Professional Documents

Culture Documents

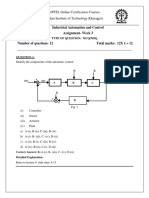

1 Ti T 0 de (T) DT

Uploaded by

Usha ROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Ti T 0 de (T) DT

Uploaded by

Usha RCopyright:

Available Formats

A PID controller is a three-term controller that has proportional, integral and derivative control coefficients.

It is

named after its three correcting terms and its sum produce a control action for manipulating variable. It

measures the output of a process and controls the input by maintaining the output at a desired value (also called

as set point).The proportional term applies appropriate proportional changes for error (which is the difference

between the set point and process variable) to the control output. The integral term examines the process

variable over time and offset of set point and then corrects the output if necessary. Derivative control monitors

the rate of change of process variable and accordingly changes the output when there are unusual changes. Each

parameter of three control functions is adjusted to get the desired performance from the process.

The conventional PID controller equation is given as follows:

1 t de(t)

u(t) = Kp [ e(t) ]+Ki[ ∫ e(τ)dτ

Ti 0

] + Kd[

dt

]

where Kp is the proportional gain, Ki is the integral gain, Ki is the derivative gain, Ti is integral time constant,

e is the error signal and u is the control output.

At present, the PI controller is most widely adopted in industrial application due to its simple structure, easy to

design and low cost. For a PI controller and when the sample time is T , this equation can be modified into a

difference equation:

T

u(k) = Kp [ e(k)]+Ki[ ∑ki=0 e(i)]

Ti

Control output u(k-1) can be expressed in form:

T

u(k-1) = Kp [ e(k-1)]+ Ki[ ∑k−1

i=0 e(i) ]

Ti

Their difference between u(k) and u(k-1) is then:

T T

u(k) - u(k-1) = Kp [ e(k)+ ∑ki=0 e(i) ] - Ki [ e(k-1) + ∑k−1

i=0 e(i) ]

Ti Ti

T

u(k) - u(k-1) = Kp [e(k)] – Ki [e(k-1) + e(k)]

Ti

T

u(k) = u(k-1) + Kp [e(k)] – Ki [e(k-1) + e(k)]

Ti

You might also like

- Complex NumbersDocument126 pagesComplex NumbersHubert SemenianoNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Simple Linear Regression ExampleDocument3 pagesSimple Linear Regression Examplekiran_wakchaure100% (1)

- LAS Prac1 Q4W1to4Document15 pagesLAS Prac1 Q4W1to4Jello Tyrone QuebuenNo ratings yet

- Mathematical Formulas for Economics and Business: A Simple IntroductionFrom EverandMathematical Formulas for Economics and Business: A Simple IntroductionRating: 4 out of 5 stars4/5 (4)

- (Graduate Texts in Mathematics 12) Richard Beals (Auth.)-Advanced Mathematical Analysis_ Periodic Functions and Distributions, Complex Analysis, Laplace Transform and Applications-Springer-Verlag NewDocument241 pages(Graduate Texts in Mathematics 12) Richard Beals (Auth.)-Advanced Mathematical Analysis_ Periodic Functions and Distributions, Complex Analysis, Laplace Transform and Applications-Springer-Verlag NewClaudio Ramón Rodriguez Mondragón100% (1)

- Discrete Time SystemsDocument19 pagesDiscrete Time SystemsGoodNo ratings yet

- Zero and First Order HoldDocument6 pagesZero and First Order Holdnirmal_inboxNo ratings yet

- Slides Robin CADDocument34 pagesSlides Robin CADJorge MunozNo ratings yet

- Applied Sciences: Discrete-Time First-Order Plus Dead-Time Model-Reference Trade-Off PID Control DesignDocument19 pagesApplied Sciences: Discrete-Time First-Order Plus Dead-Time Model-Reference Trade-Off PID Control DesignKevin AlexanderNo ratings yet

- Emulation of Analog Controllers: 2.1: Control Design Via Time-Domain EmulationDocument47 pagesEmulation of Analog Controllers: 2.1: Control Design Via Time-Domain EmulationLêNhậtMinhNo ratings yet

- 03b ModelingDocument28 pages03b ModelingAli FarhatNo ratings yet

- Proportional & Integral Controllers: S K K S E S UDocument25 pagesProportional & Integral Controllers: S K K S E S UAvik GhoshNo ratings yet

- Module 1: Introduction To Digital Control: Lecture Note 2Document4 pagesModule 1: Introduction To Digital Control: Lecture Note 2Mudit PharasiNo ratings yet

- Research On Temperature Control of Heating FurnaceDocument10 pagesResearch On Temperature Control of Heating FurnaceŠarra MkNo ratings yet

- Bse203075, Bse203076, Bse203087Document17 pagesBse203075, Bse203076, Bse203087Abrasive TuberNo ratings yet

- Digital PID For DC Motor ControlDocument7 pagesDigital PID For DC Motor ControlMohsensorNo ratings yet

- Fall2019 MidtermDocument10 pagesFall2019 MidtermHui LiNo ratings yet

- EC744 Lecture Note 1: Prof. Jianjun MiaoDocument18 pagesEC744 Lecture Note 1: Prof. Jianjun MiaobinicleNo ratings yet

- Exercise MPC1Document16 pagesExercise MPC1Ifrah AlamNo ratings yet

- Units QDocument12 pagesUnits QSoham DeNo ratings yet

- Solow Growth ModelDocument30 pagesSolow Growth ModelNadeem RaoNo ratings yet

- Controllers - by Kenil JaganiDocument24 pagesControllers - by Kenil Jaganikeniljagani513No ratings yet

- Control L2aDocument17 pagesControl L2avibhore mendirattaNo ratings yet

- EE402 Lecture 2Document10 pagesEE402 Lecture 2sdfgNo ratings yet

- Spring2016 MidtermDocument10 pagesSpring2016 MidtermHui LiNo ratings yet

- 1 s2.0 S0893965912001632 MainDocument5 pages1 s2.0 S0893965912001632 MainDr-Nitish Kumar BharadwajNo ratings yet

- Lecture 1Document8 pagesLecture 1sabbithiNo ratings yet

- 11.5 Closed Economy Is Curve DerivationDocument6 pages11.5 Closed Economy Is Curve Derivation周杨No ratings yet

- 1 PID ControllersDocument15 pages1 PID ControllersSteven AlexNo ratings yet

- Pid Controller Calculus v320Document16 pagesPid Controller Calculus v320Peter UhuleNo ratings yet

- 446-02 Mdls of Sys I (N) - HandoutDocument9 pages446-02 Mdls of Sys I (N) - HandoutFrancisco HurtadoNo ratings yet

- Chapter 4 - Transfer FunctionsDocument36 pagesChapter 4 - Transfer FunctionsFakhrulShahrilEzanie100% (1)

- Practical Aspects in Adaptive ControlDocument35 pagesPractical Aspects in Adaptive ControlSam KhanNo ratings yet

- Windkessel ProblemsDocument41 pagesWindkessel Problemsadh30No ratings yet

- CL 2016 Lecture 18Document10 pagesCL 2016 Lecture 18Leo EscobarNo ratings yet

- Symmetric Root Locus LQR Design State Estimation: Selection of 'Optimal' Poles For SISO Pole Placement Design: SRLDocument22 pagesSymmetric Root Locus LQR Design State Estimation: Selection of 'Optimal' Poles For SISO Pole Placement Design: SRLP_leeNo ratings yet

- KOM 3781 Discrete-Time Control Systems: Veysel GaziDocument72 pagesKOM 3781 Discrete-Time Control Systems: Veysel GaziFatih CanbolatNo ratings yet

- Lecture 8: From Analog To Digital Controllers, PID Control Design ApproachesDocument10 pagesLecture 8: From Analog To Digital Controllers, PID Control Design ApproachesarafatasgharNo ratings yet

- What Are Polynomial Models - MATLAB & SimulinkDocument4 pagesWhat Are Polynomial Models - MATLAB & Simulinknicanor rodolfoNo ratings yet

- Assignment 3 SolutionsDocument8 pagesAssignment 3 SolutionsAbhishek KumarNo ratings yet

- Final Exam MockDocument11 pagesFinal Exam Mockb8vfdrjff6No ratings yet

- Data-Based Approach To Feedback-Feedforward Controller Design From Closed-Loop Plant DataDocument6 pagesData-Based Approach To Feedback-Feedforward Controller Design From Closed-Loop Plant DataArif HidayatNo ratings yet

- The Basic Real Business Cycle ModelDocument12 pagesThe Basic Real Business Cycle ModelBehzad KhanNo ratings yet

- 42663-0201596121 SMDocument85 pages42663-0201596121 SMWael BazziNo ratings yet

- Assignment 5 VFI PDFDocument2 pagesAssignment 5 VFI PDFGreco S50No ratings yet

- Mathematical Modeling and Parameter Estimation of A RC CircuitDocument11 pagesMathematical Modeling and Parameter Estimation of A RC Circuitupeksha erandiNo ratings yet

- Elec2146 L9 RK V03 PDFDocument24 pagesElec2146 L9 RK V03 PDFvince kafuaNo ratings yet

- Solving Dynare Eui2014 PDFDocument84 pagesSolving Dynare Eui2014 PDFduc anhNo ratings yet

- 9 Controller DiscretizationDocument8 pages9 Controller Discretizationstephen562001No ratings yet

- 2 B - Ecuacion de Euler Y Condicion de TransversalidadDocument4 pages2 B - Ecuacion de Euler Y Condicion de TransversalidadGonzalo del FierroNo ratings yet

- Intoduction To Digital ControlDocument19 pagesIntoduction To Digital ControlKeanu Espina0% (1)

- Prof. Bart de Moor (KUL) Chapter 13: PID ControllersDocument36 pagesProf. Bart de Moor (KUL) Chapter 13: PID ControllersArshad AliNo ratings yet

- Module-1: Tensor Algebra: Lecture-5: The Principal Invariants and The Inverse of TensorDocument7 pagesModule-1: Tensor Algebra: Lecture-5: The Principal Invariants and The Inverse of TensorAnkush PratapNo ratings yet

- Digitalcontrolsystems ProblemDocument23 pagesDigitalcontrolsystems Problemjeevitha babuNo ratings yet

- Position Form & Velocity Form of PID ControllerDocument6 pagesPosition Form & Velocity Form of PID ControllerThefairman UnkownNo ratings yet

- Fund A MentosDocument1 pageFund A MentosSebastian Ospína LópezNo ratings yet

- Section 6Document8 pagesSection 6Tango BrillanteNo ratings yet

- CLL261-Dynamic Behaviour of First and Second Order Systems: Hariprasad Kodamana Iit DelhiDocument24 pagesCLL261-Dynamic Behaviour of First and Second Order Systems: Hariprasad Kodamana Iit DelhiGARGI SHARMANo ratings yet

- Diesel Cycle: R - Point 3 Is Called The Cutoff PointDocument8 pagesDiesel Cycle: R - Point 3 Is Called The Cutoff PointJethro Briza GaneloNo ratings yet

- Chapter 2. Returns: Let P Be The of An Asset at Time TDocument40 pagesChapter 2. Returns: Let P Be The of An Asset at Time TWOONGCHAE YOONo ratings yet

- Harrod Domar ModelDocument2 pagesHarrod Domar ModelTechnical AwanNo ratings yet

- Tables of Generalized Airy Functions for the Asymptotic Solution of the Differential Equation: Mathematical Tables SeriesFrom EverandTables of Generalized Airy Functions for the Asymptotic Solution of the Differential Equation: Mathematical Tables SeriesNo ratings yet

- Method of Finite Elements I: Shape Functions: Adrian EggerDocument12 pagesMethod of Finite Elements I: Shape Functions: Adrian EggerheinsteinzNo ratings yet

- Agilent Products Introductory Letter 2019Document1 pageAgilent Products Introductory Letter 2019Amit PoddarNo ratings yet

- Assignment ModelDocument2 pagesAssignment ModelADEYANJU AKEEMNo ratings yet

- Control Sol GA PDFDocument342 pagesControl Sol GA PDFRishabh ShuklaNo ratings yet

- Xercise: Single Correct (Objective Questions)Document16 pagesXercise: Single Correct (Objective Questions)Adharshan NNo ratings yet

- Nonlinear Least Squares Problems: This Lecture Is Based On The Book P. C. Hansen, V. Pereyra and G. SchererDocument20 pagesNonlinear Least Squares Problems: This Lecture Is Based On The Book P. C. Hansen, V. Pereyra and G. SchererMeriska ApriliadaraNo ratings yet

- Latihan Fungsi Gubahan ADD MATHS F4Document5 pagesLatihan Fungsi Gubahan ADD MATHS F4Fayruzz NaseerNo ratings yet

- Cemu Ucimo Djecu: AnalizaDocument78 pagesCemu Ucimo Djecu: AnalizaMaja PandžaNo ratings yet

- Successive Differentiation and Leibnitz S TheoremDocument2 pagesSuccessive Differentiation and Leibnitz S TheoremABC DEFNo ratings yet

- Chap 001Document34 pagesChap 001sarasNo ratings yet

- M439 APNCalculus A Review KEYDocument10 pagesM439 APNCalculus A Review KEYHimani PatelNo ratings yet

- ASSE 21 - Assessment of Child Learning: Prepared By: Mrs. Edelyn D. SabillaDocument13 pagesASSE 21 - Assessment of Child Learning: Prepared By: Mrs. Edelyn D. SabillaIvanne Meinel CalcitaNo ratings yet

- CD Rom 7 Slides Westgard Multirule SystemDocument11 pagesCD Rom 7 Slides Westgard Multirule SystemJeffrey RamosNo ratings yet

- Assignment 3Document5 pagesAssignment 3api-3833460100% (1)

- Artificial Intelligence Semester Project: Topic: Car Mileage Predictor Presented by Abdullah FarooqDocument17 pagesArtificial Intelligence Semester Project: Topic: Car Mileage Predictor Presented by Abdullah FarooqM. Talha NadeemNo ratings yet

- Mechanics For Academic Olympiad Basic CalculusDocument4 pagesMechanics For Academic Olympiad Basic Calculus54zf5fgpnjNo ratings yet

- EMÜ221 - Fall2016 - Week 2Document24 pagesEMÜ221 - Fall2016 - Week 2KemalNo ratings yet

- PSCV Unit-Iii Digital NotesDocument46 pagesPSCV Unit-Iii Digital NotesMr. SonuNo ratings yet

- STP 91-A-1963Document94 pagesSTP 91-A-1963Tim SchouwNo ratings yet

- Exam Paper MABY4100 2019.11 - SOLUTIONSDocument10 pagesExam Paper MABY4100 2019.11 - SOLUTIONSvilinorgelive.noNo ratings yet

- Module 1 (1,2,3)Document45 pagesModule 1 (1,2,3)vikram sethupathiNo ratings yet

- Assosa University Department of Mechanical Engineering: - Project ManagementDocument33 pagesAssosa University Department of Mechanical Engineering: - Project ManagementElijah T DhNo ratings yet

- The Introduction To Engineering CourseDocument9 pagesThe Introduction To Engineering CourseAndreea MadalinaNo ratings yet

- Chapter 2: Limits and Derivatives: X F X If X X FDocument3 pagesChapter 2: Limits and Derivatives: X F X If X X FAlex MakNo ratings yet

- High Performance Liquid ChromatographyDocument2 pagesHigh Performance Liquid ChromatographyHina KhalidNo ratings yet

- Azure Machine Learning: © Jitesh KhurkhuriyaDocument16 pagesAzure Machine Learning: © Jitesh Khurkhuriyaabbas91No ratings yet