Professional Documents

Culture Documents

What Is Switchgear and How Does It Work?

Uploaded by

IndraAtmajaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is Switchgear and How Does It Work?

Uploaded by

IndraAtmajaCopyright:

Available Formats

What Is Switchgear and How Does It Work?

Switchgear refers to electrical equipment that regulates the flow of electricity within an electrical

system. It is used by utility providers and private facilities alike for two reasons: to prevent overloads

and short circuits, and to De-energize circuits for testing and maintenance. The most familiar types of

switchgear are circuit breakers and fuses, which interrupt the flow of electricity to a circuit when its

current becomes too high; and power transfer switches, which transfer a buildings source of electricity

from a primary source to a secondary source, such as accessing generator power during a power outage.

Basic Types of Switch Gear

Switchgear is initially categorized according to its interruption technology, the method by which it

extinguishes its electrical arc. Using this categorization, there are five types of gear available on today's

market: oil circuit breaks, which vaporize oil in order to send a jet of oil through an arc; gas (SF6)

breaks, which stretch an arc and then rely on the SF6 to extinguish it; vacuum breaks, which extinguish

their comparatively small arc by stretching it; air breaks, which typically use a puff of air to extinguish

an arc; and hybrid breaks, which use more than one type of breaking technology to extinguish an arc,

such as gas and air.

Additional Classifications that Affect Equipment Choice

Within the classifications above are sub classifications that also determine what type of gear is installed

in certain facilities and how it is serviced. In addition to interruption technology, breakers have at least

eight more classifications: interruption standard (make before break/break before make, circuit break,

or isolation); voltage level (low, medium, or high); general construction type (industrial, utility, marine,

etc.); insulating medium (air, gas, oil, etc.); method of operation (manual, motor, or stored energy);

type of current (alternating or direct); application type (transmission or distribution); and purpose of

operation (isolation, load break, or grounding).

The Importance of Generator Switch Gear Maintenance

Regardless of the type of breakers a facility employs, their proper maintenance is crucial to worker

safety and the preservation of assets, as faulty electrical equipment is a common cause of fatal fires that

destroy commercial facilities. Yet, special attention is often paid to maintaining generator switches due

to their critical role in emergency power production, switching a facility's electricity source from

commercial supply to generator supply in the event of an outage, and the back again when commercial

supply resumes.

In many cases, facilities trust their switch maintenance to a provider of industrial power solutions that

specializes in servicing emergency generators, both with routine maintenance and retrofitting, the latter

when an older generator needs minor technology upgrades and not complete replacement. To learn

more about which type of gear is right for your facility, contact a provider of industrial power solutions

today.

More information at: http://switchgear.made-from-india.com/

You might also like

- Switch GearDocument3 pagesSwitch GearAsifShahzadNo ratings yet

- Introduction To Switch Gear and ProtectionDocument12 pagesIntroduction To Switch Gear and Protectionpmankad100% (7)

- What Is Switchgear? - Features, Components and ClassificationDocument4 pagesWhat Is Switchgear? - Features, Components and ClassificationAsifShahzadNo ratings yet

- SG 1Document6 pagesSG 1Jeeva BharathiNo ratings yet

- Unit 1 Switchgear and Protection: What Is Switchgear? - Features, Components and ClassificationDocument57 pagesUnit 1 Switchgear and Protection: What Is Switchgear? - Features, Components and ClassificationMadhubala DarwaiNo ratings yet

- CH 16Document9 pagesCH 16siya shahNo ratings yet

- PSP Notes 1Document13 pagesPSP Notes 1priyank srivastavaNo ratings yet

- PSP Notes PDFDocument8 pagesPSP Notes PDFpriyank srivastavaNo ratings yet

- What Is Switchgear - Features, Components and ClassificationDocument11 pagesWhat Is Switchgear - Features, Components and Classificationsudhir raiNo ratings yet

- Why Transformers Fail FinalDocument18 pagesWhy Transformers Fail FinalSellappan MuthusamyNo ratings yet

- 6th Ele SGPDDocument118 pages6th Ele SGPDAkash RawatNo ratings yet

- Electrical System Components - Switchgears DDocument38 pagesElectrical System Components - Switchgears DAbongshing MaxwellNo ratings yet

- Industrial Report On "Switch Gear and Protection" Government College of Engineering AmravatiDocument13 pagesIndustrial Report On "Switch Gear and Protection" Government College of Engineering AmravatiSominath HarneNo ratings yet

- MV/LV Switchboards in General: Minimum Possible Time Consistent With The Fault SeverityDocument20 pagesMV/LV Switchboards in General: Minimum Possible Time Consistent With The Fault SeverityzarulNo ratings yet

- Chaprer TwoDocument28 pagesChaprer Twowintabiniam43No ratings yet

- Introduction To Switch Gear and ProtectionDocument12 pagesIntroduction To Switch Gear and ProtectionKrishna PrasadNo ratings yet

- اجهزة تجربة 1Document8 pagesاجهزة تجربة 1hosenalmalke.comNo ratings yet

- Unit-3 NoteDocument21 pagesUnit-3 NoteSankara nathNo ratings yet

- Automatic Transfer SwitchDocument243 pagesAutomatic Transfer SwitchMAKENGO ELIASNo ratings yet

- CH 2Document24 pagesCH 2Moe Thant OoNo ratings yet

- 18eec305t Unit 1 UpdatedDocument85 pages18eec305t Unit 1 UpdatedShivaditya singhNo ratings yet

- Marasigan G ElecDocument3 pagesMarasigan G ElecJohn Louie PimentelNo ratings yet

- Selection of SwitchgearsDocument17 pagesSelection of SwitchgearsTarkan OdabasiNo ratings yet

- CHAPTER 2 Lecture Notes EPS115Document3 pagesCHAPTER 2 Lecture Notes EPS115NGEH SAMUEL SHUNo ratings yet

- Electric MeterDocument6 pagesElectric MeterJustine Marbie MayaoNo ratings yet

- Egyptian Electricity Transmission Co. Network Training Center Substation Training DepartmentDocument30 pagesEgyptian Electricity Transmission Co. Network Training Center Substation Training DepartmentsherifmoussaNo ratings yet

- Elements of SubstationDocument35 pagesElements of Substationjustog_12No ratings yet

- Introduction To Switchgear: Peter Rey M. Tumolva, ReeDocument57 pagesIntroduction To Switchgear: Peter Rey M. Tumolva, ReeJoy KimNo ratings yet

- Assemblies of Switchgear and Control Panels 1Document6 pagesAssemblies of Switchgear and Control Panels 1sabeerNo ratings yet

- Electrical System For High Rise BuildingDocument47 pagesElectrical System For High Rise BuildingMohammad Belal Hossain87% (30)

- Protection System of Grid Substation Transformer: Assignment - 1Document9 pagesProtection System of Grid Substation Transformer: Assignment - 1nahidNo ratings yet

- Power System Basics: Tawsif Hossain Chowdhury Thchowdhury@seu - Edu.bdDocument21 pagesPower System Basics: Tawsif Hossain Chowdhury Thchowdhury@seu - Edu.bdMahmud HasanNo ratings yet

- Types and Revolution of Electrical Relays - Electrical Notes & ArticlesDocument23 pagesTypes and Revolution of Electrical Relays - Electrical Notes & ArticlesKishan DarjiNo ratings yet

- SwitchgearDocument7 pagesSwitchgearShahid JamalNo ratings yet

- Report Siap Explain Switchgear and Switchgear MaintenanceDocument25 pagesReport Siap Explain Switchgear and Switchgear MaintenanceSaniy AhmadNo ratings yet

- Module 06Document24 pagesModule 06rajuanthati100% (1)

- Internship PPT (MGVCL)Document9 pagesInternship PPT (MGVCL)Fariha shaikhNo ratings yet

- Six Week Industrial Training Report: Submitted ToDocument31 pagesSix Week Industrial Training Report: Submitted ToEr Pritpal S SNo ratings yet

- MetalEnclosed MV SwitchgearDocument7 pagesMetalEnclosed MV SwitchgearadauNo ratings yet

- Session 12 Electric Power Ats and SwitchgearsDocument27 pagesSession 12 Electric Power Ats and SwitchgearsRichard mohammedNo ratings yet

- Clasificacion FusiblesDocument7 pagesClasificacion FusiblesFélix LovatónNo ratings yet

- Switchgear PresentationDocument28 pagesSwitchgear PresentationSaniy Ahmad67% (3)

- GAPS Guidelines: Transformers - FailuresDocument5 pagesGAPS Guidelines: Transformers - Failuresmakasad26No ratings yet

- Distribution System RelayDocument21 pagesDistribution System RelayDev KumarNo ratings yet

- 4.0 Power Distribution System XDocument33 pages4.0 Power Distribution System XhilminroziNo ratings yet

- Study of Substation Equipments & Protection: Konark Institute of Science & Technology BhubaneswarDocument19 pagesStudy of Substation Equipments & Protection: Konark Institute of Science & Technology BhubaneswarDev KumarNo ratings yet

- Transformer Protection Application GuideDocument33 pagesTransformer Protection Application GuideDulon40100% (2)

- 1.0 Power Distribution SystemDocument38 pages1.0 Power Distribution Systemadamikhwan182No ratings yet

- Electrical Panel InspectionDocument5 pagesElectrical Panel InspectionFawaaz KhurwolahNo ratings yet

- ET601 - Chapter 1Document25 pagesET601 - Chapter 1Thanaletchumy RamesamyNo ratings yet

- Selection Guide For Transformer-Primary Fuses inDocument78 pagesSelection Guide For Transformer-Primary Fuses inJose Alberto Rodriguez100% (1)

- InteroductionDocument8 pagesInteroductionsalagasimNo ratings yet

- Final ExamDocument20 pagesFinal ExamMaverick BisqueraNo ratings yet

- Electro Report Group 3Document6 pagesElectro Report Group 3John Steven DelimaNo ratings yet

- Should Transfer Switch Be Equipped With Contactors or Circuit Breakers? Manual or Automatic?Document21 pagesShould Transfer Switch Be Equipped With Contactors or Circuit Breakers? Manual or Automatic?martydavis123No ratings yet

- Internship ReportDocument6 pagesInternship ReportEngr Syed Numan ShahNo ratings yet

- Should Transfer Switch Be Equipped With Contactors or Circuit BreakersDocument11 pagesShould Transfer Switch Be Equipped With Contactors or Circuit BreakersSandro CuetoNo ratings yet

- Sola-Hd Power Quality Guidebook BrochureDocument20 pagesSola-Hd Power Quality Guidebook BrochuresolbahiaNo ratings yet

- Empowering Networks: A Comprehensive Guide to Medium Voltage SwitchgearFrom EverandEmpowering Networks: A Comprehensive Guide to Medium Voltage SwitchgearNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Grapic Builder: Day 5 - Engineering CourseDocument33 pagesGrapic Builder: Day 5 - Engineering CourseIndraAtmajaNo ratings yet

- Brass Cable - Brochure March 04Document24 pagesBrass Cable - Brochure March 04IndraAtmajaNo ratings yet

- His ConfigurationDocument80 pagesHis ConfigurationIndraAtmajaNo ratings yet

- Brass Cable Glands Brochure 0703Document18 pagesBrass Cable Glands Brochure 0703IndraAtmajaNo ratings yet

- CS3000 System OverviewDocument32 pagesCS3000 System OverviewIndraAtmajaNo ratings yet

- MV Metal-Clad Switchgear: The Safest, Most Reliable Switchgear in The Market TodayDocument50 pagesMV Metal-Clad Switchgear: The Safest, Most Reliable Switchgear in The Market TodayIndraAtmaja100% (1)

- Tapping Measuring Technology: TMT at A Glance. Equipment For Blast Furnaces & SmeltersDocument8 pagesTapping Measuring Technology: TMT at A Glance. Equipment For Blast Furnaces & SmeltersIndraAtmajaNo ratings yet

- Commissioning Procedure of Instrument Pressure TransmitterDocument5 pagesCommissioning Procedure of Instrument Pressure TransmitterIndraAtmajaNo ratings yet

- Product Information: Wear Parts and ConsumablesDocument40 pagesProduct Information: Wear Parts and ConsumablesIndraAtmajaNo ratings yet

- LAPORAN Desember 2018Document6 pagesLAPORAN Desember 2018IndraAtmajaNo ratings yet

- Mechanical Level Switches - 912 PDFDocument60 pagesMechanical Level Switches - 912 PDFIndraAtmajaNo ratings yet

- Toparts Quotation-Cat Seal Kit-Nss Ci-Cote Dovoire-2017!11!10Document3 pagesToparts Quotation-Cat Seal Kit-Nss Ci-Cote Dovoire-2017!11!10zephyrinNo ratings yet

- Swissauto 250Document51 pagesSwissauto 250Mothi Ram100% (1)

- Special Purpose Vehicles: Padhiyar Raj H Automobile Department Saffrony Institute of TechnologyDocument34 pagesSpecial Purpose Vehicles: Padhiyar Raj H Automobile Department Saffrony Institute of TechnologyBirjesh YaduvanshiNo ratings yet

- Data Sheet: TEA1533T TEA1533ATDocument24 pagesData Sheet: TEA1533T TEA1533ATjotas2525No ratings yet

- Baldor DC ServoDocument48 pagesBaldor DC Servod3xter100% (1)

- Champion C-Base - C-Line - C-Pro - C-Advanced - C-Silenced - C-Engine Piston CompressorsDocument12 pagesChampion C-Base - C-Line - C-Pro - C-Advanced - C-Silenced - C-Engine Piston Compressorssergimiravia1No ratings yet

- D3 Remote ManualDocument2 pagesD3 Remote ManualbobanmiNo ratings yet

- Product Information.: Technical Training. N47TU EngineDocument66 pagesProduct Information.: Technical Training. N47TU EngineAndreAPL100% (1)

- Foxconn Rs690m02 Rev A SCHDocument36 pagesFoxconn Rs690m02 Rev A SCHegriecoNo ratings yet

- RENR9344-02-01-ALL Troubleshooting - EngineDocument160 pagesRENR9344-02-01-ALL Troubleshooting - EngineDeusdado Pineda HuancoNo ratings yet

- RFQ Lines 2119139Document5 pagesRFQ Lines 2119139MESHELNo ratings yet

- Manual de OkumaDocument36 pagesManual de OkumaIng Roberto CisnerosNo ratings yet

- Testing 110V Appliances AN39 1 PDFDocument1 pageTesting 110V Appliances AN39 1 PDFlast730100% (1)

- Mls 2300 AcdcDocument26 pagesMls 2300 AcdcCesar ObesoNo ratings yet

- Jadwal Pelajaran Semester GENAP TAPEL. 2324Document15 pagesJadwal Pelajaran Semester GENAP TAPEL. 2324KityNo ratings yet

- Magneto Resistors: Module-2: Sensors and Signal Conditioning EEE4021Document12 pagesMagneto Resistors: Module-2: Sensors and Signal Conditioning EEE4021sabarivelan sNo ratings yet

- BOSCH D JETRONIC Fuel Injection of Renault 17 TSDocument18 pagesBOSCH D JETRONIC Fuel Injection of Renault 17 TSRaul Quispe Ramirez60% (5)

- WEG CFW300 User Manual 10003325037 en Es PT PDFDocument153 pagesWEG CFW300 User Manual 10003325037 en Es PT PDFmaurosergiorovettaNo ratings yet

- Programmable Logic Controller (PLC) Is A Digital Computer Used For The Automation of VariousDocument23 pagesProgrammable Logic Controller (PLC) Is A Digital Computer Used For The Automation of VariousSunil ChaudhariNo ratings yet

- CrosswayDocument16 pagesCrosswayMehdi SamiNo ratings yet

- Acb Master Pact CatalogueDocument159 pagesAcb Master Pact CatalogueariessukmawanNo ratings yet

- Instruction Manual AK-157Document10 pagesInstruction Manual AK-157Kalim KamNo ratings yet

- Ficha Tecnica Tomacorriente - 5825-w LevintonDocument2 pagesFicha Tecnica Tomacorriente - 5825-w LevintonCORTIN Sociedad Anonima CerradaNo ratings yet

- Dmx512-A Guide (8x10) EstaDocument112 pagesDmx512-A Guide (8x10) EstaArturo SierraNo ratings yet

- ATV930 950 Installation Manual en NHA80932 03Document143 pagesATV930 950 Installation Manual en NHA80932 03Anonymous Th1OVYPQYTNo ratings yet

- Locon32 eDocument88 pagesLocon32 eyoooo_74No ratings yet

- CONTRACT - JAP006-D73 132/11kV PALM, JUMEIRAH S/S (4 Nos) 11Kv Switchgear VT CalculationDocument6 pagesCONTRACT - JAP006-D73 132/11kV PALM, JUMEIRAH S/S (4 Nos) 11Kv Switchgear VT CalculationmadhavanNo ratings yet

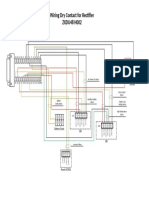

- Wiring Dry Contact ZXDU48 H002Document1 pageWiring Dry Contact ZXDU48 H002Donny Sulistyo NugrohoNo ratings yet

- Table of Contents (Troubleshooting) PDFDocument3 pagesTable of Contents (Troubleshooting) PDFTon BlokNo ratings yet

- LAN XI HardwareDocument28 pagesLAN XI HardwareRafael Sánchez CrespoNo ratings yet