Professional Documents

Culture Documents

Notes:: Fit-Up

Uploaded by

Muhammad Fahmi MahmudOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notes:: Fit-Up

Uploaded by

Muhammad Fahmi MahmudCopyright:

Available Formats

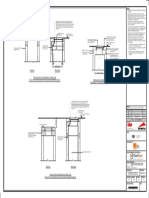

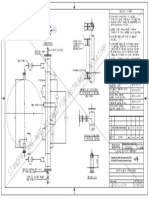

1 of 3 05 AB-036029 L 990

NOTES :

REV. NO. SHT. NO. DRAWING NUMBER INDEX PLANT NO.

1. NON-PRESSURE CONTAINING SLEEVES, FABRICATED

WITH X-60 MAT’L., ARE AVAILABLE FROM SAMS

S/N 02-579-XXX. SLEEVES, FABRICATED WITH

X-52 MAT’L., ARE AVAILABLE FROM SAMS S/N

02-578-XXX. ALL SLEEVES SHOULD BE INSTALLED

IN ACCORDANCE WITH THIS STD. DRAWING.

SLEEVE HALVES 2. THESE SLEEVES MAY BE USED FOR:

- REINFORCING MINIMUM WALL THICKNESS

SEE DETAIL-2 VIOLATIONS DUE TO EXTERNAL CORROSION

OR EXCESSIVE GRINDING.

3000 ( +

- 100 ) - REINFORCING DENTS WITHOUT GOUGES.

STANDARD LENGTH (SEE NOTE-4) - CORROSION BARRIERS.

3. THESE SLEEVES SHALL NOT BE USED FOR :

- REPAIRING LEAKS.

BOTH SIDES - REPAIRING MINIMUM WALL THICKNESS

SEE NOTE-6 tb VIOLATIONS DUE TO INTERNAL CORROSION.

- COUPLING SECTIONS OF PIPE TOGETHER.

4. DO NOT MODIFY THESE SLEEVES IN ANY

BUTT STRAP

MANNER WITHOUT THE APPROVAL OF CSD.

PIPE

C C 5. REPAIR SLEEVE FIT-UP SHOULD BE AS TIGHT

AS POSSIBLE. IN ANY CASE, THE MAXIMUM

GAP BETWEEN THE SLEEVE AND PIPE

SURFACE AT THE ENDS OF THE SLEEVE

SHOP WELD SHALL NOT EXCEED 3.2mm ( 1/8 " ). TO

(TYP. BOTH SIDES)

PROVIDE THE BEST STRESS SHARING

CAPABILITY OF THIS SLEEVE, IT IS

RECOMMENDED TO FILL THE ANNULAR

SHOP WELDS SPACE BETWEEN THE SLEEVE AND PIPE

(BOTH SIDES) WALL WITH A HARDENABLE EPOXY MATERIAL.

FIELD BEVEL SLEEVE 37^ IF NECESSARY, USE CHAINS AND HYDRAULIC

PRIOR TO FIT-UP AND INSTALLATION JACKS DURING THE FIT-UP. DO NOT

OF PRE-FORMED FILLER PIECES REMOVE THESE RESTRAINTS UNTIL THE

SEE DETAIL-1 (TYP. ALL SIDES)

WELDERS HAVE DEPOSITED AT LEAST

SEE DETAIL-3

9.6mm ( 3/8 " ) OR 25% OF THE REQUIRED

BOTH LONGITUDINAL FILLET WELD SIZE ON BOTH

SIDES tb SIDES.

t

SEE NOTE-6 s 6. WELDERS AND WELDING PROCEDURES SHALL

t BE QUALIFIED TO EITHER API 1104 OR

b

FIT-UP ASME SECTION IX. ALL WELDS SHALL BE

20^ BEVEL MADE WITH LOW HYDROGEN ELECTRODES.

+ 5^ FILLER PIECES

- THE WELDING SEQUENCE FOR A STANDARD

CUT TO FIT

3,000 mm (10 ft.) SLEEVE IS :

1/8 " MAX. GAP

(TYP.)

- WELD BOTH LONGITUDINAL FILLET WELDS.

- FIT-UP AND WELD ALL THE FILLER PIECES.

- WELD BOTH CIRCUMFERENTIAL FILLET

GIRTH WELDS ONE AT A TIME OR

SIMULTANEOUSLY. NOTE: IF APPROVAL HAS

SHOP WELDS BEEN GIVEN BY CSD TO SHORTEN

SLEEVE ts (TYP.) THE SLEEVE LENGTH TO LESS THAN

1500mm (5 ft.) , WELD ONE END OF THE

SLEEVE AT A TIME, ALLOWING IT TO

t COOL TO AMBIENT TEMPERATURE BEFORE

PIPE

STARTING THE OTHER WELD.

7. ALL FIELD WELDS, INCLUDING THE SHOP

WELDS SHALL HAVE A FINAL MAGNETIC

DETAIL-1 PARTICLE OR LIQUID PENETRANT (MT OR PT)

EXAMINATION.

SEE NOTE-5

DETAIL-3 8. REFER TO GI 434.000 FOR ADDITIONAL

INFORMATION.

DETAIL-2

TYPICAL INSTALLATION DRAWING

SEE NOTE-5 ESSD

04 OCT95 REVISED AND ADDED SHT. 003.

RLO

BOTH SIDES ESSD

03 DEC92

BOTH SIDES & ENDS AVM REVISED AS PER MARK UP

SEE NOTE-6 tb (TYP.) REVISED NOTE 9 TO CHANGE

02 11-16-91 JSM

SEE NOTE-6 REFERENCE DWG. NO.

REVISED BUTT STRAP BEVEL

05 02-17-98 HRD

ANGLE

REV.

DATE BY JO/EWO DESCRIPTION CHKD. CERT. APPD.

NO.

BOTH ENDS SAUDI ARABIAN OIL COMPANY

(TYP.) RLO NONE

ts DRAWN BY CHECKED BY SCALE

SEE NOTE-6 03-12-90 03-12-90

DATE STARTED DATE COMPLETED

OPR’G. DEPT. ENG. DEPT.

| APP’D FOR CONSTR.

THIS DRAWING IS NOT TO BE USED FOR CERTIFIED

CONSTRUCTION OR FOR ORDERING

MATERIAL UNTIL CERTIFIED AND DATED BY DATE

INSTALLATION OF PIPELINE

REPAIR SLEEVES

(NON-PRESSURE CONTAINING)

STD. DWG. METRIC

PLANT NO. INDEX DRAWING NUMBER SHT. NO. REV. NO.

990 L AB-036029 1 of 3 05

Saudi Aramco 2634 ENG. (3/91)

CADD-02

You might also like

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- SaudiAramco material list for pole installationDocument1 pageSaudiAramco material list for pole installationAbu Anas M.SalaheldinNo ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

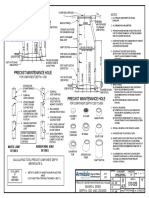

- 26 - RT609 - U - TYP - 014 - A MH Cover AdjustingDocument1 page26 - RT609 - U - TYP - 014 - A MH Cover AdjustinganooppattazhyNo ratings yet

- $RD10F7PDocument1 page$RD10F7PManishNo ratings yet

- U Wall 2 (25-01-2022) - Sheet1Document1 pageU Wall 2 (25-01-2022) - Sheet1Suneel BalaniNo ratings yet

- Structurals 2Document1 pageStructurals 2seulipark2629No ratings yet

- General Notes: Ugt Tank (15000x10200x2000) Total Capacity: 3,12,000 L Pump RoomDocument1 pageGeneral Notes: Ugt Tank (15000x10200x2000) Total Capacity: 3,12,000 L Pump RoomDary ConstanceNo ratings yet

- RCC Drawing of Open Drain 11-10-2022Document16 pagesRCC Drawing of Open Drain 11-10-2022AKB CONSULTANTSNo ratings yet

- C200-Roadworks Notes and Details-C240Document1 pageC200-Roadworks Notes and Details-C240Don WangNo ratings yet

- General Notes:: Typical Section of R.C.C. Storm Water DrainDocument2 pagesGeneral Notes:: Typical Section of R.C.C. Storm Water Drainbijnor officeNo ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyAbu Anas M.SalaheldinNo ratings yet

- D B B D: General NotesDocument1 pageD B B D: General NotessamiabdulwahabNo ratings yet

- JERSD J 0071 Instrument StandpipesDocument1 pageJERSD J 0071 Instrument StandpipescesarvalenciaperdomoNo ratings yet

- $RCFM808Document1 page$RCFM808ManishNo ratings yet

- Ramp SectionDocument1 pageRamp SectionBhavya PatelNo ratings yet

- Cover and Surround Maintenance Hole DesignDocument1 pageCover and Surround Maintenance Hole DesignHarsha nrNo ratings yet

- Installation Requirements for Bus Stop SignageDocument1 pageInstallation Requirements for Bus Stop Signagedarren dmuscat1hotmail.comNo ratings yet

- General notes and column schedule for building foundationDocument1 pageGeneral notes and column schedule for building foundation025Karthik ReddyNo ratings yet

- Transportation Idaho Department: NotesDocument1 pageTransportation Idaho Department: NotesBikash SigdelNo ratings yet

- SaudiAramco material list for steel polesDocument1 pageSaudiAramco material list for steel polesAbu Anas M.SalaheldinNo ratings yet

- Tshwane South-Western region road infrastructure notesDocument1 pageTshwane South-Western region road infrastructure notesRenier JoubertNo ratings yet

- ACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Document1 pageACM-TSC-VS-MF-GFC-DWG-ST-2001 - Rev 1Aecom IndiaNo ratings yet

- Construction notes for reinforced concrete retaining wallDocument1 pageConstruction notes for reinforced concrete retaining wallM JAVEDNo ratings yet

- Standard NZ Footbridge With Horizontal Wires Rev A March 2017 Full SetDocument7 pagesStandard NZ Footbridge With Horizontal Wires Rev A March 2017 Full SetbetsegaNo ratings yet

- Concept Plan-R1Document1 pageConcept Plan-R1akhil krisNo ratings yet

- BASEMENT PLAN DR - TANEJA-ModelDocument1 pageBASEMENT PLAN DR - TANEJA-Modelyashu tanejaNo ratings yet

- Aacm Standard DrawingsDocument7 pagesAacm Standard Drawingshussein247No ratings yet

- 2 Row HPC For BC SoilDocument1 page2 Row HPC For BC SoilShivam SharmaNo ratings yet

- General: Shoring of ExcavationDocument7 pagesGeneral: Shoring of ExcavationshanihakkNo ratings yet

- TB 135483 006Document1 pageTB 135483 006Rene HebaNo ratings yet

- Ground Floor - Plan (Bath Room-1&2) 01: BATH-1 BATH-2 A ADocument1 pageGround Floor - Plan (Bath Room-1&2) 01: BATH-1 BATH-2 A ABismo AnggoroNo ratings yet

- Jayamangal Dining BlockDocument4 pagesJayamangal Dining BlockShiwani SahNo ratings yet

- Structural 2storeyDocument11 pagesStructural 2storeyMark James Mateo100% (1)

- StructuralDocument15 pagesStructuralMark James MateoNo ratings yet

- Plan 20ld0130 - Part 3Document11 pagesPlan 20ld0130 - Part 3MarjanNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NoteschrisNo ratings yet

- Academic drawing dimensions and notesDocument17 pagesAcademic drawing dimensions and notesNeha DasNo ratings yet

- DRG 1Document1 pageDRG 1Palak BhatiaNo ratings yet

- Service Installation Pole Mount (Shown) : Notes: Grounding SystemDocument1 pageService Installation Pole Mount (Shown) : Notes: Grounding SystemEnrique Hdez. E.No ratings yet

- J414252001PADocument1 pageJ414252001PASehna SerajNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- DC 950045 001Document1 pageDC 950045 001Abu Anas M.SalaheldinNo ratings yet

- DWG. No. 117Document1 pageDWG. No. 117Mubashar Islam JadoonNo ratings yet

- Installation design for refractory anchors and insulationDocument1 pageInstallation design for refractory anchors and insulationAkhil GeorgeNo ratings yet

- QP10-U-706 Rev0 Typical Wadi CrossingsDocument1 pageQP10-U-706 Rev0 Typical Wadi CrossingsnawajhaNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- SaudiAramco material list for overhead power line polesDocument1 pageSaudiAramco material list for overhead power line polesAbu Anas M.SalaheldinNo ratings yet

- Structural Notes: Typ. CHB Partition On Suspended Slab 7Document1 pageStructural Notes: Typ. CHB Partition On Suspended Slab 7Joshua VacaroNo ratings yet

- 1009-S1-EL-EAR-4001 - 0 - SV1 - Electrical Outdoor Earthing LayoutDocument1 page1009-S1-EL-EAR-4001 - 0 - SV1 - Electrical Outdoor Earthing LayoutRashmi Ranjan MohantyNo ratings yet

- A036513004 PDFDocument1 pageA036513004 PDFWael ChouchaniNo ratings yet

- G FootingsDocument9 pagesG FootingsRiham Massoud SobhyNo ratings yet

- Section 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byDocument1 pageSection 1 - 1 Section 2 - 2 Section 3 - 3: Revision No. byPaschal MazikuNo ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyxiaoNo ratings yet

- Uecp-Sd-Cul - 12.1-R00Document3 pagesUecp-Sd-Cul - 12.1-R00Anuradha KoswaththaNo ratings yet

- Structural column and foundation detailingDocument1 pageStructural column and foundation detailingHarbhajan SinghNo ratings yet

- 1002016-0100-DRG-CC-0003 TYPICAL DETAILS PIPE MARKER DETAILDocument1 page1002016-0100-DRG-CC-0003 TYPICAL DETAILS PIPE MARKER DETAILhexiaogang167No ratings yet

- EWAC Trend & Polar PlotsDocument2 pagesEWAC Trend & Polar PlotsMuhammad Fahmi MahmudNo ratings yet

- EWAC Trend & Polar PlotsDocument2 pagesEWAC Trend & Polar PlotsMuhammad Fahmi MahmudNo ratings yet

- Cracked Rotor Demonstration Visualizes 2x Forcing FunctionDocument4 pagesCracked Rotor Demonstration Visualizes 2x Forcing FunctionMuhammad Fahmi MahmudNo ratings yet

- 08-PT11-Turbomachinery Testing (Compatibility Mode) PDFDocument104 pages08-PT11-Turbomachinery Testing (Compatibility Mode) PDFMuhammad Fahmi MahmudNo ratings yet

- Model Based Current Analysis of ElectricDocument6 pagesModel Based Current Analysis of ElectricMuhammad Fahmi MahmudNo ratings yet

- Place For Title: Resolving Cyclic Vibration On An Instrument Air CompressorDocument19 pagesPlace For Title: Resolving Cyclic Vibration On An Instrument Air CompressorMuhammad Fahmi Mahmud100% (1)

- Analysis and Investigation of Diesel Engine Vibration SignalDocument6 pagesAnalysis and Investigation of Diesel Engine Vibration SignalMuhammad Fahmi MahmudNo ratings yet

- Summary of GLOC Camera Quick Functional Check by Our TechnicianDocument1 pageSummary of GLOC Camera Quick Functional Check by Our TechnicianMuhammad Fahmi MahmudNo ratings yet

- Pihak Berkuasa Penerbangan Awam Malaysia (Civil Aviation Authority of Malaysia) Application For Unmanned Aircraft System (Uas) / DroneDocument11 pagesPihak Berkuasa Penerbangan Awam Malaysia (Civil Aviation Authority of Malaysia) Application For Unmanned Aircraft System (Uas) / DroneMuhammad Fahmi MahmudNo ratings yet

- Basic Iris M Version2.3 PDFDocument109 pagesBasic Iris M Version2.3 PDFMuhammad Fahmi MahmudNo ratings yet

- Metal Additives Impact To EngineDocument8 pagesMetal Additives Impact To EngineMuh yusupNo ratings yet

- 10.3906 Sag 1202 80 126545 PDFDocument10 pages10.3906 Sag 1202 80 126545 PDFMuhammad Fahmi MahmudNo ratings yet

- Anomalert Software Manual PDFDocument81 pagesAnomalert Software Manual PDFMuhammad Fahmi MahmudNo ratings yet

- Mazak Case Study PDFDocument63 pagesMazak Case Study PDFBrobrtNo ratings yet

- DamperX ClampDocument2 pagesDamperX ClampMuhammad Fahmi MahmudNo ratings yet

- System 1 19.1 Software Datasheet 0Document18 pagesSystem 1 19.1 Software Datasheet 0Muhammad Fahmi MahmudNo ratings yet

- A5300 Vibration TrendsDocument7 pagesA5300 Vibration TrendsMuhammad Fahmi MahmudNo ratings yet

- White Paper Understanding Data Averaging Modes en 5545142 PDFDocument3 pagesWhite Paper Understanding Data Averaging Modes en 5545142 PDFMuhammad Fahmi MahmudNo ratings yet

- 02 - Introduction To ADRE SXPDocument21 pages02 - Introduction To ADRE SXPMuhammad Fahmi MahmudNo ratings yet

- UndoButton NonRecipEngineDocument2 pagesUndoButton NonRecipEngineMuhammad Fahmi MahmudNo ratings yet

- Page No. 1 of 10: December 31, 2000Document10 pagesPage No. 1 of 10: December 31, 2000Muhammad Fahmi MahmudNo ratings yet

- BN3500 Rack Info GTC Production Cooler FanDocument533 pagesBN3500 Rack Info GTC Production Cooler FanMuhammad Fahmi MahmudNo ratings yet

- BILL OF MATERIALSDocument1 pageBILL OF MATERIALSMuhammad Fahmi MahmudNo ratings yet

- Last Measurement Deviation Report AnalysisDocument31 pagesLast Measurement Deviation Report AnalysisMuhammad Fahmi MahmudNo ratings yet

- Page No. 1 of 10: December 31, 2000Document10 pagesPage No. 1 of 10: December 31, 2000Muhammad Fahmi MahmudNo ratings yet

- Anomalert Software Manual PDFDocument81 pagesAnomalert Software Manual PDFMuhammad Fahmi MahmudNo ratings yet

- Read MeDocument1 pageRead Mecompre clikandoNo ratings yet

- Saudi Aramco Oil Pole InstallationDocument1 pageSaudi Aramco Oil Pole InstallationMuhammad Fahmi MahmudNo ratings yet

- Correspondence Phrases For LETTERDocument4 pagesCorrespondence Phrases For LETTERinbNo ratings yet

- Volza - China To IndiaDocument28 pagesVolza - China To Indiamohammed.surangiwalaNo ratings yet

- 10151A1Document3 pages10151A1Archana ShuklaNo ratings yet

- A New Scheme For Ammonia and Fertilizer GenerationDocument14 pagesA New Scheme For Ammonia and Fertilizer GenerationChiaoNo ratings yet

- Steel Slag Silo: EL (+) 0.000M FFLDocument4 pagesSteel Slag Silo: EL (+) 0.000M FFLElectrical ShahNo ratings yet

- ASME B31.3 Process Piping Wall Thickness CalculationDocument27 pagesASME B31.3 Process Piping Wall Thickness CalculationJesus Magallanes SNo ratings yet

- B42Document16 pagesB42Juan JuanNo ratings yet

- Service Manual - Sandpiper s15Document24 pagesService Manual - Sandpiper s15tineohNo ratings yet

- Refining Process-AlkylationDocument20 pagesRefining Process-AlkylationTusenkrishNo ratings yet

- The Comparative Study of The Compressive Strength of Concrete Made With Granite To That Made With River Round StoneDocument10 pagesThe Comparative Study of The Compressive Strength of Concrete Made With Granite To That Made With River Round StoneMalcolmNo ratings yet

- Excel Pipes Jacking PipesDocument4 pagesExcel Pipes Jacking PipesAli ZarehNo ratings yet

- Briquenol BB binder for pelletizationDocument1 pageBriquenol BB binder for pelletizationshrikrishna rathodNo ratings yet

- Effect of Elastane Denier and Draft Ratio of Core-Spun Cotton Weft Yarns On The Mechanical Properties of Woven FabricsDocument10 pagesEffect of Elastane Denier and Draft Ratio of Core-Spun Cotton Weft Yarns On The Mechanical Properties of Woven FabricsDyeing DyeingNo ratings yet

- Battery Thermal Management EbookDocument13 pagesBattery Thermal Management Ebooktarun100% (2)

- 4014 03Document7 pages4014 03Carlos Romero Muñoz100% (2)

- Sistem Pelumasan: - ReviewDocument72 pagesSistem Pelumasan: - ReviewUncle MTANo ratings yet

- Specification of SGP InterlayerDocument3 pagesSpecification of SGP InterlayerHAN HANNo ratings yet

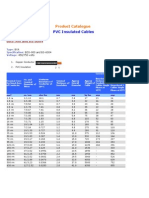

- BRB Cables PVCDocument30 pagesBRB Cables PVCMorsed Al Mamun75% (40)

- A 581 - A581M - 95b R00 - QTU4MS9BNTGXTQDocument3 pagesA 581 - A581M - 95b R00 - QTU4MS9BNTGXTQDeepak JNo ratings yet

- GGFHJDocument1 pageGGFHJanon_791172439No ratings yet

- A 160Document2 pagesA 160amirhosseinNo ratings yet

- Sreenidhi Institute of Science and TechnologyDocument15 pagesSreenidhi Institute of Science and TechnologyPrashanth GurramNo ratings yet

- Class 12 Expt 18 Preparation of Inorganic SaltDocument2 pagesClass 12 Expt 18 Preparation of Inorganic Saltsridemass321No ratings yet

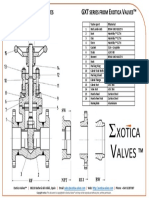

- Gate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimDocument1 pageGate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimGiovanni PetrizzoNo ratings yet

- Mitsubishi Process of Copper MakingDocument23 pagesMitsubishi Process of Copper MakingSwarnaRakshitNo ratings yet

- CSWIP 3.2 Multiple ChoiceDocument10 pagesCSWIP 3.2 Multiple Choicerandhir kumar jha0% (1)

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- 5070 w17 QP 42 PDFDocument14 pages5070 w17 QP 42 PDFdR SHAMMIR AHMEDNo ratings yet

- Boq of Dire Dawa Project Final Price AdjustedDocument67 pagesBoq of Dire Dawa Project Final Price Adjustedbings1997 BiniamNo ratings yet

- Plasma Arc Cutting: Prepared By: Raghav SinglaDocument16 pagesPlasma Arc Cutting: Prepared By: Raghav SinglarrameshsmitNo ratings yet