Professional Documents

Culture Documents

Asme Guidance Notes: Prepared by TQ. Hoa - 9/2014

Uploaded by

Trịnh Quốc Tuyến0 ratings0% found this document useful (0 votes)

23 views1 pageASME Guidance notes

Original Title

ASME Guidance Notes

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentASME Guidance notes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views1 pageAsme Guidance Notes: Prepared by TQ. Hoa - 9/2014

Uploaded by

Trịnh Quốc TuyếnASME Guidance notes

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

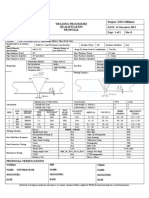

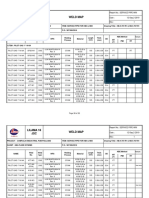

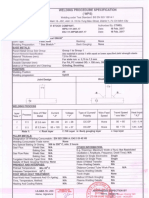

ASME GUIDANCE NOTES

Prepared by TQ. Hoa - 9/2014

ITEMS PARTS DETAIL ASME SEC. VIII DIV.1 ASME SEC. VIII DIV.2 ASME SEC. I REMARKS

G

E SCOPE U-1 AG-105 PG 1

N USER U-2(a) AG-301

E

REPONSIBILITY MANUFACTURER U-2(b) AG-302&AL-101 PG-90; PW-1

R

A INSPECTOR U-2(e); UG-90 AG-303&AL-102 PG-91

L GEOMETRIC SCOPE U-2(e) AG-120&130

PRE CERTIFICAE AG-301.2&302.3

GENERAL UG-4 AM-100&105 PG-5

MATERIAL SELECTION UG-4; UG-20(b) & UG-11 AM-100&121.2 PG-5

USAGE LIMITATION

MATERIAL IDENTIFICATION & UG-5&UCS-5;6&9 AM-510&520 PG-5;PW-5;PFT-5

M CERTIFICATE

NOT IDENTIFIED MATERIAL UG-93& UG-1(a) AM-101&AF-102 PG-10

A USAGE UG-5(b);UG5&UG-10 AD-901.1 PG-10

T

ORDER INFORMATION USC-85(b) AT-112 PARA-2.1(5)

E

RI REPAIR UG-78 AF-104 PG-76

A NDE UT UCL-11(CLAD) AM-203&220

L IMPACT UCS-66&67 AF-105

TOLERANCE UG-18 AF-105 PG-16

HEAT TREATMENT UCS-85& UHA-100-105 AF-112&AM-202

MATERIAL COMBINATION UG-18 AD-101&551

GENERAL UG-25& UG-46 AD-115&104;140

DESIGN CONDITION UG-20;21;22&25 AD-110&120

TENSION/COMPRESSION UG23(a)& UCL-23 AM-600&130 PG-21

ALLOWABLE BUCKING UG-23 AD-340&150 PG-23

SHEAR AD-132.2

JOINT EFFICIENCIES UW-12&UW-15 AF-240&AAD-920 PG-27-4

SHELL/HEMI. HEAD UG-27;28 &31 AD-201&310&320 PG-27

HEAD UG-32&33 AD-204&350 PG-29

CONE UG-29&32 AD-203&210&310&360

NOZZLE OPENING UG-36-->42 ARTICLE-D-5&D-6 PG-32-->39

D NOZZLE NECK UG-45 AD-602

E

FLANGE APPENDIX-2 APPENDIX-3

SI

G BLIND COVE UG-34 ARTICLE-7 PG-42 TEMA

N EXPANSION JOINT APPENDIX-CC PG-31 TEMA,EJMA

TUBE SHEET APPENDIX-AA ARTICLE 4-->9 PG-13

JACKET CLOSURE APPENDIX-9

MOMENT & ALLOWABLE UG-23(d) AD-15&120

TUBE TO TUBESHEET JOINT APPENDIX-A ARTICLE F-3

EXTERNAL STIFFENER UG-29 AD-330

LETHAL SERVICE UW-2 AD-416

OPENING DISTANCE UG-42 AD-501(3) PG-42

NOZZLE NECK SHAPE Fig. UG-40 Fig.AD-540.1;610.1&612

SPECIAL CONTRUCTION UG-19 AD-102

FATIGUE EVALUATION AD160; APPENDIX-4-->6

CUTTING/ FIT-UP/ ALIGNMENT UW 31 ~ 33

WELDING GENERAL UW-3;9;30&32 AD-400&410; AF-210 PARA-11.2

F SHELL/HEMI. HEAD UW-13 AD-420 PARA-12.2.4

A NOZZLE ATTACHMENT UW-16&14 AD-600 PARA-12.2.9

WELDING REQUIREMENTS

B SHELL TO TUBESHEET Fig.13.2&13.3 AD-700 PARA-12.2.7 TENSION TEST

RI

EXTERAL STIFFENER UG-30 AD 940&920 PARA-4.5.2&1.5.3

C

A REPAIR UW-38&UCS-56 AF-250&420

TI PWHT UW-2&40;UCS56;79&67( c) AF-402&415; AT 110-115 PW-39

O PREHEAT APPENDIX-R&UCS-58 AF-41-&550 PW-38

N

DIMENSION TOLERANCE UG-80&81;UW-33&35 AF-13&135&142 PG80;81;PW-33;35

MATERIAL TRANSFER UG-77 AF-102.2 PG-77

POS-WELDER TEST UW-27-->29;48 AF-235&AF-320 UW-27,28

RT UW-11;51;52;UCL-35 TABLE AF-241-1 PW-11;51

IN NDE UT UW-53&UW-11(a)(7) TABLE AF-241-1 PW-53;11.2

S MT/PT UG-93&UG-50 TABLE AF-241-1

P HYDROSTATIC TEST UG-99 ARTICLE T-3 PG-99

E

C PNEUMATIC TEST UG-100 ARTICLE T-4

TI PROOF TEST UG-101

O PRODUCTION TEST UG-84 ARTICLE T-1;T-2; AM 202 PW-53

N STAMPING & NAME PLATE UG-116&UG-119 ARTICLE S-1&S-2 PG-101;106

INSPECTION REPORT FORMAT UG-120/ APPENDIX W ARTICLE S-3/ APPENDIX I PG-103

You might also like

- Threaded JointsDocument9 pagesThreaded JointsEssKayNo ratings yet

- Minimum Practical Wall ThicknessDocument5 pagesMinimum Practical Wall ThicknessDiana CarolinaNo ratings yet

- Catalogue Revolloy Welding ConsumablesDocument30 pagesCatalogue Revolloy Welding ConsumablesAdi SutardiNo ratings yet

- Ok-Hydraulic Oil Flushing at Terminal AreaDocument4 pagesOk-Hydraulic Oil Flushing at Terminal AreaEric TingNo ratings yet

- Material Conversion TableDocument1 pageMaterial Conversion TableravikumarangNo ratings yet

- MS-M2101 (S09) - HSSE-GP-003 ERP Rev 0Document32 pagesMS-M2101 (S09) - HSSE-GP-003 ERP Rev 0Lau Poung HieNo ratings yet

- Weld Defect Wall ChartDocument6 pagesWeld Defect Wall ChartMuhammad Attaulla KhanNo ratings yet

- Asme P NumberDocument1 pageAsme P NumberSebastian RajeshNo ratings yet

- Hims Masterlist MatrixDocument3 pagesHims Masterlist MatrixFarghud EismethNo ratings yet

- MTH - Spec Cross-Ref Chartr1Document1 pageMTH - Spec Cross-Ref Chartr1RamuAlagappanNo ratings yet

- 6 Contractor QC Resume Review ChecklistDocument1 page6 Contractor QC Resume Review ChecklistMudabbir HussainNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- Summary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTDocument11 pagesSummary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTTin Aung KyiNo ratings yet

- Doc. No Revision No Revision DateDocument6 pagesDoc. No Revision No Revision DateShyam SinghNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document2 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- Pressure Vessel Hydrotest Procedure - Google SearchDocument3 pagesPressure Vessel Hydrotest Procedure - Google SearchAsad KhanNo ratings yet

- Impact Test Requirements Enigma - ABSADocument13 pagesImpact Test Requirements Enigma - ABSASH1961No ratings yet

- Asme 1325-18 (2007)Document1 pageAsme 1325-18 (2007)Matthew TaylorNo ratings yet

- dpvc-09 Petrobras PDFDocument47 pagesdpvc-09 Petrobras PDFBilly TanNo ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Contractor QC Supervisor Resume Review ChecklistDocument1 pageContractor QC Supervisor Resume Review ChecklistAdnan ArshidNo ratings yet

- WIWA Airless Spray GunsDocument52 pagesWIWA Airless Spray Gunsosvaldo lopezNo ratings yet

- Weld Repairs:: 1) Production Repairs 2) In-Service RepairsDocument4 pagesWeld Repairs:: 1) Production Repairs 2) In-Service RepairsEhsan KhanNo ratings yet

- JIT Supervisor Verifier Training v10Document51 pagesJIT Supervisor Verifier Training v10Farghud EismethNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- ThyssenDocument0 pagesThyssenAbbas RizviNo ratings yet

- 2G & 5GDocument2 pages2G & 5GRahul MoottolikandyNo ratings yet

- Hardness Procedure OF Heat Exchanger and Pressure VesselDocument3 pagesHardness Procedure OF Heat Exchanger and Pressure VesselAozoraLazoraNo ratings yet

- Part 02 - Review of PWPS and WPSDocument9 pagesPart 02 - Review of PWPS and WPSYan FerizalNo ratings yet

- Itp For All MaterialsDocument59 pagesItp For All MaterialsTauqueerAhmad100% (1)

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNo ratings yet

- Welder Wise Repair PercentageDocument135 pagesWelder Wise Repair PercentageaakashNo ratings yet

- ITP-format For VesselsDocument5 pagesITP-format For VesselsHanuman RaoNo ratings yet

- Sensitization of Inconel 625Document9 pagesSensitization of Inconel 625nantha kumarNo ratings yet

- GRE INS-009, Flange Bolting ProcedureDocument6 pagesGRE INS-009, Flange Bolting Proceduresyed jafar100% (1)

- PWHT Procedure For Petrol Steel - CoreDocument9 pagesPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluNo ratings yet

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDocument18 pages4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNo ratings yet

- NCR AG I 055 With Vendors ReplyDocument12 pagesNCR AG I 055 With Vendors ReplymuhammedemraanNo ratings yet

- Itp PWHTDocument1 pageItp PWHTTridib DeyNo ratings yet

- HDC Quality Assurance ManualDocument9 pagesHDC Quality Assurance ManualHaniNo ratings yet

- Covered Electrodes For Stainless Steel: Avesta Electrodes Product ProgrammeDocument4 pagesCovered Electrodes For Stainless Steel: Avesta Electrodes Product Programmekamals55No ratings yet

- Wps PQR p918908091328904 PDFDocument7 pagesWps PQR p918908091328904 PDF채종언No ratings yet

- NDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofDocument9 pagesNDE TABLE For HEADER BOX - R0 Modified With Type 1 Joint ofrony16novNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- Hot Tap ProcedureDocument6 pagesHot Tap ProcedureNatarajan MurugesanNo ratings yet

- Ix+ 3. (WPQ) Welding Performance QualificationsDocument7 pagesIx+ 3. (WPQ) Welding Performance QualificationsAMAL VISHNUNo ratings yet

- P Q R - 005Document2 pagesP Q R - 005Courtney DukeNo ratings yet

- Humade Msds MaDocument5 pagesHumade Msds MadchyNo ratings yet

- Design List For Hvac Equipments: Project: Hvac System - Living Quarter Bk3-Bk10 VietsovpetroDocument2 pagesDesign List For Hvac Equipments: Project: Hvac System - Living Quarter Bk3-Bk10 VietsovpetrovamcodongNo ratings yet

- A F E S: Process Piping 670.200Document17 pagesA F E S: Process Piping 670.200puwarin najaNo ratings yet

- Ocs Engineering & Construction (India) PVT LTD: Quality Assurance DepartmentDocument1 pageOcs Engineering & Construction (India) PVT LTD: Quality Assurance DepartmentvinothNo ratings yet

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNo ratings yet

- Welding and Fabrication TechnologyDocument2 pagesWelding and Fabrication TechnologyLeonicia MarquinezNo ratings yet

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngNo ratings yet

- Snoop Leak Test LiquidDocument6 pagesSnoop Leak Test Liquidaldi_crisNo ratings yet

- 0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDocument11 pages0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDenny AgusNo ratings yet

- Test Pack ProcedureDocument10 pagesTest Pack ProcedureDaengkulle Firmansyah PuteraNo ratings yet

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDocument5 pagesSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- 3.0. Section 3 1-Itt Technical RequirementDocument12 pages3.0. Section 3 1-Itt Technical RequirementnadaNo ratings yet

- Welding Terminology and DefinitionsDocument66 pagesWelding Terminology and DefinitionsTrịnh Quốc TuyếnNo ratings yet

- 1.0 Typical Duties of Welding InspectorsDocument27 pages1.0 Typical Duties of Welding InspectorsTrịnh Quốc TuyếnNo ratings yet

- 0.0 Welding Inspector ExaminationDocument12 pages0.0 Welding Inspector ExaminationTrịnh Quốc TuyếnNo ratings yet

- 1811 611 RC 0 B PDFDocument277 pages1811 611 RC 0 B PDFTrịnh Quốc TuyếnNo ratings yet

- 1811 614 RC 0 B PDFDocument201 pages1811 614 RC 0 B PDFTrịnh Quốc TuyếnNo ratings yet

- Tta Power 2015 Vi 001Document31 pagesTta Power 2015 Vi 001Trịnh Quốc TuyếnNo ratings yet

- TTA-NDT-PMI-001 Rev.00 PDFDocument8 pagesTTA-NDT-PMI-001 Rev.00 PDFTrịnh Quốc TuyếnNo ratings yet

- Described As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Document2 pagesDescribed As 1.7225 42crmo4 in en 10083 - 1: 2006 Previously 709M40 in PD 970: 2001Trịnh Quốc TuyếnNo ratings yet

- Service Pipe Weldmap111Document38 pagesService Pipe Weldmap111Trịnh Quốc TuyếnNo ratings yet

- Joint Efficiency - Pressure Vessel EngineeringDocument5 pagesJoint Efficiency - Pressure Vessel EngineeringMuthuKumar100% (1)

- WPS 111 001.17Document10 pagesWPS 111 001.17Trịnh Quốc TuyếnNo ratings yet

- 22 Nitofill EPLVDocument3 pages22 Nitofill EPLVmyke_0101100% (1)

- Big Bore Spade & BlindDocument1 pageBig Bore Spade & Blindnedumaran.sNo ratings yet

- Polyester 20 Resin 20 FinalDocument5 pagesPolyester 20 Resin 20 FinalZdravko GrbićNo ratings yet

- WPS - 0601 00112 01 PDFDocument1 pageWPS - 0601 00112 01 PDFAnonymous zzMwR2aNNo ratings yet

- Aircraft Materials, Construction and RepairDocument41 pagesAircraft Materials, Construction and RepairMark Jovince CardenasNo ratings yet

- Robert Sorby Pyrography ManualDocument12 pagesRobert Sorby Pyrography ManualAnonymous Hz5fBwKmR100% (2)

- Asme Section Ii A Sa-351 Sa-351m PDFDocument8 pagesAsme Section Ii A Sa-351 Sa-351m PDFdavid perezNo ratings yet

- How To Avoid Cracks in PlasterDocument3 pagesHow To Avoid Cracks in PlasterShativel ViswanathanNo ratings yet

- Walter Prototype Product Handbook Threading Walter ToolsDocument124 pagesWalter Prototype Product Handbook Threading Walter ToolsChristian MedelNo ratings yet

- 13CrMo45 P12 T12 Engl PDFDocument3 pages13CrMo45 P12 T12 Engl PDFYankMulya MusaNo ratings yet

- Press ToolDocument71 pagesPress Toolamolnjainajgmail.com 7507254906No ratings yet

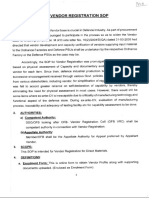

- OFB Vendor Registration SOPDocument19 pagesOFB Vendor Registration SOPramkumarNo ratings yet

- Heat Treatment Online Notes PDFDocument10 pagesHeat Treatment Online Notes PDFSandeep KadamNo ratings yet

- Key Facts Typical Wire Analysis: - Bossweld 71T-1Document1 pageKey Facts Typical Wire Analysis: - Bossweld 71T-1cj elec techNo ratings yet

- Pidicrete 55EDocument1 pagePidicrete 55Enickdash09No ratings yet

- National Standards Overview FEFCODocument4 pagesNational Standards Overview FEFCOgirisharyamane123No ratings yet

- Medical: ApplicationsDocument20 pagesMedical: ApplicationsKasia MazurNo ratings yet

- P&ID and Mass Balance Production Waste 130921-B-ModelDocument1 pageP&ID and Mass Balance Production Waste 130921-B-ModelmaizanazaNo ratings yet

- JNKI-SOP-011-Holing ProcedureDocument2 pagesJNKI-SOP-011-Holing ProcedureAvishek GuptaNo ratings yet

- MAT 2510 MCGB - Data Sheet For Suppliers Old MAT No.: 320: PropertiesDocument3 pagesMAT 2510 MCGB - Data Sheet For Suppliers Old MAT No.: 320: PropertiesDiógenes da Silva PereiraNo ratings yet

- Specifications Threaded Rod 67030045Document3 pagesSpecifications Threaded Rod 67030045Abdul RahmanNo ratings yet

- HAZOPDocument1 pageHAZOPLois ReyesNo ratings yet

- Secondary Wastewater TreatmentDocument18 pagesSecondary Wastewater TreatmentSumaiya Rashid100% (1)

- Lapox AR 101 PDFDocument2 pagesLapox AR 101 PDFOsama GabrNo ratings yet

- 204 Cu Technical DatasheetDocument6 pages204 Cu Technical Datasheetvinod kumarNo ratings yet

- VAUTID ASW 145 Engl 041016Document1 pageVAUTID ASW 145 Engl 041016maiquelernNo ratings yet

- Copper and Copper AlloysDocument19 pagesCopper and Copper AlloysYousef Adel HassanenNo ratings yet

- DOW™ LDPE 4012: The Dow Chemical Company - Low Density Polyethylene ResinDocument2 pagesDOW™ LDPE 4012: The Dow Chemical Company - Low Density Polyethylene ResinGia Dinh HotrokithuatNo ratings yet

- PT. Gapura Liqua Solutions ProductsDocument12 pagesPT. Gapura Liqua Solutions ProductsAnastasiaCMNo ratings yet

- Cerakote Brochure 2014 WebDocument2 pagesCerakote Brochure 2014 WebImaful HansaNo ratings yet