5 -u, they may be

‘assumed to be equal to 1,0. Intermediate values may be

‘obtained by linear interpolation,

33.3 Non-uniform pressures

33.31 General

During the emptying process, bulk material ean produce

non-uniform pressures which shall be taken into account,

in adition to pressure Pug a follows.

In the case of silos of circular eross section, a horizontal

partial pressure asin subclause 3.3.3.2 shall be used.

Where sitos are braced horizontally at top and bottom

{and have wails which ensure adequate horizontal distri

bution of the pressure, then, instead of the additional

sumption ofa partial pressure, an increase inthe uniform

horizontal pressure in accordance with subclauze 3.3.3.3

may be assumed.

In the case of silos with a cross section having n comers,

subclause 3.3.3.3 shall be observed.

Where groups of silo bins are concerned, mutual inter-

action between the bins need not be taken into account.

3.3.3.2 Assumption of a partial pressure

For square surfaces, with a side length, , of 0,8 A/a,

a parial pressure equal to B- Puy (with fas in subclause

3.3.34) shall be used, the load that maintains equilibr-

um,p=5?-2 - Pye, being assumed to act diametrically,

For calculation purposes, itis sufficient to take the par-

tial pressure halfway up the bin and to assume the per-

‘centage increase in resulting stress to act over the whole

silo height, It shall be assumed that the bulk material

sivega6y_support tothe silo wall

3.3.33 {nerease in Ueitorm horizontal pressure

If, by way of departure from the method described in

subclause 3.3.3.2, a higher uniform horizontal pressure,

X” Pia» May be OF has to be allowed for, the increment

to be assumed shall be

2) for silos of circular grass section:

X=1405:84+0,02-f-rit forr/t $70 (10)

and

x0143:B-VRI forr/t 2100 wn

Where r/t is greater than 70 but less than 100, a linear

interpolation is to be made between the values of x for

Flt 70 and r/t = 100.

You might also like

- PVDB PackingDocument1 pagePVDB PackingSenthil KumarNo ratings yet

- PVDB 71Document1 pagePVDB 71Senthil KumarNo ratings yet

- PVDB 72Document1 pagePVDB 72Senthil KumarNo ratings yet

- PVDB 75Document1 pagePVDB 75Senthil KumarNo ratings yet

- PVDM Part-1.5Document1 pagePVDM Part-1.5Senthil KumarNo ratings yet

- PVDM Part-1.4Document1 pagePVDM Part-1.4Senthil KumarNo ratings yet

- PVDB - Force and MomentDocument1 pagePVDB - Force and MomentSenthil KumarNo ratings yet

- Vertical Load Per SaddleDocument1 pageVertical Load Per SaddleSenthil KumarNo ratings yet

- PVDM 4Document1 pagePVDM 4Senthil KumarNo ratings yet

- PVDM Part-1.4Document1 pagePVDM Part-1.4Senthil KumarNo ratings yet

- PVDM Part-5Document1 pagePVDM Part-5Senthil KumarNo ratings yet

- PVDM Part-1.5Document1 pagePVDM Part-1.5Senthil KumarNo ratings yet

- PVDM Part-1.2Document1 pagePVDM Part-1.2Senthil KumarNo ratings yet

- PVDM - Outside RibsDocument1 pagePVDM - Outside RibsSenthil KumarNo ratings yet

- PVDM - Anchor BoltDocument1 pagePVDM - Anchor BoltSenthil KumarNo ratings yet

- Skirt Fireproofing:: Brick or Concrete Applied Inside and Outside of Skirt To Prevent Damage To Skirt in Case of FireDocument1 pageSkirt Fireproofing:: Brick or Concrete Applied Inside and Outside of Skirt To Prevent Damage To Skirt in Case of FireSenthil KumarNo ratings yet

- PV Base Plate With Center WebDocument1 pagePV Base Plate With Center WebSenthil KumarNo ratings yet

- PVDM 8Document1 pagePVDM 8Senthil KumarNo ratings yet

- PVDM 8Document1 pagePVDM 8Senthil KumarNo ratings yet

- PV HTCDocument1 pagePV HTCSenthil KumarNo ratings yet

- PVDM 5Document1 pagePVDM 5Senthil KumarNo ratings yet

- PVDM 6Document1 pagePVDM 6Senthil KumarNo ratings yet

- PVDM 3Document1 pagePVDM 3Senthil KumarNo ratings yet

- PV - Struds SupportsDocument1 pagePV - Struds SupportsSenthil KumarNo ratings yet

- PV - Deep Bims Granular or Powder Filled TanksDocument1 pagePV - Deep Bims Granular or Powder Filled TanksSenthil KumarNo ratings yet

- PV - Types of ImpellersDocument1 pagePV - Types of ImpellersSenthil KumarNo ratings yet

- PV - Pressure Drop and Heat TransferDocument1 pagePV - Pressure Drop and Heat TransferSenthil KumarNo ratings yet

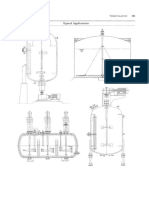

- PV - Typical ApplicationsDocument1 pagePV - Typical ApplicationsSenthil KumarNo ratings yet

- PV - Related EquipmentDocument1 pagePV - Related EquipmentSenthil KumarNo ratings yet

- PV - High Temperature BracketsDocument1 pagePV - High Temperature BracketsSenthil KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)