Professional Documents

Culture Documents

Prestressed Concrete Tension Piles and Their Connections PDF

Uploaded by

lsatchithananthanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prestressed Concrete Tension Piles and Their Connections PDF

Uploaded by

lsatchithananthanCopyright:

Available Formats

TECHNICAL NOTE

Prestressed Concrete Tension

Piles and Their Connections

by

Mcleod C. Nigels, P.E.

Senior Associate

Davis & Floyd, Inc.

Charleston, South Carolina

restressed concrete piles are sign of the foundation. Dowels can be method is sometimes objectionable

P vital elements in many struc-

tures. Generally, the prime pur-

pose of piles is to carry compression

cast into the pile head to protrude for

embedment in the pile cap. However,

dowels that protrude from the pile

because it requires fie ld-cutting of the

pile head.

A method for grouting dowels into

loads. It is not unusual, however, to head are an obstruction to the pile holes cast in the piling is given in the

encounter projects that require tension hammer. following example. This is the pre-

piles. Lateral loads from wind and Dowels can also be totally cast in ferred method for providing mild steel

earthquakes often create overturning, and exposed after pile driving by dowels and is best used when pile

resulting in uplift on piles supporting breaking off the top of the pile. This lengths can be predetermined. A simi-

the structure. When piles are subjected practice requires increased pile lengths lar connection can be used in other in-

to uplift, connections are required be- to account for the part that is to be cut stances where piles are driven to re-

tween the pile and pile cap that must off. The practice of field-cutting is fusal (impenetrable foundation). In

be properly designed to resist tensile time consuming and expensive. Be- these instances, dowel holes are field-

forces. cause it is generally possible to cast in drilled and dowels are grouted in just

Proper connection details transfer on ly straight bars, field bending is as they are in formed holes.

the axial tension from the structure to sometimes required to develop bars in If dowel holes are drilled in, special

the prestressed section of the pile. relatively shallow pile caps. The field care must be taken to ensure that the

Mild steel dowels are the most often bending of bars as large as a No. 11 holes are thoroughly cleaned prior to

used means of connecting pile caps to size can be an obvious problem for the grouting in the dowels. Any concrete

prestressed concrete piling, although contractor. dust or soft paste resulting from

connections are sometimes made to Another method of connecting a drilling must be removed in order to

the prestressing strands. pile to a pile cap is to remove the con- ensure a good bonding surface. The

The method by which connections crete at the head of the pile, thus ex- presence of a good bonding surface

are made via mild steel dowels is a posing the prestressing strands for for the grout is an implicit assumption

very important consideration in the de- connection to the pile cap. Again, this in the design of grouted dowels.

138 PCI JOURNAL

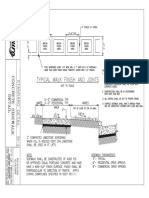

1'-0 1/4"

( 4) 0" ¢ 270K LOW

RELAXATION STRAND

@ 30,980#

DOWEL HOLES ::

~ ::

1'-J

::

~

1'-J

'

~

C'\J

SPIRAL

Fig . 1. Cross section of pile.

PROBLEM SOLUTION (45 mm) diameter spiral metal tube in

each corner of the pile.

12 x 12 in. (305 x 305 mm) square Certain criteria must be satisfied in

prestressed concrete piles are being order to provide a proper connection

designed for a building foundation. and ensure against failure of the pile in 1. Dowel Size Required

Seismic analysis indicates that resis- tension. Tu = 1.87 (50) = 93.5 kips (415.9 kN)

tance to overturning subjects piles to • The dowel holes must be fully de-

Dowel area required :

an axial tensile working load of 50 veloped in the pile. In this example,

kips (222.4 kN) per pile. tubing will consist of spiral metal A _ _Tu ----

93.5

Design the connection between the tubing similar to that common ly s- l/J!y- 0.9x60

pile and the pile cap and check the de- used for post-tensioning sheathing.

= 1.73 sq in. (1116 mm 2 )

sign of the pile for an uplift of 50 kips This type of tubing conforms to

(222.4 kN) . Using ACI 318-95 , Sec- ASTM A525 requirements. Smooth Provide four #6 dowels= 1.76 sq in.

tion 9.2.3,' the required load factor is tubing should not be used to form (1136 mm 2).

1.7(1.1£) or 1.87E. dowel holes unless special means

The piles are to be prestressed using are taken to ens ure against bond 2. Dowel Embedment

four 1/z in. (12.7 mm) diameter low re- failure between the tube and the sur-

Embedment length required = ld.

laxation strands, 270 ksi, tensioned to rounding concrete.

From ACI 318 , Chapter 12, Eq.

75 percent ultimate [Aps per strand = • The dowel must be fully developed

(12- 1), ld is calculated as 17.43 in .

0.153 sq in. (98 .7 mm2)]. in the grouted dowel hole. Refer to

(443 mm).

fc'=6000 psi (41MPa) ACI 318-95, Chapter 12.'

The PCI Design Handbook, Fifth

The method chosen to provide a • The strands must be developed suf-

Edition , Table 6.5.1, 2 indicates a de-

connection at the top of the piles is to ficiently, at a distance equal to the

velopment length of 18 .25 in . (464

provide dowel holes cast in at the embedment depth of the dowel, to

mm).

head of the piles and, after the piles prevent tensile failure of the pile at a

Try an embedment length of 20 in.

have been driven to grade , grout plane at the bottom of the dowel.

(508 mm).

dowe l s into the holes using non- Refer to the PCI Design Handbook,

shrink grout. The dowels will extend Fifth Edition, Fig. 4.12.4.2

above the head of the piles to be em- A section through the 12 in . (305 3. Check Pile Capacity at 20 in.

bedded into the pile cap when the pile mm) pile is shown in Fig. 1. Dowel (508 mm) From Head

cap is cast. holes will be formed with a 13/ 4 in. Prior calculations show that the ef-

July-August 1998 139

CONCRETE PILE CAP

12"x12" PRESTRESSED 4-#6 DOWELS GROUTED

CONCRETE PILE INTO DOWEL HOLES 4'-0"

DEEP

Fig. 2. Pile section showing reinforcement details.

fective prestress in the pile is 749 psi Dowel holes must extend farther sec tional area of the dowel holes

(5 MPa) and that the effective stress fse into the pile in order to achieve a should not exceed 6 percent of the

in the strand is approximately 170 ksi greater percentage of the full develop- gross cross-sectional area of the pile.

(1172 MPa). ment length for the strands. The practice of providing dowel

Using the PCI Design Handbook, Extend the dowels 48 in . (1219 mm) holes cast into the heads of piles

Fifth Edition, Design Aid 11.2.6, with below the head of the pile. works very well whe n pile lengths

fse = 170 ksi (1172 MPa) and / ps = 270 Using Fig . 4 .12.4 of the Desig n can be predetermined . If a pile with

ksi (1862 MPa ), the development Handbook , with ld = 48 in . (1219 cast-in holes reaches refusal prior to

length for 1h in. (12.7 mm) strand = mm )Jps = 195 ksi (1345 MPa): being driven to grade, it mu st be cut

78.3 in. (1990 mm). The available de- Tn=0.9x 195 x 4 x 0.153 off. In thi s in sta nce, when dowel

velopment length at the bottom end of = 107 kips > 93.5 kips holes no longer exist, they mu st be

the dowels = 24 in. (610 mm). There- (475936 N > 415.9 kN) (ok) field-drilled. Dowels are then grouted

fore, the tensile capacity of the strands into the drilled holes as they would

will be less than the ultimate strength . 4. Check Stresses in Piles have been had the cast-in holes been

Using the PCI Design Handbook , avai lable.

Fig 4.12.4, with ld = 24 in. (610 mm), Stress due to prestress = 749 psi (5 MPa) The completed detail is shown in

/p 5 = 150 ksi (1034 kN). Stress due to 50 kip upli ft = TIA Fig. 2.

Ultimate tensile capacity: = 50,000/144 = 347 psi (2.4 MPa)

Tn = 1/JfpsAps = 0.9 X 150 X 4 X 0.153 Total stress 749 - 347 = 402 psi (2.8 REFERENCES

= 82.6 kips< 93 .5 kips MPa) compression (ok) l. ACI Committee 3 18, " ACI Building

(367526 N <415.9 kN) Code for Structural Concrete (ACI 318-

The net area at the head of a pile is 95) ," American Concrete In stit ute ,

The calculated tensile capacity, as reduced when dowel holes are cast in Farmington Hills, MI, 1995.

governed by the strength of the strands and driving stresses are therefore in- 2. PCI Design Handbook, Fifth Edition ,

at the lower end of the dowel s, will be creased. Past practice has shown that, Precast/Prestressed Concrete Institute,

less than required . as a general rule, the total cross- Chicago, IL, 1998.

140 PCI JOURNAL

You might also like

- 6 PMP6 CostDocument62 pages6 PMP6 CostKareem Mohammad100% (1)

- PM Time ManagementDocument78 pagesPM Time ManagementMANZA05No ratings yet

- Piling Work Rates and MeasurementsDocument4 pagesPiling Work Rates and MeasurementsArif NofiyantoNo ratings yet

- Shipbuilding Supervision On Behalf of Ship Owner 2Document1 pageShipbuilding Supervision On Behalf of Ship Owner 2everstaNo ratings yet

- 01-03 Framework (PMP 6)Document139 pages01-03 Framework (PMP 6)Ahmed AshrafNo ratings yet

- BAM Clough Woodside LNG JettyDocument2 pagesBAM Clough Woodside LNG JettyjomafebaNo ratings yet

- PMBOK COSTING - Earned Value ManagementDocument11 pagesPMBOK COSTING - Earned Value ManagementtobagothtiNo ratings yet

- Buku Panduan Project Management Institute-USADocument90 pagesBuku Panduan Project Management Institute-USADavid Yudha Prasetya50% (2)

- Holistic Appraisal of Value Engineering in Construction in United StatesDocument5 pagesHolistic Appraisal of Value Engineering in Construction in United StatesTheGimhan123No ratings yet

- 1.9. Project Human Resource ManagementDocument60 pages1.9. Project Human Resource Managementdeanz_75100% (2)

- 352geo Bas Sand Specepfications PDFDocument9 pages352geo Bas Sand Specepfications PDFNurul AlamNo ratings yet

- JettyDocument7 pagesJettyCesillia MardillaNo ratings yet

- Pembuatan proposal proyekDocument41 pagesPembuatan proposal proyekpudjijatiNo ratings yet

- Project Time Management Lecture: Estimation Techniques and ImportanceDocument60 pagesProject Time Management Lecture: Estimation Techniques and ImportanceSarmad Mumtaz Saharan100% (1)

- Pekerjaan Persiapan: Panjang Renc. Pondasi (P) - M Lebar Pondasi (B) - M Tinggi Pondasi (H) - MDocument11 pagesPekerjaan Persiapan: Panjang Renc. Pondasi (P) - M Lebar Pondasi (B) - M Tinggi Pondasi (H) - MFaral Arc TecNo ratings yet

- Project Management and Construction EngineeringDocument8 pagesProject Management and Construction EngineeringJohn AbaoNo ratings yet

- Practical Design of Stepped Columns PDFDocument12 pagesPractical Design of Stepped Columns PDFNikola IvanovicNo ratings yet

- Lit ResuspendedSedimentsDocument140 pagesLit ResuspendedSedimentsgheijoNo ratings yet

- Experience Gained During Construction of The First RCC Dam in Bolivia (Ortega & Gross, 2002)Document12 pagesExperience Gained During Construction of The First RCC Dam in Bolivia (Ortega & Gross, 2002)c_gs008010No ratings yet

- SKPP SKPI Dirjen Migas 84K38DJM1998 PDFDocument19 pagesSKPP SKPI Dirjen Migas 84K38DJM1998 PDFCak NhassNo ratings yet

- Simulasi Tes TOEICDocument16 pagesSimulasi Tes TOEICAlfi CahyaNo ratings yet

- Project ManagementDocument76 pagesProject Managementlim_loong_3No ratings yet

- M.Tech Civil Engineering Scheme and SyllabusDocument45 pagesM.Tech Civil Engineering Scheme and SyllabusCandace Buckner0% (1)

- Comprehensive Critical Chain MethodDocument27 pagesComprehensive Critical Chain MethodSimba NcubeNo ratings yet

- Belt Conveyor Roller Product CatalogueDocument32 pagesBelt Conveyor Roller Product Cataloguebhq76No ratings yet

- Experience Certificate Mechanical EngineerDocument2 pagesExperience Certificate Mechanical EngineerEr. Meraj Equbal0% (1)

- Toyota Harrier Main Specification Sheet PDFDocument1 pageToyota Harrier Main Specification Sheet PDFsampathNo ratings yet

- P.O.Box:1832, P.C:112, Ruwi, Sultanate of OmanDocument38 pagesP.O.Box:1832, P.C:112, Ruwi, Sultanate of OmanKumarNo ratings yet

- Fundamentals of Petroleum Project Management PDFDocument65 pagesFundamentals of Petroleum Project Management PDFmbw000012378No ratings yet

- List of Referenced Codes and StandardsDocument1 pageList of Referenced Codes and StandardsHaridevNo ratings yet

- Cement composite road recyclingDocument19 pagesCement composite road recyclingAnonymous AEt3M9TNo ratings yet

- ERKE Group, SEMW Diesel Pile Hammer CatalogDocument6 pagesERKE Group, SEMW Diesel Pile Hammer CatalogerkegroupNo ratings yet

- Optimasi Pelaksanaan Proyek Dengan CPM Dan PERTDocument16 pagesOptimasi Pelaksanaan Proyek Dengan CPM Dan PERTRobertoNo ratings yet

- Week 3 - History - Introduction and Current Developments of Project Management (Student's Version 2.0)Document67 pagesWeek 3 - History - Introduction and Current Developments of Project Management (Student's Version 2.0)Fadhli Fegious100% (1)

- MSc in Offshore & Dredging Engineering at Delft UniversityDocument4 pagesMSc in Offshore & Dredging Engineering at Delft UniversitySheikh Mizanur RahmanNo ratings yet

- TechnipDocument36 pagesTechnipShashwat Nigam0% (1)

- Construction Crane RuleDocument57 pagesConstruction Crane RuleBeste Ardıç ArslanNo ratings yet

- PT. Wijaya Karya (Persero), Tbk. Company ProfileDocument31 pagesPT. Wijaya Karya (Persero), Tbk. Company Profilerizanindya100% (1)

- Master's Program Curriculum Guide for Industrial EngineeringDocument46 pagesMaster's Program Curriculum Guide for Industrial EngineeringFazri Yanth Alfarizzi100% (1)

- Risk Management: Presentasi Untuk: PT - Truba Jurong EngineeringDocument18 pagesRisk Management: Presentasi Untuk: PT - Truba Jurong Engineeringrieza_fNo ratings yet

- Doka Formwork Magazine Highlights Innovative ProjectsDocument12 pagesDoka Formwork Magazine Highlights Innovative ProjectssatyapennintiNo ratings yet

- Percepatan Waktu Pelaksanaan Proyek Dengan Metode CPMDocument7 pagesPercepatan Waktu Pelaksanaan Proyek Dengan Metode CPMteknis_12No ratings yet

- Esza R 01 LDocument145 pagesEsza R 01 Lcesar eafaelNo ratings yet

- Material Take OffDocument2 pagesMaterial Take OffZaher Mhd Sharaf100% (1)

- Value Engineering On Executing of Jetty ConstructionDocument8 pagesValue Engineering On Executing of Jetty ConstructionDudi MustofaNo ratings yet

- Project Management Process Key Inputs Key Outputs Initiating Process GroupDocument6 pagesProject Management Process Key Inputs Key Outputs Initiating Process GroupSaqib NaeemNo ratings yet

- Project Management Professional Syllabus - PDF - Multimatics 1Document5 pagesProject Management Professional Syllabus - PDF - Multimatics 1Anonymous wIPMQ5rhNo ratings yet

- BestFit TutorialDocument45 pagesBestFit TutorialRizky NoorNo ratings yet

- Project Management PlanDocument53 pagesProject Management Planvictor egharevbaNo ratings yet

- CV Mechanical Engineer Experienced Oil Gas ProjectsDocument4 pagesCV Mechanical Engineer Experienced Oil Gas ProjectspoetoetNo ratings yet

- Guide to flange facing: types of damage, finishes, gaskets and machine typesDocument1 pageGuide to flange facing: types of damage, finishes, gaskets and machine typesjksankar100% (1)

- PMHSA R&D Forum Dent Assessment Methods & Challenges: David Chittick/Millan Sen June 24, 2009Document7 pagesPMHSA R&D Forum Dent Assessment Methods & Challenges: David Chittick/Millan Sen June 24, 2009Hafizul Hisyam Maysih LuzifahNo ratings yet

- JIS A 5525-2019 Steel Pipe PilesDocument31 pagesJIS A 5525-2019 Steel Pipe PilesRajinda BintangNo ratings yet

- American Wide F Beam 6Document1 pageAmerican Wide F Beam 6bhaskarNo ratings yet

- Technical Specification Pile Foundation Transmission LinesDocument35 pagesTechnical Specification Pile Foundation Transmission LinesAnonymous YN4aNlNo ratings yet

- E26.To2 Steel PDFDocument10 pagesE26.To2 Steel PDFAmolsingh100No ratings yet

- Chap 03-Rotary Percussive Drilling Accessories PDFDocument12 pagesChap 03-Rotary Percussive Drilling Accessories PDFpnakurNo ratings yet

- Understanding The Steel in PrestressingDocument13 pagesUnderstanding The Steel in PrestressingAsim Bashir KhajwalNo ratings yet

- Anchorage of Steel Building Components To Concrete - Lee Marsh - JournalDocument7 pagesAnchorage of Steel Building Components To Concrete - Lee Marsh - JournalRMKD PrabhuNo ratings yet

- Casting Adjustment (S-28) - 1Document1 pageCasting Adjustment (S-28) - 1lsatchithananthanNo ratings yet

- Concrete Sidewalk Detail (S-3) - 1Document1 pageConcrete Sidewalk Detail (S-3) - 1lsatchithananthanNo ratings yet

- Rebar Drill & Fix MethodDocument3 pagesRebar Drill & Fix Methodlsatchithananthan100% (1)

- Centralizer & Spacer Systems: For The Drilling & Civil Construction IndustriesDocument3 pagesCentralizer & Spacer Systems: For The Drilling & Civil Construction IndustrieslsatchithananthanNo ratings yet

- Construction Management StatementDocument1 pageConstruction Management StatementlsatchithananthanNo ratings yet

- Pengurusan Air Selangor Sdn. Bhd. KA 1/2 (Rev - 2019) : Part ADocument10 pagesPengurusan Air Selangor Sdn. Bhd. KA 1/2 (Rev - 2019) : Part AlsatchithananthanNo ratings yet

- Construction HazardsDocument2 pagesConstruction HazardslsatchithananthanNo ratings yet

- Fire Safety in ConstructionDocument3 pagesFire Safety in ConstructionlsatchithananthanNo ratings yet

- Lifting OperationsDocument1 pageLifting OperationslsatchithananthanNo ratings yet

- Method Statement For ConstructionDocument2 pagesMethod Statement For ConstructionlsatchithananthanNo ratings yet

- kwik-ZIP HD Installation GuideDocument2 pageskwik-ZIP HD Installation GuidelsatchithananthanNo ratings yet

- Kwikzip Info Sheets 380Document2 pagesKwikzip Info Sheets 380lsatchithananthanNo ratings yet

- PLEM Design Methodology - OilfieldWikiDocument4 pagesPLEM Design Methodology - OilfieldWikilsatchithananthanNo ratings yet

- Water Reticulation Handover FormDocument4 pagesWater Reticulation Handover FormlsatchithananthanNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- Q235 Steel Q235A Q235B Q235C Q235D Equivalent, Properties, Specification, Composition - The World MaterialDocument6 pagesQ235 Steel Q235A Q235B Q235C Q235D Equivalent, Properties, Specification, Composition - The World MateriallsatchithananthanNo ratings yet

- Graphs To Calculate Settlement - Calculation of Pile Base Settlement - GEO5 - Online HelpDocument4 pagesGraphs To Calculate Settlement - Calculation of Pile Base Settlement - GEO5 - Online HelplsatchithananthanNo ratings yet

- Plem Design and Analysis - OilfieldWikiDocument4 pagesPlem Design and Analysis - OilfieldWikilsatchithananthanNo ratings yet

- Calculation of Pile Base SettlementDocument3 pagesCalculation of Pile Base SettlementlsatchithananthanNo ratings yet

- Calculation of Pile Base SettlementDocument3 pagesCalculation of Pile Base SettlementlsatchithananthanNo ratings yet

- Prestress Presentation SAB4323 OCW Topic 1Document50 pagesPrestress Presentation SAB4323 OCW Topic 1dasdhjhkjNo ratings yet

- 2020 ESAH Complete v3.1Document130 pages2020 ESAH Complete v3.1lsatchithananthanNo ratings yet

- AS 2159 & 3600 Concrete Pile Design - SkyCiv Cloud Structural Analysis SoftwareDocument10 pagesAS 2159 & 3600 Concrete Pile Design - SkyCiv Cloud Structural Analysis SoftwarelsatchithananthanNo ratings yet

- Plastering RequirementDocument4 pagesPlastering RequirementlsatchithananthanNo ratings yet

- TNB Door - Vicmeta SDN BHDDocument5 pagesTNB Door - Vicmeta SDN BHDlsatchithananthanNo ratings yet

- Tolerances of Errors in Pile Foundation ConstructionDocument3 pagesTolerances of Errors in Pile Foundation ConstructionlsatchithananthanNo ratings yet

- Typical Reinforcement Details of A Cantilever SlabDocument1 pageTypical Reinforcement Details of A Cantilever SlablsatchithananthanNo ratings yet

- Design For Bending For Rectangular Sections (Beams - BS 8110)Document2 pagesDesign For Bending For Rectangular Sections (Beams - BS 8110)lsatchithananthanNo ratings yet

- Static Analysis Laterally Loaded Pile Design PPTX CaliendoDocument55 pagesStatic Analysis Laterally Loaded Pile Design PPTX CaliendoAshishNo ratings yet

- Tolerances of Errors in Pile Foundation ConstructionDocument3 pagesTolerances of Errors in Pile Foundation ConstructionlsatchithananthanNo ratings yet

- 153C Final Exam Study Guide-2Document6 pages153C Final Exam Study Guide-2Soji AdimulaNo ratings yet

- Voltaire's Candide and the Role of Free WillDocument3 pagesVoltaire's Candide and the Role of Free WillAngy ShoogzNo ratings yet

- RestrukturisasiDocument17 pagesRestrukturisasimuhammad hayel wallaNo ratings yet

- ASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150Document1 pageASD Manual and AISC LRFD Manual For Bolt Diameters Up To 6 Inches (150rabzihNo ratings yet

- Learn Square Roots & Plot on Number LineDocument11 pagesLearn Square Roots & Plot on Number LineADAM CRISOLOGONo ratings yet

- January 2013 Igcse Timetable 22-06-2012Document2 pagesJanuary 2013 Igcse Timetable 22-06-2012Rizwanur RahmanNo ratings yet

- BMXNRPDocument60 pagesBMXNRPSivaprasad KcNo ratings yet

- The Rich Hues of Purple Murex DyeDocument44 pagesThe Rich Hues of Purple Murex DyeYiğit KılıçNo ratings yet

- Mesopotamia CivilizationDocument56 pagesMesopotamia CivilizationYashika TharwaniNo ratings yet

- The Bloodless GospelDocument7 pagesThe Bloodless GospelKJVNo ratings yet

- Av1 OnDocument7 pagesAv1 OnLê Hà Thanh TrúcNo ratings yet

- Arduino Nano based K1EL Winkeyer compatible CW contest keyerDocument35 pagesArduino Nano based K1EL Winkeyer compatible CW contest keyerSreejith SreedharanNo ratings yet

- Quality CircleDocument33 pagesQuality CircleSudeesh SudevanNo ratings yet

- COT EnglishDocument4 pagesCOT EnglishTypie ZapNo ratings yet

- Exam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023Document285 pagesExam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023maniNo ratings yet

- T23 Field Weld Guidelines Rev 01Document4 pagesT23 Field Weld Guidelines Rev 01tek_surinderNo ratings yet

- Kastanakis 2014Document8 pagesKastanakis 2014Andreea Georgiana MocanuNo ratings yet

- Zhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Document24 pagesZhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Carlos Caicedo-Russi100% (1)

- Lesson Plan 2018-2019 Term 1Document205 pagesLesson Plan 2018-2019 Term 1Athlyn DurandNo ratings yet

- Docking 1Document12 pagesDocking 1Naveen Virendra SinghNo ratings yet

- Ne 01 20 09 2018Document436 pagesNe 01 20 09 2018VaradrajNo ratings yet

- Febrile SeizureDocument3 pagesFebrile SeizureClyxille GiradoNo ratings yet

- IE399 Summer Training ReportDocument17 pagesIE399 Summer Training ReportgokanayazNo ratings yet

- Fisher FIELDVUE DVC2000 Digital Valve Controller: Instruction ManualDocument108 pagesFisher FIELDVUE DVC2000 Digital Valve Controller: Instruction ManualsrinuvoodiNo ratings yet

- EMMS SpecificationsDocument18 pagesEMMS SpecificationsAnonymous dJtVwACc100% (2)

- Tupperware India's Perception StudyDocument10 pagesTupperware India's Perception StudyAnmol RahangdaleNo ratings yet

- Manual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDocument106 pagesManual - Sentron Pac Profibus Do Modul - 2009 02 - en PDFDante Renee Mendoza DelgadoNo ratings yet

- Indian Institute OF Management, BangaloreDocument20 pagesIndian Institute OF Management, BangaloreGagandeep SinghNo ratings yet

- Executive Education Portfolio Soft Copy-INSEADDocument58 pagesExecutive Education Portfolio Soft Copy-INSEADОля КусраеваNo ratings yet

- Chapter 9-10 (PPE) Reinzo GallegoDocument48 pagesChapter 9-10 (PPE) Reinzo GallegoReinzo GallegoNo ratings yet