Professional Documents

Culture Documents

Battery Filling

Uploaded by

MajdiSahnoun0 ratings0% found this document useful (0 votes)

411 views3 pagesOriginal Title

BATTERY FILLING.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

411 views3 pagesBattery Filling

Uploaded by

MajdiSahnounCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

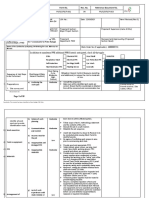

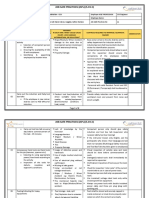

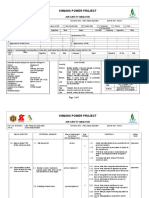

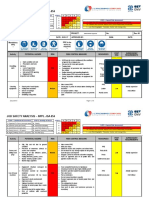

JOB SAFETY ANALYSIS

Facility / Site: Location within Site: Permit No: Permit Type: Date:

Task Description: ACID BATTERY FILLING

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

or Safe Work Practices been reviewed? Yes N/A

Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the

significant Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be

Yes No Name / Signature: Company:

modified to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario-Based Yes No

Risk Assessment required)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

Name / Signature: Company:MSBI

FALL PROTECTION

FALL RESTRAINT

COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

GLOVES:

COTTON Work Team Declaration:

LEATHER I acknowledge that I have reviewed the attached JSA, I understand my roles

and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask OTHER (specify):

Work clothes

OTHER PPE (specify): High-Vis Jacket

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

1. Permitting work Work condition unsafe HSE team to assess continuously the PTW system

Procedures and tasks not clear conditions of work in the assigned area Tool Box Talk

Lack of supervision One person responsible for PTW inspection of all

Miscommunication Toolbox talks activity hazards

PPE does not fit for the activity Competent and qualified person

Define hierarchy and reporting flowcharts

Define proper PPE to be used for the work

Check inspection certificates of equipment

for the job

Check the status of the floor and mobile

scaffolding

Standard PPE must be worn MSBI Emergency

MSDS communicated during the TBT response Plan

Apply the manual handling techniques for Proper fire

Acid spill manual handling extinguisher

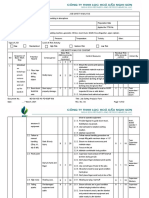

2. Transportation of Fire Spill kit in place

electrolyte Vehicle crash Only authorized person in the pick up

Respect speed limit on site

Pick up to be escorted

Adequate Retention tray in the pick up

Standard PPE must be worn MSBI Emergency

MSDS to be communicated to all workers response Plan

Apply the manual handling techniques for Spill kit

Chemical handling manual handling Eye wash

Mobile scaffolding not stable Ensure that the mobile scaffolding is stable Fire extinguisher

Inhalation before battery filling First aid kit

Ingestion Adequate ventilation

3. Acid battery filling

Eyes irritation Adequate retention tray before proceeding

Environmental impact for work

Death Spill kit, eye wash and detector to be in place

Asphyxiated Regular breaks

Safety signs

Safe access to be provided

plan for rests & breaks

Good housekeeping & waste management

Only authorised person on battery room

Presence of watchman obligatory

MSBI Emergency

response Plan

Acid spill kit in place MSBI Emergency

Keep work area tidy and clean response Plan

Slips trips fall

Regular Housekeeping and keep all area free Spill kit

Environmental impact

4. Housekeeping from hazards Eye wash

Fire extinguisher

First aid kit

Name Position Date Signed

Prepared By HSSE Site Manager

Checked By Area HSSE Supervisor

Approved By PTW Coordinator

You might also like

- CPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night ShiftDocument3 pagesCPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night Shiftaioudi100% (1)

- JSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Document15 pagesJSA For Excavation of Fiber Optical Cable WR-501 To WR-617 Community To Petro Rabigh......Habib ur rahmanNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNo ratings yet

- JSA-Use of Temporary Energization (Power Generator)Document4 pagesJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnounNo ratings yet

- Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewDocument4 pagesJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewMoaatazz Nouisri100% (1)

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- SS JSP - 007 Excavation Work Using EquipmentDocument6 pagesSS JSP - 007 Excavation Work Using EquipmentFarhat SetharNo ratings yet

- Job Safety Analysis - Civil WorksDocument7 pagesJob Safety Analysis - Civil WorksMoaatazz Nouisri67% (3)

- Man Machine InterfaceDocument22 pagesMan Machine Interfaceamdarrif3723100% (1)

- Jsa - Cable Termination PDFDocument4 pagesJsa - Cable Termination PDFD FiransyahNo ratings yet

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- TEIPL-JSA-044 Maintenance Vehicle, Machine or Const EqmntsDocument4 pagesTEIPL-JSA-044 Maintenance Vehicle, Machine or Const Eqmntsba ratnaparkheNo ratings yet

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Document9 pagesSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- JSA Electrical IsolationDocument4 pagesJSA Electrical IsolationASLAM MULANINo ratings yet

- JSP For AsphaltDocument8 pagesJSP For Asphaltmohammed tofiqNo ratings yet

- Backfilling, Leveling RISK ASSESSMENTDocument6 pagesBackfilling, Leveling RISK ASSESSMENTVimal ViswanathNo ratings yet

- Risk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Document16 pagesRisk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Mohsin MohdNo ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- jesa-INSTALLATION OF Toilet Cubicle PartitionDocument5 pagesjesa-INSTALLATION OF Toilet Cubicle PartitionLeo PascualNo ratings yet

- JSA-RHI-ARZ-0-004 ASU - Lifting Works Rev01 - ArzewDocument6 pagesJSA-RHI-ARZ-0-004 ASU - Lifting Works Rev01 - ArzewUmit KaymakNo ratings yet

- JSA-Using A Type Ladder 2015Document1 pageJSA-Using A Type Ladder 2015nishanthNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- 003-JSA Pipe Loading and OffloadingDocument8 pages003-JSA Pipe Loading and OffloadingMoaatazz NouisriNo ratings yet

- JSA Cable Pulling and Laying WorksDocument6 pagesJSA Cable Pulling and Laying Workskabir100% (1)

- Hse Daily Report 25 Jan 23Document5 pagesHse Daily Report 25 Jan 23FdrianRidhoNo ratings yet

- Job Safety Analysis Report: DG Lifting & InstallationDocument2 pagesJob Safety Analysis Report: DG Lifting & Installationvijay kumar singh100% (1)

- Job Safety Analysis Erection SiloDocument3 pagesJob Safety Analysis Erection SiloDanangNo ratings yet

- JSA For Diesel Filling at Del CampDocument6 pagesJSA For Diesel Filling at Del CampMohammed Ali QaziNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- 003 SWMS - ExcavationDocument11 pages003 SWMS - Excavationsasi kumar50% (2)

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. Ahmad100% (1)

- S07 Tank Project - JSA - Erection of Scaffolding 2nd LevelDocument6 pagesS07 Tank Project - JSA - Erection of Scaffolding 2nd LevelKrishVy KumærNo ratings yet

- GroutingDocument1 pageGroutingraphael damanikNo ratings yet

- SOR-IFM2-Fire Safety-22 Nov. 2020Document2 pagesSOR-IFM2-Fire Safety-22 Nov. 2020haniNo ratings yet

- JHA LiftingDocument4 pagesJHA Liftingsyamimi balkhisNo ratings yet

- JSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Document10 pagesJSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Zubair Khan100% (1)

- Activity Hazard AnalysisDocument4 pagesActivity Hazard AnalysisGerrard Singh100% (1)

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Risk Assessment For Earth Works (Excavation Back Filling) Require...Document13 pagesRisk Assessment For Earth Works (Excavation Back Filling) Require...khalid khan100% (1)

- Hazard Identification & Risk Assessment Sheet ForDocument6 pagesHazard Identification & Risk Assessment Sheet Forasathish.eee100% (1)

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- AHA - Working On Slope RoofDocument2 pagesAHA - Working On Slope RoofTopsun EnergyNo ratings yet

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- RA - Concrete PouringDocument1 pageRA - Concrete PouringعمروNo ratings yet

- ZFP Sor 2023-1-17Document8 pagesZFP Sor 2023-1-17irfan shafiqueNo ratings yet

- Jsa For PCCDocument6 pagesJsa For PCCCICON EngineersNo ratings yet

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- JSA-02-trench Excavation by EquipmentDocument1 pageJSA-02-trench Excavation by Equipmentabou bakarNo ratings yet

- RA - Plumbing Works Rev. BDocument8 pagesRA - Plumbing Works Rev. BResearcherNo ratings yet

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- SAFETY PLAN For Pilling Work at Making AreaDocument8 pagesSAFETY PLAN For Pilling Work at Making AreaBalogun Isaac100% (1)

- Jsa-046 Highway Crossing and Steel CasingDocument11 pagesJsa-046 Highway Crossing and Steel CasingMajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- Andamios PDFDocument69 pagesAndamios PDFleonciomavarezNo ratings yet

- CPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0Document5 pagesCPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0MajdiSahnounNo ratings yet

- 904studyguide O&G Well InspectionDocument88 pages904studyguide O&G Well InspectionMajdiSahnounNo ratings yet

- Process Safety - Recommended Practice On Key Performance IndicatorsDocument36 pagesProcess Safety - Recommended Practice On Key Performance IndicatorsmarianalourenNo ratings yet

- Safety in Drilling ManualDocument151 pagesSafety in Drilling Manualstoianz100% (1)

- CPF-JSA-010 Scaffolding Erection ZONE CLASS0Document5 pagesCPF-JSA-010 Scaffolding Erection ZONE CLASS0MajdiSahnounNo ratings yet

- Case HistoriesDocument4 pagesCase HistoriesMajdiSahnounNo ratings yet

- 4 652225233830281222 PDFDocument89 pages4 652225233830281222 PDFMajdiSahnounNo ratings yet

- Ladder Inspection ChecklistDocument1 pageLadder Inspection ChecklistMajdiSahnounNo ratings yet

- Seat Belt AccDocument6 pagesSeat Belt AccMajdiSahnounNo ratings yet

- Driving Accident TruckDocument8 pagesDriving Accident TruckMajdiSahnounNo ratings yet

- HSNO Er Ug 05Document190 pagesHSNO Er Ug 05MajdiSahnounNo ratings yet

- 5 Behavior and DrivingDocument11 pages5 Behavior and DrivingMajdiSahnounNo ratings yet

- EulaDocument3 pagesEulaBrandon YorkNo ratings yet

- Lifting Plan GuidelinesDocument45 pagesLifting Plan GuidelinesFerry H. Sitohang100% (5)

- 1 - Workplace Safety Inspections TextDocument36 pages1 - Workplace Safety Inspections TextDodi DodoNo ratings yet

- Jsa-046 Highway Crossing and Steel CasingDocument11 pagesJsa-046 Highway Crossing and Steel CasingMajdiSahnounNo ratings yet

- 4 968738115655041029Document16 pages4 968738115655041029MajdiSahnounNo ratings yet

- شرح مصطلحات النيبوشDocument22 pagesشرح مصطلحات النيبوشYasser Bouzeghaia100% (1)

- ItemDocument2 pagesItemMajdiSahnounNo ratings yet

- NA-OTP-PMT-0805-HS-SPE-0006 - Security Standards For Temporary Construction Facilities For CPF Scope PDFDocument15 pagesNA-OTP-PMT-0805-HS-SPE-0006 - Security Standards For Temporary Construction Facilities For CPF Scope PDFMajdiSahnounNo ratings yet

- Safety Slogan CollectionDocument42 pagesSafety Slogan CollectionSreedhar Patnaik.MNo ratings yet

- 300 English WordsDocument11 pages300 English WordsjojaiNo ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsDocument2 pagesJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsMajdiSahnoun100% (1)

- Annex 17 - Induction Nawara ProjDocument18 pagesAnnex 17 - Induction Nawara ProjMajdiSahnounNo ratings yet

- JSA-Loading-Offloading of Chemical Products With ForkliftDocument4 pagesJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- Lip Prints: IntroductionDocument4 pagesLip Prints: Introductionkaran desaiNo ratings yet

- Probability Form 4Document10 pagesProbability Form 4Deen ZakariaNo ratings yet

- Drim 1201 Classification (Theory and Practice)Document26 pagesDrim 1201 Classification (Theory and Practice)businge innocentNo ratings yet

- Chemistry Chemical EngineeringDocument124 pagesChemistry Chemical Engineeringjrobs314No ratings yet

- UCO 359 Key & Solution 05Document3 pagesUCO 359 Key & Solution 05Anwesha SatpathyNo ratings yet

- Psych ManualDocument340 pagesPsych ManualMarius_20100% (1)

- OM Version 1Document497 pagesOM Version 1Sushant SinghNo ratings yet

- Conceptualizing Teacher Professional LearningDocument33 pagesConceptualizing Teacher Professional LearningPaula Reis Kasmirski100% (1)

- Labacha CatalogueDocument282 pagesLabacha CatalogueChaitanya KrishnaNo ratings yet

- DS - en 1991-1-7 DK Na - 2007 eDocument6 pagesDS - en 1991-1-7 DK Na - 2007 ep_meulendijks108No ratings yet

- Forecasting The Return Volatility of The Exchange RateDocument53 pagesForecasting The Return Volatility of The Exchange RateProdan IoanaNo ratings yet

- Fruits Basket - MemoryDocument1 pageFruits Basket - Memorywane10132100% (1)

- BS 8901 SEG Press ReleaseDocument3 pagesBS 8901 SEG Press Releasetjsunder449No ratings yet

- Stone ChapaisDocument6 pagesStone ChapaisMaría GallardoNo ratings yet

- Seismic Earth Pressures On Retaining WallsDocument71 pagesSeismic Earth Pressures On Retaining Wallsradespino1No ratings yet

- Human Pose Estimtion SeminarDocument5 pagesHuman Pose Estimtion Seminarsangamnath teliNo ratings yet

- English II Homework Module 6Document5 pagesEnglish II Homework Module 6Yojana DubonNo ratings yet

- Modicon M580 Quick Start - v1.0 - Training ManualDocument169 pagesModicon M580 Quick Start - v1.0 - Training Manualaryan_iust0% (1)

- TM Matematika X IPA 8Document31 pagesTM Matematika X IPA 8Muhammad Ilyas ArradyaNo ratings yet

- Emergency Stop in PL E: SINUMERIK Safety IntegratedDocument10 pagesEmergency Stop in PL E: SINUMERIK Safety IntegratedVladimirAgeevNo ratings yet

- P1 88thminutesDocument42 pagesP1 88thminutesVaishnavi JayakumarNo ratings yet

- Assignment 4: Chitresh KumarDocument7 pagesAssignment 4: Chitresh KumarChitreshKumarNo ratings yet

- How To Install Windows Drivers With Software Applications: August 1, 2006Document12 pagesHow To Install Windows Drivers With Software Applications: August 1, 2006Mohamad Lutfi IsmailNo ratings yet

- Water TableDocument5 pagesWater TableJay DoshiNo ratings yet

- Exp#4-Gas TurbineDocument9 pagesExp#4-Gas TurbineLilo17xiNo ratings yet

- Critical Incident Stress DebriefingDocument20 pagesCritical Incident Stress DebriefingatenampNo ratings yet

- PhantasmagoriaDocument161 pagesPhantasmagoriamontgomeryhughes100% (1)

- Delegate Handbook: The National Final of The Evatt Trophy CompetitionDocument19 pagesDelegate Handbook: The National Final of The Evatt Trophy Competitionevatt2012No ratings yet

- Business Decision MakingDocument5 pagesBusiness Decision MakingShafiya CaderNo ratings yet

- Gad Practical-No - 09Document4 pagesGad Practical-No - 09Amal fanseNo ratings yet