Professional Documents

Culture Documents

Heating Mixers and Mixer Motors

Uploaded by

Dejan MitrovićCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heating Mixers and Mixer Motors

Uploaded by

Dejan MitrovićCopyright:

Available Formats

VIESMANN Heating mixers and mixer motors

Datasheet

Part numbers and prices: see pricelist

Heating mixers

Heating mixer-4, DN 20 to DN 50, and R ¾" to R 1¼"

Special heating mixer-4, R ½" to R 1"

Heating mixer-3, DN 20 to DN 100

Special heating mixer-3, R ½" to R 1"

Mixer motors

For fitting to a heating mixer

5822 077–6 GB 4/2008

Product description

Heating mixer-4 – dual mixing for boilers and heating circuits

Heating mixer-4 – weld fitting

Int. dia. a

DN mm

20 150

25 150

32 170

40 180

50 210

& With four connections;

mixes in the heating flow and boiler return directions

& In conjunction with heating circuits, connect directly to the

return line

& Permiss. operating pressure: 6 bar (PN 6)

& Permissible flow temperature: 120 °C

& To DIN 3336

& Shaft and separators made from stainless steel, internal compo-

nents made from copper alloy

& Direct welding

& Replacement of the shaft seals (O-ring) without draining the

heating system

& For sizing, see diagram on page 4.

Heating mixer-4 – threaded fitting

Connection a

R mm

¾" 190

1" 190

1¼" 214

& With four connections;

mixes in the heating flow and boiler return directions

& In conjunction with heating circuits, connect directly to the

return line

& Permiss. operating pressure: 6 bar (PN 6)

& Permissible flow temperature: 120 °C

& To DIN 3336

& Shaft and separators made from stainless steel, internal compo-

nents made from copper alloy

& with threaded fitting (R ¾" to 1¼")

& Replacement of the shaft seals (O-ring) without draining the

heating system

& For sizing, see diagram on page 4.

5822 077–6 GB

2 VIESMANN Heating mixers and mixer motors

Heating mixer-4 – dual mixing for boilers and heating circuits (cont.)

Special heating mixer-4 – also for underfloor heating systems

Mixer with soldered internal components

Connection Internal Ø a

R mm mm

½" 15 152

½" 18 148

¾" 22 162

1" 28 191

& Permiss. operating pressure: 6 bar (PN 6)

& Permissible flow temperature: 120 °C

& To DIN 3336

& Low leakage rate and corrosion-resistant when using perme-

able plastic pipes (to DIN 4726) in conjunction with system

separation

& Housing and rotary damper made from brass, cast shaft made

from stainless steel

Mixer with compression fitting inserts & Low leakage rate through close fit

Connection a & Replacement of the shaft seals (O-ring) without draining the

R mm heating system

& Compression or solder fitting inserts

½" 168

& For sizing, see diagram on page 4.

¾" 187

1" 209 Observe the technical guide "Control of underfloor heating sys-

tems".

Mixer curve

A Boiler flow C Heating flow

B Boiler return D Heating return

5822 077–6 GB

Heating mixers and mixer motors VIESMANN 3

Heating mixer-4 – dual mixing for boilers and heating circuits (cont.)

Calculating the internal diameter and pressure drop

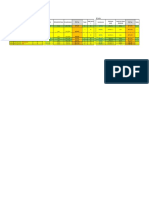

Int. dia. Connection k vs value max. Δp v100

DN R m 3/h

– ½" 3.8 See shaded sizing area in the diagram

20 ¾" 6.9

25 1" 10.5

32 1¼" 18.5

40 – 28.5

50 – 42.0

Heating mixer-3 – one-way mixing for heating circuits

Heating mixer-3 – DN 20 to DN 50

Int. dia. a b

DN mm mm

20 150 123

25 150 123

32 170 142

40 180 154

50 210 177

& For vertical installation

& With 3 connections, mixes only in the heating flow direction

& Heating return optionally on the l.h. or r.h. side

& Permiss. operating pressure: 6 bar (PN 6)

& Permissible flow temperature: 120 °C

& To DIN 3336

& Shaft and separators made from stainless steel, internal compo-

nents made from copper alloy

& Direct welding

& Replacement of the shaft seals (O-ring) without draining the

heating system

& For sizing, see diagram on page 6.

5822 077–6 GB

4 VIESMANN Heating mixers and mixer motors

Heating mixer-3 – one-way mixing for heating circuits (cont.)

Special heating mixer-3 – also for underfloor heating systems – R 1/2" to R 1"

Mixer with soldered internal components

Connection Internal Ø a b

R mm mm mm

½" 15 152 111

½" 18 148 109

¾" 22 162 121

1" 28 191 140

& Permiss. operating pressure: 6 bar (PN 6)

& Permissible flow temperature: 120 °C

& To DIN 3336

& Low leakage rate and corrosion-resistant when using perme-

able plastic pipes (to DIN 4726) in conjunction with system

separation

& Housing and rotary damper made from brass, cast shaft made

from stainless steel

& Low leakage rate through close fit

Mixer with compression fitting inserts & Replacement of the shaft seals (O-ring) without draining the

Connection a b heating system

R mm mm & Compression or solder fitting inserts

& For sizing, see diagram on page 6. Observe the technical guide

½" 168 120

¾" 187 136 "Control of underfloor heating systems".

1" 209 151

Mixer curve

A Boiler flow

B Heating flow

C Heating return

5822 077–6 GB

Heating mixers and mixer motors VIESMANN 5

Heating mixer-3 – one-way mixing for heating circuits (cont.)

Calculating the internal diameter and pressure drop

Int. dia. Connection k vs value max. Δp v100

DN R m 3/h

– ½" 3.8 see shaded sizing area in the diagram

20 ¾" 6.9

25 1" 10.5

32 – 18.5

40 – 28.5

50 – 42.0

Heating mixer-3 – DN 40 and DN 50

Int. dia. a b Weight

DN mm mm kg

40 96 56 6.0

50 103 63 6.5

& With PN 6 flanges

& Permiss. operating pressure: 6 bar (PN 6)

& Permissible flow temperature: 110 °C

& Flange connections to ISO 7005

& Casing: Cast iron GG 20

– Shaft: stainless steel

– Rotary damper: Hot-pressed brass

& Leakage max. 0.1 % of k vs value

& With manual control lever

& Flow and bypass curve: Linear

5822 077–6 GB

6 VIESMANN Heating mixers and mixer motors

Heating mixer-3 – one-way mixing for heating circuits (cont.)

Heating mixer-3 – DN 65 to DN 100

Int. dia. a b c Weight

DN mm mm mm kg

65 200 100 43 9.5

80 230 115 52 14.5

100 260 130 68 18.3

& With PN 6 flanges

& Permiss. operating pressure: 6 bar (PN 6)

& Permissible flow temperature: 110 °C

& Flange connections to ISO 7005

& Casing: Cast iron GG 20

– Shaft: stainless steel

– Rotary damper: Hot-pressed brass

& Leakage max. 0.1 % of k vs value

& Flow and bypass curve: Linear

Calculating the internal diameter and pressure drop for ΔT = 20 K

Pressure drops below 40 mbar should be avoided; in these cases

use the next smallest mixer.

Pressure drop

A = 100 mbar

B = 80 mbar

C = 60 mbar

D = 40 mbar

E = 20 mbar

Int. dia. k vs value max. Δpv100 k vs/k vR Example:

DN m 3/h mbar

40 25 300 > 100 Heating circuit output: 280 kW

50 40 300 > 100 Temperature differential

65 63 300 > 100 (Heating water) ΔT: 20 K

5822 077–6 GB

80 100 300 > 100 Mixer: DN 50

100 160 300 > 100 Pressure drop: ≈ 80 mbar

Heating mixers and mixer motors VIESMANN 7

Heating mixer-3 – one-way mixing for heating circuits (cont.)

For other temperature differentials (ΔTnew), the required internal Heating circuit output: 224 kW

diameter of the mixer and the pressure drop can be determined Mixer: DN 50

via the calculated output(² new) at a constant mass flow rate: Pressure drop: ≈ 60 mbar

Mixer motors

For heating mixer DN 20 to 50 and R ½" to 1¼"

Part no. 7450 657 & Single-phase synchronous motor with gearbox and 2 limit

switches; reversible rotation

& Order plug-in connector gS for mixer motor and plug-in connec-

tor sÖ for heating circuit pump separately (see control unit

accessories).

Rated voltage: 230 V~

Rated frequency: 50 Hz

Power consumption: 4W

Protection: IP 42 to EN 60529; safeguard

through appropriate design and

installation

Permissible ambient temp.

during operation: 0 to +40 °C

during storage and

transport: -20 to +65 °C

Torque: 3 Nm

Runtime for 90° ∢: 120 s

For heating mixer-3 with flanges DN 40 and 50

Part no. 9522 487 & Single-phase synchronous motor with gearbox and 2 limit

switches; reversible rotation

& With manual adjusting button and switch for automatic or man-

ual operation

& Order plug-in connector gS for mixer motor and plug-in connec-

tor sÖ for heating circuit pump separately (see control unit

accessories).

Rated voltage: 230 V~

Rated frequency: 50 Hz

Power consumption: 3W

Protection: IP 42 to EN 60529; safeguard

through appropriate design and

installation

Permissible ambient temp.

during operation: -15 to +50 °C

during storage and

transport: -30 to +65 °C

Torque: 5 Nm

Runtime for 90° ∢: 135 s

5822 077–6 GB

8 VIESMANN Heating mixers and mixer motors

Mixer motors (cont.)

For heating mixer-3 with flanges DN 65 to 100

Part no. Z004 344 & Single-phase synchronous motor with gearbox and 2 limit

switches; reversible rotation

& With manual adjusting button and switch for automatic or man-

ual operation

& Order plug-in connector gS for mixer motor and plug-in connec-

tor sÖ for heating circuit pump separately (see control unit

accessories).

Rated voltage: 230 V~

Rated frequency: 50 Hz

Power consumption: 4W

Protection: IP 42 to EN 60529; safeguard

through appropriate design and

installation

Permissible ambient temp.

during operation: -15 to +50 °C

during storage and

transport: -30 to +65 °C

Torque: 12 Nm

Runtime for 90° ∢: 125 s

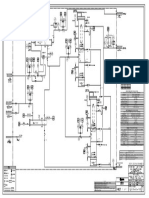

Installation examples

Connections between the boiler and the safety equipment to Capturing the temperature when using plastic pipes

EN 12828 must not be able to be shut off. For plastic pipes the temperature should be captured by the flow

Therefore when installing mixers-4 install special safety flow and temperature sensor, which must be fitted downstream of the heat-

return pipes. ing circuit pump on a metal pipe.

For this, Viessmann boilers offer separate connections.

The heating circuit pumps should be installed in the flow lines of Use of special heating mixers in underfloor heating systems

the heating circuit downstream of the mixer. The pump pressure see the technical guide "Control of underfloor heating systems".

does not affect the mixer for closed mixers, but is reduced in the

system.

Boiler with a heating circuit with mixer-4

C Safety valve

D Spring-loaded check valve

E Heating circuit pump

F Heating circuit

G Mixer-4 with mixer motor or heating circuit control unit

H Drain

K Expansion vessel

A Air vent valve

B Pressure gauge

5822 077–6 GB

Heating mixers and mixer motors VIESMANN 9

Installation examples (cont.)

Boiler with two heating circuits with mixer-4

A Air vent valve H Special heating mixer-4 with mixer motor or heating circuit

B Pressure gauge control unit

C Safety valve K Drain

D Spring-loaded check valve L Expansion vessel

E Heating circuit pump M Underfloor heating circuit

F Heating circuit N Temperature limiter (maximum limit)

G Mixer-4 with mixer motor or heating circuit control unit O Bypass

P Butterfly valve bypass

Heating group control with mixer-3

A Mixer-3 D Heating circuit

B Heating circuit pump E Flow distributor

C Spring-loaded check valve F Return collector

5822 077–6 GB

10 VIESMANN Heating mixers and mixer motors

5822 077–6 GB

Heating mixers and mixer motors VIESMANN 11

Printed on environmentally friendly,

chlorine-free bleached paper

Subject to technical modifications.

5822 077–6 GB

Viessmann Werke GmbH&Co KG Viessmann Limited

D-35107 Allendorf Hortonwood 30, Telford

Telephone: +49 6452 70-0 Shropshire, TF1 7YP, GB

Fax: +49 6452 70-2780 Telephone: +44 1952 675000

www.viessmann.com Fax: +44 1952 675040

E-mail: info-uk@viessmann.com

12 VIESMANN Heating mixers and mixer motors

You might also like

- DCV1 Ti P134 05 enDocument4 pagesDCV1 Ti P134 05 enDavid ChanNo ratings yet

- Boa-S PN6 DN40Document14 pagesBoa-S PN6 DN40melaNo ratings yet

- MP2010 345 Product Brochure S Series RevEDocument2 pagesMP2010 345 Product Brochure S Series RevEJackNo ratings yet

- Boa SDocument4 pagesBoa SdgarciabNo ratings yet

- Date Tehnice Ventil TermostatDocument24 pagesDate Tehnice Ventil Termostatnaname2000No ratings yet

- Streamline Copper Tube Type K Submittal Sheet 1596864Document9 pagesStreamline Copper Tube Type K Submittal Sheet 1596864Miguel RodriguezNo ratings yet

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDocument2 pagesHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNo ratings yet

- E Series: Back Pull Out End ScutionDocument7 pagesE Series: Back Pull Out End ScutionOkello Paul100% (1)

- Ball ValvesDocument26 pagesBall ValvesHải Nguyễn VănNo ratings yet

- NKM-G NKP-G: Standardised Enbloc Centrifugal PumpsDocument36 pagesNKM-G NKP-G: Standardised Enbloc Centrifugal PumpsRoberthNo ratings yet

- Cast Iron Regulating Globe Valves PN 16Document3 pagesCast Iron Regulating Globe Valves PN 16Mohamed RaafatNo ratings yet

- Dcv1 Disc Check Valve: DescriptionDocument2 pagesDcv1 Disc Check Valve: DescriptionInbarasu SNo ratings yet

- Light Oil Burner Quemador de Gasóleo: One Stage Operation Funcionamiento de Una LlamaDocument24 pagesLight Oil Burner Quemador de Gasóleo: One Stage Operation Funcionamiento de Una LlamaAlejandro CanoNo ratings yet

- DK DIN Bite Type Tube FittingDocument62 pagesDK DIN Bite Type Tube FittingLuisFranciscoMarinMedranoNo ratings yet

- 2016 - 03 - 11 - 16 - 24 - Barton 202e 202n 242e J8a Tech DataDocument3 pages2016 - 03 - 11 - 16 - 24 - Barton 202e 202n 242e J8a Tech DataMounica PallaNo ratings yet

- Technical Sheet A3SDocument4 pagesTechnical Sheet A3SMalik DaniyalNo ratings yet

- Tyco Relief ValveDocument6 pagesTyco Relief ValvePablo DonariNo ratings yet

- Reguladora de T (WWW - Vaporisa.cl)Document8 pagesReguladora de T (WWW - Vaporisa.cl)Luis Gutiérrez AlvarezNo ratings yet

- 1315 EKN Hotwater Steelwelded Edition3 enDocument7 pages1315 EKN Hotwater Steelwelded Edition3 enAhmedRamadanNo ratings yet

- Inlet Inlet From Crossover: ASME VIII Div.1 2019 ASME B31.3 ASME B31.1Document1 pageInlet Inlet From Crossover: ASME VIII Div.1 2019 ASME B31.3 ASME B31.1mohdfirdausNo ratings yet

- 1316 EKN Hotwater Edition3Document11 pages1316 EKN Hotwater Edition3AhmedRamadanNo ratings yet

- 27 July - TVA-TI-P192-01-ENDocument4 pages27 July - TVA-TI-P192-01-ENMalik DaniyalNo ratings yet

- Volute Casing Centrifugal Pumps of Block Design Series NB: VM 528 GB/2012.06 - Ident No. 795 261Document20 pagesVolute Casing Centrifugal Pumps of Block Design Series NB: VM 528 GB/2012.06 - Ident No. 795 261safwan azizNo ratings yet

- ALLWEILER - Volute Casing Centrifugal Pumps of Inline DesignDocument16 pagesALLWEILER - Volute Casing Centrifugal Pumps of Inline DesignHamza AbdelhamidNo ratings yet

- Technical Sheet 900 Series Inverted Bucket Steam TrapsDocument3 pagesTechnical Sheet 900 Series Inverted Bucket Steam TrapsMalik DaniyalNo ratings yet

- Convectoare de Pardoseala Isan Practic - Carte TehnicaDocument25 pagesConvectoare de Pardoseala Isan Practic - Carte TehnicaDaniel MihaiNo ratings yet

- BSK1 Bellows Sealed Globe ValvesDocument4 pagesBSK1 Bellows Sealed Globe ValvesAhmed RamadanNo ratings yet

- HD Series: Butterfly ValvesDocument16 pagesHD Series: Butterfly ValvesGourav SharmaNo ratings yet

- Valvulas de SeguridadDocument4 pagesValvulas de SeguridadLuisFernandoCalderónMartínezNo ratings yet

- Bosch EV6 3868 - 7626Document5 pagesBosch EV6 3868 - 7626hacvuaNo ratings yet

- Etanorm Sya ModelDocument4 pagesEtanorm Sya ModelIna MeranNo ratings yet

- Vulcan Msa24Document2 pagesVulcan Msa24Victor GuanchezNo ratings yet

- FT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Document7 pagesFT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Liêm HàNo ratings yet

- Bite Type Tube Fittings (DIN 2353) : The Best Partner For Value Creation We Support The Innovations of CustomersDocument54 pagesBite Type Tube Fittings (DIN 2353) : The Best Partner For Value Creation We Support The Innovations of CustomersNIKESHNo ratings yet

- 4A Figure 31-41 Bronze SeriesDocument8 pages4A Figure 31-41 Bronze SeriesCarlos Alberto OspinaNo ratings yet

- Plate Heat Exchangers PDFDocument32 pagesPlate Heat Exchangers PDFKaushalKishoreNo ratings yet

- Flue Gas Line Systems Gas Condensing Boiler Dn80 To Topgas Comfort, Combi, Classic (12-45)Document108 pagesFlue Gas Line Systems Gas Condensing Boiler Dn80 To Topgas Comfort, Combi, Classic (12-45)laura elenaNo ratings yet

- Centrifugal Horizontal Volute Casing Pumps Series NT According To DIN EN 733Document29 pagesCentrifugal Horizontal Volute Casing Pumps Series NT According To DIN EN 733شادي العزبيNo ratings yet

- English GPW Catalog 2016Document8 pagesEnglish GPW Catalog 2016YioYin100% (1)

- A700 EnglishDocument16 pagesA700 EnglishPablo MNo ratings yet

- Pneumatic ActuatorsDocument8 pagesPneumatic ActuatorsShah Jehan HanifNo ratings yet

- Goodman ARUF Air Handler SpecsDocument8 pagesGoodman ARUF Air Handler SpecsEdward PeñaNo ratings yet

- FAMAT Cold Reheat Check Valves 2013 PDFDocument11 pagesFAMAT Cold Reheat Check Valves 2013 PDFAMITNo ratings yet

- Rotary FittingsDocument21 pagesRotary FittingscarmaNo ratings yet

- CartridgeDocument26 pagesCartridgewawa_opzNo ratings yet

- Y023 PDFDocument12 pagesY023 PDFMohammed sabatinNo ratings yet

- Technical DataDocument3 pagesTechnical DataLuis Marcelo HinojosaNo ratings yet

- 2240 1312 EKN Steelwelded Edition3 en 0607Document7 pages2240 1312 EKN Steelwelded Edition3 en 0607AhmedRamadanNo ratings yet

- General: AP-A203169A Technical Specification Rev.00Document4 pagesGeneral: AP-A203169A Technical Specification Rev.00Honesto BautistaNo ratings yet

- Serie 2000Document6 pagesSerie 2000Alvaro Yaciel Rodríguez LagunesNo ratings yet

- Electric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Document1 pageElectric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Manuel SerranoNo ratings yet

- Technical Sheet BPT13Document2 pagesTechnical Sheet BPT13Malik DaniyalNo ratings yet

- Slab Gate Valves Api 6ADocument39 pagesSlab Gate Valves Api 6AJuan Pablo100% (1)

- T 80001 enDocument24 pagesT 80001 enEnda MNo ratings yet

- 7200 Series Rochester GaugesDocument2 pages7200 Series Rochester GaugesShafqat IqbalNo ratings yet

- Stainless Steel Pressure Filters - BrochureDocument20 pagesStainless Steel Pressure Filters - Brochureviktor_gligorovNo ratings yet

- Multitec / Multitec-RO: High-Pressure Pumps in Ring-Section DesignDocument24 pagesMultitec / Multitec-RO: High-Pressure Pumps in Ring-Section DesignAnonymous nZcViIP0h100% (1)

- SS Manifold 2Document16 pagesSS Manifold 2andreshuertascalderon02No ratings yet

- In Fine On Heat Pump Web in Ar 1657122562261Document31 pagesIn Fine On Heat Pump Web in Ar 1657122562261Dejan MitrovićNo ratings yet

- 3001 en Grilamid-L-PA12 PDFDocument40 pages3001 en Grilamid-L-PA12 PDFDejan MitrovićNo ratings yet

- 6709 enDocument105 pages6709 enDejan MitrovićNo ratings yet

- Geometrija Zobnikov - Gradivo Za Vaje 2014-15Document6 pagesGeometrija Zobnikov - Gradivo Za Vaje 2014-15Dejan MitrovićNo ratings yet

- Technical English Vocabulary and Grammar Alison Pohl Nick Brieger 2002Document148 pagesTechnical English Vocabulary and Grammar Alison Pohl Nick Brieger 2002StellaMarisEnglish0% (1)

- Extrusion Press Maintenance ManualDocument55 pagesExtrusion Press Maintenance ManualDejan Mitrović100% (6)

- E3120.07vratex - Pvcexcon 3F30 PG62 V07V20 As Ar Fa FR AtexDocument1 pageE3120.07vratex - Pvcexcon 3F30 PG62 V07V20 As Ar Fa FR AtexCustomer ServiceNo ratings yet

- Banda Lido Datasheet - uni-OWLDocument2 pagesBanda Lido Datasheet - uni-OWLVilma sagresaNo ratings yet

- BOQ Hotel CiputraDocument2 pagesBOQ Hotel CiputraHendra AdriansyahNo ratings yet

- 2022 Chassis Cab: Owner'S ManualDocument420 pages2022 Chassis Cab: Owner'S Manualmbadarau1206No ratings yet

- A320-Mel-Cdl-Cdd StatusDocument18 pagesA320-Mel-Cdl-Cdd StatusvproNo ratings yet

- V20 120kW Product DescriptionDocument4 pagesV20 120kW Product DescriptiongarmeloNo ratings yet

- Math EE IBDocument13 pagesMath EE IBCalc girl ReddingtonNo ratings yet

- MIP BOHLER DrysystemDocument8 pagesMIP BOHLER DrysystemKarthi KeyanNo ratings yet

- 1 s2.0 S0003491615003504 Main PDFDocument50 pages1 s2.0 S0003491615003504 Main PDFAishee ChakrabortyNo ratings yet

- 3xGE 9E.04 (GT Only)Document1 page3xGE 9E.04 (GT Only)Ade Okta YurwendraNo ratings yet

- 0.1 Hire Charges of Plants & Machinery: Basic RatesDocument4 pages0.1 Hire Charges of Plants & Machinery: Basic RatesSanjan SameerNo ratings yet

- Especificaciones de Rectificadora de CigueñalDocument10 pagesEspecificaciones de Rectificadora de CigueñalCR OtinianoNo ratings yet

- N67 MNT F41: Air InductionDocument3 pagesN67 MNT F41: Air InductionHabineza RemyNo ratings yet

- Instruction Manual: Alfa Laval i-CP100 Centrifugal PumpDocument36 pagesInstruction Manual: Alfa Laval i-CP100 Centrifugal PumpAndres HurtadoNo ratings yet

- DC Motor Modeling and Controller DesignDocument26 pagesDC Motor Modeling and Controller DesignMauricio bonilla GarageNo ratings yet

- Major Project ReportDocument58 pagesMajor Project ReportHIMANSHU GANWANINo ratings yet

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDocument2 pagesBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyNo ratings yet

- Chemistry 231 Tutorial Session # 5: The Following Questions Will Be Answered On The Tutorial SessionDocument8 pagesChemistry 231 Tutorial Session # 5: The Following Questions Will Be Answered On The Tutorial SessionFiqkyAkbarNo ratings yet

- 577 API ExercisesDocument41 pages577 API Exercisesadel100% (1)

- 301-302 Flanged BAA SUCT DIFFUSER SDIDocument2 pages301-302 Flanged BAA SUCT DIFFUSER SDIIan OsorioNo ratings yet

- Isogen Symbol Key (SKEY) DefinitionsDocument92 pagesIsogen Symbol Key (SKEY) DefinitionsMehranNo ratings yet

- Em7281-0 Chassis FaultsDocument5 pagesEm7281-0 Chassis FaultsJose ZorrillaNo ratings yet

- P3E Choke: Valve SpecificationsDocument4 pagesP3E Choke: Valve SpecificationsJairo andres Guarnizo SuarezNo ratings yet

- Natural Convection Heat Transfer in Horizonal Cylindrical Cavities (ASME)Document4 pagesNatural Convection Heat Transfer in Horizonal Cylindrical Cavities (ASME)jmpandolfiNo ratings yet

- Hyundai H380 TrucksDocument12 pagesHyundai H380 TrucksIrfan SaeedNo ratings yet

- Omega - Installation ManualDocument25 pagesOmega - Installation ManualCreaciones VilberNo ratings yet

- WDH-SL3 Product Information SP13L002GB-04 - 1542713324933Document2 pagesWDH-SL3 Product Information SP13L002GB-04 - 1542713324933irwantino susiloNo ratings yet

- MC 7 007 Fc008 VentiladorDocument3 pagesMC 7 007 Fc008 VentiladorLeandro CiceroNo ratings yet

- Bernoullis Equation EngineeringduniyacomDocument26 pagesBernoullis Equation EngineeringduniyacomMuhammad DodyNo ratings yet

- Manual Compresor Water FurnaceDocument50 pagesManual Compresor Water FurnaceFred GarciaNo ratings yet