Professional Documents

Culture Documents

Switching Devices - Low Voltage 28.0-1: February 2017

Uploaded by

John Philip BuntalesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Switching Devices - Low Voltage 28.0-1: February 2017

Uploaded by

John Philip BuntalesCopyright:

Available Formats

Switching Devices —Low Voltage 28.

0-1

February 2017

Sheet 28 001

Contents

—Low Voltage

Switching Devices Switching Devices—Low Voltage

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-2

22

23

General-Duty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-3

Heavy-Duty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-3 24

Enhanced Visible Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-3

EnviroLine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-4

Shunt Trip Safety Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-5

25

Six-Pole Motor Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-5

Heavy-Duty Double-Throw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-6 26

Quick-Connect Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-6

Elevator Control Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-7 27

OEM Line Isolation (OLI) Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-10

NEMA 7/9—Hazardous Location Disconnect Switch . . . . . . . . . . . . . . . . . . . 28.0-11 28

Auxiliary Power Heavy-Duty Safety Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-11

Heavy-Duty—Solar Photovoltaic Switch Single-Circuit . . . . . . . . . . . . . . . 28.0-12

Heavy-Duty—Solar Photovoltaic Switch Multi-Circuit . . . . . . . . . . . . . . . . 28.0-12

29

Enclosed Rotary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-12

Flex Center Factory Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-13 30

Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-14

Catalog Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-15 31

K-Series Switch Design Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-18

Accessories, Hubs, Lug Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-19

32

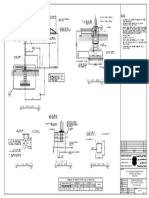

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-24

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-36

Short-Circuit Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-38

33

Typical Fuse Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0-39

Specifications 34

See Eaton’s Product Specification Guide, available on the Web.

CSI Format: . . . . . . . . . . . . . . . . . . . . . . . . 1995 2010 35

Safety Switches . . . . . . . . . . . . . . . . . . Section 16441A Section 26 28 16.16

Auxiliary Power Heavy-Duty

Safety Switch . . . . . . . . . . . . . . . . . . . . . . Section 16441B Section 26 28 16.23

36

Elevator Control Switch. . . . . . . . . . . . . . Section 16445 Section 26 28 16.17

Quick-Connect Double-Throw . . . . . . . . Section 16441A Section 26 28 16.16 37

Paragraph 2.05 Paragraph 2.05

1000 Vdc Solar Safety Switches . . . . . Section 16441D Section 26 28 16.16

38

600 Vdc Solar Safety Switches . . . . . . Section 16441E Section 26 28 16.16

Shunt Trip Safety Switch . . . . . . . . . . . . . Section 16441A Section 26 28 16.16

Paragraph 2.03.B.16 39

40

41

42

43

Quick-Connect Double-Throw Safety Switches

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-2 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 002

General Description

22 Safety Switches

23

24

25

General-Duty Heavy-Duty Shunt Trip Elevator Control Double-Throw Rotary

26 Safety Switch Safety Switch

Safety switches have a number of ■ Quick connect switches for quick If you don’t see your specific

27 applications from service entrance connection of portable generators application listed above, make sure

to branch circuit protection. They are and loads to call your local Eaton salesperson

also horsepower rated for use as ■ Shunt trippable switches for a quick to discuss the capabilities of our

28 motor circuit switches. Table 28.0-1 and safe means to remotely open a Flex Center that will provide custom

summarizes major differences and switch in an emergency situation switches to meet many industry needs.

similarities between the heavy-duty

29 and general-duty type of Eaton’s safety

■ Elevator control switches to provide The following pages give more

a one-stop method to meet details on the many types of switching

switches. In addition to heavy-duty and demands of the NEC and building

general-duty applications, we have devices Eaton can provide to meet

30 seen many industry trends that have

codes for elevator circuits your every need.

■ Auxiliary power switches for

created needs for specialized versions

of safety switches: providing control power for HVAC Seismic Qualification

31 and other applications that may

■ Eaton’s EnviroLine line of switches require disconnect and receptacle to

come with options for stainless steel meet NEC requirements

32 enclosures, mechanisms and ■ Rotary switches for OEM and

springs, various types of interlocked compact applications where space

receptacles, viewing windows and is limited

33 also non-metallic enclosures for use ■ NEMA Type 7/9 switches—Class I,

in abnormal environments. Solar Refer to Tab 1 for information on

Div I and II rated—for harsh seismic qualification for this and

switches made to meet specific industrial applications and

34 requirements and demands of the environments

other Eaton products.

solar industry

35

Table 28.0-1. Safety Switch Application Guide—See Catalog Selection Tables for Specific Ratings

Application/ General-Duty Heavy-Duty

36 Features Safety Switches Safety Switches

Type of facility Residential, commercial, light industrial Commercial, institutional, industrial

37 Maximum voltages 240 Vac—250 Vdc in larger sizes 600 Vac—250 Vdc and 600 Vdc

Short-circuit rating for 10,000 rms symmetrical amperes 10,000 rms symmetrical amperes. Higher combination ratings

non-fused switches available with upstream Eaton molded-case circuit breakers

38 and fuses.

Short-circuit rating with With Class H fuse clips—10,000 rms Switches with Class H Fuse Clips—10,000 rms amperes

standard fuse clips symmetrical amperes 800–1200 A switches with Class L fusing—200,000 rms

39 Short-circuit rating with

fuse options

Class R fuse adaptation and 400–600 A switches with

T or J fuse adaptation—100,000 rms amperes

Switches with Class R or Class J fusing and 200–800 A

switches with Class T fuse adaptation—200,000 A at 480 V

and 100,000 rms symmetrical amperes at 600 V

40 Ampere sizes 30, 60, 100, 200, 400, 600 30, 60, 100, 200, 400, 600, 800, 1200

Maximum horsepower ratings 200 hp at 240 Vac 250 hp at 240 V, 500 hp at 480 and 600 Vac

UL (NEMA) enclosure types Type 1—general purpose indoor use Type 1 indoor, 3R outdoor

41 Type 3R—rainproof and sleet-resistant Type 4 watertight and dust-tight

Type 4X watertight, dust-tight and corrosion-resistant

Type 12 indoor falling dust, dirt and liquids

Type 12/3R convertible to outdoor use

42 Type 7/9 hazardous (classified) locations

Terminals Box lug (screw pressure) for Al/Cu wire Box lug (screw pressure) for Al/Cu wire

43 Electrical interlock—

snap-switch type

Field-installed kit, 200–600 A sizes Field- or factory-installed for all sizes

Control pole interlock Field-installed kit, 400–600 A sizes Field- or factory-installed for K-Series switches

Fuse pullers Not available Standard in Type 4X and 12 enclosed switches through 200 A

field- or factory-installed for all other 30–200 A switches

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-3

February 2017 Safety Switches

Sheet 28 003

General Description—Selection Guide

General-Duty Heavy-Duty Enhanced Visible Blade 22

23

24

25

26

General-Duty (Plug Fuse) Advanced Visibility Blade

■ Heavy-duty safety switches with 27

enhanced visible blade provide a

highly visible means of disconnect

Heavy-Duty to help improve personnel safety 28

For heavy commercial and industrial and equipment protection

■ Enhanced visible means of

applications where reliable performance

disconnect allows personnel

29

and service continuity are critical.

to clearly see that blades are

■ 600 Vac, 600 Vdc maximum disengaged from stationary contacts

■ 30–1200 A when the switch handle is in the

30

■ For short-circuit ratings, see OFF position

Technical Data ■ New visible blade design provides 31

■ Horsepower rated increased visibility over each pole,

General-Duty (Cartridge Fuse) allowing users to clearly see the

■ Fusible and non-fusible switches

For residential and commercial are 100% load break and load

trailing edge of the blade 32

make rated ■ Material color update from red to

applications. Suitable for light-duty

yellow creates greater contrast

motor circuits and service entrance. ■ The continuous load current of

fusible switches is not to exceed

between blades and arc shield 33

■ 240 Vac ■ Available in 30–1200 A ratings

80% of the rating of fuses employed

■ 30–600 A in other than motor circuits. Non- ■ Fusible and non-fusible

■ For short-circuit ratings, see fusible switches are 100% fully rated configurations in two-, three-,

34

Technical Data ■ Suitable for service entrance four- and six-pole

■ Suitable for service entrance applications unless otherwise noted ■ NEMA 1, 3R, 12, 4 and 4X 35

applications unless otherwise noted ■ Visible double break rotary blade enclosures for robust environmental

■ Fusible and non-fusible switches mechanism. Two points of contact protection

are 100% load break and load provide a positive open and close, ■ Modifications available such as 36

make rated easier operation, and also help to auxiliary contacts, pilot lights

■ The continuous load current of prevent contact burning for longer and more. Call the Flex Center

fusible switches is not to exceed contact life at 888-329-9272 or email 37

80% of the rating of fuses employed ■ Triple padlocking capability. FlexSwitches@eaton.com

in other than motor circuits. Non- Personnel safety feature because ■ To order safety switches with

fusible switches are 100% fully rated the large hasp can accommodate enhanced visible blade features 38

■ 200–600 A features K-Series design up to three 3/8-inch (9.5 mm) shank and no viewing window, the

locks. Cabinet door can be further standard heavy-duty catalog

■ Horsepower rated

padlocked at the top and bottom number should be used with the 39

■ Ample wire bending space provides addition of a ‘V’ suffix

■ Interlocking mechanism. Door

for easier installation

cannot be opened when the handle 40

■ With Class R fuses, switches may be is in the ON position. Built-in

used on systems capable of delivering defeater mechanism provides for

100,000 A rms symmetrical user access when necessary 41

Note: Plug fuse switches are not service ■ De-ionizing arc chutes. Arc chutes

entrance rated. confine and suppress the arcs

produced by contacts under load 42

43

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-4 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 004

General Description—Selection Guide

22 EnviroLine

23

24

25

26 Stainless Steel Switch Advanced Visibility Features Receptacle Switches

Eaton offers a line of safety switches Window Switches Receptacle Switches

27 designed for your special application

These heavy-duty switches are pre-

and/or extreme environmental conditions. These switches incorporate a new

external viewing window to replace wired and interlocked to polarized

28 EnviroLine Stainless Steel Switch the internal design. The new design receptacles for three-phase, three-wire,

instills confidence by allowing users grounded type power plugs.

Primarily for use in the meatpacking to easily view the trailing edge of the

and food processing industries, or ■ Used for portable power applica-

29 any application where water is

blade to confirm disconnect is open

tions such as welders, infrared

while the switch handle is in the

frequently used to hose down OFF position. ovens, batch feeders, conveyors,

equipment. and truck and marine docks

30 ■ All Eaton safety switches featuring ■ Receptacles are interlocked to

■ Stainless steel NEMA 4X enclosure a viewing window incorporates handle mechanisms so that power

■ Stainless steel interior mechanism, enhanced visible blade components plugs may not be inserted or

31 back pan and springs as standard removed when the switch is in the

■ Available in 30–400 A ratings, ■ Viewing window provides clear path ON position unless noted otherwise.

32 240–600 Vac to view switch interior ■ Ratings are 30–100 A, 600 Vac

■ Fusible and non-fusible ■ Window material is high-quality ■ Available in NEMA 12 and 4X

configurations laminated safety glass stainless steel enclosures

33 ■ 316 grade stainless steel option ■ External viewing window design is

replaces standard 304 grade field replaceable—kits available for

stainless steel and hardware with switches 30–1200 A

34 316 stainless. 316 stainless holds ■ 30 A and 60 A heavy-duty safety

up better in high salt environments switches feature a vertical viewing

found in coastal areas, and in window

35 water/wastewater applications ■ 100–1200 A heavy-duty safety

switches feature a horizontal

36 viewing window(s)

■ Ratings are 30–1200 A, 240–600 Vac,

fusible and non-fusible. Available

37 in NEMA 12/3R, 4X stainless steel

enclosures Non-Metallic Switches

38 Non-Metallic Switch

This switch has a KRYDON™

39 enclosure. This is a compression

molded fiberglass reinforced polyester

enclosure, which is capable of

40 withstanding almost any corrosive

environment. Ratings are 30–200 A,

240–600 Vac, fusible and non-fusible.

41 Enclosure is NEMA 4X rated.

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-5

February 2017 Safety Switches

Sheet 28 005

General Description—Selection Guide

Shunt Trip Safety Switch Six-Pole Motor Circuit 22

23

24

25

26

Six-Pole Motor Circuit

27

A compact safety switch that’s ideal for

Shunt Trip Safety Switch

use in heavy industry...when an “in sight” 28

Integrates shunt trip technology, disconnecting means is required for two-

enhancing safety by providing a means to speed motors that are remote from their

remotely open a safety switch electrically. motor control devices. 29

■ 600 Vac, 250 Vdc maximum

■ Heavy-duty safety switch design

with integrated shunt trip module ■ 30–800 A 30

■ Visible means of disconnect— ■ Fusible or non-fusible

■ Trunk-type latches keep the cover

visible blade

tightly closed and a neoprene

31

■ 30–800 A (240–600 Vac)

gasket seals out moisture and dust

■ NEMA® Type 12/3R, 4 (painted steel)

and 4X (stainless steel) enclosures

from the switch assembly 32

■ Visible double break rotary blade

■ Horsepower ratings same as

mechanism. Two points of contact

standard safety switches

■ Passes Class 1 ground fault testing

provide a positive open and close, 33

easier operation, and also help to

(1200% opening) prevent contact burning for longer

■ Maximum response time of 50 ms contact life 34

■ Switch arcing time less than ■ Clear line shield protection

10 ms (AC) ■ Built-in fuse pullers

■ Class H fuse clips supplied as ■ Clearly visible handle

35

standard on fusible devices

■ Triple padlocking capability. Cabinet

30–600 A, Class L for 800 A;

Class R, J, T fuse clips available

door can be further padlocked at the 36

top and bottom

Modifications available, such ■ De-ionizing arc chutes. Arc chutes

as viewing windows, pilot lights, confine and suppress the arcs 37

and more. Call the Flex Center at produced by contacts under load

888-329-9272 for more information.

38

39

40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-6 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 006

General Description—Selection Guide

22 Heavy-Duty Double-Throw Quick-Connect Switches

■ Wiring configuration from factory

allows a single load to be supplied

23 by a normal or alternate source.

Can be field modified to allow two

loads to be alternately supplied by

24 a single source

■ Ample wire bending space provides

for easier installation

25 ■ Visible double-break rotary blade

mechanism. Two points of contact

provide a positive open and close,

26 easier operation, and also help to

prevent contact burning for longer

contact life

27 ■ Triple padlocking capability.

Personnel safety feature because

the large hasp can accommodate

28 up to three 3/8-inch (9.5 mm)

Heavy-Duty Double-Throw

shank locks

29 Used to transfer service from a normal ■ Clearly visible handle. The position

power source to an alternate source, or to (ON or OFF) can be clearly seen Quick-Connect Double-Throw

switch from one load circuit to another. from a distance Provides a safe and quick means of

30 ■ For short-circuit ratings, see

■ Additional locking capability. connecting portable generators to

Cabinet door can be further facilities, transferring the building

Technical Data

padlocked at the top and bottom to backup power, or providing for

31 ■ 30–1200 A switches are

■ Clear line shield protects against temporary connection of portable loads.

horsepower rated

accidental contact with energized

■ 600 Vac, 250 Vdc maximum parts. Probe holes enable the user ■ Single-throw and double-throw

32 ■ Fusible or non-fusible to test if the line side is energized designs

■ Fusible and non-fusible switches without removing the shield ■ Single-throw receptacles can wire to

are 100% load break and load ■ De-ionizing arc chutes. Arc chutes the line side or the load side

33 make rated confine and suppress the arcs ■ Safety interlocks prevent access to

■ The continuous load current of produced by contacts under load the receptacle compartment unless

34 fusible switches is not to exceed ■ UL listed switching neutral capability the lower switch is in the “open”

80% of the rating of fuses employed is available on three-pole and position. This prevents against

in other than motor circuits. Non- four-pole non-fusible double-throw accidentally unplugging a circuit

35 fusible switches are 100% fully rated switches with the installation of under load

■ Suitable for service entrance the proper bonding kit shown on ■ For short-circuit ratings, see

applications unless otherwise noted Page 28.0-19 Technical Data

36 ■ 600–1200 A fusible utilizes a ■ 30–800 A switches

common set of fuses; two source,

■ 600 Vac, 600 Vdc maximum

one load applications

37 ■ Fusible or non-fusible

■ Fusible and non-fusible switches

are 100% load break and load

38 make rated

■ Cam-Lok® or Posi-Lok® receptacle

options

39 ■ NEMA 1 or NEMA 3R enclosure

ratings

40 ■ Switching neutral option

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-7

February 2017 Safety Switches

Sheet 28 007

General Description—Selection Guide

Elevator Control Switch 22

Why do Buildings Require Eaton 2. The ASME A17.1 Safety Code

Elevator Disconnects? for Elevators and Escalators,

Eaton’s Elevator Disconnect is a Rule 102.2 (c) (3), requires the 23

simple, all-in-one solution that takes shutdown of power to the elevator

the mystery out of meeting the many prior to the application of water

codes associated with fire protection in the elevator machine room 24

and safety in elevator shafts. The model or hoistway.

national building codes that prescribe Shutdown of power is usually

the requirements for sprinklers, elevators accomplished with the use of a

25

and electrical equipment, and how the shunt trip device in the elevator

various systems shall interact are: circuit, and is done for two valid

safety concerns.

26

■ NFPA® 70

(National Electrical Code®) The first of these is to minimize

■ NFPA 72 the potential for electric shock 27

(National Fire Alarm Code®) due to the release of water on

■ ANSI/ASME A17.1 energized electrical equipment.

Elevator Control Switch (Safety Code for Elevators and The second, and less obvious, 28

The elevator control switch provides Escalators) is to reduce the possibility of

■ NFPA 13 (Installation of elevator car slippage after the

an all-in-one product solution and 29

Sprinkler Systems) car has gone to the recall floor

selective coordination for elevator

circuits. The elevator control switch and the doors have opened. Slip-

In addition to these national codes, page is possible when the hoisting

uses a shunt trip disconnect as standard

with Class J time-delay current-limiting

state and local jurisdictions or other equipment (cables, sheave, braking 30

agencies of the government (such as system, etc.) become wet from

fuses for meeting several code and user

the Veteran’s Administration) may edit discharged water.

requirements for such circuits. Ratings

or amend the codes, as they deem 31

are 30–200 A, 600 Vac, NEMA 1, 3R, Eaton’s Elevator Disconnect is

necessary for public safety.

12 and 4 enclosures. The elevator a fusible switch that is equipped

control switch carries a 200 kAIC rms Eaton’s Elevator Disconnect enables with a shunt trip mechanism. The 32

symmetrical short-circuit rating. consultants, contractors and building shunt trip is operated by a control

owners to install a single device that relay (called a Fire Safety Interface

meets the requirements of the Relay) in the unit that is wired to 33

various codes. a normally open contact in the

remote Fire Alarm Control

Why is There a Need for the Eaton Panel (FACP). 34

Elevator Disconnect?

1. According to 2010 NFPA 13, fire When the FACP receives a signal

sprinkler protection is required from the fire alarm system that 35

(with some exceptions) at the top there is going to be a sprinkler

and bottom of elevator shafts. release in an elevator shaft, a

Additionally, NFPA 13 requires normally open contact in the FACP 36

the installation of sprinklers in closes, energizing the Fire Safety

the elevator machine room. Interface Relay and completing a

When sprinkler heads are installed circuit to initiate a trip. 37

in elevator shafts, or in elevator The Fire Safety Interface Relay

machine rooms, then they must is available with a 120 Vac or

also be installed according to the 24 Vdc coil. The 120 Vac coil 38

State-Adopted Elevator Code (in should be selected when powered

many cases, ANSI/ASME A17.1). by the Elevator Disconnect control

circuit, and the 24 Vdc relay 39

should be selected when the

power is supplied from the fire

alarm system. 40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-8 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 008

General Description—Selection Guide

3. In addition to turning off power,

22 Sprinkler System the model codes require other

functions that are satisfied by the

Sprinklers Eaton Elevator Disconnect. One

23 of these requirements is that the

shunt trip control circuit requires

1 monitoring. The NFPA 72

24 (Fire Alarm Code) requires:

Control circuits to shut down

25 elevator power shall be monitored

for the presence of operating

voltage. Loss of voltage to the

26 control circuit for the disconnecting

means shall cause a supervisory

signal to be indicated at the

27 control unit and required remote

annunciation.

Thus, there is a requirement to

28 monitor and to annunciate the

presence of shunt trip control

power. This is accomplished in

29 the Eaton Elevator Disconnect by

the Fire Alarm Voltage Monitoring

Relay option. This relay is either

30 1 a SPDT or a 3PDT relay. When

3 control power is present, the

2

closed relay contacts complete

31 Elevator

Disconnect a circuit to the FACP that indicate

the presence of control voltage.

If control voltage is lost, the con-

32 tact opens, signaling an alarm at

Fluid Tank

Controller the FACP and/or monitoring and

33 annunciating a single elevator; all

that is required is the single-pole

relay. When wiring multiple

4

34 switches (for multiple elevators),

Battery the three-pole relay option should

Lowering

Device be chosen. However, if there is a

35 doubt, selecting the three-pole

relay will provide all the function-

ality that is needed.

36

37

1 NFPA 13 requires sprinklers in 3 NFPA 72 (Fire Alarm Code)

elevator shaft (with exceptions) requires control circuit for

38 and in control room. elevator shutdown to be

monitored for the loss of voltage.

2 ASME A17.1 (Safety Code for 4 NEC requires standby power

39 Elevators and Escalators) requires systems such as a battery

shutdown of power to the lowering device to be

elevator prior to the release disconnected by an auxiliary

40 of water. contact in the elevator disconnect.

Figure 28.0-1. Typical Hydraulic Elevator Components and Requirements

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-9

February 2017 Safety Switches

Sheet 28 009

General Description

Additional Requirements and Concerns

Many elevators are equipped with 22

backup power supplies to allow the

elevator to be lowered if power is lost.

For example, many hydraulic elevators From Feeder 1. A shunt trip device is required if the 23

are equipped with a battery system hoistway and/or machine room is sprinklered.

that opens a solenoid to lower the 2. The location of the shunt trip device is required

24

L1

L2

L3

elevator, and then provides power to be in the elevator machine room.

to open the elevator doors.

Shunt Trip

This battery-lowering device is viewed Device 25

by the NEC as an “emergency or

standby power system,” and is Shunt trip control voltage

governed by Article 620.91. must be monitored for

To heat sensor(s)

26

loss of voltage. Loss of

or flow control

4. Paragraph (C) requires that the voltage is required to sensor.

main disconnect be provided with activate an annunciator

on the control unit. The

27

an auxiliary contact that discon-

building fire alarm control

nects the additional power source unit may be utilized for

from the load when the discon- this purpose 28

necting means is in the open (ref. NFPA 72 3.9.4).

position. The purpose of this

auxiliary contact is to disconnect 29

the backup power system when

the elevator switch is opened

■ Auxiliary Contact for Battery Lowering device

to prevent the elevator from auto- required by Art. 620.91(C). Purpose of this 30

matically lowering while being contact is to distinguish between an actual

maintained—which would power failure and the opening of the

endanger maintenance personnel. disconnect for maintenance.

■ Must be provided with overcurrent protection.

31

Eaton’s Elevator Disconnect ■ Must be lockable in the open position.

is supplied with a standard set ■ Must be externally operable.

of 1NO and 1NC auxiliary

32

contacts that are wired to the

terminal blocks for this feature.

Other manufacturers offer this

33

as an option.

Battery Lowering Device

An additional concern that is not code 34

related is accidental signaling of a loss

of voltage if a switch is turned off for

maintenance or testing. For example, if To Elevator Controller 35

an Eaton Elevator Disconnect is turned

off to perform routine maintenance, Figure 28.0-2. Shunt Trip Device Wiring Diagram

the control voltage will be 36

disconnected and it will send a signal

to the FACP—which may alert the local

fire department and initiate a fire call. 37

To solve this problem, an optional

micro switch mounted on the main 38

switch can be supplied and field-wired

in parallel with the alarm contact on

the Voltage Monitoring relay. Wiring in 39

this fashion would prevent an alarm

signal from being sent when the Eaton

Elevator Disconnect is turned off for 40

routine maintenance.

An additional standard feature on the 41

Eaton Elevator Disconnect is a Key-

To-Test switch to perform a functional

test of the operation of the shunt trip. 42

A pilot light signaling that the switch is

ON and a neutral lug are the only other

available options. 43

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-10 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 010

General Description—Selection Guide

22 OEM Line Isolation (OLI) Features and Benefits

Switch

Gasketed Side Wall Modified Heavy-Duty

23 Mounts to OEM Cabinet Safety Switch—NEMA

Type 12/3R and 4/4X

Enclosures Available

24 Oversized Line Shield

(Internal to Switch) Voltage Indicators for

Line, Load, or Line and

Load Side of Switch

25 Voltage Portal(s)

(Optional)

(Optional) Mechanical Interlock—

cannot Open Switch or

26 OEM Cabinet when

Handle is in ON Position

Custom Flex Shaft

27 Operator Modified to

OLI Switch Integrated Work with Safety Switch

onto Disconnect Enclosure

28 Flange Handle

(for Mounting

General Description on OEM Cabinet) a

Traditional control panels may expose

29 operators to line side system voltage

(i.e., 480 Vac) even when the internal

main disconnect is in the OFF position.

30 Many panel-building OEMs and OEM

customers are concerned with arc

flash hazards and arc flash categories a Flex shaft operator and handle assembly is included

31 and may be looking for ways to reduce and shipped with switch loose, for field installation.

them.

32 The solution is the OEM Line Isolation Modifications

(OLI) switch—the newest product in

Eaton’s expanding offering of safer Additions are available such as custom

33 switching devices. The OLI switch pro- paint, 316-stainless enclosures,

vides an external disconnecting means custom OEM labeling and more. Call

for industrial control panels. It allows the Flex Center at 1-888-329-9272 for

34 an operator to access the control panel more information.

without exposure to the line side volt-

age, thus enhancing safety and allow- Standards and Certifications

35 ing for reduced PPE, which improves ■ UL/cUL

worker dexterity and mobility. ■ UL 98 standard, file no. e222859

36 The OLI switch is designed to univer- ■ UL 50 standard, file no. e478865

sally integrate to major manufacturers’

“disconnect enclosures” that will work

37 with the Eaton C371-style handle and

operating mechanism. The Eaton solu-

tion is a complete package, including

38 enclosure, disconnect, handle, flex-

cable operator and all other necessary

components.

39

40

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-11

February 2017 Safety Switches

Sheet 28 011

General Description—Selection Guide

NEMA 7/9—Hazardous Location Auxiliary Power Heavy-Duty Safety Switch 22

Disconnect Switch The Auxiliary Power Heavy-Duty

Safety Switch combines a safety

switch, 2 kVA control transformer, 23

and 15 A GFI receptacle in a single

product. Ratings are 30–200 A, 240 or

600 Vac, NEMA 3R outdoor enclosures. 24

The auxiliary circuit is tapped off of the

line side of the safety switch and can

be operated independently of the main 25

switch circuit. Auxiliary circuit voltages

are available at either 208, 240, 480 or

600 V. In 480 V and 600 V applications, 26

the auxiliary circuit disconnect and

overcurrent protection are provided by

Auxiliary Power Heavy-Duty Safety Switch a fusible deadfront disconnect switch 27

with Class J fuses. The short-circuit

NEC Section 210.63 for Heating,

rating is 200 kAIC. 208 V and 240 V

Air-Conditioning and Refrigeration

NEMA Type 7/9 Equipment requires a 125 V, single-

applications have a molded-case 28

breaker with a 100 kAIC rating as the

■ The cast aluminum enclosure is phase, 15 A- or 20 A-rated receptacle

auxiliary circuit disconnect. The use of

outlet be installed at an accessible

ideally suited for harsh industrial

location for the servicing of heating,

the Auxiliary Power Heavy-Duty Safety 29

applications including petrochemi- Switch eliminates the need for running

cal facilities, mining operations, air-conditioning and refrigeration

a separate 120 V circuit common to

equipment. The receptacle must

pharmaceutical plants and waste-

be located on the same level and

rooftop air-conditioning applications. 30

water treatment facilities. Eaton’s

Type DS switch is used as the within 25 ft (7.5 m) of the heating,

air-conditioning and refrigeration

switching device. Ratings are

equipment. The receptacle outlet is

31

30–100 A, 600 Vac, fusible and

non-fusible not to be connected to the load side of

the equipment disconnecting means.

Certifications and Compliances

32

■ Class I, Divisions 1 and 2,

Groups B, C, D

2-Pole

Incoming Lugs 33

■ Class I, Zones 1 and 2 Breaker

■ Class II, Division 1, Groups E, F, G Receptacle

■ Class III

Secondary 34

Fuse

■ NEMA 3, 3R, 4, 4X, 7BCD, 9EFG

■ UL® standard: 1203 35

■ cUL® to CSA® C22.2 No. 30

Standard Materials Fuses 36

■ Body and cover—copper-free Control Power

aluminum 15 Ampere or Optional Transformer

■ Gasket—neoprene

20 Ampere Available Load 37

■ Cover bolts—steel, stainless steel (GFCI Receptacle Option Available — 3 kVA

Transformer Required)

■ Hinges—stainless steel 38

■ Mounting plate sheet—aluminum

Figure 28.0-3. Auxiliary Power Heavy-Duty Safety Switch Circuit Diagram

■ Rotary actuating handle—aluminum

39

Standard Finishes

■ Copper-free aluminum—natural

■ Steel—electrogalvanized 40

41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-12 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 012

General Description—Selection Guide

22 Heavy-Duty—Solar Heavy-Duty Solar Enclosed Rotary

Photovoltaic Switch Photovoltaic Switch

23 Single-Circuit Multi-Circuit

24

25

26

27

Enclosed Rotary

28 Provides users with the ability to lock

directly wired motor loads in the OFF

29 Heavy-Duty—Solar Photovoltaic Switch position to comply with new OSHA lock-

Heavy-Duty Solar Photovoltaic Switch

Multi-Circuit

out/tagout regulations. Also for machine

Marked as suitable for NEC 690 PV applications that require compact,

applications up to 600 Vdc.

30 Marked as suitable for NEC 690 PV economical disconnect switches.

■ UL 98 listed applications per UL 1741 requirements.

■ UL listed

600 Vdc per pole and 1000 Vdc.

■ All switches are single-pole and ■

31 suitable for switching one circuit ■ UL Listed to the UL 98B standard

Meets NEC Article 430 require-

ments for a separate disconnect

■ Clear polycarbonate deadfront to ■ Products designed and available means within sight of all motor

32 guard against accidental contact for grounded and ungrounded loads

with live parts (floating) systems ■ Padlockable in the OFF position

■ Suitable for positive and negative Note: Catalog numbers beginning with DCG (up to three padlocks) to meet OSHA

33 grounded systems—100% load are for use on grounded systems. Catalog lockout requirements

break rated with current flowing in numbers beginning with DCU are for use on

■ Available 16–80 A ratings

either direction ungrounded systems.

■ 600 Vac, three- and four-pole

34 ■ NEC 690.17—compliant labeling

■ Grounded designs can be non-fusible device

warning that the switch terminals

used on positive and negative ■ Rated at highest available hp rating

may be energized in the open

grounded systems (at 480 Vac, 16 A–10 hp, 25 A–15 hp,

35 position

30 A–15 hp, 40 A–20 hp, 60 A–30 hp,

❑ Not polarity sensitive

■ NEC 690.14.(C) two required “PV 80 A–40 hp)

System Disconnect” labels included ■ Bi-directional functionality

36 ■ Isolated ground terminals (neutral) ❑ Will break high-energy DC

■ Rated for making and breaking loads

arc regardless of direction ■ Accepts auxiliary contacts

for grounded conductors

of current flow ■ Capability to signal PLC controllers

37 ■ Ground lug for equipment

■ Ampacity range—30, 60, 100, ■ Ground lug connection provided

grounding conductor

■ NEMA 3R, 12 and 4X stainless 200 and 400 A ■ Can be rated up to 65 kAIC,

38 enclosures ■ Clear polycarbonate when protected by applicable

deadfront shield upstream fusing

■ Fusible and non-fusible configura-

tions—Class R fuse clips standard ■ Equipment ground

39 ■ Fuse clips are located on the center ■ NEMA 3R, 4 and 4X stainless

pole to ensure that both fuse clips steel enclosures

are de-energized—meets NEC ■ Flex Center modification available,

40 Article 690.16, which requires such as viewing windows, pilot

isolation of the fuse from all lights and more

potential supply sources

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-13

February 2017 Safety Switches

Sheet 28 013

Factory Modifications—Flex Center Facility

Flex Center 22

Introduction

The Switching Device Flex Center is a special facility at the site of Eaton’s Cleveland, Tennessee plant that is dedicated 23

to providing customized safety switches and enclosed breakers that meet customer’s challenging applications.

Table 28.0-2. Common Flex Center Design Offerings

Modification Catalog Description

24

Suffix

Custom paint (varies) Special paint colors are available such as red, orange, yellow, green, black, white. Other colors may be 25

available upon request. Custom color is applied over the standard ANSI-61 gray finish.

Nameplates -00NP Plastic or phenolic nameplates are available. Up to three lines of text, 25 characters per line. Standard offering

is white with black letters. Custom colors and sizes available upon request. Specify text at order entry. 26

Lock on provisions -00LO Available on heavy-duty and double-throw safety switches. Provision will accept a single lock.

Trapped key interlock -00TK Available on heavy-duty and double-throw safety switches. Trapped key systems are used on safety switches

to prevent unauthorized operations or to predetermine a series of power transfers by an authorized operator. 27

Upper viewing W An upper viewing window is centered over the switching contacts to provide visual verification of ON/OFF status.

window Available on NEMA 12/3R and NEMA 4X stainless steel heavy-duty and double-throw safety switches.

Note: 30–100 A switches are now provided with a full view cover window for both blade and blown fuse viewing. 28

Lower viewing LW A lower viewing window is centered over the fuses and provides visual verification of blown fuse indicators.

window Available on 200–1200 A NEMA 12/3R and NEMA 4X stainless steel heavy-duty and double-throw safety switches.

Available for fusible switches only.

Note: 30–100 A switches are now provided with a full view cover window for both blade and blown fuse viewing. 29

Neutral assemblies N Factory install of field neutral accessory kits. Add Suffix N on non-fusible switches, or replace the 6th character “F”

with “N” on fusible switches.

Class “R” fuse clips 5 or 6 Factory installed Class R fuse clips/provisions. Add Suffix 5 for 240 V switches, and Suffix 6 for 600 V switches.

30

Available on 30–600 A safety switches.

Class “T” fuse clips T Factory installed Class T fuse clips/provisions. Available on 200–1200 A safety switches.

Class “J” fuse clips J Factory installed Class J fuse clips/provisions. Available on 30–600 A safety switches.

31

Note: Field modification kits are not available for 30 A heavy-duty safety switches.

30 A switches requiring Class J fusing must be ordered factory installed with J suffix.

Fungus proofing -00FP All non-metallic components of the switch are coated with a moisture and fungus-resistant varnish. The inhibitor 32

used meets military specification: MIL-V-173C for MOISTURE AND FUNGUS-RESISTANT TREATMENT. The treated

switch meets military specification MIL-T-152E for MOISTURE AND FUNGUS-RESISTANT TREATMENT OF

COMMUNICATIONS, ELECTRONICS, AND ASSOCIATED EQUIPMENT. Not UL Listed. 33

Fuse pullers FE Factory installed fuse pullers.

Note: Standard NEMA 12/3R and 4X switches 30–200 A are supplied with fuse pullers from the factory.

Crimp lug pads -00CK Factory installed crimp lug pad kits. Available on 400–800 A safety switches. Crimp lugs are not included. 34

Note: Standard heavy-duty Type DH switches 30–200 A are adaptable to crimp lugs; simply remove the box lugs.

Copper lugs -00CL Factory installed copper lug kits. Available on 30–800 A safety switches.

Ground lug kits G Factory installed ground lug kits. Provides additional ground lug capacity when compared to ground lugs that come 35

factory installed with standard safety switches. Available on 30–1200 A safety switches.

Custom lugs -000L Customer-specified lug arrangements are available on heavy-duty and double-throw safety switches.

Auxiliary contacts 2 or 3 Factory installed auxiliary contact kits (DS200EK1 or DS200EK2). Auxiliary contacts are Early-Make/Early-Break 36

operation. To specify 1NO/1NC contact, add Suffix 2. To specify 2NO/2NC contacts, add Suffix 3.

Control pole -00CP The K-Series control pole provides one NO contact. It mounts in the exact location as the neutral block using the same

pre-drilled holes. This is directly connected to the power pole operating shaft. Direct connection and visible blades pro- 37

vide more secure electrical interlocking than handle linkage operation of a snap/switch type interlock. This reliability

meets the requirements of many specifications for four-pole switches when the fourth pole is required for secure elec-

trical interlocking. This control pole provides Same-Make/Same-Break operation.

Control pole -0CP2 Same as above except this control pole provides Late-Make/Early-Break operation.

38

with offset Both Control Pole options are provided when you purchase the DS16CP field kit.

Switching neutral

double throws

SN UL Listed for three-pole and four-pole non-fusible double-throw safety switches. Switching neutrals are required for

separately derived systems when bonding the neutral of the generator to a grounding system at the generator.

39

Surge protection (varies) Factory installed Eaton Type 1 (SP1 series) or Type 2 (CVX series) surge protective device products.

SPD installed and wired to load side of disconnect.

40

Additional Flex Center Design Offerings ■ Irrigation switches Contact

■ Left-hand design (30–200 A) ■ Fuses installed For more information on these or

any other modifications, please

41

■ Cover controls ■ Hook stick handles

■ 200% neutrals (heavy-duty switches only) contact the Switching Device Flex

■ Custom labels Center at 1-888-329-9272, email 42

■ Seam-welded stainless steel FlexSwitches@eaton.com or visit

■ Quick Connect products with ■ Custom mounting Eaton.com/FlexCenter.

Cam-Lok and Posi-Lok receptacles ■ Pad-mount designs

■ Custom enclosures ■ Non-standard receptacles

43

■ 316 grade stainless steel ■ Enhanced visible blade

■ Mill duty switches ■ Voltage indicators

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-14 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 014

General Description—Selection Guide

Safety Switch Selection Guide

22 Table 28.0-3. Safety Switch Selection Guide

Type Fuse Fuse Ampere Number Enclosure Types

23 Type Class Rating of Poles NEMA 1 NEMA 3R NEMA 12 NEMA 4 NEMA 4X NEMA 4X NEMA 4X NEMA

Painted Stainless Non- 316 Grade 7/9

Steel Steel Metallic Stainless

24 Steel

General- Single-throw Fusible Plug — 30 1 and 2 Yes Yes — — — — — —

duty max. 240 Vac Cartridge H a 30–600 2 and 3 Yes Yes — — — — — —

25 horsepower

Non- — — 30–600 2 and 3 Yes Yes — — — — — —

rated

fusible

Single-throw Fusible Cartridge H a Yes b

26 Shunt

trip max. 600 Vac L

30–600

800

2, 3

and 4

— — Yes Yes — Yes —

horsepower Non- — — 30–800 2, 3 — — Yes b Yes Yes — Yes —

rated fusible and 4

27 Heavy- Single-throw Fusible Cartridge H a 30–600 2, 3 Yes Yes Yes b Yes Yes Yes Yes Yes c

duty max. 600 Vac L 800–1200 and 4 up to up to up to 400– up to up to up to up to

horsepower 1200 A 1200 A 1200 A 1200 A 1200 A 200 A 1200 A 100 A

28 rated Non- — — 30–1200 2, 3 Yes Yes Yes b Yes Yes Yes Yes Yes

fusible and 4 up to 400– up to up to up to up to

1200 A 1200 A 1200 A 200 A 1200 A 100 A

29 Six-pole Single-throw Fusible Cartridge H a 30–800 6 — Yes Yes b — Yes — Yes —

motor max. 600 Vac Non- — — 30–800 6 — Yes Yes b — Yes — — —

circuit fusible

30 Double- Max. 600 Vac Fusible Cartridge H a 30–400 2 and 3 Yes Yes Yes — Yes — Yes —

throw horsepower T (600 V) 400 up to up to up to

rated J 600 600 A b 400 A 400 A

31 L 800–1200

Non- — — 30–1200 2, 3, 4 Yes Yes Yes — Yes — Yes —

fusible and 6 up to up to up to

32 800 A b 600 A 600 A

Rotary Max. 600 Vac Non- — — 16–80 3, 4 Yes Yes Yes b — Yes Yes Yes —

switches fusible

33 Auxiliary Max. 600 Vac Fusible Cartridge H a 30–200 3 — Yes — — — — — —

power horsepower Non- — — 30–200 3 — Yes — — — — — —

heavy- rated fusible

34 duty

Elevator Max. 600 Vac Fusible Cartridge J 30–400 3 Yes Yes Yes Yes Yes — — —

control horsepower

35 switch

a

rated

Class J, R and T available in many instances with the use of adapter kits listed on Page 28.0-19.

b NEMA Type 12 enclosures (30–1200 A) can be field modified to meet NEMA 3R rainproof requirements when a factory provided drain screw is removed.

36 c Class J clips provided.

Table 28.0-4. EnviroLine Safety Switch Selection Guide

37 EnviroLine Fuse Fuse Ampere Number Enclosure Types

Type Class Rating of Poles NEMA 1 NEMA 3R NEMA 12 NEMA 4 NEMA 4X NEMA 4X

Painted Stainless Non-

38 Steel Steel Metallic

Stainless enclosure Fusible Cartridge H d 30–400 2 and 3 — — — — Yes —

with stainless Non- — — 30–400 3 — — — — Yes —

39 mechanism fusible

Viewing window Fusible Cartridge H d 30–600 2, 3, 4 — — Yes e Yes Yes —

L 800–1200 and 6

40 Non- — — 30–1200 2, 3, 4 — — Yes e Yes Yes —

fusible and 6

Fusible Cartridge H d Yes e

41 Welding receptacle 30–100 3 — — — Yes —

Non- — — 30–100 3 — — Yes e — Yes —

fusible

42 Non-metallic Fusible Cartridge H d 30–200 3 — — — — — Yes

Non- — — 30–200 3 — — — — — Yes

fusible

43 d Class J, R and T available in many instances with the use of adapter kits listed on Page 28.0-19.

e NEMA Type 12 enclosures (30–1200 A) can be field modified to meet NEMA 3R rainproof requirements when a factory provided drain screw is removed.

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-15

February 2017 Safety Switches

Sheet 28 015

General Description—Catalog Numbering System

Catalog Numbering System

Table 28.0-5. Safety Switch Catalog Numbering System

22

DH 3 6 1 N D K W 23

Switch Type Options 24

DP = General-duty/ W = Viewing window b

plug fuse Voltage a V = Enhanced visible blade

DG = General-duty/ 1 = 120 Vac

Amperes Fusible/Non-Fusible X = EnviroLine stainless 25

cartridge fuse or Neutral (enclosure and mechanism)

2 = 240 Vac 1 = 30 A

DH = Heavy-duty 6 = 600 Vac 2 = 60 A F = Fusible without GCL = Mill duty

DT = Double-throw

DS = Classified

3 = 100 A neutral CB = Provisions for cube fuses

(30–100 A, 600 V)

26

4 = 200 A U = Non-fusible

location with 5 = 400 A N = Fusible with neutral 316 = 316 Grade stainless steel

DS interior enclosure and hardware

6

7

= 600 A

= 800 A

27

8 = 1200 A NEMA Enclosure Ratings

Poles/Blades Series

G = NEMA 1

1

2

= Single-pole

= Two-pole

R = NEMA 3R K = Design—All general-duty

switches above 200 A and

28

D = NEMA 12

3 = Three-pole P = NEMA 4 (painted steel) all heavy-duty switches

4 = Four-pole incorporate K-Series switch

6 = Six-pole

W = NEMA 4X corrosion resistant

(304 Grade stainless steel) design features listed on 29

C = NEMA 4X non-metallic the following page

KRYDON (for Type DH) B = Design general-duty 30–100 A

X = NEMA 7 and 9 (for Type DS) H = Design general-duty double-

throw switch (compact design

30

30–100 A)

a

31

For DC ratings, check individual switch ratings.

b All window switches feature enhanced visible blade design as standard.

Table 28.0-6. Shunt Trip Safety Switch Catalog Numbering System

32

STS 3 6 4 U D 3 2 33

Switch Series Accessories/Options 34

STS = Shunt trip Blank = No accessories

switch (UL) Shunt Trip CL = Copper lugs

CTS = Shunt trip Protection Coil Voltage CP = Control pole 35

switch (CSA) F = Fusible without neutral 1 = 24 Vac J = Factory converted provision

U = Non-fusible 2 = 48 Vac for Class J fusing

Poles N = Fusible with neutral 3 = 120 Vac N = Factory installed neutral for

non-fused switch

36

4 = 240 Vac

2 = Two-pole 5 = 480 Vac T = Factory converted provision

3 = Three-pole NEMA Enclosure Rating for Class T fusing

4 = Four-pole D = NEMA 12/3R

6 = 24 Vdc

7 = 48 Vdc W = Viewing window 37

8 = 125 Vdc within door

P = NEMA 4 (painted steel)

W = NEMA 4X, stainless 304

Maximum System

Voltage X = NEMA 4X, stainless 316 Auxiliary Switch 38

2 = 240 Vac Blank = No auxiliary switches

1 = 1NO/NC alarm switch only

6 = 600 Vac

2 = 1NO/1NC auxiliary contact only 39

3 = 2NO/2NC auxiliary contacts only

Switch Ampacity 4 = 1NO/1NC auxiliary contact and

1 = 30 A

5

1NO/NC alarm switch

= 2NO/2NC auxiliary contacts and

40

2 = 60 A

3 = 100 A 1NO/NC alarm switch

4

5

= 200 A

= 400 A

41

6 = 600 A

7 = 800 A

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-16 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 016

General Description—Catalog Numbering System

Table 28.0-7. Quick-Connect Safety Switch Catalog Numbering System

22

DT 3 6 5 N U R K LC

23

Switch Type Receptacle Type

24 DT = Heavy-duty

double-throw Series

LC = Cam-Lok

LCR = Cam-Lok reverse pin

DH = Heavy-duty K=K LP = Posi-Lok

single-throw Upper Switch a PLR = Posi-Lok reverse pin

25

U = Non-fusible Enclosure

Poles F = Fusible Neutral c

N = Fusible with solid neutral G = NEMA 1

26 2 = Two-pole

SN = Fusible with switched neutral R = NEMA 3R Blank = No neutral or included

3 = Three-pole with switch designation

4 = Four-pole N = Solid neutral

Lower Switch ab SN

27 = Switched neutral

Maximum Voltage U = Non-fusible

F = Fusible

2 = 240 Vac

N = Fusible with solid neutral

28 6 = 600 Vac

SN = Fusible with switched neutral

Switch Ampacity

29 3 = 100 A

4 = 200 A

5 = 400 A

30 6 = 600 A

7 = 800 A

31 a When upper and lower switches are the same, the switch configuration is consolidated in one letter (e.g.,”U” not “UU”). Also, a switch with a neutral will have

either a solid neutral or a switched neutral, not both. Lastly, a switched neutral pole is never fused.

b Heavy-duty single-throw switches will not have a lower switch option.

32 c This field is only used when a switch is completely non-fused.

Table 28.0-8. Elevator Control Switch Catalog Numbering System

33

ES 1 T2 R2 G F1 R N B

34

Switch Type Auxiliary Contacts

1NO/1NC

35 ES = Elevator

control switch Industrial Control B = Main switch

Transformer d Fire Alarm Voltage

Fire Safety Pilot Light Monitoring Relay e

36 Amperes T2 = 208 V

T3 = 240 V Interface Relay ON

F1 = Single-pole

Isolated Full Capacity

(3PDT, 10 A, 120 V) Neutral Lug

1 = 30 A T1 = 480 V G = Green F3 = Three-pole

2 = 60 A T4 = 600 V R2 = 24 Vdc coil R = Red N = Neutral lug

37 3 = 100 A R1 = 120 Vac coil W = White

4 = 200 A

5 = 400 A Enclosure Options f

38 3 = NEMA 3R

D = NEMA 12

P = NEMA 4 painted steel

W = NEMA 4X stainless

39

d 100 VA with primary and secondary fusing (120 V secondary).

e To monitor shunt trip voltage.

40 f NEMA 1 standard with no suffix designation required.

Note: All modules are three-pole, 600 V and contain a key to test switch and mechanically interlocked auxiliary contact as standard.

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-17

February 2017 Safety Switches

Sheet 28 017

General Description—Catalog Numbering System

Table 28.0-9. OEM Line Isolation Switch Catalog Numbering System

22

OLI 3 6 3 F D J B - OOVP

23

Switch Type Options/Modifications a

OEM Line Isolation

Voltage Fuse Class Provisions

0000 = None 24

0002 = 1NO/1NC aux

6 = 600 Vac max. J = Class J 0003 = 2NO/2NC aux

Poles/Blades BLAK = Painted black

2 = Two-pole

X = Non (non-fused)

ORNG= Painted orange

25

3 = Three-pole Ampere Rating 0RED = Painted red

NEMA Enclosure 0316 = 316 stainless steel

2 = 60 A

3 = 100 A D = NEMA 12/3R 00NP = Custom nameplate 26

4 = 200 A W = NEMA 4X stainless 000G = Additional grounding

5 = 400 A 00VP = Voltage portal b

Fusible/Non-Fusible 27

Voltage Indicator Location

F = Fusible without neutral

U = Non-fusible without neutral X = None

A = Load side 28

B = Line and load side

C = Line side

29

a More combinations and options are available.

b One voltage portal for each voltage indicator specified.

30

Table 28.0-10. Auxiliary Power Heavy-Duty Safety Switch Catalog Numbering System

DH 3 6 1 F R K A1 480 31

Switch Type Auxiliary Circuit Voltage 32

GFI Receptacle 208 = 208 V

DH = Heavy-duty

Voltage 240 = 240 V

2 = 240 Vac

A1 = 15 A

A2 = 20 A 480 = 480 V 33

Poles/Blades Fusible/Non-Fusible 600 = 600 V

6 = 600 Vac

3 = Three-pole or Neutral

Amperes F = Fusible without Series

34

neutral

1 = 30 A U = Non-fusible K = Design—All general-duty switches above

2

3

= 60 A

= 100 A

N = Fusible with neutral 200 A and all heavy-duty switches incorporate

K-Series switch design features listed on the

35

4 = 200 A following page

NEMA Enclosure Ratings

R = NEMA 3R 36

Table 28.0-11. DC Disconnect Catalog Numbering System

37

DCG 3 06 1 U R M 38

Class and Type Accessories/Options 39

DCG = DC Disconnect/ Blank = No accessories

grounded system Maximum System 2 = 1NO/1NC auxiliary contact

DCU = DC Disconnect/ Voltage Protection 3 = 2NO/2NC auxiliary contact 40

ungrounded system 06 = 600 Vdc F = Fusible W = Viewing window

10 = 1000 Vdc U = Non-fusible J = Factory-converted Class J

Number of Circuits c

fuse provisions 41

1 = 1 circuit Ampacity NEMA Enclosure Rating

Switch Series

2 = 2 circuits 1 = 30 A

3 = 3 circuits 2 = 60 A

R

P

= NEMA 3R

= NEMA 4 M = DC photovoltaic applications 42

4 = 4 circuits 3 = 100 A W = NEMA 4X, stainless 304

5 = 5 circuits 4 = 200 A X = NEMA 4X, stainless 316

6 = 6 circuits 5 = 400 A 43

c Not all configurations for ampere rating and number of circuits are available.All circuit configurations can be found in the product dimension tables.

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-18 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 018

General Description

22 All General-Duty Switches Above 100 A and All Heavy-Duty Switches

Incorporate These K-Series Switch Design Features

23

24

25

26

27

Visible Double Break Rotary Blade Mechanism Clearly Visible Handle Interlocking Mechanism

28

Two points of contact provide a The position (ON or OFF) can be Door cannot be opened when the

positive open and close, easier clearly seen from a distance and the handle is in the ON position. Front side

29 operation, and also help prevent length provides for easy operation. operable defeater mechanism provides

contact burning for longer contact life. for user access when necessary.

30

31

32

33

34

Clear Line Shield Triple Padlocking Capability Tangential Knockouts

35 Protects against accidental contact with Personnel safety feature because the An ample number are provided on the

energized parts. Probe holes enable large hasp can accommodate up to top, bottom and sides of both NEMA

the user to test if the line side is ener- three 3/8-inch (9.5 mm) shank locks to Types 1 and 3R enclosures through 200 A.

36 gized without removing the shield. lock switch in the OFF position.

Not provided on general-duty switches.

37

38

39

40

41

Built-in Fuse Pullers (NEMA 12 and Bolt-On Hub Kits

4X 30–200 A Only) Additional Locking Capability

42 For switches in a NEMA Type 3R, 12,

Provide easy removal of fuses. Cabinet door can be further padlocked 4 or 4X enclosure.

at the top and bottom as applicable.

43

Note: Size of hasp in inches (mm):

30–100 A—0.344 (8.7) 0.250 shank

200–1200 A—0.50 (12.7) 0.375 shank

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-19

February 2017 Safety Switches

Sheet 28 019

General Description—Accessories, Hubs, Lug Data

Accessories, Hubs, Lug Data 22

23

24

DH030NK DS16CP DS200EK1 DS200GK DS22JK 25

26

27

28

DS36CL DS56CK DS30FP DS12FK DS426TK

Table 28.0-12. Safety Switches—Accessories 29

Description Catalog Description Catalog

Number Number

30

Neutral Kits/Ground Kits Fuse Puller Kits

30 A DG DG030NB 30 A DH e DS30FP

60–100 A DG

200 A DG, DH (NEMA 1, 3R enclosures)

DG100NB

DG200NK

60 A DH

100 A DH e

DS60FP

DS100FP

31

30–60 A DH DH030NK 200 A DH e DS200FP

100 A DH DH100NK “J” Fuse Adapter Kits gh

200 A DH (NEMA 4X, 12 enclosures)

400 A DG, DH

DH200NK

DS400NK

60 A 240 V DH e DS22JK 32

60 A DT and receptacle switches e DS26JK

600 A DG, DH DS600NK 400 A 600 V DT i DT400JK

400–600 A Fusible DT, 800–1200 A DH DS800NK 600 A 240–600 V DH only f

30–100 A DT DT100NK

DS600JK

33

200 A DT DT200NK “R” Fuse Adapter Kits e

400 A Non-fusible DT DT400NK 30 A DG DG030RB

600 A Non-fusible DT DT600NK 100 A DG DG100RB

800 A DT DT800NK 30 A 240 V DH, DT DS12FK 34

1200 A DT DT1200NK 30 A 600 V DH, DT, 60 A 240 V DH, DT, 60 A DG DS16FK

60 A 600 V DH, DT DS26FK

Ground Lug Kits a 100 A 240–600 V DH, DT DS36FK

30–100 A DG DG030GB 200 A 240–600 V DH, DT, 200 A DG DS46FK 35

30–100 A DH, DT b DS100GK 400 A 240–600 V DH, 240 V DT, 400 A DG DS56FK

200 A DG, DH, DT DS200GK 600 A 240–600 V DH, 600 A DG DS66FK

400–600 A DG, 400–1200 A DH, 400–1200 A DT DS468GK

Switching Neutral Bonding Kits c

“T” Fuse Adapter Kits 36

200 A 240 V DH e DS426TK

30–100 A DT, three-pole, four-pole, non-fusible DT100BK 200 A 600 V DH e DS466TK

200 A DT, three-pole, four-pole, non-fusible DT200BK 400 A 240 V DG, DH f DS526TK

400 A DT, three-pole, four-pole, non-fusible

600 A DT, three-pole, four-pole, non-fusible

DT400BK

DT600BK

400 A 600 V DH f DS566TK 37

600 A 240 V DG, DH f DS626TK

800 A DT, three-pole, four-pole, non-fusible DT800BK 600 A 600 V DH f DS666TK

600 A 240 V f

Control Pole Kit

400–600 A DG, 30–1200 A DH, 30–800 A DT DS16CP 600 A 600 V f

DT626TK

DT666TK

38

800 A 240 V DH, DT f DS726TK

Auxiliary Contact Kits

800 A 600 V DH, DT f DS766TK

All switches (except 30–100 A DG) 1NO/1NC DS200EK1 d

All switches (except 30–100 A DG) 2NO/2NC DS200EK2 d

1200 A 240 V DH DT j

1200 A 600 V DH DT j

—

—

39

NEMA 7/9 switches (30–100 A) 1NO/1NC 178C265G05

NEMA 7/9 switches (30–100 A) 2NO/2NC 178C265G06 Hookstick handle DH800HSH

Copper Lug Kits Lubricating grease for safety switch blades and contacts DSLUBEKIT 40

30 A DH, DT e DS16CL (Each kit contains three 30 cc tubes of lubricating grease.)

60 A DH, DT e DS26CL d For duty ratings, see table on Page 28.0-20.

100 A DH, DT e DS36CL

200 A DH e DS46CL

e Order one kit for three poles. 41

f

400 A DH (NEMA 4, 4X, 12 enclosures) f DS56CL Order one kit for each pole.

600–800 A DH (NEMA 4, 4X, 12 enclosures) f DS66CL g 30 A Class J available as factory option only.

Crimp Lug Pad Kit (NEMA 4, 4X, 12 Enclosures) h If no kit is listed, the switch will accept Class J fusing by repositioning 42

400–600 A DH e DS56CK either the fuse base or fuse clips. No drilling required.

800 A DH f DS76CK i Order one kit for six poles.

400–800 A neutral DH c DS800CNK j

a Provides additional ground lug capacity when compared to ground lugs that

No kit needed, simply move fuse bases forward.

Note: Accessories are not applicable to NEMA 7/9 switches unless

43

are provided as standard on all safety switches. indicated otherwise.

b Ground bar kit is not listed on device publications.

c Order one kit per switch.

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-20 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 020

General Description—Accessories, Hubs, Lug Data

22 Auxiliary Contact Rating Table 28.0-16. Myers Type Hubs

NEMA Type 3R (400 A and Above)

Table 28.0-13. AC Pilot Duty Ratings NEMA Types 4, 4X (Stainless Steel), 12

Description Volts Break Make Catalog Conduit Size Catalog

23 (Amperes) (Amperes) Number

Inches mm Number

1NO-1NC 110 15.0 40.0 DS200EK1

1/2 12.7 DS050MH

24 1NO-1NC 220 10.0 20.0 DS200EK1 3/4 19.1 DS075MH

1NO-1NC 440 6.0 10.0 DS200EK1 1 25.4 DS100MH

1NO-1NC 600 5.0 8.0 DS200EK1 1-1/4 31.8 DS125MH

25 2NO/2NC 110 3.0 30.0 DS200EK2

1-1/2

2

38.1

50.8

DS150MH

DS200MH

2NO/2NC 220 1.5 15.0 DS200EK2

2-1/2 63.5 DS250MH

2NO/2NC 440 1.0 8.0 DS200EK2

26 2NO/2NC 600 0.8 6.0 DS200EK2

3

3-1/2

76.2

88.9

DS300MH

DS350MH

4 101.6 DS400MH

Table 28.0-14. DC Pilot Duty Ratings 5 127.0 DS500MH

27

Single Throw Double Throw Catalog

Description Volts (Amperes) (Amperes) Number

Note: Contact the Flex Center at 1-888-329-9272 for information on

hubs for non-metallic NEMA 4X switches.

28 1NO-1NC 115 2.0 0.5 DS200EK1

1NO-1NC 230 0.5 0.2 DS200EK1

Table 28.0-17. Standard Lug Capacities

Ampere Minimum Maximum Wire

29 1NO-1NC 600 0.1 0.02 DS200EK1

Rating Wire Size Wire Size Type

2NO/2NC 115 1.0 0.2 DS200EK2

2NO/2NC 230 0.3 0.1 DS200EK2 30 A DP #14 #10 Cu OR

30 2NO/2NC 600 0.1 — DS200EK2 30 A DG

#12

#14

#10

#6

Al

Cu/Al

30 A DH, DT #14 #2 Cu/Al

31 Hubs 60 A DG

60 A DH, DT

#14

#14

#1/0

#2

Cu/Al

Cu/Al

100 A DG a #14 #1/0 Cu/Al

100 A DH, DT #14 #1/0 Cu/Al

32 200 A DG, DT #6 250 kcmil Cu/Al

200 A DH Type 1 and 3R #6 250 kcmil Cu/Al

200 A DH Type 4 and 12 #6 300 kcmil Cu/Al

33 400 A DG, DH, DT (2) #1/0 (2) 300 kcmil Cu/Al OR b

(1) #1/0 (1) 750 kcmil Cu/Al

600 A DG (1) #2 (1) 600 kcmil Cu/Al AND c

34 600 A DH (1) #1/0 (1) 750 kcmil Cu/Al

600 A DT (Non-fusible) (2) #250 (2) 500 kcmil Cu/Al

35 DS075H1

800 A DH

800 A DT, 600 A Fusible DT

(4) #1/0

(3) #250

(4) 750 kcmil

(3) 500 kcmil

Cu/Al

Cu/Al

Table 28.0-15. Plate Type Hubs 1200 A DH, DT (4) #1/0 (4) 750 kcmil Cu/Al

36 for NEMA Type 3R Enclosures (Up to 200 A) Copper-Bodied Lugs

Group 1 Group 2 30 A Cu #14 #6 Cu

General-Duty, Heavy-Duty, General-Duty, Heavy-Duty, 60 A Cu #14 #4 Cu

37 Double-Throw Through 100 A Double-Throw—200 A 100 A Cu #6 #1/0 Cu

Conduit Size Catalog Conduit Size Catalog 200 A Cu #6 250 kcmil Cu

Number Number 400 A Cu #1/0 500 kcmil Cu

Inches mm Inches mm

38 600–800 A Cu (2) #1/0 (2) 500 kcmil Cu

3/4 19.1 DS075H1 2 50.8 DS200H2 a The maximum size aluminum or copper-clad aluminum wire allowable for

1 25.4 DS100H1 2-1/2 63.5 DS250H2 applications where the conductor enters or leaves the enclosure through the

39 1-1/4

1-1/2

31.8

38.1

DS125H1

DS150H1

3

—

76.2

—

DS300H2

— b

wall opposite its terminal is #1 gauge.

Single-barrel lug accepts one OR two cables per phase as detailed above.

2 50.8 DS200H1 — — — c Double-barrel lug accepts two cables per phase as detailed above.

Note: Although certain lug capacities are larger than required, only

40 Note: Catalog Number DS900AK Adapter Kit—Permits Installation of minimum wire bending space is provided per the requirements

Group 1 Hubs on 200 A Type General-Duty, Heavy-Duty and Double- noted in NEC Tables 373.6 (a) and (b) for respective ampere ratings.

Throw Switches.

41

42

43

For more information, visit: www.eaton.com/consultants CA08104001E

Switching Devices —Low Voltage 28.0-21

February 2017 Safety Switches

Sheet 28 021

General Description—Lug Data, Connection Plugs

Table 28.0-18. Available Lug Capacities of the Double-Throw Switch Assembly with Cam-Lok or Posi-Lok Receptacles

Double Throw Switch Service Load Switched Neutral Solid Neutral Ground Receptacle 22

Size—Cam-Lok or Terminal Terminal Pole Load Terminal Terminal Terminal Bypass

Posi-Lok Receptacles Openings Openings Openings Openings Openings Terminal

100 (1) 1/0–14 (1) 1/0–14 (1) 1/0–14 (2) 1/0–14 AWG, (3) 2–14 (1) 10–32

23

AWG Cu/Al AWG Cu/Al AWG Cu/Al (1) 2–14 AWG Cu/Al AWG Cu/Al Screw mounting

200 (1) 300 kcmil–

6 AWG Cu/Al

(1) 250 kcmil–

6 AWG Cu/Al

(1) 250 kcmil–

6 AWG Cu/Al

(2) 250 kcmil–6 AWG,

(1) 1/0–14 AWG,

(3) 2–14

AWG Cu/Al

(2) 1/4 Studs,

1.75-inch spacing

24

(1) 2–14 AWG Cu/Al

400 (1) 750 kcmil–1/0 or (1) 750 kcmil–1/0 or (1) 750 kcmil–1/0 or (6) 500 kcmil, (4) 250 kcmil– (2) 1/2-13 UNC studs,

(2) 300 kcmil–1/0 (2) 300 kcmil–1/0 (2) 300 kcmil–1/0 (6) 250 kcmil– 6 AWG Cu/Al 1.75-inch spacing 25

Cu/Al Cu/Al Cu/Al 6 AWG Cu/Al

600 (4) 750 kcmil– (4) 750 kcmil– (4) 750 kcmil– (6) 500–250 kcmil, (4) 250 kcmil– (2) 1/2-13 UNC studs,

3/0 Cu/Al 3/0 Cu/Al 3/0 Cu/Al (4) 250 kcmil– 6 AWG Cu/Al 1.75-inch spacing 26

6 AWG Cu/Al

800 (4) 750 kcmil– (4) 750 kcmil– (4) 750 kcmil– (6) 500–250 kcmil, (4) 250 kcmil– (2) 1/2-13 UNC studs,

3/0 Cu/Al 3/0 Cu/Al 3/0 Cu/Al (4) 250 kcmil– 6 AWG Cu/Al 1.75-inch spacing 27

6 AWG Cu/Al

Table 28.0-19. Quick-Connect Double-Throw Standard Receptacles and Corresponding Connection Plugs (Part Numbers are Crouse-Hinds) 28

Switch Connector Cam-Lok Connectors Posi-Lok Connectors

Ampacity Color Receptacle a Plug b Receptacle Panel Plug c

240 Vac

29

100, 200 Ground (green) E1016-1635S E-Z1016-8366 Two-pole, three-wire with solid neutral or three-pole, three-wire with E0200-281

Neutral (white)

A Phase (black)

E1016-1636S

E1016-1600S

E-Z1016-8367

E-Z1016-8387

switched neutral pole (two-phase and one neutral pole): E0200-1672/

three-pole, three-wire (no neutral): E0200-1661-NN/ three-pole, four-wire

E0200-282

E0200-283

30

B Phase (red) E1016-1602S E-Z1016-8389 with solid neutral or four-pole, four-wire with solid neutral or four-pole, E0200-284

C Phase (blue) E1016-1612S E-Z1016-8393 four-wire with switched neutral pole (three-phase and one neutral pole): E0200-285

E0200-1662 31

400 Ground (green) E1016-1635S E-Z1016-8366 Two-pole, three-wire with solid neutral or three-pole, three-wire with E0400-281

Neutral (white) E1016-1636S E-Z1016-8367 switched neutral pole (two-phase and one neutral pole): E0400-1672/ E0400-282

A Phase (black)

B Phase (red)

E1016-1600S

E1016-1602S

E-Z1016-8387

E-Z1016-8389

three-pole, three-wire (no neutral): E0400-1661-NN/ three-pole, four-wire

with solid neutral or four-pole, four-wire with solid neutral or four-pole,

E0400-283

E0400-284

32

C Phase (blue) E1016-1612S E-Z1016-8393 four-wire with switched neutral pole (three-phase and one neutral pole): E0400-285

E0400-1662

600, 800 Ground (green) (2) E1016-1635S (2) E-Z1016-8366 Two-pole, three-wire with solid neutral or three-pole, three-wire with (2) E0400-281

33

Neutral (white) (2) E1016-1636S (2) E-Z1016-8367 switched neutral pole (two-phase and one neutral pole): (2) E0400-1672/ (2) E0400-282

A Phase (black) (2) E1016-1600S (2) E-Z1016-8387 three-pole, three-wire (no neutral): (2) E0400-1661-NN/ three-pole, (2) E0400-283

B Phase (red) (2) E1016-1602S (2) E-Z1016-8389 four-wire with solid neutral or four-pole, four-wire with solid neutral (2) E0400-284 34

C Phase (blue) (2) E1016-1612S (2) E-Z1016-8393 or four-pole, four-wire with switched neutral pole (three-phase and one (2) E0400-285

neutral pole): (2) E0400-1662

600 Vac d 35

100, 200 Ground (green) E1016-1635S E-Z1016-8366 Three-pole, three-wire (no neutral): E0200-1891-NN/ three-pole, four-wire E0200-281

Neutral (white) E1016-1636S E-Z1016-8367 with solid neutral or four-pole, four-wire with solid neutral or four-pole, E0200-282

A Phase (brown) E1016-1619S E-Z1016-8394 four-wire with switched neutral pole (three-phase and one neutral pole): E0200-288 36

B Phase (orange) E1016-1603S E-Z1016-8390 E0200-1891 E0200-289

C Phase (yellow) E1016-1601S E-Z1016-8388 E0200-286

400 Ground (green)

Neutral (white)

E1016-1635S

E1016-1636S

E-Z1016-8366

E-Z1016-8367

Three-pole, three-wire (no neutral): E0400-1862-NN/ three-pole, four-wire

with solid neutral or four-pole, four-wire with solid neutral or four-pole,

E0400-281

E0400-282

37

A Phase (brown) E1016-1619S E-Z1016-8394 four-wire with switched neutral pole (three-phase and one neutral pole): E0400-299

B Phase (orange) E1016-1603S E-Z1016-8390 E0400-1703 E0400-295

C Phase (yellow E1016-1601S E-Z1016-8388 E0400-292 38

600, 800 Ground (green) (2) E1016-1635S (2) E-Z1016-8366 Three-pole, three-wire (no neutral): (2) E0400-1862-NN/ three-pole, (2) E0400-281

Neutral (white) (2) E1016-1636S (2) E-Z1016-8367 four-wire with solid neutral or four-pole, four-wire with solid neutral (2) E0400-282

A Phase (brown) (2) E1016-1619S (2) E-Z1016-8394 or four-pole, four-wire with switched neutral pole (three-phase and one (2) E0400-299 39

B Phase (orange) (2) E1016-1603S (2) E-Z1016-8390 neutral pole): (2) E0400-1703 (2) E0400-295

C Phase (yellow (2) E1016-1601S (2) E-Z1016-8388 (2) E0400-292

a For non-standard receptacle options, please contact the Flex Center at 888-329-9272. 40

b E/E-Z 1016 type plugs listed in above table accept 2/0–4/0 size cable.

c E0200 type plugs listed in above table accept #2–2/0 size cable. E0400 type plugs listed accept 3/0–4/0 size cable.

d For Canadian switches, 600 Vac products have the same color configurations as the 240 Vac versions (green, white, black, red, blue). 41

42

43

CA08104001E For more information, visit: www.eaton.com/consultants

28.0-22 Switching Devices —Low Voltage

Safety Switches February 2017

Sheet 28 022

General Description—Lug Data, Connection Plugs

Table 28.0-20. Company Switch Available Lug Capacities of the Single-Throw Switch Assembly with Cam-Lok™ or Posi-Lok™ Receptacles

22 Switch Service Terminal Load Terminal Switched Neutral Solid Neutral Ground Terminal Receptacle

Ampacity Openings Cu/AI Openings Cu/AI Pole Load Terminal Terminal Openings Openings Cu/AI Bypass Terminal

Openings Cu/AI

23 100 (1) 1/0–14 AWG (1) 1/0–14 AWG (1) 1/0–14 AWG (2) 14 AWG–1/0 (1) 2–14 AWG (1) 1/0–14 AWG

and (2) 6–14 AWG

24 200 (1) 300 kcmil–6 AWG (1) 300 kcmil–6 AWG (1) 300 kcmil–6 AWG (2) 6 AWG–300 kcmil

and (2) 6–14 AWG

(2) 2–14 AWG (1) 300 kcmil–6 AWG

400 (1) 750 kcmil–1/0 or (1) 750 kcmil–1/0 or (1) 750 kcmil–1/0 or (2x) (2) 1/0–300 kcmil (2) 250 kcmil–6 AWG Crimp lug