Professional Documents

Culture Documents

Ril Painting Procedure

Uploaded by

Mukesh RorOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ril Painting Procedure

Uploaded by

Mukesh RorCopyright:

Available Formats

J3 Program Adde. 10080-1-SS-PP-014-2.

2

Standard Specification Date: 29/03/2013, Rev. 0

1. SCOPE

This procedure covers the surface preparation, method of application and materials to

be used for Aluminum Dome painting for J3 Gasification project. This paint system shall

be applied at shop or field as instructed by Construction In-charge.

2. STANDARDS AND CODES

Work shall be performed in accordance with the standards and codes mentioned in

standard specification for shop and field painting, document No. 10080-1-SS-PP-014 and

also in accordance with manufacturer’s recommendations.

3. SURFACE PREPARATION

3.1 Weld spatter shall be removed and sharp or rough welds rounded and contoured.

Sharp edges shall be rounded, chamfered.

3.2 The Aluminum surface should be cleaned by high pressure fresh water wash using a

degreaser / detergent suitable for use on Aluminum surfaces to remove any traces of

oil , grease , fat contamination , soluble salt , dirt and welding flux prior to secondary

surface preparation.

3.3 When the surface is dry, sweep blasting with Aluminum oxide grains or fine grade

garnet or glass beads or any other non-metallic blasting media suitable to be used as

abrasive on Aluminum surfaces. Abrasives shall be free from any chlorides, zinc, and

iron/steel contamination. Wherever sweep blasting is practically not possible, then light

abrading to be done with suitable emery paper (3m). This can be achieved by manual or

using power tool. The surface profile shall be maintained in between 20 to 40 microns.

3.4 Prior to any coating application the substrate shall be checked for dry, clean and soluble

salt contamination by using a suitable salt contamination meter.

3.5 The maximum allowable level of contamination shall be 20mg/ M2. Surfaces that do not

meet these criteria shall be reprocessed. Should this problem occur on a frequent basis

the abrasive medium shall be re-examined for quality and if necessary the abrasive

media to be replaced.

Addendum to Field & Shop Painting Page 2 of 3

J3 Program Adde. 10080-1-SS-PP-014-2.2

Standard Specification Date: 29/03/2013, Rev. 0

3.6 Surfaces prepared for coating shall be coated the same day or before any contamination

and visible rusting occurs (the time elapsed between blast cleaning and commencement

of Painting shall under no circumstances exceed 4 hours, but in any case must

commence before signs of degradation occur).

4. PAINT STORAGE AND APPLICATION

Primer and Paint materials shall be delivered to the job site in the original container

bearing the batch No., Manufacturer’s name, product designation, shelf life, date of

manufacturing etc. Detailed storage and application procedures are described in Clause

No. 6.2 of field and shop painting specification No. 10080-1-SS-PP-014.

5. COLOUR SCHEDULE

The Color schedule shall be matched with camouflaging as Instructed by Construction

In-charge. Color equivalent standards are mentioned in Appendix-D of field and shop

painting specification No. 10080-1-SS-PP-014.

6. PAINT MATERIALS

The following Type of paints shall be used for application on aluminum Dome. The paint

details and recommended product names are mentioned in Appendix-A and Appendix-B

of field and shop painting specification No. 10080-1-SS-PP-014.

Primer – Type-8 (High built epoxy for SS/Aluminium)

Intermediate coat – Type-5 (High built MIO epoxy)

Top coat – Type-6 (Aliphatic urethane finish)

(Color as instructed by construction In-charge)

7. INSPECTION AND TESTING

Stage wise Inspection to be carried out for surface preparation, Method of application,

Dry Film thickness, and Adhesion test etc as mentioned in Appendix-F of field and shop

painting specification No. 10080-1-SS-PP-014.

Addendum to Field & Shop Painting Page 3 of 3

You might also like

- Project Supplier List: Item Code: Item DescriptionDocument3 pagesProject Supplier List: Item Code: Item Descriptionradheshyam0% (1)

- Cathodic Protection BOMDocument4 pagesCathodic Protection BOManonymous542No ratings yet

- General Specification FOR Pressure VesselsDocument13 pagesGeneral Specification FOR Pressure Vesselssumit kumarNo ratings yet

- Painting Release RFIDocument2 pagesPainting Release RFISivaratnam NavatharanNo ratings yet

- AG Piping Specification SPEL en M SG 12 002 Rev0Document31 pagesAG Piping Specification SPEL en M SG 12 002 Rev0cchristt2584No ratings yet

- DS - Epilux - 9 - HB - Phenolic - Coating F15Document2 pagesDS - Epilux - 9 - HB - Phenolic - Coating F15parvez_ameenNo ratings yet

- 6-79-0013 Rev 2Document6 pages6-79-0013 Rev 2MONER MANUSNo ratings yet

- Eil SpecDocument37 pagesEil SpecJames100% (1)

- QW-403.2 InterpretationDocument1 pageQW-403.2 Interpretationlaz_kNo ratings yet

- 6 MM TCDocument1 page6 MM TCpranesh kadamNo ratings yet

- Line List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubDocument1 pageLine List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubAli AsadiNo ratings yet

- Electrode Consumption On Pipe WeldingDocument2 pagesElectrode Consumption On Pipe Weldinganjangandak2932100% (1)

- Siropol 7440Document3 pagesSiropol 7440shafeeqm3086No ratings yet

- Specification For NDE For Piping B016-6-44-0016 - Rev. 3Document21 pagesSpecification For NDE For Piping B016-6-44-0016 - Rev. 3Ayush Choudhary50% (2)

- Sor BPCL KochiDocument79 pagesSor BPCL KochiPrafulla PatilNo ratings yet

- Duplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Document13 pagesDuplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)aleeimeran100% (1)

- Summary Paint Mix RatioDocument1 pageSummary Paint Mix RatioVijay Kumar Konathala100% (1)

- Form 167Document239 pagesForm 167Kumar Navneet SinghNo ratings yet

- Piping Material EquivalentsDocument1 pagePiping Material EquivalentspejnorozyNo ratings yet

- Rationalise List Welding ConsumablesDocument19 pagesRationalise List Welding ConsumablesMayank SadaniNo ratings yet

- Protocol Column AlignmentDocument9 pagesProtocol Column AlignmentManikandan elumalaiNo ratings yet

- Static Method of Wind Analysis of Piping Systems in Caesar II Using Pressure Vs Elevation MethodDocument6 pagesStatic Method of Wind Analysis of Piping Systems in Caesar II Using Pressure Vs Elevation MethodPrakashNo ratings yet

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 pagesA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNo ratings yet

- CHT Report On Hsaw Vs Lsaw PipesDocument5 pagesCHT Report On Hsaw Vs Lsaw Pipesmahotkat100% (1)

- Tender Document PT 051 PDFDocument148 pagesTender Document PT 051 PDFMadhav PurohitNo ratings yet

- Saddle Build-Up Lamination & Nozzle Fixation Method Statement (5222)Document13 pagesSaddle Build-Up Lamination & Nozzle Fixation Method Statement (5222)ABAID ULLAHNo ratings yet

- Material Test Certificate: Diamond Pipe Supports Pvt. LTDDocument1 pageMaterial Test Certificate: Diamond Pipe Supports Pvt. LTDAneesh ConstantineNo ratings yet

- 4711Document10 pages4711Gaurav AgarwalNo ratings yet

- Jun 2018 153707867T2JQPG3GPFRDocument61 pagesJun 2018 153707867T2JQPG3GPFRANIL KUMARNo ratings yet

- Electrode SelectionDocument85 pagesElectrode SelectionVaibhavNo ratings yet

- Mfjo694 MRB 0001 IndexDocument2 pagesMfjo694 MRB 0001 IndexAkhtar Ansari100% (1)

- 7-12-0037 Rev 3Document1 page7-12-0037 Rev 3cynideNo ratings yet

- Eil RFQDocument221 pagesEil RFQBIRANCHI100% (1)

- A. For Welding Sa 210 Gra1 To Sa 210 GR A1Document1 pageA. For Welding Sa 210 Gra1 To Sa 210 GR A1911targa100% (1)

- 6 77 0001 Rev - 4 PDFDocument40 pages6 77 0001 Rev - 4 PDFRam Kadam0% (1)

- General Specification For Welding and Weld Inspection (EIL)Document19 pagesGeneral Specification For Welding and Weld Inspection (EIL)Mitchel Fernandes100% (6)

- B1ADocument7 pagesB1ASumantrra Chattopadhyay0% (1)

- Saep 122Document18 pagesSaep 122Handa Bin AdiNo ratings yet

- Is 3502 2009 PDFDocument10 pagesIs 3502 2009 PDFRajashekar.PNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- EIL Painting Spec B16!79!41 PLS 01Document61 pagesEIL Painting Spec B16!79!41 PLS 01mANISH THIRANI100% (3)

- Method Statement For Repair Deethanizer Reflux Pump - CommentsDocument5 pagesMethod Statement For Repair Deethanizer Reflux Pump - CommentsRahmat HidayatNo ratings yet

- Reliance - 10080-1-SS-PP-014 - REV2Document58 pagesReliance - 10080-1-SS-PP-014 - REV2Blain86% (7)

- HPCL - Palanpur Terminal EIADocument130 pagesHPCL - Palanpur Terminal EIAKalai SelvanNo ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- BIT Project EIL 91020Document41 pagesBIT Project EIL 91020Gourab KunduNo ratings yet

- Line History SheetDocument46 pagesLine History SheetBhanu Pratap Choudhury33% (3)

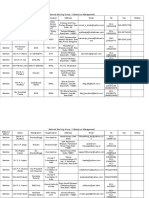

- Composite Construction Works For CNG Station at Kovvur, West Godavari District, A.PDocument209 pagesComposite Construction Works For CNG Station at Kovvur, West Godavari District, A.Pvinay1999No ratings yet

- Responsibility Matrix For Shop Piping WorksDocument5 pagesResponsibility Matrix For Shop Piping WorksRenny DevassyNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- 3500-00 Simathane Gloss (Finish Coat)Document3 pages3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoNo ratings yet

- Strainer DescriptionDocument321 pagesStrainer DescriptionChirag ShahNo ratings yet

- Specifications of LR BendDocument11 pagesSpecifications of LR BendPrafulla PatilNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- Job Card For Welders Qualification: Hi-TECH Engineering Corporation India Pvt. LTD., BaramatiDocument2 pagesJob Card For Welders Qualification: Hi-TECH Engineering Corporation India Pvt. LTD., Baramatig_sanchetiNo ratings yet

- A223 6 44 0074Document15 pagesA223 6 44 0074mishtinilNo ratings yet

- Metal Chemical CompositionDocument1 pageMetal Chemical CompositionprathmeshNo ratings yet

- SATIP-N-001-02 Rev. 4Document2 pagesSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- Rates of Pakur Variety Stone Aggregates at Different Railway Yards PDFDocument5 pagesRates of Pakur Variety Stone Aggregates at Different Railway Yards PDFSwapan Kumar DharaNo ratings yet

- 1 SS PP 014 Add2.2Document3 pages1 SS PP 014 Add2.2Niraj PandyaNo ratings yet

- REVIEWDocument12 pagesREVIEWGoka Agbesi GokaNo ratings yet

- Applichem Case-SCM Sec B Group-2Document11 pagesApplichem Case-SCM Sec B Group-2Ayush RanjanNo ratings yet

- HR Report ON Moser BaerDocument77 pagesHR Report ON Moser BaerKomal DhaliwalNo ratings yet

- Segmentation - Ipynb - ColaboratoryDocument8 pagesSegmentation - Ipynb - ColaboratoryManjot KaurNo ratings yet

- Sony Video Camera Manual PDFDocument118 pagesSony Video Camera Manual PDFGary Hoehler100% (1)

- Multiquadrant Dynamics in The Speed-Torque PlaneDocument41 pagesMultiquadrant Dynamics in The Speed-Torque PlanethanvandhNo ratings yet

- Graphics in C LanguageDocument8 pagesGraphics in C LanguagePattabhi RamaraoNo ratings yet

- Contact List For All NWGDocument22 pagesContact List For All NWGKarthickNo ratings yet

- Compact FlashDocument9 pagesCompact Flashenpr87reddyNo ratings yet

- XDocument20 pagesXAlberto BarrosNo ratings yet

- TemplateDocument17 pagesTemplatedaveNo ratings yet

- Man Ssa Ug en 0698Document43 pagesMan Ssa Ug en 0698Andy LNo ratings yet

- Colebrook EquationDocument3 pagesColebrook EquationMuhammad Ghufran KhanNo ratings yet

- Firearms in America 1600 - 1899Document310 pagesFirearms in America 1600 - 1899Mike100% (3)

- Technology A Way of RevealingDocument24 pagesTechnology A Way of RevealingSheena jhane Magana100% (1)

- Risk Solver Platform ReferenceDocument247 pagesRisk Solver Platform Referencemj_davis04No ratings yet

- Monthly Ladder Inspection ChecklistDocument4 pagesMonthly Ladder Inspection ChecklistPeter Sare WolloNo ratings yet

- TCAD Workshop Volume IDocument69 pagesTCAD Workshop Volume IVipan SharmaNo ratings yet

- Classroom PoliciesDocument4 pagesClassroom PoliciesadrianrivalNo ratings yet

- Fuses & Circuit Breakers PDFDocument13 pagesFuses & Circuit Breakers PDFCarlos Luis Santos SomcarNo ratings yet

- Centaour 50 Solar TurbineDocument2 pagesCentaour 50 Solar TurbineTifano KhristiyantoNo ratings yet

- Tyco SprinklerDocument3 pagesTyco SprinklerVitor BrandaoNo ratings yet

- PS User Security SetupDocument30 pagesPS User Security Setupabhi10augNo ratings yet

- Riviera Sponsorship LetterDocument7 pagesRiviera Sponsorship LetterAnirudh Reddy YalalaNo ratings yet

- Differences Between Huawei ATCA-Based and CPCI-Based SoftSwitches ISSUE2.0Document46 pagesDifferences Between Huawei ATCA-Based and CPCI-Based SoftSwitches ISSUE2.0Syed Tassadaq100% (3)

- Oct 15 Action Research PLT AgendaDocument2 pagesOct 15 Action Research PLT Agendaapi-231962429No ratings yet

- Ibm 3592 Tape Cartridge CatalogueDocument4 pagesIbm 3592 Tape Cartridge CatalogueamsfibNo ratings yet

- Chapter 8 Designing and Developing Effective HRD ProgramsDocument37 pagesChapter 8 Designing and Developing Effective HRD ProgramsVincent Raj KumarNo ratings yet

- CM Line Catalog ENUDocument68 pagesCM Line Catalog ENUdmugalloyNo ratings yet