Professional Documents

Culture Documents

HVAC Fans Initial Energisation Battery Room

Uploaded by

MajdiSahnoun0 ratings0% found this document useful (0 votes)

129 views3 pagesThis job safety analysis identifies the tasks, hazards, and controls for the initial energization and running of battery room HVAC supply fans. The tasks include permitting the work, checking equipment, initial energization of the fans, and testing associated safety circuits. Hazards include electrical shock, burns from potential fires, and injuries from moving machinery. Controls involve wearing proper PPE, establishing communications between work teams, verifying emergency response equipment is in place, and ensuring all safety systems and guards are operational before starting equipment.

Original Description:

Original Title

HVAC fans initial energisation battery room.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis job safety analysis identifies the tasks, hazards, and controls for the initial energization and running of battery room HVAC supply fans. The tasks include permitting the work, checking equipment, initial energization of the fans, and testing associated safety circuits. Hazards include electrical shock, burns from potential fires, and injuries from moving machinery. Controls involve wearing proper PPE, establishing communications between work teams, verifying emergency response equipment is in place, and ensuring all safety systems and guards are operational before starting equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

129 views3 pagesHVAC Fans Initial Energisation Battery Room

Uploaded by

MajdiSahnounThis job safety analysis identifies the tasks, hazards, and controls for the initial energization and running of battery room HVAC supply fans. The tasks include permitting the work, checking equipment, initial energization of the fans, and testing associated safety circuits. Hazards include electrical shock, burns from potential fires, and injuries from moving machinery. Controls involve wearing proper PPE, establishing communications between work teams, verifying emergency response equipment is in place, and ensuring all safety systems and guards are operational before starting equipment.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

JOB SAFETY ANALYSIS

Ref: – JSA–

Facility / Site:……………………………………………… Location within Site:………………………. Permit No:……………………. Permit Type: ……………… Date:…………………….

Task Description: Initial energization and running of Battery room HVAC supply Fans

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

or Safe Work Practices been reviewed? Yes N/A

Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the

significant Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be

Yes No Name / Signature: Company:

modified to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario-Based Yes No

Risk Assessment required)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

FALL PROTECTION Name / Signature: Company:

FALL RESTRAINT GLOVES: COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

COTTON Work Team Declaration:

LEATHER I acknowledge that I have reviewed the attached JSA, I understand my roles

and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask

OTHER (specify):

Work clothes

OTHER PPE (specify):

TASKS/STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT MITIGATION

(Number) (What could go wrong?) (How can harm be prevented?) STATES

1. Permitting work Work condition not safe COMM PTW signed by authorized person ERP System in

Procedures and tasks not clear HSE team to assess continuously the conditions of place.

Lack of supervisory work in the assigned area

One person to issue work permits

Miscommunication

Toolbox talks

Not correct PPE worn Competency of personnel and supervisory for the

Equipment not inspected and activity

certified Define hierarchy and reporting flowcharts

Define proper NOMEX PPE to be used for the work

Check inspection certificates of equipment for the

job

2. Checking equipment Pinch point / hand & fingers injuries Wearing adequate NOMEX PPE First aid box

Tripping Electrical cables Chemical gloves Trained first aiders in place.

Arrange cables to avoid tripping

Use proper tools

3. Initial Uncontrolled energisation

Confirm equipment identification label MSBI ERP

energization resulting in electrocution or

corresponds with PTW and associated Fire extinguishers (CO2)

running of serious injury.

work pack engineering drawings, and is

battery room Insulated hock

within commissioning subsystem boundary.

HVAC supply Fire resulting in or serious

fans injury, burns or Equipment Confirm a LUN has been issued for the

damage. equipment/sub-system

Display signs and barriers around work

Moving machinery with the area.

potential cause serious injury,

equipment damage Verify rescue hook, fire extinguishers, etc.

are in the area as needed.

Ensure all mechanical guards are in place

prior to starting the fans.

Mechanical commissioning to be in

attendance to confirm all associated

dampers are in the correct position before

starting the fans and confirm correct

rotation and airflow

Mc certificate

4. Functional tests Electrocution or serious 1. Ensure open communications are MSBI ERP

of associated injury.

established between start/stop stations and Fire extinguishers (CO2)

safety circuits.

battery room

Test start/stop Fire resulting in serious injury, Insulated hock

stations with burns Equipment damage Ensure fire extinguishers (CO2) is in place

.

associated

HVAC fans.

5. Completion of Equipment to be left in 1. All commissioning signs and barriers to be left MSBI ERP

Testing as required indicating equipment is in service

operation

‘LIVE’.

Work permit and ICC is signed off and returned to

the PTW office

6. Housekeeping Equipment and tools remain on site. Proper communication during TBTs. Plastic bags

Slip trip and fall. Put back equipment to proper place Trash bins

Trash left in the work place. Clear all work place from trash

Fire hazards. Segregate trash

Name Position Date Signed

Prepared By

Checked By

Approved By

You might also like

- JSA-Use of Temporary Energization (Power Generator)Document4 pagesJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- JSA-Loading-Offloading of Chemical Products With ForkliftDocument4 pagesJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsDocument2 pagesJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsMajdiSahnoun100% (1)

- Jsa-046 Highway Crossing and Steel CasingDocument11 pagesJsa-046 Highway Crossing and Steel CasingMajdiSahnounNo ratings yet

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- Revised JHA HDDDocument12 pagesRevised JHA HDDHariharan RajaramanNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Cable Tray Installation JSA 21-11-2017 N°0022Document5 pagesCable Tray Installation JSA 21-11-2017 N°0022azerNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDocument8 pagesSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajNo ratings yet

- JSP For Electrical and HV TestingDocument4 pagesJSP For Electrical and HV TestingmohammedNo ratings yet

- 80010360Document2 pages80010360mdisicNo ratings yet

- JSA-02-trench Excavation by EquipmentDocument1 pageJSA-02-trench Excavation by Equipmentabou bakarNo ratings yet

- JSADocument8 pagesJSAr afrianto100% (1)

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- JSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling ActivityDocument12 pagesJSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling Activitybagas prakoso100% (1)

- JSA Formet New Structural Steel FabricationDocument7 pagesJSA Formet New Structural Steel Fabricationsakthi venkatNo ratings yet

- Metco 16C 10-040Document8 pagesMetco 16C 10-040JSH100No ratings yet

- Harc OffshoreDocument5 pagesHarc OffshoreMajdiSahnounNo ratings yet

- JHA Maintenance Tech HVACDocument2 pagesJHA Maintenance Tech HVACMdavaNo ratings yet

- Petrochina International Jabung LTD.: Job Safety AnalysisDocument4 pagesPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNo ratings yet

- Construction Site Inspection Check List ALMCDocument2 pagesConstruction Site Inspection Check List ALMCAmeerHamzaWarraichNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNo ratings yet

- PDF Gi 0002721 2016 Arc Flash CompressDocument23 pagesPDF Gi 0002721 2016 Arc Flash CompressMark DingalNo ratings yet

- Work Permit-Form PDFDocument1 pageWork Permit-Form PDFNijo JosephNo ratings yet

- SWMS HYD VAYUCON 04 Marking & Installation of DuctsDocument9 pagesSWMS HYD VAYUCON 04 Marking & Installation of DuctsBodakunta Ajay VarmaNo ratings yet

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Updated JSA For SAPMTofficeDocument30 pagesUpdated JSA For SAPMTofficeShaikh Abu bakarNo ratings yet

- Jha Region7 GeoprobeDocument10 pagesJha Region7 Geoprobewasif ahmedNo ratings yet

- Bsee201 B - Fluid MechanicsDocument150 pagesBsee201 B - Fluid MechanicsMarvin GagarinNo ratings yet

- Electrical Maintenance & Testing Hazard IdentificationDocument10 pagesElectrical Maintenance & Testing Hazard IdentificationRavi ValiyaNo ratings yet

- C32 Electronic Unit Injector - Adjust PDFDocument4 pagesC32 Electronic Unit Injector - Adjust PDFmanu luvunga100% (2)

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Jsa Psa & GisDocument3 pagesJsa Psa & GisMohammed NouzalNo ratings yet

- 07 - JSA Compaction and BackfillingDocument4 pages07 - JSA Compaction and Backfillingsatti100% (2)

- DOD-MST-INS-008 (Rev-1) Installation, Splicing and Testing of Fiber Optic CableDocument8 pagesDOD-MST-INS-008 (Rev-1) Installation, Splicing and Testing of Fiber Optic CableProfessional Trust100% (1)

- HITRA For PiggingDocument6 pagesHITRA For PiggingAhmedNo ratings yet

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocument2 pagesJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNo ratings yet

- Welding ProceduresDocument11 pagesWelding ProceduresnamasralNo ratings yet

- Plastering & RenderingDocument7 pagesPlastering & Renderingmohd firdausNo ratings yet

- Acidizing TreatmentsDocument93 pagesAcidizing TreatmentsPeña Lucia100% (2)

- RadiographyDocument1 pageRadiographyNature BeautiesNo ratings yet

- Jha For - TransformerDocument7 pagesJha For - Transformermujahid1137No ratings yet

- Permit To Work Shafts and Elevators: Compliance ChecklistDocument1 pagePermit To Work Shafts and Elevators: Compliance ChecklistNeil Buyco VillamorNo ratings yet

- JSA - Low Voltage PanelDocument19 pagesJSA - Low Voltage PanelASLAM MULANINo ratings yet

- Working at Height TrainingDocument47 pagesWorking at Height TrainingthinkpadNo ratings yet

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- JHA Vessel EntryDocument2 pagesJHA Vessel EntryRiyadh SalehNo ratings yet

- Harc Snoop Test OperationDocument7 pagesHarc Snoop Test OperationMajdiSahnounNo ratings yet

- All Over India Company DataDocument32 pagesAll Over India Company DataViren PatelNo ratings yet

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- Jsa PolypipeDocument2 pagesJsa PolypipeHow Chin Engineering Sdn BhdNo ratings yet

- Nasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetDocument2 pagesNasda Wind Power Project: Sub-Station Excavation Job Safety Analysis WorksheetRaza Muhammad SoomroNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- Appendix A-Job Safety Analysis FormDocument3 pagesAppendix A-Job Safety Analysis Formjiks_i4uNo ratings yet

- Jsa Ducting Rev 00Document1 pageJsa Ducting Rev 00SRR HSE Department, Sandvik Project,No ratings yet

- What Is The Difference Between TstiDocument4 pagesWhat Is The Difference Between TstiFortuna HunilaNo ratings yet

- JSA of Charging UnitDocument3 pagesJSA of Charging UnitMuhammad AliNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- 3216 JSA Roof PlumbingDocument14 pages3216 JSA Roof Plumbingmalimsaidi_160040895100% (2)

- SWP Working Safely at Height Version 2.01Document7 pagesSWP Working Safely at Height Version 2.01marvinNo ratings yet

- Rock Breaker Self ChecklistDocument1 pageRock Breaker Self ChecklistNair R RakeshNo ratings yet

- Jsa CompressorDocument9 pagesJsa CompressorRavi thokalNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- Tool Box Talk - MK - Emergency Response ProceduresDocument2 pagesTool Box Talk - MK - Emergency Response ProceduresPaul McGahanNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 pageConstruction Job Hazards Analysis: This Is A TEMPLATETamNo ratings yet

- JSA PRE-TEST UploadDocument2 pagesJSA PRE-TEST UploadDenny Kurniawan PrawiraNo ratings yet

- Assad Ullah Jan: ObjectiveDocument6 pagesAssad Ullah Jan: ObjectiveManda Khel Apna DesNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Jsa For Alignment of Vessel and DrumDocument3 pagesJsa For Alignment of Vessel and DrumMohammed MinhajNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- Method Statement For Worker WelfereDocument4 pagesMethod Statement For Worker WelfereMohamad Hidayat Zainul MasriNo ratings yet

- 9 Use of Hand Roller Compactor SafetyDocument2 pages9 Use of Hand Roller Compactor SafetyarchieNo ratings yet

- CPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0Document5 pagesCPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0MajdiSahnounNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- Annex 17 - Induction Nawara ProjDocument18 pagesAnnex 17 - Induction Nawara ProjMajdiSahnounNo ratings yet

- Nawara Project - Introduction of Positive Pressure Hazards and ControlsDocument1 pageNawara Project - Introduction of Positive Pressure Hazards and ControlsMajdiSahnounNo ratings yet

- JSA For Hydro Test Activites GenericDocument4 pagesJSA For Hydro Test Activites GenericMajdiSahnounNo ratings yet

- Lecture 1 - Intro and SolidWorks PCBDocument17 pagesLecture 1 - Intro and SolidWorks PCBmyturtle gameNo ratings yet

- XCMG Construction Machinery Co., LTDDocument4 pagesXCMG Construction Machinery Co., LTD余No ratings yet

- Bomba de Vácuo Sotorbilt 4mrDocument12 pagesBomba de Vácuo Sotorbilt 4mrWormInchNo ratings yet

- Taipei 102Document2 pagesTaipei 102militansinaNo ratings yet

- TSA Surface Preparation and ApplicationDocument7 pagesTSA Surface Preparation and ApplicationMythri Metallizing Pvt Ltd Projects100% (1)

- Getting Started With Java: Atul PrakashDocument20 pagesGetting Started With Java: Atul PrakashOwsozeroNo ratings yet

- Saurabh ShrivastavaDocument37 pagesSaurabh ShrivastavaMahendraNo ratings yet

- Chapter.8: Oscillators: ObjectivesDocument13 pagesChapter.8: Oscillators: ObjectivessivasankarnaiduNo ratings yet

- Investigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProDocument4 pagesInvestigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProEditor IJTSRDNo ratings yet

- Tensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositeDocument4 pagesTensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositemhmmdzulvaNo ratings yet

- DP Chipset 15045 DriversDocument592 pagesDP Chipset 15045 DriversRajesh1146No ratings yet

- Shaft Design Problem 10 - 12Document9 pagesShaft Design Problem 10 - 12BernalynMalinaoNo ratings yet

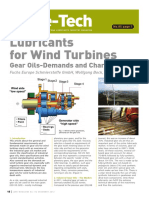

- Lube-Tech: Lubricants For Wind TurbinesDocument6 pagesLube-Tech: Lubricants For Wind TurbinesMC ANo ratings yet

- Dataproducts - LZR 1260 Laser Printer (1989)Document6 pagesDataproducts - LZR 1260 Laser Printer (1989)Bobby ChippingNo ratings yet

- Basic Electronics - AC - DC PDFDocument20 pagesBasic Electronics - AC - DC PDFRowena ResurreccionNo ratings yet

- Manual Técnico Sony HDC-DX70Document72 pagesManual Técnico Sony HDC-DX70Cristian MoraisNo ratings yet

- 101.S-4501 Steamer Cyclone Cleaning ProcedureDocument6 pages101.S-4501 Steamer Cyclone Cleaning ProcedureTRONGKIMNo ratings yet

- 2014 Summer Model Answer PaperDocument20 pages2014 Summer Model Answer Papercivil gpkpNo ratings yet

- Project Title: Hotel Management Software Project: PurposeDocument3 pagesProject Title: Hotel Management Software Project: PurposesuryaNo ratings yet

- Parameters by Functional CategoryDocument6 pagesParameters by Functional Categoryapi-3819698No ratings yet

- Sensores AvDocument12 pagesSensores Avhb CorpNo ratings yet

- Hela Bojuna - Comparative StatementDocument27 pagesHela Bojuna - Comparative StatementNadeeshani MunasingheNo ratings yet

- UAMDocument35 pagesUAMVishnu R PuthusseryNo ratings yet