Professional Documents

Culture Documents

Fabrication of Peltier Cooling System: An Alternative for Refrigeration

Uploaded by

Isabella MuñozOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication of Peltier Cooling System: An Alternative for Refrigeration

Uploaded by

Isabella MuñozCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/302859927

" Fabrication of Peltier Cooling System: Alternative for Refrigeration "

Article · May 2016

CITATIONS READS

2 1,487

8 authors, including:

Yogesh Joshi Amarjeet R Gupta

Datta Meghe Institute of Engineering , Technology & Research Datta Meghe Institute of Engineering, Technology & Research Wardha

18 PUBLICATIONS 4 CITATIONS 15 PUBLICATIONS 3 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Production Engineering View project

Material Engineering View project

All content following this page was uploaded by Amarjeet R Gupta on 10 May 2016.

The user has requested enhancement of the downloaded file.

Vol-2 Issue-3 2016 IJARIIE-ISSN(O)-2395-4396

“Fabrication of Peltier Cooling System:

Alternative for Refrigeration”

H. C. Kuttarmare1 , R. D. Vaidya 2 , S. M. Chaudhari3 , K.G.Sontakke4 , Y. G. Joshi5 ,

A R Gupta6 , A. R Raghatate7 , D K Padal8 ,

1,2,3,4,5,6,7

Asst. Prof . ,Mechanical Department, DMIETR Sawangi Meghe, Maharashtra, India

8

Asst. Prof . ,Mechanical Department, BDCE, Sevagram, Maharashtra, India

ABSTRACT

In this paper aims towards developing a system which will produce cooling effect without the use of mechanical

devices and also refrigerant. Thermoelectric cooling system does not require working fluids or any moving

parts. Thermoelectric refrigeration devices have a distinct place in medical applications, electronic

applications, scientific equipment and other applications.

The difference between the existing methods and this model is that a thermoelectric cooling system

refrigerates without use of mechanical devices (Conventional Condenser fins and Compressor) and without

refrigerant.

Key Words: Thermoelectric cooling, medical applications, refrigerant.

1. INTRODUCTION

“We have pleasure in introducing our idea “FABRICATION OF PELTIER COOLING SYSTEM”,

which is equipped by heat sinks, peltier (thermoelectric module) element, etc.

It is the system which is designed to produce cooling but the main objective behind the project is that

the thermoelectric module (peltier module) to produce cooling effect. This means that food stub cooling is done

without the use of greenhouse gases which would ultimately reduce the global warming which is usually caused

by other refrigeration system.

Thermoelectric cooling, also known as "The Peltier Effect“, is a solid-state method of heat transfer

through dissimilar semiconductor materials. Thermoelectric cooler (TEC), or Peltier Cooler uses the Peltier

effect for the exchange of heat.

The modern commercial TEC consists of a number of p - and n- type semiconductor couples. The heat

pumping direction can be altered by altering the polarity of the charging DC current. Heat will be rejected

through the module from inner side to the outer surface. Inner module face will be cooled while the outer face is

simultaneously heated.

Current Contribution:-

This paper aim is to investigate the feasibility and produce a prototype of a rapid cooling device using

peltier technology with the intention of introducing this technology in the consumer market in future.

2. OBJECTIVES

The material used to fabricate the model is lower graded and economical because the cost of product will less as

possible as, which will play an advantage should this product be rolled out in large numbers into the market.

The discussion of this report will include the positive aspects of the project and its flaws, and will explain how

the latter can be overcome should this project continue in the future.

To provide cooling system in rural area.

To reduce the overall cost of refrigeration to cool water.

To investigate methods to increase the efficiency in order to conserve power.

2124 www.ijariie.com 260

Vol-2 Issue-3 2016 IJARIIE-ISSN(O)-2395-4396

3. Working principle

The working principle of the peltier cooling system as follows:-

Peltier effect thermoelectric coolers operate by the Peltier effect (which also goes by the more general name

thermoelectric effect). The device has two sides, and when DC current flows through the device, it reject heat

from inner side to the outer, so that inner side gets cooler while the outer gets hotter. The hot" side is attached to

a heat sink so that it remains at ambient temperature, while the cool side goes below room temperature. In some

applications, multiple coolers can be arranged for lower temperature.

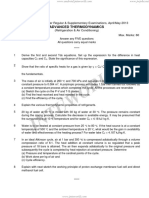

Fig. 1 “Working principle of thermoelectric module”

Figure no. 1 The diagram shows Working principle of thermoelectric module shows a simple diagram

of peltier. Two elements of semiconductor, primarily Bismuth Telluride, heavily doped to create either an

excess (n-type) or deficiency (p-type) of electrons.

If the peltier module gets cooled on one side it transfers it’s cooling to the heat sink used on that same side. Due

to this transfer of cooling, the fans provided to the heat sinks spred the cool air and gives out to the required

place needed for cooling.

On the other hand another fan on opposite side of the peltier module draws the hot air from the heat

sink and expels out to the atmosphere in order to decrease the temperature of the peltier module.

In this way the whole system works.

Fig. 2 Heat sink showing thermal resistances along with circuit diagram.

2124 www.ijariie.com 261

Vol-2 Issue-3 2016 IJARIIE-ISSN(O)-2395-4396

4. Cabinet

Figure No. 3 “Schematic diagram of Peltier Cooling System”

Figure no. 3 picture is schematic diagram of peltier cooling system which shows all the components

required to the cooling system. Before going to fab ricate actual cooling system this line diagram help to

arrangement of the components at their positions so that it is easy to design CAD model.

Figure No. 4 “CAD Model of Peltier Cooling System”

Figure No. 4 shows the CAD Model of Peltier Cooling System with different views. In this figure the

view gives the idea of various side of Peltier Cooling System. CAD software increase the accuracy and

productivity of the design, also with the help of CAD software we can improve the performance of cooling

system. CAD is used to create the model and take the advantage of its application in fabrication.

CAD software used graphics to shows the real product in nature. It provides the document of

information for required properties of material, processes, and design . As in the manual drafting of technical and

engineering drawings, the output of CAD must convey information.

CAD is used to design curves and figures in two-dimensional (2D) space; or curves, surfaces, and solids in

three-dimensional (3D) model.

2124 www.ijariie.com 262

Vol-2 Issue-3 2016 IJARIIE-ISSN(O)-2395-4396

Figure No.5 “Peltier Cooling System”

Figure No. 5 shows the actual fabricated Peltier Cooling System. The purpose of this figure is to

explore ideas, not to provide detailed step-by-step instructions on how to create an actual curriculum design, let

alone an actual curriculum. It is way of analogy, the figure deals with how general design principles may seem

to apply to designing any kind of buildings, but not to how to produce detailed engineering plans for use in

constructing actual buildings. To make the argument easy to follow, the this work.

Purpose of insulation

The insulation is used to protect the absorption of heat from the outer environment. Heat is rejected

from the inner surface and rejected to the surrounding but if the heat from the surrounding wil g ets absorbed in

inner side the performance of the system will poor. Insulation material also protects the human being from the

accident. Such materials are porous, containing large number of dormant air cells. Thermal insulation delivers

the following benefits:

1. Energy consumption will reduces.

2. Offers better process control by maintaining process temperature.

3. Corrosion of the system get protected.

4. Provide the heat absorption barrier.

5. Vibration will reduce.

5. CONCLUSIONS

The “PELTIER COOLING SYSTEM” is working with satisfactory conditions. We are able to understand the

difficulties in maintaining the tolerances and also the quality. We have done to our ability and skill making

maximum use of available facilities. In conclusion remarks of our project work, let us add a few more lines

about our impressive project work.

The portable refrigerator has no moving parts, fluid, or refrigerants. In particular, its size is very small

so it is convenient for travelers to store the medicine. Temperature was controllable via changing the input

voltage/current so we can maintain the medicine as desired level of temperature and the cost of the device is

very low. This system achieves 40% to 60% of cooling effect compare to conventional refrigerator. For the

above reasons this is most effective for poor people (by the cost) and travelling people (because of size).

REFERENCES

[1] Hsin-Hung Chang, “A New Design of Mobile Thermoelectric Power Generation System” International

Journal of Electrical, Computer, Electronics and Communication Engineering. Y 2013, P-13128.

2124 www.ijariie.com 263

Vol-2 Issue-3 2016 IJARIIE-ISSN(O)-2395-4396

[2] Manoj S. Raut, Dr.P. V. Walke, “Thermoelectric Air Cooling For Cars” ISSN: 0975-5462, May 2012, P-

2394.

[3] Surith Nivas M1, “Photovoltaic Driven Dual Purpose Thermoelectric Refrigerator for Rural Ind ia”, June-

2013, ISSN 2278-7763, p-111.

[4] Edson Nogueira José Rui Camargo, “Performance analysis of a thermoelectric air conditioning” Rev. ciênc.

exatas, Taubaté, 2003/2004 , p. 9-11.

[5] Rehab Noor Mohammed, “Study Of Thermal Performance Of Thermoelect ric Cooling System”,

unpublished.

[6] Manoj Kumar Rawat1*, Himadri Chattopadhyay2, Subhasis Neogi3, “ A NOVEL POTENTIAL GREEN

REFRIGERATION AND AIR CONDITIONING TECHNOLOGY”, ICERTSD 2013, Feb 2013, pages 362-

367.

2124 www.ijariie.com 264

View publication stats

You might also like

- Design and Development of Solar Powered 360degree Automatic Air CoolerDocument6 pagesDesign and Development of Solar Powered 360degree Automatic Air CoolerIJRASETPublicationsNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Ijetae Ncetet 2018 01Document2 pagesIjetae Ncetet 2018 01Ajaysinh SolankiNo ratings yet

- Design and Modification of Radiator in I.C. Engine Cooling System For Maximizing Efficiency and LifeDocument8 pagesDesign and Modification of Radiator in I.C. Engine Cooling System For Maximizing Efficiency and LifeNabajyoti DeyNo ratings yet

- 1 - A Review On Fabrication of Combined Refrigerator Cum Air Conditioning Cum Water Heater Unit by VCRS - MDocument6 pages1 - A Review On Fabrication of Combined Refrigerator Cum Air Conditioning Cum Water Heater Unit by VCRS - Mnadeemq_0786100% (2)

- 22 ModificationofRadiator PDFDocument8 pages22 ModificationofRadiator PDFhtunhtunlynn07No ratings yet

- Experimental Work On Solar Powered Portable Refrigeration System For Rural AreasDocument9 pagesExperimental Work On Solar Powered Portable Refrigeration System For Rural AreasIJRASETPublicationsNo ratings yet

- Research Paper RadiatorDocument5 pagesResearch Paper RadiatorAbhishek SinghNo ratings yet

- Modificationof RadiatorDocument8 pagesModificationof Radiatorflorin chisNo ratings yet

- Air Conditioner Using Peltier ModuleDocument6 pagesAir Conditioner Using Peltier ModuleMuhammad AtifNo ratings yet

- Ampacet ReportDocument27 pagesAmpacet ReportsaiNo ratings yet

- 22 I C CoolingSystem-ModificationofRadiator PDFDocument8 pages22 I C CoolingSystem-ModificationofRadiator PDFFelipe CruzNo ratings yet

- Simulation Based Interpretation and Recent Trends On Performance Analysis On Automobile Radiator Through Nano Particle FluidsDocument3 pagesSimulation Based Interpretation and Recent Trends On Performance Analysis On Automobile Radiator Through Nano Particle FluidsEditor IJTSRDNo ratings yet

- Air Conditioner Using Peltier ModuleDocument7 pagesAir Conditioner Using Peltier Modulekadamarya2005No ratings yet

- Analysis and Design Methodology For Thermoelectric Power Generation System From Waste HeatDocument7 pagesAnalysis and Design Methodology For Thermoelectric Power Generation System From Waste HeatLohiyaNo ratings yet

- Nternational Ournal of Ngineering Ciences & Esearch EchnologyDocument9 pagesNternational Ournal of Ngineering Ciences & Esearch EchnologyAppam NiharNo ratings yet

- Cooling System For Electronics in Computer System-An OverviewDocument4 pagesCooling System For Electronics in Computer System-An OverviewAzhariArdyNo ratings yet

- Iarjset 2023 104091Document7 pagesIarjset 2023 104091Aditya DoyaleNo ratings yet

- Enhancing The Efficiency of Industrial Airconditioning System Using Nano ParticleDocument10 pagesEnhancing The Efficiency of Industrial Airconditioning System Using Nano ParticleIJRASETPublicationsNo ratings yet

- Modified Air Cooler With Split Unit For HumidityDocument13 pagesModified Air Cooler With Split Unit For HumiditySuraj Kumar 603-M-21No ratings yet

- Literature Review On Design and Fabrication of Refrigerant Based Air CoolerDocument11 pagesLiterature Review On Design and Fabrication of Refrigerant Based Air CoolerIJRASETPublicationsNo ratings yet

- I.C. engine cooling system design improves performance and reduces costsDocument9 pagesI.C. engine cooling system design improves performance and reduces costsNavneet HannurkarNo ratings yet

- ICEngine Cooling SystemDocument9 pagesICEngine Cooling SystemNavneet HannurkarNo ratings yet

- JETIR1806098Document5 pagesJETIR1806098Belay AyalewNo ratings yet

- I.C. engine cooling system design improves performance and reduces costsDocument9 pagesI.C. engine cooling system design improves performance and reduces costsSaurabh JadonNo ratings yet

- 1.0 Chapter 01 (: Introduction)Document39 pages1.0 Chapter 01 (: Introduction)Ever TwinsNo ratings yet

- SAMPLE - OutdoorCooling-Partial Draft ASSGNDocument12 pagesSAMPLE - OutdoorCooling-Partial Draft ASSGNman manNo ratings yet

- CFD analysis of steam boiler tube used in power plantDocument10 pagesCFD analysis of steam boiler tube used in power plantADVOKASI PPI MALAYSIANo ratings yet

- Multi-Objective Heat Sink Optimization by Using Taguchi MethodDocument9 pagesMulti-Objective Heat Sink Optimization by Using Taguchi MethodIJRASETPublicationsNo ratings yet

- ICEngine Cooling SystemDocument9 pagesICEngine Cooling SystemMudit YadavNo ratings yet

- SKMM 3443 Heat Transfer Project: Sustainable Energy in A Heat Exchanger System'Document9 pagesSKMM 3443 Heat Transfer Project: Sustainable Energy in A Heat Exchanger System'Izzat AshraffNo ratings yet

- Design of Air Conditioning System For Residential/Office BuildingDocument5 pagesDesign of Air Conditioning System For Residential/Office BuildingmuskanNo ratings yet

- 200-Manuscript With Authors Details-11841-1-10-20201209Document16 pages200-Manuscript With Authors Details-11841-1-10-20201209550 SAi CHARAN REDDYNo ratings yet

- 10 VII July 2022Document20 pages10 VII July 2022IJRASETPublicationsNo ratings yet

- Downloads Papers N5be7db375ef81 PDFDocument39 pagesDownloads Papers N5be7db375ef81 PDFtedy ekoNo ratings yet

- Introduction of Heat SinkDocument10 pagesIntroduction of Heat Sinkmanvitha varmaNo ratings yet

- 118-Chapter Manuscript-1585-1-10-20211213Document4 pages118-Chapter Manuscript-1585-1-10-20211213Aditya DoyaleNo ratings yet

- Peltier-Based Air Conditioning SystemDocument6 pagesPeltier-Based Air Conditioning SystemIJRASETPublicationsNo ratings yet

- Investigation of CPU Fan Cooling PerformanceDocument13 pagesInvestigation of CPU Fan Cooling Performancev121vNo ratings yet

- Mini Automated Refrigerator: Mahatma Gandhi Mission'S College of Engineering and Technology NoidaDocument25 pagesMini Automated Refrigerator: Mahatma Gandhi Mission'S College of Engineering and Technology NoidaSumit KumarNo ratings yet

- A Review On Experimental Analysis On Hybrid Vapour Compression Refrigeration SystemDocument7 pagesA Review On Experimental Analysis On Hybrid Vapour Compression Refrigeration SystemIJRASETPublicationsNo ratings yet

- Design New Medium-Temperature Stirling Engine For Distributed Cogeneration ApplicationsDocument10 pagesDesign New Medium-Temperature Stirling Engine For Distributed Cogeneration ApplicationsLima CostaNo ratings yet

- Computer Program For Calculation Microchannel Heat Exchangers For Air Conditioning SystemsDocument5 pagesComputer Program For Calculation Microchannel Heat Exchangers For Air Conditioning Systemsmido ahmedNo ratings yet

- Fabrication Solar Refrigeration System by Peltier Effect Ijariie8926Document6 pagesFabrication Solar Refrigeration System by Peltier Effect Ijariie8926Prachurjya BaruahNo ratings yet

- Products Guide CRADLEDocument16 pagesProducts Guide CRADLEdddidsNo ratings yet

- A Review of Literature On Various Techniques of COP Improvement in Vapor Compression Refrigeration SystemDocument9 pagesA Review of Literature On Various Techniques of COP Improvement in Vapor Compression Refrigeration SystemIJRASETPublicationsNo ratings yet

- VolumefiveDocument11 pagesVolumefiveabhishek singhNo ratings yet

- IJAIEM Journal Article on Designing an Air Conditioning SystemDocument3 pagesIJAIEM Journal Article on Designing an Air Conditioning SystemAsok AyyappanNo ratings yet

- IJRAR1CXP057Document7 pagesIJRAR1CXP057Enrique FloresNo ratings yet

- Liquid Cooling System and Air Cooling System in Data Center: A ComparisonDocument5 pagesLiquid Cooling System and Air Cooling System in Data Center: A ComparisonIJRASETPublicationsNo ratings yet

- Design and Prototype Development of A Self-Cleaning Portable Air Conditioning Device and SystemDocument7 pagesDesign and Prototype Development of A Self-Cleaning Portable Air Conditioning Device and SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Review On Design and Analysis of Forced Type Axial Fan Evaporative CondenserDocument5 pagesReview On Design and Analysis of Forced Type Axial Fan Evaporative CondenserIJRASETPublicationsNo ratings yet

- A System Dynamics Simulation Model of A Blast FurnaceDocument20 pagesA System Dynamics Simulation Model of A Blast FurnaceSWAPNILNo ratings yet

- A Brief Review of Thermal SolutionDocument5 pagesA Brief Review of Thermal Solutionseraph705No ratings yet

- Design of Air Conditioning System For Residential/Office BuildingDocument5 pagesDesign of Air Conditioning System For Residential/Office BuildingDareyoss NegussieNo ratings yet

- Solar-Driven Refrigeration SystemDocument7 pagesSolar-Driven Refrigeration SystemIJAMTESNo ratings yet

- Steady and Transient Analysis of Engine Cylinder Head With Fins at 3000C and 5000CDocument11 pagesSteady and Transient Analysis of Engine Cylinder Head With Fins at 3000C and 5000CIJRASETPublicationsNo ratings yet

- On-Off Controller Design for Portable RefrigeratorDocument5 pagesOn-Off Controller Design for Portable RefrigeratorYogeshwar SarvankarNo ratings yet

- Michaelis-Menten model accounts for enzyme kineticsDocument11 pagesMichaelis-Menten model accounts for enzyme kineticsPhenyo Mmereki100% (2)

- CHM s2Document9 pagesCHM s2kolapo feyisetanNo ratings yet

- Modeling and Simulation of A Falling Film Evaporator For A Water Vapor Heat Pump SystemDocument8 pagesModeling and Simulation of A Falling Film Evaporator For A Water Vapor Heat Pump SystemZenNo ratings yet

- Inquiry LabDocument2 pagesInquiry Labapi-568508101No ratings yet

- Faraday's Law WorksheetDocument4 pagesFaraday's Law WorksheetBrianna MalcolmNo ratings yet

- 3M Fluorinert Liquids For Electronics ManufacturingDocument4 pages3M Fluorinert Liquids For Electronics ManufacturingIon ZabetNo ratings yet

- Optimization of Fin Type and Fin Per Inch On Heat Transfer and Pressure Drop of An Air CoolerDocument4 pagesOptimization of Fin Type and Fin Per Inch On Heat Transfer and Pressure Drop of An Air Coolerjetee0082No ratings yet

- AFE Cavite: Product BulletinDocument2 pagesAFE Cavite: Product BulletinyfcozNo ratings yet

- Ibong Tiririt Pipe 3Document29 pagesIbong Tiririt Pipe 3Mc LesterNo ratings yet

- Lecture 2 Electrodeposition of CoatingDocument23 pagesLecture 2 Electrodeposition of Coatingชนพัทธ์ คงพ่วงNo ratings yet

- Electrolysis Class XIDocument17 pagesElectrolysis Class XIPrashantNo ratings yet

- Differential Thermal Analysis & Differential Scanning CalorimetryDocument51 pagesDifferential Thermal Analysis & Differential Scanning CalorimetryBesma Hamdi100% (1)

- Lecture 3Document32 pagesLecture 3Quang TrườngNo ratings yet

- Chul Park The Limits of Two-Temperature ModelDocument13 pagesChul Park The Limits of Two-Temperature ModellazharNo ratings yet

- 2012 Perrier2012 DGA Comparison Between Ester and Mineral OilsDocument6 pages2012 Perrier2012 DGA Comparison Between Ester and Mineral OilsViviane CalixtoNo ratings yet

- VSL Primary Gas StandardsDocument59 pagesVSL Primary Gas Standards分析室信箱No ratings yet

- A Single Step Non-Catalytic Esterification of Palm Fatty Acid Distillate (PFAD) ForDocument8 pagesA Single Step Non-Catalytic Esterification of Palm Fatty Acid Distillate (PFAD) ForNestor Armando Marin SolanoNo ratings yet

- 2023 Specimen Paper 3 Mark SchemeDocument10 pages2023 Specimen Paper 3 Mark SchemejamesNo ratings yet

- Philippine Central Islands College Chemistry ExamDocument1 pagePhilippine Central Islands College Chemistry ExamJarah Abimael Dela CruzNo ratings yet

- Heat Transfer Lecture Notes 2 (2016)Document10 pagesHeat Transfer Lecture Notes 2 (2016)Michael Belmonte UrdanetaNo ratings yet

- Introduction to Compressible Gas Flow DynamicsDocument2 pagesIntroduction to Compressible Gas Flow DynamicsMeetu KaurNo ratings yet

- Controlling Steam HeatersDocument12 pagesControlling Steam HeatersSreedhar Patnaik.MNo ratings yet

- Particle Nature of MatterDocument6 pagesParticle Nature of MatterAlvin John Song ConcepcionNo ratings yet

- Separation Process 1Document86 pagesSeparation Process 1hanisshi50% (4)

- Semi Detailed Lesson Plan in Electricity g71Document6 pagesSemi Detailed Lesson Plan in Electricity g71Edessa MasinasNo ratings yet

- Materials Science & Engineering B: SciencedirectDocument10 pagesMaterials Science & Engineering B: SciencedirectMuhammad BramansyahNo ratings yet

- 9D17101 Advanced ThermodynamicsDocument1 page9D17101 Advanced ThermodynamicssubbuNo ratings yet

- ACID BASE EQULIBRIA LectDocument126 pagesACID BASE EQULIBRIA LectAdrian ChombaNo ratings yet

- Bio-Soft N-Series PDFDocument9 pagesBio-Soft N-Series PDFGina AriasNo ratings yet

- Questions On ISE Choose The Correct AnswerDocument3 pagesQuestions On ISE Choose The Correct Answerنيرمين احمدNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Radium Girls: Women and Industrial Health Reform, 1910-1935From EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Rating: 4.5 out of 5 stars4.5/5 (4)

- Fusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.From EverandFusion 360 | Step by Step: CAD Design, FEM Simulation & CAM for Beginners.No ratings yet

- Mastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressFrom EverandMastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- SolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)From EverandSolidWorks 2015 Learn by doing-Part 2 (Surface Design, Mold Tools, and Weldments)Rating: 4.5 out of 5 stars4.5/5 (5)