Professional Documents

Culture Documents

Chapter 5 PDF

Uploaded by

Ismail MohammadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 5 PDF

Uploaded by

Ismail MohammadCopyright:

Available Formats

Chapter 5

Meter Design Standards

Network Development & Design Standards

Chapter 5

Meter Design Standards

Table of Contents

I. PURPOSE ............................................................................................................................................. 1

II. SCOPE .................................................................................................................................................. 1

III. RESPONSIBILITIES & AUTHORITIES ................................................................................................. 1

IV. ABBREVIATIONS, DEFINITION OF TERMS & KEY REFERENCES ................................................. 2

IV.1 Abbreviations & Definition of Terms .................................................................................... 2

IV.2 Key References......................................................................................................................... 2

V. TYPES OF FLOW METERS................................................................................................................. 2

V.1 KAHRAMAA Approved Meter List ........................................................................................ 3

V.2 Magnetic Flow Meters............................................................................................................. 3

V.3 Transit-Time Ultrasonic Flow Meters ..................................................................................... 4

V.4 Fluidic Oscillator Flow Meters................................................................................................ 5

V.4.1 Domestic Meter Model SM700 Failures .................................................................. 6

VI. KAHRAMAA SELECTION OF STANDARD FLOW METERS .......................................................... 7

VI.1 Life cycle costs .......................................................................................................................... 7

VII. METER CONFIGURATIONS ............................................................................................................10

VII.1 Domestic Meters .....................................................................................................................10

VII.1.1 Small Meters ...............................................................................................................10

VII.1.2 Large Meters ..............................................................................................................10

VII.2 Bulk Customer Meters ............................................................................................................10

VII.3 District Meters .........................................................................................................................11

VII.4 Facility Meters ........................................................................................................................11

VII.5 Monitoring Stations ................................................................................................................11

VII.6 Special Considerations..........................................................................................................12

VII.6.1 Meter Data Collection ...............................................................................................12

VIII. METER SIZING CRITERIA .................................................................................................................12

IX. METER INSTALLATION .....................................................................................................................14

IX.1 Installation Conditions ...........................................................................................................14

IX.2 Chambers and Meter Box Sizing ........................................................................................14

IX.2.1 Chambers ....................................................................................................................14

IX.2.2 Meter Boxes ................................................................................................................14

IX.3 Installation Standard Drawings ...........................................................................................14

X. KEY PERFORMANCE INDICATORS................................................................................................15

XI. RECORDS ...........................................................................................................................................16

XII. LIST OF TABLES .................................................................................................................................16

XIII. LIST OF FIGURES ..............................................................................................................................16

Issue : 0.0 24-04-2012 Page i of i

Chapter 5

Meter Design Standards

I. PURPOSE

The purpose of this chapter is to discuss and provide meter design standards for the

KAHRAMAA (KM) water distribution system.

II. SCOPE

This chapter includes meter design standards that cover all types and sizes of:

■ Customer Metering

o small and large meter customers

o bulk customers

■ District Metering

■ Facilities Metering

o Independent Water and Power Producers (IWPP) delivery point,

o inlet and outlet of Reservoir Pumping Station (RPS)

■ Meter Selection

■ Other monitoring requirements in the system for the purpose of measuring periodic and

real time data for the following parameters (including Quadrina Insertion Points):

o pressure

o pH

o residual chlorine

o conductivity

o temperature

All of the above mentioned metering standards should also include the design of

corresponding meter assemblies and chambers of various applicable diameter sizes according

to the various customer demands.

Reasoning behind each design standard recommendation is also covered.

III. RESPONSIBILITIES & AUTHORITIES

The standards provided in this chapter are established and applied by KM. All KM staff, as

well as consultants providing design services to KM, are responsible for designing meters in

accordance with the standards contained herein and any other official KM published and/or

approved design standards. Standard meters are selected by KM based on the guidance

contained in this document. When meter selections change, KM staff will update Table V-1 of

this chapter accordingly.

Any deviation from the standards/guidelines outlined in this document must be reviewed and

approved by KM.

Issue : 0.0 24-04-2012 Page 1 of 16

Chapter 5

Meter Design Standards

IV. ABBREVIATIONS, DEFINITION OF TERMS & KEY REFERENCES

IV.1 Abbreviations & Definition of Terms

Abbreviations and definition of terms used in this chapter are consistent with the Standard

Terminologies, Abbreviations, Acronyms, and Definitions provided in the Glossary of

Documents. The Glossary of Documents is located at the beginning of this Manual.

IV.2 Key References

■ General Specifications of Main Laying Materials for Waterworks, Latest Edition.

■ General Specifications for Mainlaying Contracts.

■ Water Network Standard Drawings.

■ Qatar Construction Standards, Plumbing Work Section, Latest Edition.

■ Regulations of Internal Water Installations and Connection Works.

■ Water Grid Code.

■ Related Standards from the International Organization of Legal Metrology (OIML)

■ American Water Works Association (2001). Manual of Practice M6 – Water Meters

Selection, Installation, Testing and Maintenance.

V. TYPES OF FLOW METERS

Water flow meters can be categorized as either displacement or non-displacement type

meters. Non-displacement types can further be divided into various types as depicted in

Table V-1. For additional understanding of each type of meter, the American Water Works

Association (AWWA) Manual of Practice M6 provides in-depth descriptions of various types

of meters.

Table V-1 Meter Types from AWWA Manual of Practice M6

Type Usual Range of Sizes

I. Displacement mm

A. Rotating disc 13-50

B. Oscillating piston 13-50

II. Non-displacement

A. Velocity

Multi-jet 15-50

Magnetic-pickup turbine 6-300

Turbine 20-500

Propeller 50-1800

Proportional 80-300

B. Differential Pressure

Fixed opening, variable differential

Orifice 50-600

Venturi, flow nozzle, flow tube 50-2100

Pitot tube Unlimited

Variable opening, fixed differential rotameter 6-100

Page 2 of 16 Issue: 0.0 24-04-2012

Chapter 5

Meter Design Standards

Table V-1 Meter Types from AWWA Manual of Practice M6

Type Usual Range of Sizes

C. Electronic velocity

Electromagnetic 2-1800

Ultrasonic 13-1800

D. Level measurement

Weir, Parshall flume, etc. Unlimited

III. Compound

A. Standard compound 50-200

B. Fire service 80-300

V.1 KAHRAMAA Approved Meter List

KAHRAMAA Material Specifications require electronic flow meters with no moving parts and

emphasize the use of magnetic (magmeter), ultrasonic, or fluidic oscillator flow meter types.

The advantages and disadvantages of these three meter types are discussed later in this

chapter.

Table V-2 KM List of Suppliers provides a current list of approved suppliers documented by

the Materials Standards & Specifications (Water) Section (MSSWS). One company is

approved for meters 15mm – 40mm and three companies for 50mm and larger meters. This

data is continuously updated and is only for reference. For any official waterworks matter,

please refer to the MSSWS Section for further inquiries and verification.

Table V-2 KM List of Suppliers

Electronic Meters

A) Domestic Meters (15mm- 40mm)

17.01 Severn Trent (Smart Meter), UK

M/s. Pegos

(Model SM700)

B) Bulk Meters (50mm and above)

17.01 M/s. ABB Instrumentation Ltd

M/s. ABB Instrumentation Ltd

(Model AquaMaster S)

17.02 M/s. Siemens

M/s. Al Gaith Oilfield Supplies

(Model MAG 8000)

17.03 M/s. Endress Hauser, France;

Switzerland M/s. Darwish Petroleum and Industrial Services W.L.L.

(Model Promag 53W)

V.2 Magnetic Flow Meters

A magnetic flow meter generates a magnetic field around a section of pipe. As water passes

through the magnetic field it induces a small electric current. The current is proportional to the

velocity of the water flow which allows the meter to convert the electric current value to a flow

value.

Advantages of magnetic flow meters include:

■ No obstruction to flow.

Issue : 0.0 24-04-2012 Page 3 of 16

Chapter 5

Meter Design Standards

■ Minimum effective head loss, essentially that of the straight pipe equivalent of the

meter (unless meter spool size is reduced from pipe size, causing head loss);

■ Magnetic flow meters are highly suitable for applications where low head loss is

essential.

■ Available over a wide range of sizes from 2.5 mm to 1.5 m in diameter.

■ Bidirectional, therefore, suitable for measuring reverse or net flows.

■ Variations in fluid density, viscosity, pressure, and temperature have little effect on

performance.

Disadvantages of magnetic flow meters include:

■ Metered liquid must have an electrical conductivity of 5 µS/cm or greater (this is not a

problem with finished drinking water).

■ For smaller pipe sizes, the meters become relatively bulky and expensive.

■ High accuracy is expensive, and each meter must be individually calibrated in a water

test circuit.

■ The meter is sensitive to the geometry and electric properties of the flow tube and

magnetic core, and is sensitive to variations in the coil supply current.

V.3 Transit-Time Ultrasonic Flow Meters

In a transit-time sonic (or ultrasonic) flow meter, a pair of transceivers (transmitter/receiver) is

positioned diagonally across the meter body. The transceivers transmit and receive an

ultrasonic pulse in the direction of flow, followed by a return pulse against the direction of

flow. The time difference between the two pulse transmissions through the stream is a function

of fluid velocity and, by computation, the rate of flow.

Advantages of transit-time ultrasonic flow meters include:

■ No obstruction to flow, thus no head loss.

■ Not restricted to use with conductive liquids (as are magnetic flow meters).

■ Clamp-mounted meters do not jeopardize or penetrate pipe wall structure.

■ Clamp-mounted meters do not interrupt process flow during maintenance or

replacement.

■ No mechanical moving parts.

■ Adaptable to a wide range of pipe diameters and materials.

■ Accurate readings of flows down to 0.03 m/sec.

■ Low installation and operating costs.

■ Bidirectional flow is allowable.

Disadvantages of transit-time ultrasonic flow meters include:

■ Sensitive to change in fluid composition.

■ High solids content or entrained bubbles distort and block propagation of sound

waves.

■ Sensitive to flow-velocity profile; accuracy can be impaired by changes in pipe wall

roughness and by changes from laminar to turbulent flow.

■ Accuracy impaired by upstream and downstream flow disturbances, such as elbows

and valves, which affect the velocity profile.

■ Positioning of the opposing transceivers is critical to ensure signal interception.

Page 4 of 16 Issue: 0.0 24-04-2012

Chapter 5

Meter Design Standards

■ In clamp-mounted use, the presence of sound absorptive or scattering scale or coating

on the inner walls of the pipe may prevent the meter from working (this is not true

when transceivers are mounted through the wall on a spool piece).

■ Sensitive to noise and vibration.

V.4 Fluidic Oscillator Flow Meters

In a fluidic oscillator flow meter, water enters the fluidic oscillator through a nozzle that forms

an accelerated jet. The jet will initially be drawn to one of two diffuser walls once it enters

the flow chamber and travel along that wall and exit the flow chamber. A small portion of

this flow will not exit the flow chamber, but instead get caught in the feedback channel, which

returns the water to the base of the incoming jet. Subsequently, this causes the jet to flip to the

opposite side of the chamber where it will travel along the other diffuser wall to then exit the

flow chamber. Once again, a small portion of this will be returned via the other feedback

channel and the whole process is repeated. The frequency of this oscillation between the

diffuser walls is measured by electrodes placed next to each diffuser wall and relates to the

rate of flow through the chamber. A pair of powerful magnets held within the flow chamber

induces an electrical charge in the jet of water. The electrodes then sense the induced current

and the rate of oscillation is calculated, allowing a measure of total flow to be found. 1 A

visual of this process is shown in Figure V-1 Fluidic Oscillator Flow Meter.

Figure V-1 Fluidic Oscillator Flow Meter

Advantages of fluidic oscillator flow meters include:

■No moving parts to wear out or jam.

■ Unaffected by particulates.

■ Does not measure air.

■ Can be read visually or electronically, avoiding manual input errors.

■ Accurate at low flow velocities.

Disadvantages of fluidic oscillator flow meters inlcude:

1 Severn Trent Services, United Kingdom

Issue : 0.0 24-04-2012 Page 5 of 16

Chapter 5

Meter Design Standards

■ Flow pattern through meter results in significant head loss (See Table V-3).

Metallic electrodes can corrode due to contact with the measured substance, which can

cause leak paths to the electronic components. This can lead to failure. 2

Table V-3 Domestic Meter Model SM700 Data

Performance Data - SM700 110 m3/day 110 m3/day 165 m3/day

(All Models) 16 mm 16 mm x 20 mm 20 mm

Pressure Rating (bar) 10 10 10

Pressure Loss at 55 m3/day (bar) 0.3 0.2 0.1

Pressure Loss at 110 m3/day (bar) 1.0 0.6 0.45

Pressure Loss at 165 m3/day (bar) N/A N/A 1.0

Normal Flow Limits (m3/day) 5.5-110 5.5-110 11-165

Low Flow Accuracy > 95% (m3/day) 0.7 0.7 1.4

Starting Flow (m3/day) 0.5 0.5 0.8

V.4.1 Domestic Meter Model SM700 Failures

Meter problems may still arise even if proper selection protocol and good judgment are

followed when selecting a meter. This is the case with the current domestic meter model

SM700. The readout goes blank and the meters are failing in unacceptable numbers.

The failures are attributed to high temperatures due to the harsh Qatar environment. To

resolve issues when they occur requires experienced personnel to provide insight to develop a

plan. First, the problem must be positively identified. Usually this will require an investigation

to document observed conditions that coincide with the failures. For this specific issue with the

S700 model meter, a recommendation was developed to resolve this problem by

implementing the following actions:

■Verify the meter is failing and not the battery power source.

■ Install a recording temperature sensor at selected locations representing each type of

installation configuration to determine the peak temperature in various cabinet or open

arrangements.

■ Install a shade over several of the cabinets such that the sun’s rays do not reach any

part of the cabinet between approximately 10 a.m. and 4 p.m. Record the

temperature with shades on the cabinets to determine the impact of the shades. Note if

cabinets are vented or not.

■ Contact the manufacturer with a request to verify that the temperatures encountered

are within the operational parameters of the selected meter.

■ If temperatures are within acceptable limits for the meter, the manufacturer should

replace the faulty meters with fully functioning units.

■ If the temperatures are greater than the acceptable range for the meter, have the

manufacturer propose a solution that may include replacing the meter readout with a

high temperature readout that will work within the required temperature range.

The above actions should resolve the meter failures. If, however, a satisfactory resolution is not

produced, alternative actions must be taken. Two possible solutions include:

2 Universal Metering Ltd., United Kingdom

Page 6 of 16 Issue: 0.0 24-04-2012

Chapter 5

Meter Design Standards

■ Reject continued use of the current meter model and select a different meter suitable

for the conditions.

■ Modify installation conditions to reduce the ambient temperature if it is above the

meter’s stated specifications. This could possibly require shading all installations or

even adding mechanical fans to cabinets to reduce the temperature.

VI. KAHRAMAA SELECTION OF STANDARD FLOW METERS

Measuring the quantity of water produced by IWPPs and customer usage for billing purposes

is a primary function for meters. Accurate and convenient methods of measuring flow, volume,

pressure, and other parameters throughout the distribution network provide data necessary to

evaluate system performance for planning effective improvements and to efficiently manage

the day-to-day operation of the water system.

Proper selection of both the size and type of meter for each installation is critical to insure

accurate flow measuring. The service connecting pipe is often oversized to allow for future

increase in flows, to reduce pressure for long pipe runs, or for emergency flow requirements

during a fire event. In such instances, simply matching the pipe size will often result in too

large a meter for the current flows and the meter accuracy suffers. The type of meter to use is

determined by the anticipated range of flow rates, plus allowable pressure loss. Low flow

values can impact meter accuracy and significant flow volume below the low flow value will

result in unaccounted water. KM selects meter manufacturers and only allows installation of the

currently approved meter models. Figure VI-1, Meter Selection Flow Chart, provides meter

selection criteria to consider when evaluating different meters from prospective suppliers.

VI.1 Life cycle costs

Life cycle costs for meters, other instruments, and appurtenances are very important to

consider when selecting the right flow meter. Life cycle costs that should be evaluated include:

■ Initial cost

■ Installation cost

■ Replacement cost

■ Maintenance cost

■ Availability of parts and technical support (present and future)

■ Longevity

■ Energy cost to operate

■ Risks of trying new, unproven types.

Issue : 0.0 24-04-2012 Page 7 of 16

Chapter 5

Meter Design Standards

Figure VI-1 Meter Selection Flow Chart

Page 8 of 16 Issue: 0.0 24-04-2012

Chapter 5

Meter Design Standards

Several references are available for meter selection guidelines. One source is AWWA

Manual of Practice M6, Water Meters- Selection, Installation, Testing, and Maintenance.

Recommended factors and features to be considered when selecting meters include:

1. Accuracy limits

Meters should meet International Organization of Legal Metrology – OIML R49

standards.

2. Flow display unit for customer meters

The meter must include an integrated flow display unit for the display of flow data.

The flow display unit must be resistant to corrosion. The flow display unit must be of a

size and type that is easy to read with clearly specified units and must indicate and/or

enable a determination of the following parameters to be made:

Cumulative flow totalizer able to be expressed in megalitres (ML) with a minimum of a

six digit display, and instantaneous flow rate able to be expressed in litres/second

(L/s).

3. Output requirements

The meter must have the capability to provide an electronic output suitable for its

application.

4. Electrical power source

Where an installed meter relies in any way on an electrical power source, it should

have a non-volatile memory to ensure that recorded data is not lost in the event of a

power or battery failure. The meter must be designed such that in the event of an

external power supply failure (AC or DC), the meter indication of volume just before

failure is not lost, and remains accessible for a minimum of one year. Any other

properties or parameters of the meter should not be affected by an interruption of the

electrical supply. The power supply should be secured from tampering or any such

tampering will be evident.

5. Water quality

The meter must be able to operate accurately where water contains suspended solids

and/or entrained air.

6. Flow direction for District Meters

The meter must be labeled so as to show the direction of flow, orientation and any

other necessary installation information to achieve the required accuracy. The flow

volume totalized must measure and subtract backflow from forward flow to give an

actual total volume in the labeled flow direction.

Issue : 0.0 24-04-2012 Page 9 of 16

Chapter 5

Meter Design Standards

7. Security

The meter must be tamper proof and include protection devices that prevent and/or

indicate tampering of the meter.

8. Materials

The meter must be manufactured from sound, durable, and corrosion resistant

materials. Plastic should not be allowed for the body or threaded connections.

All parts of the meter in contact with water must be manufactured from materials that

are non-toxic, non-reactive and biologically inert.

9. Maintenance

The meter must be designed for easy and quick maintenance and cleaning. It should

be of a type that incorporates a self-cleaning mechanism.

VII. METER CONFIGURATIONS

Installation requirements vary based upon the meter configuration category. All meter

installations should be provided with isolation valves. KM Standard Drawings show typical

configurations that should be followed. Table IX-1 listing the standard drawings applicable to

meter installations is found in Section IX.3 Installation Standard Drawings. Deviations from the

standards must be approved by Head, Materials Specifications and Standards (Water)

Section.

VII.1 Domestic Meters

Domestic meters can be broken down into small and large configurations. Installation of both

small and large configurations should comply with the standard drawings listed in Table IX-1

of Section IX.3 Installation Standard Drawings .

VII.1.1 Small Meters

Flows less than 165 m3/day (6.9 m3/hr) are considered small meters. See General

Specifications of Main Laying Materials for Waterworks, Section - 14 Electronic Flow meter-

Domestic Type 1/2"(15mm) – 1 1/2"(40mm) and other references for material and installation

specifications and details.

VII.1.2 Large Meters

Flows greater than 165 m3/day (6.9 m3/hr) but less than 600 m3/day (25 m3/hr) are

considered large meter customers. See General Specifications of Main Laying Materials for

Waterworks, Section – 15 Electronic Flow meters [Bulk & District] and other references for

material and installation specifications and details.

VII.2 Bulk Customer Meters

Flows equal to or in excess of 600 m3/day (25 m3/hr) are considered bulk customers. A bulk

customer meter will be required to measure flow into the development. Depending upon the

nature of the development, such as a housing complex, additional meters inside the customer’s

property may be required.

Page 10 of 16 Issue: 0.0 24-04-2012

Chapter 5

Meter Design Standards

In addition to measuring flow, other parameters to be monitored include pressure and water

quality. Locations of monitoring facilities will be as directed by KM during project

development.

See General Specifications of Main Laying Materials for Waterworks (Latest Edition), Section –

15 Electronic Flow meters [Bulk & District] and other references for material and installation

specifications and details.

Installation of bulk customer meters should comply with standard details adopted by KM.

Appropriate details can be found in Table IX-1 in Section IX.3 Installation Standard Drawings.

VII.3 District Meters

Flow meters should be installed at the points where major supplies enter the network,

downstream of main divergence points on the transmission or distribution system main, and at

entry points to water zones/districts, and other distribution blocks. A monitoring insertion

point should be provided at each meter location as described in the following Section VIII.5

Monitoring Stations.

Additional monitoring requirements for district metering locations are to be determined by KM

during the project development phase which may include the following parameters:

■ Pressure

■ Water Quality Stations

o pH

o residual chlorine

o conductivity

o temperature

o Oxidation-Reduction Potential (ORP)

Installation of district meters, Quadrina Insertion Points, and miscellaneous monitoring

instruments should comply with the standard drawings identified and listed in Table IX-2 in

Section IX.3 Installation Standard Drawings.

VII.4 Facility Meters

IWPP connection points and inlet and outlet piping to RPS facilities require metering and

pressure sensing instruments with SCADA for continuous real-time monitoring.

Additional requirements for Facility Meters are found in the Water Grid Code.

Installation of Facility Meters should comply with standard drawings identified and listed in

Table IX-1 in Section IX.3 Installation Standard Drawings.

VII.5 Monitoring Stations

Monitoring stations to allow insertion of instruments to monitor various functions are required

for special purposes as identified in the meter classification descriptions above. Quadrina

Insertion points at each district and bulk metering point are required to allow installation of

temporary flow meters to verify proper function and calibration of the meter. Insertion

stations are required in DMAs at high and low points for monitoring system pressures. Insertion

points are also required at select locations as determined by KM throughout the distribution

Issue : 0.0 24-04-2012 Page 11 of 16

Chapter 5

Meter Design Standards

network where water quality or system parameters must be determined for reliable

operation.

Monitoring stations consist of a ferrule with an isolation valve that provides a minimum of 50

mm clear opening. The station should be located in a straight section of pipe at a minimum of

10 pipe diameters downstream and 5 pipe diameters upstream of any fittings or connections

that may influence the water flow pattern. At locations where flow may reverse, the minimum

downstream straight pipe length should be increased to 10 pipe diameters.

VII.6 Special Considerations

VII.6.1 Meter Data Collection

Remote reading meters are considered most economical and in some cases essential. For

example, if a meter is located in a traffic lane or in a large chamber that qualifies as a

confined space, a remote reading meter allows access to data without putting the meter

reader in danger.

Units that allow encoding devices to collect data remove a level of error from the data

collection process.

KM’s current specifications and standards regarding remote reading meters promote the best

technology and procedures available today. This is in line with the industry standards and

should be continued.

VIII. METER SIZING CRITERIA

The flow demand against the development has to be determined when sizing a meter. After

determining the range of flows required, select the smallest meter that will measure the

required flow at an acceptable level of accuracy.

Meter sizing is based on manufacturer’s recommendations for minimum and maximum velocities

through their specific meter. Table VIII-1 presents the manufacturers’ data for currently

approved meters. Meter manufacturers may change and this data may not always be current.

It is to be used only as reference information. For any official waterworks matter, please

refer to the Materials Specifications and Standards (Water) Section for further inquiries and

verification of manufacturers and the current meter model accepted by KM.

The pressure loss through the meter should be considered when designing the pipeline or

service connection. For residential meter installations, Table V-3 previously presented in

Section V.4 of this chapter for the S700 model meter should be reviewed. The designer should

verify if this model is still the one currently used by KM.

The larger meters currently used by KM are of the magmeter type described in Section V.2 of

this chapter. Headloss through the meter is negligible and does not need to be considered as

significant. Again, the designer should verify the model currently used by KM.

Page 12 of 16 Issue: 0.0 24-04-2012

Chapter 5

Meter Design Standards

Table VIII-1, Meter Sizing Chart

Minimum to Manufacturer & Model

Maximum Flow Severn Trent ABB Siemens Endress Hauser

(m3/hr) (SM 700) (AquaMaster S) (MAG 8000) (Promag 53W)

0.1 to 4.5 16 x 20 - - -

0.15 to 6.9 20 - - -

0.45 to 25 - 50 50 -

0.45 to 63 - 65 50 -

2.1 to 66 - 80 65 50

0.64 to 100 - 80 65 -

3.6 to 120 - 100 80 65

1.0 to 160 - 100 80 -

5.4 to 180 - 150 100 80

1.6 to 250 - 150 100 -

8.7 to 282 - 150 125 100

2.5 to 400 - 150 125 -

13.2 to 450 - 200 150 125

20 to 600 - 200 150 150

4.0 to 630 - 200 150 -

6.4 to 1000 - 250 200 -

35 to 1100 - 300 250 200

10.0 to 1600 - - 250 -

16.0 to 1600 - 300 300 -

25 to 1600 - 350 - -

55 to 1700 - 400 - 250

80 to 2400 - 400 - 375

31 to 2500 - 400 - -

44 to 3500 - 450 - -

63 to 4000 - 500 - -

140 to 4200 - 600 - 375, 400

180 to 5400 - 600 - 450

79 to 6300 - 600 - -

220 to 6600 - - - 500

310 to 9600 - - - 600

420 to 13500 - - - 700

550 to 18000 - - - 800

690 to 22500 - - - 900

850 to 28000 - - - 1000

1250 to 40000 - - - 1200

1700 to 55000 - - - 1400

2200 to 70000 - - - 1600

2800 to 90000 - - - 1800

3400 to 110000 - - - 2000

Issue : 0.0 24-04-2012 Page 13 of 16

Chapter 5

Meter Design Standards

IX. METER INSTALLATION

IX.1 Installation Conditions

Plastic and electronic parts and other equipment should be protected from UV radiation and

sheltered from direct sunlight by enclosures or shelters.

Manufacturers’ data should be reviewed to determine limitations of specific meters to verify

installation specifications are acceptable. Examples would be the minimum length of straight

pipe required upstream and downstream of the meter to ensure accurate measurement or the

maximum temperature the meter must not exceed for reliable operation.

Provisions should be made for continued operation of the water system should a large meter

be removed for maintenance. District and IWPP meters should be provided with by-pass

piping and valves.

All meter installations shall be made under the direct supervision of KM and shall conform to

the references and specifications mentioned in the Key References provided in Section IV.2 of

this chapter.

IX.2 Chambers and Meter Box Sizing

IX.2.1 Chambers

For developments that are proposed to be phased, the meter chamber and piping must be

sized for the meter required for the ultimate build out of the development. However, the initial

meter installed must be sized to accurately capture the range of flows for the first phase. It is

expected that in most cases the water meter size will be at least 1-2 sizes smaller than the

water service connection pipeline.

IX.2.2 Meter Boxes

Consideration should be given for future conditions when sizing the box for meters and

instruments. Provide adequate space for future modifications if anticipated. Provide precast

structures unless sizes or special conditions require in-situ placed concrete.

IX.3 Installation Standard Drawings

Table IX-1 is provided for convenience and is a summary lists drawings applicable for Meter

Design Standards. Refer to the Standard Drawings for a complete list of available standards.

Page 14 of 16 Issue: 0.0 24-04-2012

Chapter 5

Meter Design Standards

Table IX-1, Standard Drawing List

Subject Description Drawing Number

Domestic Customer Metering Domestic Meter Installation and

NDS-SD-220

Details Trench Details

District Meter Chamber (100mm

NDS-SD-214

Bulk Customer Metering & 150mm)

Details District Meter Chamber (200mm

NDS-SD-215

to 400mm Mains)

GRP Service Cabinet for District

Flowmeter with Electrical NDS-SD-286

Connections

Details of various sizes and

types of Meterings and Flow Meter Chamber with By-

NDS-SD-218

assemblies covering IPWP pass (150-600mm Mains)

boundary metering, Typical Details of Flow Meter

Reservoir Inlet/Outlet NDS-SD-207

Chamber (800mm to 1200mm)

metering, District Metering

Typical Arrangement for

Installation of Flow Meter (800 NDS-SD-209

to 1200mm)

Pressure Tapping Point Chamber NDS-SD-228

Bulk Flow Meter for

Aboveground Reservoir (100mm NDS-SD-219

– 300mm)

Details of various sizes and Circular Washout Chamber NDS-SD-225

types of Meterings (flow, Typical Chlorination Building

pressure, QIP, & disinfection NDS-SD-586

Equipment Layout Plan

monitoring) and its

assemblies Chlorination Bilding Piping

NDS-SD-587

Sections (Sheet 01 of 03)

Chlorination Bilding Piping

NDS-SD-588

Sections (Sheet 02 of 03)

Chlorination Bilding Piping

NDS-SD-589

Sections (Sheet 03 of 03)

X. KEY PERFORMANCE INDICATORS

■ Meter accessibility and ability to be read by meter readers

■ Meter reliability and rate of failure

■ Reduction in water unaccounted for

Issue : 0.0 24-04-2012 Page 15 of 16

Chapter 5

Meter Design Standards

XI. RECORDS

Table XI-1 lists details on the various meter records that should be retained.

Table XI-1 Meter Records

Records Custodian Record Location Retention Time

Meter Design Criteria and Soft copy in the server

DC 5 Years

Calculations (N Drive)

Soft copy in the server

Final Design Documents DC 5 Years

(N Drive)

Soft copy in the server

Calibration Records DC 5 Years

(N Drive)

Maintenance Records with Soft copy in the server

DC 5 Years

Failure Rates (N Drive)

XII. LIST OF TABLES

■ Table V-1 Meter Types from AWWA Manual of Practice M6

■ Table V-2 KM List of Suppliers

■ Table V-3 Domestic Meter Model SM700 Data

■ Table VIII-1Meter Sizing Chart

■ Table IX-1Standard Drawing List

■ Table XI-1 Meter Records

XIII. LIST OF FIGURES

■ Figure V-1 Fluidic Oscillator Flow Meter

■ FigureVI-1 Meter Selection Flow Chart

Page 16 of 16 Issue: 0.0 24-04-2012

You might also like

- T10 Turbine Meters PDFDocument59 pagesT10 Turbine Meters PDFVictor Enrique Rosales Parada100% (1)

- ABB Distribution Transformer GuideDocument92 pagesABB Distribution Transformer GuideDavid Pauline McHattie100% (1)

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- ABB Rota Bsics PDFDocument26 pagesABB Rota Bsics PDFAvik BhaiNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- SECTION 13420 Instruments Rev 0Document43 pagesSECTION 13420 Instruments Rev 0Azhar AliNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Barton 7000 Series Turbine Flowmeters User ManualDocument36 pagesBarton 7000 Series Turbine Flowmeters User ManualVItoNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- HIS For Vertical PumpDocument72 pagesHIS For Vertical PumpVaibhavSharma100% (2)

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansFrom EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansRating: 4 out of 5 stars4/5 (8)

- BEL Catalog 2008Document76 pagesBEL Catalog 2008YogiIndraPrayogaNo ratings yet

- Operation and Maintenance Manual: Model 20 & 50 Vibro With Model 260 Power UnitDocument33 pagesOperation and Maintenance Manual: Model 20 & 50 Vibro With Model 260 Power UnitPrince Nero100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- DC30-005 QS-500 Service Manual - Rev LDocument83 pagesDC30-005 QS-500 Service Manual - Rev Lmario feuillade50% (2)

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Minor Losses in Pipe Fittings BendsDocument8 pagesMinor Losses in Pipe Fittings BendsHashim AnsariNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Rexroth Pump CatalogDocument92 pagesRexroth Pump CatalogSetyohdWNo ratings yet

- Pip Resp003v 1997Document47 pagesPip Resp003v 1997zufriateguiNo ratings yet

- Heavy Duty Hydraulic Cylinders: Series 2H / 2HD & 3H / 3HDDocument132 pagesHeavy Duty Hydraulic Cylinders: Series 2H / 2HD & 3H / 3HDcarlosorizabaNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Working Procedure: Recommended: S. Evelyn Approved: Rev. DateDocument33 pagesWorking Procedure: Recommended: S. Evelyn Approved: Rev. DateMuhammad RosihanNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Manual Martillo IceDocument51 pagesManual Martillo IceMauricioNo ratings yet

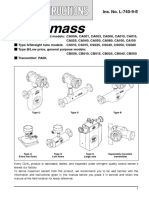

- Instructions Alti Mass L 740 9 eDocument118 pagesInstructions Alti Mass L 740 9 eitamarpereiraNo ratings yet

- Etech VS4 50Hz SerieDocument38 pagesEtech VS4 50Hz SerieMladen MuskinjaNo ratings yet

- Subsea Valves and Actuators for the Oil and Gas IndustryFrom EverandSubsea Valves and Actuators for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (1)

- Gen 042 V 1Document28 pagesGen 042 V 1Yung Jia ChoongNo ratings yet

- Pip Resp003v-2004Document48 pagesPip Resp003v-2004zufriateguiNo ratings yet

- 131 AcDocument25 pages131 AcTuấn VũNo ratings yet

- Preparation of Transformer Specifications1Document56 pagesPreparation of Transformer Specifications1ahmaborashedNo ratings yet

- Is 14615 1 1999Document85 pagesIs 14615 1 1999Satish Kumar BonthuNo ratings yet

- Technique Lavabos Chirurgicaux - enDocument74 pagesTechnique Lavabos Chirurgicaux - enrizky bsNo ratings yet

- Model 5550 HPHT Viscometer ManualDocument72 pagesModel 5550 HPHT Viscometer ManualMalik KNo ratings yet

- MCC Catalog Nov 2014 WebDocument346 pagesMCC Catalog Nov 2014 WebRômulo MagalhãesNo ratings yet

- Specification For PumpsDocument29 pagesSpecification For PumpsEmad Rakat100% (1)

- Trans HandbkDocument213 pagesTrans HandbkRubal Kathait100% (1)

- PIP PCCCV001 Control Valves Selection CriteriaDocument29 pagesPIP PCCCV001 Control Valves Selection CriteriaMehdi orojluNo ratings yet

- Etech VS4 50Hz SerieDocument38 pagesEtech VS4 50Hz SerieAlijimal JimalNo ratings yet

- wsn924 1Document6 pageswsn924 1Lim Kang HaiNo ratings yet

- API 6A Purchasing Guide 2015-08-29Document20 pagesAPI 6A Purchasing Guide 2015-08-29xaviereduardo100% (1)

- Act BrochureDocument101 pagesAct BrochurePHILIPUAENo ratings yet

- Brookfield Manual PDFDocument36 pagesBrookfield Manual PDFAnonymous T32l1RNo ratings yet

- Navair 01 1a 17 (With Change 2)Document218 pagesNavair 01 1a 17 (With Change 2)Ozkhar AFNo ratings yet

- Asme Iso IbrDocument63 pagesAsme Iso IbrdhaneshquilonNo ratings yet

- 00-STD-EL-0008 - Medium Voltage MCC's - 600vacDocument10 pages00-STD-EL-0008 - Medium Voltage MCC's - 600vacKalpesh PatelNo ratings yet

- Flowave Saw Flowmeter: Type 8098Document33 pagesFlowave Saw Flowmeter: Type 8098Edson Jacinto JacintoNo ratings yet

- Automation Engineering Practice For Pressure Definitions: AEP-32e 13 January 2010Document25 pagesAutomation Engineering Practice For Pressure Definitions: AEP-32e 13 January 2010arraziy fauzanNo ratings yet

- PNSMV026Document26 pagesPNSMV026Philippe AlexandreNo ratings yet

- Resp003s 0204Document32 pagesResp003s 0204Hakim BERDINo ratings yet

- ABB Distribution Transformer Guide PDFDocument92 pagesABB Distribution Transformer Guide PDFHoang100% (2)

- APE - Manual For200, 200T & 200-6-ADocument41 pagesAPE - Manual For200, 200T & 200-6-ALuis gamboa corderoNo ratings yet

- B.08.02 Att 2 Conceptual Site PlanDocument1 pageB.08.02 Att 2 Conceptual Site PlanIsmail MohammadNo ratings yet

- B.08.02 Att 4 Existing Conditions PhotographsDocument13 pagesB.08.02 Att 4 Existing Conditions PhotographsIsmail MohammadNo ratings yet

- B.08.02 Att 6 Structural Calculations Guidelines - AOR AFRICOMDocument8 pagesB.08.02 Att 6 Structural Calculations Guidelines - AOR AFRICOMIsmail MohammadNo ratings yet

- B.08.02 Att 6 Structural Calculations Guidelines - AOR AFRICOMDocument8 pagesB.08.02 Att 6 Structural Calculations Guidelines - AOR AFRICOMIsmail MohammadNo ratings yet

- Section 21 05 48Document1 pageSection 21 05 48Ismail MohammadNo ratings yet

- Section 21 05 00Document6 pagesSection 21 05 00Ismail MohammadNo ratings yet

- Section 21 05 23Document6 pagesSection 21 05 23Ismail MohammadNo ratings yet

- Section 21 12 00Document3 pagesSection 21 12 00Ismail MohammadNo ratings yet

- 02.04.2020-ATCCO-AV-CA-2020-294-House Energy Meter - Engineer's Letter Ref. CA-ATCCO-2675-CA272-2020Document2 pages02.04.2020-ATCCO-AV-CA-2020-294-House Energy Meter - Engineer's Letter Ref. CA-ATCCO-2675-CA272-2020Ismail MohammadNo ratings yet

- Section 25 30 00Document15 pagesSection 25 30 00Ismail MohammadNo ratings yet

- Section 23 81 26Document16 pagesSection 23 81 26Ismail MohammadNo ratings yet

- Section 25 10 00Document27 pagesSection 25 10 00Ismail MohammadNo ratings yet

- 00 - Table of ContentsDocument3 pages00 - Table of ContentsIsmail MohammadNo ratings yet

- Section 23 40 00Document4 pagesSection 23 40 00Ismail MohammadNo ratings yet

- Section 23 81 24Document5 pagesSection 23 81 24Ismail MohammadNo ratings yet

- Section 21 11 00Document10 pagesSection 21 11 00Ismail MohammadNo ratings yet

- Section 21 13 00Document4 pagesSection 21 13 00Ismail MohammadNo ratings yet

- S.G-ATC-MAS-M-0062-Rev.03 Malleable Iron Threaded FittingsDocument4 pagesS.G-ATC-MAS-M-0062-Rev.03 Malleable Iron Threaded FittingsIsmail MohammadNo ratings yet

- S.g-atC-MAS-M-0078 Gaskets Sheets & Flat Hose GasketsDocument9 pagesS.g-atC-MAS-M-0078 Gaskets Sheets & Flat Hose GasketsIsmail MohammadNo ratings yet

- 04 - Diffusers - SD-S4Document14 pages04 - Diffusers - SD-S4Ismail MohammadNo ratings yet

- 01.04.2020-ATCCO-AV-CA-2020-293-Additional Works Garbage Chute - Engineer's Letter Ref. CA-ATCCO-2675-CA278-2020Document2 pages01.04.2020-ATCCO-AV-CA-2020-293-Additional Works Garbage Chute - Engineer's Letter Ref. CA-ATCCO-2675-CA278-2020Ismail MohammadNo ratings yet

- S.g-atC-MAS-M-0070 Galvanized ERW Welded Steel PipesDocument75 pagesS.g-atC-MAS-M-0070 Galvanized ERW Welded Steel PipesIsmail MohammadNo ratings yet

- 06.06.2020-CA-ATCCO-2675-CA319-Additional Drain Outlets at RoofDocument1 page06.06.2020-CA-ATCCO-2675-CA319-Additional Drain Outlets at RoofIsmail MohammadNo ratings yet

- 201908271351Document4 pages201908271351Ismail MohammadNo ratings yet

- Engineered Electrical and Fastening Solutions +1.440.248.0100 Main +1.440.248.0723 Fax Pentair, PLC 31700 Solon Road Solon, OH 44139 United StatesDocument1 pageEngineered Electrical and Fastening Solutions +1.440.248.0100 Main +1.440.248.0723 Fax Pentair, PLC 31700 Solon Road Solon, OH 44139 United StatesIsmail MohammadNo ratings yet

- 201908070843Document35 pages201908070843Ismail MohammadNo ratings yet

- Air Curtains: For A Comfortable Indoor ClimateDocument258 pagesAir Curtains: For A Comfortable Indoor ClimateMadhankumarNo ratings yet

- 201910241053Document4 pages201910241053Ismail MohammadNo ratings yet

- 201910161030Document1 page201910161030Ismail MohammadNo ratings yet

- PicvDocument30 pagesPicvIsmail MohammadNo ratings yet

- Non-Destructive Testing of Concrete A Review of MethodsDocument9 pagesNon-Destructive Testing of Concrete A Review of Methodspatricklim1982No ratings yet

- Ultrasonic Testing Ut Q Bank A-12: 5° From The Test SurfaceDocument11 pagesUltrasonic Testing Ut Q Bank A-12: 5° From The Test Surfacekingston100% (1)

- Sonorad k40Document5 pagesSonorad k40jayramdeepakNo ratings yet

- 2017 - 12 - Repairing Ultrasonic Welded Carbon Fiber - Reinforced Nylon 66 CompositeDocument12 pages2017 - 12 - Repairing Ultrasonic Welded Carbon Fiber - Reinforced Nylon 66 CompositeAnonymous GhPzn1xNo ratings yet

- Automatic Mini Floor CleanerDocument20 pagesAutomatic Mini Floor CleanerJeevaniswaran ThangarajNo ratings yet

- Asme Ultrasonic Examination ReportDocument8 pagesAsme Ultrasonic Examination ReportKariza Gritania Sabila100% (2)

- Ultrasonic TransducersDocument23 pagesUltrasonic Transducerspablodanielrigo100% (2)

- Calculating The Sos in Natural Gas - Aga Report No. 10 To Aga Report No. 8Document11 pagesCalculating The Sos in Natural Gas - Aga Report No. 10 To Aga Report No. 8Malouk CheniouniNo ratings yet

- Assignment 3 - Mechanical VibrationDocument6 pagesAssignment 3 - Mechanical Vibrationbaba sugarNo ratings yet

- AlphagerManual v2 1021hffhbhDocument83 pagesAlphagerManual v2 1021hffhbhFirdaus AriefatosaNo ratings yet

- New UTDocument17 pagesNew UTNayan VyasNo ratings yet

- Color Based Object Sorting Machine: International Research Journal of Engineering and Technology (IRJET)Document6 pagesColor Based Object Sorting Machine: International Research Journal of Engineering and Technology (IRJET)anand pujariNo ratings yet

- HiS SYSTEM - METAL Welding MachineDocument18 pagesHiS SYSTEM - METAL Welding MachineSharmishta AngreNo ratings yet

- Ut Q 1Document6 pagesUt Q 1JithuJohn100% (1)

- Cement Mapping ToolsDocument7 pagesCement Mapping ToolsJosefa Maria Cardozo100% (1)

- Assessing The Acceptability of Flaws in Metallic Structures - Introducing BS 7910:2013 TWI EventsDocument8 pagesAssessing The Acceptability of Flaws in Metallic Structures - Introducing BS 7910:2013 TWI EventsMrk BrkngNo ratings yet

- PLL Frequency Control For Ultrasonic GeneratorsDocument2 pagesPLL Frequency Control For Ultrasonic Generatorsapi-3809613No ratings yet

- MuraltDocument12 pagesMuraltJezero RozkaNo ratings yet

- Paut Full PDFDocument353 pagesPaut Full PDFTrịnh Thành96% (26)

- A Non-Destructive Testing Techniques For Aerospace IndustriesDocument12 pagesA Non-Destructive Testing Techniques For Aerospace IndustriesSubrata PatraNo ratings yet

- Cryo 5 in 1 WL-7005CDocument21 pagesCryo 5 in 1 WL-7005Ccar-lirous custNo ratings yet

- Mettler Sonicator 740 and 740x User ManualDocument38 pagesMettler Sonicator 740 and 740x User Manualphcproducts0% (1)

- Vivid Tool Rev1Document2 pagesVivid Tool Rev1Yovaraj KarunakaranNo ratings yet

- Evaluating Performance Characteristics of Ultrasonic Pulse-Echo Examination Instruments and Systems Without The Use of Electronic Measurement InstrumentsDocument12 pagesEvaluating Performance Characteristics of Ultrasonic Pulse-Echo Examination Instruments and Systems Without The Use of Electronic Measurement InstrumentsorlandoNo ratings yet

- Stulz DRH Humidifier Service ManualDocument32 pagesStulz DRH Humidifier Service ManualBryan JonesNo ratings yet

- Working Principle: Ultrasonic Welding Process - Working Principle, Parts, Advantages and Disadvantages With ApplicationDocument6 pagesWorking Principle: Ultrasonic Welding Process - Working Principle, Parts, Advantages and Disadvantages With ApplicationbrahmaNo ratings yet

- 1642990216class 9 Questions - Sound ChapterDocument9 pages1642990216class 9 Questions - Sound ChapterMANISHA GARGNo ratings yet

- Crack Monitoring TechniquesDocument34 pagesCrack Monitoring TechniquesharishankarnadarNo ratings yet

- Corporate e ProfileDocument10 pagesCorporate e ProfileNurilNo ratings yet

- E428-08 (2013) Standard Practice For Fabrication and Control of Metal, Other Than Aluminum, Reference Blocks Used in Ultrasonic TestingDocument7 pagesE428-08 (2013) Standard Practice For Fabrication and Control of Metal, Other Than Aluminum, Reference Blocks Used in Ultrasonic TestingAhmed Shaban KotbNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsFrom EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsRating: 4.5 out of 5 stars4.5/5 (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Electric Motors and Drives: Fundamentals, Types and ApplicationsFrom EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsRating: 4.5 out of 5 stars4.5/5 (12)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Heat Transfer Engineering: Fundamentals and TechniquesFrom EverandHeat Transfer Engineering: Fundamentals and TechniquesRating: 4 out of 5 stars4/5 (1)

- Smart Power Distribution Systems: Control, Communication, and OptimizationFrom EverandSmart Power Distribution Systems: Control, Communication, and OptimizationNo ratings yet

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerFrom EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo ratings yet

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsFrom EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsNo ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceFrom EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo ratings yet

- A Pathway to Decarbonise the Shipping Sector by 2050From EverandA Pathway to Decarbonise the Shipping Sector by 2050No ratings yet

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksFrom EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksNo ratings yet

- Renewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksFrom EverandRenewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksNo ratings yet