Professional Documents

Culture Documents

Heavy-Duty Diesel Engine Test Category For API CI-4 and CI-4 PLUS

Uploaded by

sreehari0 ratings0% found this document useful (0 votes)

27 views1 pageAPI CI-4 Specs

Original Title

API CI-4 2010 (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAPI CI-4 Specs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views1 pageHeavy-Duty Diesel Engine Test Category For API CI-4 and CI-4 PLUS

Uploaded by

sreehariAPI CI-4 Specs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Heavy-Duty Diesel Engine Test Category For API CI-4 and CI-4 PLUS

Requirements Test Properties Unit Limits

Method 1 Test 2 Tests 3 Test

1. LABORATORY TESTS FOR API CI-4 AND CI-4 PLUS

1.1 Viscosity Grades SAE J300 Manufacturer specifies viscosity target

within SAE J300 specification

1.2 High Temperature ASTM D6594 Copper increase, max ppm 20 No MTAC(1),(2)

Corrosion Bench Test Lead increase, max ppm 120

Copper strip rating, max (D130) 3

1.3 Foam Test ASTM D892 Foaming/Settling, max No MTAC(1),(2)

(Option A not allowed) Sequence I mL 10/0

Sequence II mL 20/0

Sequence III mL 10/0

1.4 Shear Stability ASTM D6278 After shear viscosity, SAE 10W-30, min cSt 9.3 No MTAC(1),(2),(3)

After shear viscosity, SAE 15W-40, min cSt 12.5

1.5 Volatility ASTM D5800 Evaporative loss at 250oC, max % 15 No MTAC(1),(2)

(Noack)

1.6 High Temperature/ As allowed in Viscosity, min mPa-s 3.5 No MTAC(1),(2)

High Shear SAE J300

1.7 Low Temperature ASTM D4684 Viscosity of 75h used oil sample mPa-s 25000 No MTAC(1),(2)

Pumpability (MRV TP-1) from T-10 Test at -20oC, max

Modified D4684 Viscosity at -20oC, max mPa-s 25000

(if yield stress) Yield stress, max Pa 35

1.8 Elastomer Limits

Compatibility Volume Change Hardness Tensile Strength Elongation

Nitrile +5/-3 +7/-5 +10/-TMC1006 +10/-TMC1006

Silicone +TMC1006/-3 +5/-TMC1006 +10/-45 +20/-30

Polyacrylate +5/-3 +8/-5 +18/-15 +10/-35

FKM +5/-2 +7/-5 +10/-TMC1006 +10/-TMC1006

2. ENGINE TESTS FOR API CI-4

2.1 Mack T-8E ASTM D5967 Relative viscosity at 4.8% soot, max 1.8 1.9 2.0

(Ext. T8-E) (RV=Visc. at 4.8% soot/Visc.

of new oil sheared in D6278)

2.2 Mack T-10 T10 test with EGR Merit Rating, min 1000 1000 1000

2.3 Cummins M11-EGR ASTM D6975 Crosshead weight loss, max mg 20.0 21.8 22.6

Top ring weight loss, max mg 175 186 191

Filter delta pressure at 250h, max kPa 275 320 341

Sludge rating, min merits 7.8 7.6 7.5

2.4 Caterpillar 1R ASTM D6923 WDR, max demerits 382 396 402

TGC, max demerits 52 57 59

TLC, max demerits 31 35 36

Initial Oil Consumption, max g/h 13.1 13.1 13.1

Final Oil Consumption, max g/h IOC+1.8 IOC+1.8 10C+1.8

Piston ring and liner scuffing None None None

Ring Sticking None None None

2.5 Caterpillar 1K ASTM D6750 WDK, max demerits 332 347 353

TGF, max % 24 27 29

TLHC, max % 4 5 5

or Oil Consumption (0-252h), max g/kW-h 0.5 0.5 0.5

Piston ring and liner scuffing None None None

Caterpillar 1N ASTM D6750 WDN, max demerits 286.2 311.7 323.0

TGF, max % 20 23 25

TLHC, max % 3 4 5

Oil Consumption (0-252h), max g/kW-h 0.5 0.5 0.5

Piston ring and liner scuffing None None None

Ring Sticking None None None

2.6 Roller Follower Wear Test ASTM D5966 Average Pin Wear, max µm 7.6 8.4 9.1

(mils) (0.30) (0.33) (0.36)

2.7 Engine Oil Aeration Test ASTM D6984 Aeration, max Vol % 8.0 MTAC applies(2)

2.8 Sequence IIIF ASTM D6984 Viscosity increase at 80h, max % 275 MTAC applies(2)

3. ENGINE TESTS FOR API CI-4 PLUS (same as API CI-4 Engine Tests above in addition to following)

3.1 Mack T-11 T-11 Soot/ Minimum TGA Soot Content at 12.0 cSt % 6.00 5.89 5.85

Viscosity Control increase at 100o C

(1)

Not an ACC Test.

(2)

MTAC is a statistical method for treating engine test results. Consult your sales representative for further information.

(3)

Limit of 30 pass for API CI-4, 90 pass for API CI-4 PLUS.

You might also like

- API Engine Oil Classifications Infineum 2017Document12 pagesAPI Engine Oil Classifications Infineum 2017iosalcido100% (1)

- Infineum - API Engine Oil Classifications PDFDocument12 pagesInfineum - API Engine Oil Classifications PDFAnca DanNo ratings yet

- API Engine Oil Classifications 2010Document6 pagesAPI Engine Oil Classifications 2010amsoilromaniaNo ratings yet

- KN-10069-CP-101-EL-MT-00009 OilDocument3 pagesKN-10069-CP-101-EL-MT-00009 Oilahffg nnffNo ratings yet

- TDS Nycogrease GN3058 1E10Document1 pageTDS Nycogrease GN3058 1E10Sameen Khan100% (1)

- AaaaDocument141 pagesAaaaDương Nguyễn TùngNo ratings yet

- TDS Turbonycoil TN160 1E9Document2 pagesTDS Turbonycoil TN160 1E9HimalayaNo ratings yet

- Standard STD 417-0002: Engine Oil 97487Document7 pagesStandard STD 417-0002: Engine Oil 97487hansiiiNo ratings yet

- Shell GT32 1451468381Document2 pagesShell GT32 1451468381Pramod SokhariyaNo ratings yet

- TGF - (M) 32 Extreme Pressure Gas Turbine OilDocument3 pagesTGF - (M) 32 Extreme Pressure Gas Turbine OilQuy NguyenNo ratings yet

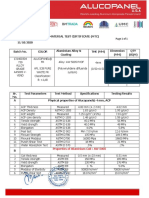

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- Castrol Magna 150 Ep - TDSDocument2 pagesCastrol Magna 150 Ep - TDSHector Martin BarajasNo ratings yet

- 001 - Shell Turbo Oil CC 32Document2 pages001 - Shell Turbo Oil CC 32Irvan NandaNo ratings yet

- TTN3512 3e2aDocument1 pageTTN3512 3e2aMarcos RojasNo ratings yet

- Shell Turbo T 68Document2 pagesShell Turbo T 68Eid EeidNo ratings yet

- TDS Nycolube NL3525-9E2 PDFDocument1 pageTDS Nycolube NL3525-9E2 PDFRoman GrantNo ratings yet

- Cement Mill Test - Fairborn Cement Company Type-IA - Jan2022Document2 pagesCement Mill Test - Fairborn Cement Company Type-IA - Jan2022mohamed ElsayedNo ratings yet

- UAE Shell Turbo Oil T 46Document3 pagesUAE Shell Turbo Oil T 46diego lizaldes valarezoNo ratings yet

- Type 1 BricksDocument20 pagesType 1 Bricksprachi410No ratings yet

- Granit Maximum 15w40 EngDocument1 pageGranit Maximum 15w40 EngTAREK HAMADNo ratings yet

- Shell Turbo Oil T 68Document2 pagesShell Turbo Oil T 68Muhammad SaputraNo ratings yet

- MDS SHELL Turbo Oil T68Document2 pagesMDS SHELL Turbo Oil T68Antonio CardosoNo ratings yet

- 7.OWC CLASS G HSR AKCC TDS v2Document2 pages7.OWC CLASS G HSR AKCC TDS v2jami yosryNo ratings yet

- Toparts Pte LTD: Laboratory ReportDocument1 pageToparts Pte LTD: Laboratory ReportkmulyadiNo ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- Kaiser Aluminum 7075 Rod and BarDocument2 pagesKaiser Aluminum 7075 Rod and BarH VNo ratings yet

- Malaca Sas: ManufactureDocument25 pagesMalaca Sas: Manufacturesamuel rondon upeguiNo ratings yet

- DTE 20 UltraDocument16 pagesDTE 20 UltraSly LumbaNo ratings yet

- Shell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsDocument4 pagesShell Turbo Oil T46: Performance, Features & Benefits Main Applicationshaider100% (1)

- Technical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Document1 pageTechnical Data Sheet Polyfoam Normal: Extruded Polystyrene Insulation (Non Fire R Etardant)Raha Trading and ContactingNo ratings yet

- Specification of High Speed DieselDocument1 pageSpecification of High Speed DieselCHARAN AjmeeraNo ratings yet

- 002DP48 PDFDocument2 pages002DP48 PDFDiadam SharmaNo ratings yet

- TGSB (M) Turbine OilDocument3 pagesTGSB (M) Turbine OilQuy NguyenNo ratings yet

- Shell Turbo Oil J 32Document2 pagesShell Turbo Oil J 32Muhammad SaputraNo ratings yet

- Hand Book On Road PDFDocument56 pagesHand Book On Road PDFrajan sharma100% (1)

- Russia OilgasDocument6 pagesRussia OilgasAlexanderNo ratings yet

- Low Viscosity Petroleum Lubricating OilDocument1 pageLow Viscosity Petroleum Lubricating OilSyed Wajih Ul HassanNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- Shell Turbo T 32 PDFDocument2 pagesShell Turbo T 32 PDFaqas_khanNo ratings yet

- ACFoam II DataSheetDocument1 pageACFoam II DataSheetChristopher Woodbridge GomezNo ratings yet

- EMC EM827 PCB ManufacturerDocument6 pagesEMC EM827 PCB ManufacturerHenry zhangNo ratings yet

- Optigear 1100 RangeDocument3 pagesOptigear 1100 RangeResistenciaDisidenteNo ratings yet

- Kyodo Yushi Multemp SRLDocument1 pageKyodo Yushi Multemp SRLtxto2881No ratings yet

- T800S Technical Data Sheet 1 PDFDocument2 pagesT800S Technical Data Sheet 1 PDFAmal AvNo ratings yet

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentDocument2 pagesJordan Petroleum Refinery Co. Ltd. Diesel Specification QS-PL 112 Laboratories & Quality Control DepartmentMohammed Nuseir100% (1)

- Shell Turbo Oil T32: Performance, Features & BenefitsDocument2 pagesShell Turbo Oil T32: Performance, Features & BenefitsHANIF AKBARNo ratings yet

- Vistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore ADocument2 pagesVistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore AShalom JohnNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Shell Turbo Oil J 32Document2 pagesShell Turbo Oil J 32Agus F RahmanNo ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- STC White Paper Zta Zirconia Toughened Alumina 01062021Document4 pagesSTC White Paper Zta Zirconia Toughened Alumina 01062021王柏昆No ratings yet

- Foodmax Grease CAS S 2 LS - TDS - 263701301 - ENDocument2 pagesFoodmax Grease CAS S 2 LS - TDS - 263701301 - ENDeath Heart100% (1)

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDocument2 pagesGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitNo ratings yet

- L-TSE Turbine OilDocument3 pagesL-TSE Turbine OilYoong TanNo ratings yet

- Aludecor Al 45 Firewall En13501-1 Class A2 Technical SpecificationDocument2 pagesAludecor Al 45 Firewall En13501-1 Class A2 Technical Specificationsoham senNo ratings yet

- Tidal Power Super Uhpd 10w-40Document1 pageTidal Power Super Uhpd 10w-40陳技安No ratings yet

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Machine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignDocument26 pagesMachine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignDull PersonNo ratings yet

- Exp - P7 - UPCTDocument11 pagesExp - P7 - UPCTSiddesh PatilNo ratings yet

- Curriculum Improvement v2Document47 pagesCurriculum Improvement v2Nica Lagrimas100% (1)

- Xii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Document13 pagesXii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Stephen SatwikNo ratings yet

- Slipform Construction TechniqueDocument6 pagesSlipform Construction TechniqueDivyansh NandwaniNo ratings yet

- Form No. 1 Gangtok Municipal Corporation Deorali, SikkimDocument2 pagesForm No. 1 Gangtok Municipal Corporation Deorali, SikkimMUSKAANNo ratings yet

- FS-C8025MFP Release NotesDocument22 pagesFS-C8025MFP Release NotesFirmware SM-SHNo ratings yet

- Creative LibrarianDocument13 pagesCreative LibrarianulorNo ratings yet

- A12 CanSat Technlology Forclimate Monitoring PDFDocument10 pagesA12 CanSat Technlology Forclimate Monitoring PDFDany PABON VILLAMIZARNo ratings yet

- IVISOR Mentor IVISOR Mentor QVGADocument2 pagesIVISOR Mentor IVISOR Mentor QVGAwoulkanNo ratings yet

- Riveted JointsDocument28 pagesRiveted Jointsgnbabuiitg0% (1)

- Research Paper On N Queen ProblemDocument7 pagesResearch Paper On N Queen Problemxvrdskrif100% (1)

- Report Painter GR55Document17 pagesReport Painter GR55Islam EldeebNo ratings yet

- Chen 2021Document13 pagesChen 2021Aitor UzkudunNo ratings yet

- Grimm (2015) WisdomDocument17 pagesGrimm (2015) WisdomBruce WayneNo ratings yet

- Jazz PrepaidDocument4 pagesJazz PrepaidHoney BunnyNo ratings yet

- Graduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Document25 pagesGraduate Macro Theory II: The Real Business Cycle Model: Eric Sims University of Notre Dame Spring 2017Joab Dan Valdivia CoriaNo ratings yet

- Electronics 12 00811Document11 pagesElectronics 12 00811Amber MishraNo ratings yet

- Manual - Rapid Literacy AssessmentDocument16 pagesManual - Rapid Literacy AssessmentBaldeo PreciousNo ratings yet

- Dimmable Bulbs SamplesDocument11 pagesDimmable Bulbs SamplesBOSS BalaNo ratings yet

- Column Buckling TestDocument8 pagesColumn Buckling TestWiy GuomNo ratings yet

- Handbook+for+Participants+ +GCC+TeenDocument59 pagesHandbook+for+Participants+ +GCC+Teenchloe.2021164No ratings yet

- Tourism PlanningDocument36 pagesTourism PlanningAvegael Tonido Rotugal100% (1)

- 【SIEMENS】Cios Spin-FlyerDocument8 pages【SIEMENS】Cios Spin-FlyerAshleyNo ratings yet

- Power - Factor - Correction - LegrandDocument24 pagesPower - Factor - Correction - LegrandrehanNo ratings yet

- DAB Submersible PumpsDocument24 pagesDAB Submersible PumpsMohamed MamdouhNo ratings yet

- Placa 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Document39 pagesPlaca 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Sergio GalliNo ratings yet

- Gauss' Law: F A FADocument14 pagesGauss' Law: F A FAValentina DuarteNo ratings yet

- VPZ M BrochureDocument2 pagesVPZ M BrochuresundyaNo ratings yet

- Power Quality Lab Manual (EE-801)Document12 pagesPower Quality Lab Manual (EE-801)ASHU KNo ratings yet