Professional Documents

Culture Documents

Procedure

Uploaded by

Badrudin Jundaili0 ratings0% found this document useful (0 votes)

6 views1 pageOriginal Title

Procedure.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageProcedure

Uploaded by

Badrudin JundailiCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

Procedure

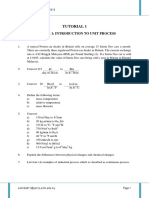

1. The stirrer was set up in the MDI beaker.

2. Polymeg-bitanediol mixture was added while continuous stirring in the MDI. The power of the

stirrer was increased as the viscosity rises.

3. The temperature was recoded and measured every 15 second.

4. The agitation was stopped after 4 minutes or when 2 consecutive temperature reading are the

same.

5. The stirrer was remove and poured into a pre-coated aluminum pan.

6. The polymer was spread to a thin layer and cooled quickly in ice water.

7. The polyurethane was weighed and recorded.

8. The structure of polyurethane structure was observed using a microscope.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Experiment 7: Analysis of Chlorpyrifos in Water by Solid-Phase Extraction (SPE) and Gas Chromatography-Electron Capture Detector (GC-ECD)Document2 pagesExperiment 7: Analysis of Chlorpyrifos in Water by Solid-Phase Extraction (SPE) and Gas Chromatography-Electron Capture Detector (GC-ECD)Badrudin JundailiNo ratings yet

- ProcedureDocument1 pageProcedureBadrudin JundailiNo ratings yet

- Ozone Depletion AssignmentDocument5 pagesOzone Depletion AssignmentBadrudin JundailiNo ratings yet

- Water Use and QualityDocument49 pagesWater Use and QualityBadrudin JundailiNo ratings yet

- Lab 5Document1 pageLab 5Badrudin JundailiNo ratings yet

- Experiment 6Document5 pagesExperiment 6Badrudin JundailiNo ratings yet

- Experiment 3 Oxidation of Cyclohexanol WDocument5 pagesExperiment 3 Oxidation of Cyclohexanol WBadrudin JundailiNo ratings yet

- QuestionDocument2 pagesQuestionBadrudin JundailiNo ratings yet

- Lab 1 Polymer 6,6 NylonDocument4 pagesLab 1 Polymer 6,6 NylonBadrudin JundailiNo ratings yet

- ResultDocument1 pageResultBadrudin JundailiNo ratings yet

- ProcedureDocument1 pageProcedureBadrudin JundailiNo ratings yet

- ResultDocument1 pageResultBadrudin JundailiNo ratings yet

- QuestionDocument2 pagesQuestionBadrudin JundailiNo ratings yet

- ProcedureDocument1 pageProcedureBadrudin JundailiNo ratings yet

- CHM 475: Lab Report: Student NameDocument5 pagesCHM 475: Lab Report: Student NameBadrudin JundailiNo ratings yet

- CHM 221 Chemical Analysis: Errors and Statistical Evaluation of Experiment DataDocument71 pagesCHM 221 Chemical Analysis: Errors and Statistical Evaluation of Experiment DataBadrudin JundailiNo ratings yet

- CMT 200Document3 pagesCMT 200Badrudin JundailiNo ratings yet

- AssignmentDocument3 pagesAssignmentBadrudin JundailiNo ratings yet

- CHM574' Inorganic'Chemistry'Ii': Chapter'1:'Molecular'Orbital'Theory'Document29 pagesCHM574' Inorganic'Chemistry'Ii': Chapter'1:'Molecular'Orbital'Theory'Badrudin JundailiNo ratings yet

- Chm221 Chapter 2Document57 pagesChm221 Chapter 2Badrudin JundailiNo ratings yet

- Chm221 Chapter 7Document64 pagesChm221 Chapter 7Badrudin JundailiNo ratings yet

- Chm221 Chapter 1Document45 pagesChm221 Chapter 1Badrudin JundailiNo ratings yet

- Chm221 Chapter 6Document31 pagesChm221 Chapter 6Badrudin JundailiNo ratings yet

- The Nightingale and The RoseDocument5 pagesThe Nightingale and The RoseBadrudin JundailiNo ratings yet

- CHM 207 Chapter 2-AlkanesDocument69 pagesCHM 207 Chapter 2-AlkanesBadrudin Jundaili100% (1)

- Chm221 Chapter 5Document42 pagesChm221 Chapter 5Badrudin JundailiNo ratings yet

- Chapter 3 Alkenes - chm207pptDocument81 pagesChapter 3 Alkenes - chm207pptBadrudin JundailiNo ratings yet

- Chapter 1 Introduction To Org Chemistry 21 Jun 2012Document77 pagesChapter 1 Introduction To Org Chemistry 21 Jun 2012Badrudin JundailiNo ratings yet

- Persuasive Speech Rhetorical DevicesDocument2 pagesPersuasive Speech Rhetorical DevicesafifiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)