Professional Documents

Culture Documents

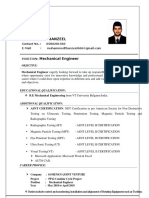

ALSayed Hashim

Uploaded by

Aya AbdoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ALSayed Hashim

Uploaded by

Aya AbdoCopyright:

Available Formats

ALSayed Hashim

sayedf43@gmail.com

linkedin.com/in/sayedfhashim https://sayedhashim.tech.blog/

Summary

Career Summary

• Team oriented Mechanical Engineer with +5 years of experience in product design, analysis, manufacturing and efficiently

working with all levels of employees in cross-functional teams.

• Experience in developing cost-efficient designs from the operation, maintenance and manufacturing standpoints.

• Strong analytical and research skills. Proficient in stress analysis, flow analysis, thermal load analysis.

• Proficient in 3D-CAD modelling SolidWorks, AutoCAD), organized engineering drawings, detailed documentation.

Experience with machining processes (milling, turning, drilling, grinding and CNC drilling).

Recognized for the keen ability to improve component designs, increase efficiency and decrease the need for re-

engineering. Ability to communicate and motivate the team members to enhance strategic goals and bottom line objectives.

Design, Analysis & Validation Rotating Equipment Static Equipment

EPC, EPCM, Oil & Gas Creative Problem-Solving Manufacturing Strategies Root-Cause Analysis Product Improvement

ASME & ISO CSWE

Highlights

• Product design based on detailed engineering calculations following codes and standards

• Finite element analysis (SolidWorks, Solid Edge)

• Computational fluid dynamics (FLUENT)

• Energy modelling and thermal load analysis (HAP)

• Sheet metal design(Solidworks)

• Component and assembly drawings in 3-D CAD SolidWorks

Geometric dimensioning &tolerancing

• Piping and instrumentation diagrams

• Equipment specifications, schedules, bill of materials

• Strong knowledge of manufacturing processes

• Time management skills with strategic prioritization

• Self-motivated with problem-solving ability through detailed analysis

• Strong written and verbal communication skills

• Work with minimum supervision by utilizing technical competency and experience

• Assist in development and submission of proposal packages and bid clarification

• Ability to quickly develop competency with software packages

Experience

Production Manager Feb 2019- Present

ATCO Group 2 months +

Planning and organising production schedules

Assessing project and resource requirements

Estimating, negotiating and agreeing with budgets and timescales with clients and managers

Ensuring that health and safety regulations are met

Determining quality control standards

Overseeing production processes

Re-negotiating timescales or schedules as necessary

Selecting, ordering and purchasing materials

Organising the repair and routine maintenance of production equipment

Liaising with buyers and marketing and sales staff

Supervising the work of junior team

Arranging a relevant training session

Establish workflow policies that enhance speed and efficiency without compromising product safety or integrity

set product quality standards

monitor quality standards of products

implement and enforce quality control and tracking programs to meet quality objectives

analyse production and quality control to detect and correct problems

determine and implement improvements to the production process

prepare and maintain production reports

Review plans and specifications for new machinery and equipment to make sure they meet safety requirements

Identify and correct potential hazards by inspecting facilities, machinery, and safety equipment

Evaluate the effectiveness of various industrial control mechanisms

Ensure that a building or product complies with health and safety regulations, especially after an inspection that

required changes

Install safety devices on machinery or direct the installation of these devices

Review employee safety programs and recommend improvements

Maintain and apply knowledge of current policies, regulations, and industrial processes

Design And Development Engineer Feb 2018- Present

ATCO Group 1 year 2 months +

• Lead R&D team and enhance their skills to match the latest engineering technology.

• Design new Products and source the proper material to increase the profit.

• Periodic enhance product design to fit with the latest engineering technology and Market needs.

• Following design development and, where possible, suggesting economical construction details to be

incorporated into design drawings and specifications.

• Supervising and coordinating work activities of the mechanical field engineering staff and maintaining overall

responsibility for mechanical quality.

• Providing technical assistance to the mechanical superintendents and craft. Trouble-shooting engineering design

and resolving issues with engineering and/or fabricators.

• Working within TEAMWorks to verify accurate data from engineering and suppliers.

• Supervising the development of work packages and test packages for all of the mechanical equipment.

• Use FEA through SolidWorks simulation to validate products.

• Bring efficiency in the design process, using SolidWorks.

• Evaluation of skill level of design team and arrange for customized training modules

• Completion of SolidWorks implementation, library feature, and component

Built a complete library for all accessories to have accurate BOM during a design process.

• Established a link between engineering design and ERP system.

• Prepared cost and time study template to be used for any product to calculate an accurate price for

any new design

• Arrange SolidWorks simulation training, create on the job training for simulation usage.

• Supporting customer through solving design problems for a lot of industrial fields like (sheet

metal, Factories, Oil, and Gas, plastic design field…etc.)

Production Engineer Apr 2016 - Apr 2017

Cairo Electricity Production Company 1 year 1 month

Perform troubleshooting, field activities, and maintenance activities for all gas turbines including all auxiliary

systems, particularly frame 9FA GE gas turbines.

Supervise and monitor the progress of routine, breakdown and planned maintenance activities, to minimize

downtime for the equipment to increase plant availability.

Prepare overhaul work details for Mechanical Plants/Equipment.

Plan, manage time and manpower for executing the annual and major overhauls.

Perform hands-on repair, overhaul, combustion inspection activities, baroscopic inspection, gas turbine alignment,

and all auxiliary systems maintenance. Maintain the history maintenance records.

Provide the assessment of Spare parts storage and make necessary Spare parts orders during a major overhaul

of the plant for increased plant availability. Arrange all necessary resources for all type of maintenances.

Establish gas turbines tracking sheets relative to FFH (Factored Firing Hours) and plan the short term and long

term inspection plan for each gas turbine

Follow up all gas turbines spare parts stock balance. Follow up the inventory safety stock quantities, min/max

quantities, land long lead items.

Review maintenance procedures, job plans, standing instruction, operating manuals, and to update company

manuals for safe maintenance and operation.

Operation engineer for six months. Maintenance engineer and participate in the following outages:- Combustion

Inspection outage (CI). Responsible for spare parts preparation.

oversee mechanical technician in removing, marking and store of related piping and Combustion

Chambers.Responsible for implementation of outage activities according to O&M specs and TA instructions.

Hot Gas Path Inspections (HGP).

Responsible for spare parts preparation.

oversee mechanical technician in removing, marking and store of related hot gas parts. • Responsible for

implementation of outage activities according to O&M specs and TA instructionRecord Hot gas Path section

clearances.

Design and Production Engineer(graduation project) Apr 2013 - Jun 2015

EL-hady workshop 2 years 3 months

Wankel rotary internal combustion Engine & design of material selection

About 4-5% of accidents are caused by structural failure of the engine. The vast majority of aircraft

accidents are caused by pilot error, fuel mismanagement, weather, airframe structural failure, engine

accessory failure, and faulty maintenance. But still, wouldn't it be nice to essentially eliminate that 4-5%?

When a rotary is turning at, say 7500 RPM, that is perfectly OK. That straight e-shaft has none of the long

crank throws (journals) that are such the weak link in certified engines. At 7500 engine RPM, the rotors are

only turning at 2500 RPM - those components are not going to fail anywhere in the aircraft operation realm.

And oh, those ARE the only moving components. There are no valves, cam shafts, lifters, lifter springs,

pistons, heads, or head gaskets that all fail occasionally in certified aircraft engines.

Education

King Fahd University of Petroleum & Minerals 2018 - 2020

Master’s Degree, mechanical Design engineer

Aim of the course is to provide students with in-depth knowledge on:

design and management of industrial production systems

structural and functional design

materials and relevant working technologies

modelling and analysis of products and processes life-cycle

design and management of plants for energy conversion.

Moreover, students can deepen still further some specific topics concerning: energy, biomedical engineering,

mechatronics, production, design.

Higher Technological Institute 2010 - 2015

Bachelor’s Degree, Mechanical Engineering

All of my software Department of Mechanical Engineering students the following outputs include:

A) the ability to apply knowledge in science, mathematics and engineering.

B) the ability to design and conduct experiments, as well as data analysis.

C) the ability to design practical mechanical system to meet the requirements under realistic environmental

constraints such as economic, social, political, health and moral factors.

D) the ability to work within a multidisciplinary team members.

E) the ability to identify, formulate and solve engineering problems.

F) understanding of professional and ethical responsibility.

G) the ability to communicate effectively.

H) recognize the need to understand the positive impact of engineering solutions on the economy and

the environment, and the community ..

K) the ability to use the techniques, skills and modern engineering tools necessary for engineering practice

Skills

Gas turbine • Manufacturing • Project Management • Electrical Engineering • Piping

Certifications

AUTOCAD • Autodesk

Aug 2013 - Present

Jet Engine • Higher Technological Institute

Mar 2014 - Jul 2014

Certified SOLIDWORKS Associate • Dassault Systèmes

Dec 2013 - Present

Certified SOLIDWORKS Professional • Dassault Systèmes

Feb 2014 - Present

Introduction to the Project Management Professional (PMP)® Exam • LinkedIn

Mar 2017 - Present

Surfacing with SOLIDWORKS • LinkedIn

Mar 2017 - Present

Sheet Metal with SOLIDWORKS: Enclosure Design Project • LinkedIn

Mar 2017 - Present

AutoCAD 2017 Essential Training • LinkedIn

Mar 2017 - Present

Steel Building Design with SOLIDWORKS Weldments • Lynda.com

93ED4D0817004B5D9EFAF5E1251DDEA7 • Mar 2017 - Present

You might also like

- Isx Front Gear CoverDocument21 pagesIsx Front Gear CoverHarsimran Sidhu100% (11)

- Sr. Process Engineer CVDocument6 pagesSr. Process Engineer CVTayebASherif50% (2)

- 2007 POLARIS 600 HO IQ LX CFI SNOWMOBILE Service Repair Manual PDFDocument57 pages2007 POLARIS 600 HO IQ LX CFI SNOWMOBILE Service Repair Manual PDFfjjskeksemmde0% (2)

- Overview of TSDDocument7 pagesOverview of TSDMuhammad Abdul RaufNo ratings yet

- Ieng Competence Exemplars PDFDocument7 pagesIeng Competence Exemplars PDFAnoop Vadakke PurayatheNo ratings yet

- Troubleshoot A Diesel EngineDocument9 pagesTroubleshoot A Diesel EngineRachel Torres Alegado100% (2)

- TAD1641GE: Volvo Penta Genset EngineDocument2 pagesTAD1641GE: Volvo Penta Genset EnginesIMPEX sHARMANo ratings yet

- Model:KM2800: Rating RangeDocument4 pagesModel:KM2800: Rating RangeT.S. Anklesaria100% (1)

- Tosin Akinwunmi: ExperienceDocument5 pagesTosin Akinwunmi: ExperienceXtianNo ratings yet

- CV of Muhammad Adeel RajputDocument4 pagesCV of Muhammad Adeel RajputFarhan SaghirNo ratings yet

- Amir Naveed - Resume Oil and GasDocument3 pagesAmir Naveed - Resume Oil and GasAbdul Mahid KhattakNo ratings yet

- Senior Project Engineer - Afsal - 30 Nov 2015Document3 pagesSenior Project Engineer - Afsal - 30 Nov 2015Mohamed AfsalNo ratings yet

- Project Engineer - Afsal - 30 Mar 2016Document3 pagesProject Engineer - Afsal - 30 Mar 2016Mohamed AfsalNo ratings yet

- CV Mhammed Lahlaba En-4Document5 pagesCV Mhammed Lahlaba En-4lahlabaNo ratings yet

- Asad AliDocument5 pagesAsad AliMisbhasaeedaNo ratings yet

- Senior Process Engineer (External)Document3 pagesSenior Process Engineer (External)kebiskygmailNo ratings yet

- Fletcher Theophilus Ato CVDocument7 pagesFletcher Theophilus Ato CVTHEOPHILUS ATO FLETCHERNo ratings yet

- Process Engineer III - V Basic FunctionDocument4 pagesProcess Engineer III - V Basic FunctionmessiNo ratings yet

- Fletcher Theophilus Ato CVDocument7 pagesFletcher Theophilus Ato CVTHEOPHILUS ATO FLETCHERNo ratings yet

- Sureshkumar+CV 020622Document5 pagesSureshkumar+CV 020622Razvan GheorghiesNo ratings yet

- Desired Skills and ExperienceDocument3 pagesDesired Skills and ExperienceSyed Mujtaba Ali BukhariNo ratings yet

- Afsal - Mechanical - Technical Engineer - 28 APR 2014Document4 pagesAfsal - Mechanical - Technical Engineer - 28 APR 2014afsalmohmdNo ratings yet

- CV - Asset IntegrityDocument4 pagesCV - Asset IntegritySyed Shiraz Ali100% (1)

- MD Shahnewaz: Manufacturing EngineerDocument4 pagesMD Shahnewaz: Manufacturing Engineerkiran2710No ratings yet

- R.Madhavan: Curriculum VitaeDocument4 pagesR.Madhavan: Curriculum VitaeMadhavan RengarajNo ratings yet

- Mahmoud Fathallah Abdelmotaleb Mansour: Career SummaryDocument4 pagesMahmoud Fathallah Abdelmotaleb Mansour: Career SummaryHatem HusseinNo ratings yet

- Senior Manufacturing EngineerDocument4 pagesSenior Manufacturing Engineerapi-78878905No ratings yet

- Naukri ShirishThak (17y 0m)Document4 pagesNaukri ShirishThak (17y 0m)Amit SinhaNo ratings yet

- Quality Manager & Production Manager CompetencyDocument6 pagesQuality Manager & Production Manager CompetencyManoj MehraNo ratings yet

- Achieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivateDocument12 pagesAchieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivatestrganeshkumarNo ratings yet

- Mechanical Design Engineer2Document8 pagesMechanical Design Engineer2Arnold LicayanNo ratings yet

- Mechanical Maintenance & Planning EngineerDocument6 pagesMechanical Maintenance & Planning EngineerIrshad Akhter100% (1)

- Afsal - Mechanical - Technical Engineer - 12 Feb 2015Document4 pagesAfsal - Mechanical - Technical Engineer - 12 Feb 2015afsalmohmdNo ratings yet

- RCM Based Critical Equipment TrainingDocument6 pagesRCM Based Critical Equipment TrainingSyedNadeemAhmedNo ratings yet

- Arshad Resume - Dot PDFDocument6 pagesArshad Resume - Dot PDFArshad AnsariNo ratings yet

- Radient's Updated Resume.Document3 pagesRadient's Updated Resume.Radient MushfikNo ratings yet

- المستندDocument5 pagesالمستندMahdi HassanNo ratings yet

- Tcs Gas TurbineDocument3 pagesTcs Gas TurbineAmir SafwanNo ratings yet

- Theophilus Ato Fletcher: Career ObjectivesDocument5 pagesTheophilus Ato Fletcher: Career ObjectivesTHEOPHILUS ATO FLETCHERNo ratings yet

- HK CV VBDocument5 pagesHK CV VBVijayBharati100% (2)

- Machine Shop SupervisorsDocument16 pagesMachine Shop Supervisorsphutthawongdanchai041215No ratings yet

- Mechanical Engineer - Static & Rotry - ThanzeelDocument5 pagesMechanical Engineer - Static & Rotry - ThanzeelMuhammed ThanzeelNo ratings yet

- Rajesh Kumar Sethi - 5+years - Project Control Engineer - Foster Wheeler - SenabiDocument4 pagesRajesh Kumar Sethi - 5+years - Project Control Engineer - Foster Wheeler - SenabiSubrata DuttaNo ratings yet

- Senior Instrument Engineer Key ResponsibilitiesDocument2 pagesSenior Instrument Engineer Key ResponsibilitiesE.C.MADHUDUDHANA REDDYNo ratings yet

- Umar Ali Khan ResumeDocument3 pagesUmar Ali Khan Resumeuak107080No ratings yet

- MD Shahnewaz Sabit Faisal: Phone: Home: EmailDocument4 pagesMD Shahnewaz Sabit Faisal: Phone: Home: Emailkiran2710No ratings yet

- Abdul Muhis P CV 02 Jun 2023Document3 pagesAbdul Muhis P CV 02 Jun 2023Abdul MuhisNo ratings yet

- RMG Industry Expert - K. M. MUNIR HUSSAINDocument4 pagesRMG Industry Expert - K. M. MUNIR HUSSAINAshish J. GeorgeNo ratings yet

- Power Plant Reliability and Maintenance Cost Online Course Brochure PDFDocument6 pagesPower Plant Reliability and Maintenance Cost Online Course Brochure PDFSyedNadeemAhmedNo ratings yet

- Durga Prasad CVDocument4 pagesDurga Prasad CVSathi MechNo ratings yet

- Design Review Procedure For Projects in Fertilizer PlantsDocument9 pagesDesign Review Procedure For Projects in Fertilizer PlantsmanuNo ratings yet

- Rawad HilalDocument2 pagesRawad Hilalmaroun machaalanyNo ratings yet

- Faliure Root Cause AnlaysisDocument4 pagesFaliure Root Cause AnlaysisSyedNadeemAhmedNo ratings yet

- AngloGold Ashanti (Ghana) Limited Is Hiring Staff - 221030 - 133951Document46 pagesAngloGold Ashanti (Ghana) Limited Is Hiring Staff - 221030 - 133951Marc WrldNo ratings yet

- Dy. Manager (Process Engg.)Document3 pagesDy. Manager (Process Engg.)vishal9patel-63No ratings yet

- Mr.R.Ravindran - Deputy General Manager - MechanicalDocument5 pagesMr.R.Ravindran - Deputy General Manager - MechanicalAdithi RNo ratings yet

- Functional Area:: ManufacturingDocument4 pagesFunctional Area:: ManufacturingHuman ResorceNo ratings yet

- Zeeshan Pathan Mechanical EngineerDocument4 pagesZeeshan Pathan Mechanical EngineerZeeshan PathanNo ratings yet

- Mark Knofler: Career OverviewDocument2 pagesMark Knofler: Career OverviewknoflerNo ratings yet

- Mohammed Abdalla - Rotating Equipment Engineer BN PDFDocument12 pagesMohammed Abdalla - Rotating Equipment Engineer BN PDFMohammed AbdallaNo ratings yet

- CV Engr. Gravides 1Document4 pagesCV Engr. Gravides 1jherson gravidesNo ratings yet

- CV For Nurul Amin 2021 PDFDocument9 pagesCV For Nurul Amin 2021 PDFPiplu DasNo ratings yet

- Dan Cameron Cojocaru: Chemical/Process Engineer MieaustDocument6 pagesDan Cameron Cojocaru: Chemical/Process Engineer MieaustrkshishodiaNo ratings yet

- Venkadachalapathy Thangavel: LinkedinDocument4 pagesVenkadachalapathy Thangavel: Linkedinvenkatachalapathy.thNo ratings yet

- Design of A Stirling Engine (Final Draft) 3Document16 pagesDesign of A Stirling Engine (Final Draft) 3Sherif El-soudy0% (1)

- Jonas Biteus - Mean Value Engine Model of A Heavy Duty Diesel EngineDocument34 pagesJonas Biteus - Mean Value Engine Model of A Heavy Duty Diesel EngineMuhidin ArifinNo ratings yet

- Aeb010171 ISX 15 BaseDocument12 pagesAeb010171 ISX 15 BaseJose SantosNo ratings yet

- Handbook - Warranty CoverageDocument10 pagesHandbook - Warranty Coveragedeepaknagar981No ratings yet

- Spark 2011 - Delphi ECMDocument9 pagesSpark 2011 - Delphi ECMalejandro sanchezNo ratings yet

- Rock Valve: Stationary Concrete PumpsDocument8 pagesRock Valve: Stationary Concrete PumpsRafael R ANo ratings yet

- Beverly Tourer 250 IeDocument318 pagesBeverly Tourer 250 IeIvan CerovsekNo ratings yet

- Air Compressor 2475 Parts ListDocument24 pagesAir Compressor 2475 Parts ListJupray0% (1)

- Service Bulletin Trucks: SpecificationsDocument35 pagesService Bulletin Trucks: SpecificationsCEVegaONo ratings yet

- Experiment # 3Document10 pagesExperiment # 3Farhan AliNo ratings yet

- Renegade Le 200Document48 pagesRenegade Le 200Profesor Román Azócar FontealbaNo ratings yet

- Report On Air CompressorDocument35 pagesReport On Air CompressorKrishna Kanth ChinthaNo ratings yet

- Design and Development of Cylinder and Cylinder Head of 4-Stroke SI Engine For Weight ReductionDocument7 pagesDesign and Development of Cylinder and Cylinder Head of 4-Stroke SI Engine For Weight ReductionPrashant GuptaNo ratings yet

- Engine Timing Tools: Ford Duratorq 1.4 - 1.6 - 2.0 - 2.2 - 2.4 Psa 1.4 - 1.6 HdiDocument8 pagesEngine Timing Tools: Ford Duratorq 1.4 - 1.6 - 2.0 - 2.2 - 2.4 Psa 1.4 - 1.6 Hdikane brownlowNo ratings yet

- Teknik Permesinan Kapal Ii: Pps Teknologi Kelautan ITS SurabayaDocument11 pagesTeknik Permesinan Kapal Ii: Pps Teknologi Kelautan ITS SurabayaRazaq PayapoNo ratings yet

- W8L20 - Spare PartsDocument2 pagesW8L20 - Spare PartsTuan Linh VoNo ratings yet

- Manual SharonDocument84 pagesManual SharonJose Ramirez DiazNo ratings yet

- Bason Genset04Document33 pagesBason Genset04GiangDoNo ratings yet

- Unit KG (LB) Model SK200 - 8 SK210LC - 8 Item: 2. SpecificationsDocument20 pagesUnit KG (LB) Model SK200 - 8 SK210LC - 8 Item: 2. SpecificationsShop ManualNo ratings yet

- 08 Deutz Common RailDocument20 pages08 Deutz Common RailGiovaniBalzaniNo ratings yet

- MfitDocument19 pagesMfitMhalou Padilla VeneracionNo ratings yet

- Pegaso 650 - '97 - Service ManualDocument311 pagesPegaso 650 - '97 - Service ManualMihai MafteianuNo ratings yet

- Cessna 182Q Skylane Normal Checklists: Preflight InspectionDocument4 pagesCessna 182Q Skylane Normal Checklists: Preflight InspectionAlessandro PaulinNo ratings yet

- Engine Performance Curve: Rating: Application:MarineDocument4 pagesEngine Performance Curve: Rating: Application:Marinekman548No ratings yet

- Catalogo de Partes VERSYS 1000 PDFDocument117 pagesCatalogo de Partes VERSYS 1000 PDFpablocalle5No ratings yet