Professional Documents

Culture Documents

3.5X3.5 MM SMD Chip Led Lamp: Attention

Uploaded by

Abel GaunaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.5X3.5 MM SMD Chip Led Lamp: Attention

Uploaded by

Abel GaunaCopyright:

Available Formats

3.5x3.

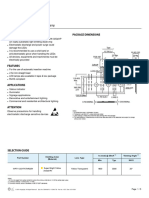

5 mm SMD CHIP LED LAMP

ATTENTION Part Number: AA3535SEL1Z1S Hyper Orange

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

DISCHARGE

SENSITIVE

DEVICES

Features Descriptions

z White SMD package, silicone resin. z The Hyper Orange device is made with TS AlGaInP

z Low thermal resistance. light emitting diode.

z Compatible with IR-reflow processes. z Electrostatic discharge and power surge could damage

z ESD protection. the LEDs.

z Package: 2000pcs / reel. z It is recommended to use a wrist band or anti-

z Moisture sensitivity level : level 2a. electrostatic glove when handling the LEDs.

z RoHS compliant. z All devices, equipments and machineries must be

electrically grounded.

Applications

z Signal and symbol luminaire for orientation.

z Marker lights (e.g. steps, exit ways, etc).

z Decorative and entertainment lighting.

z Commercial and residential lighting.

Package Dimensions z Automotive interior lighting.

Recommended Soldering Pattern

(Units : mm; Tolerance: ±0.1)

Notes:

1. All dimensions are in millimeters (inches).

2. Tolerance is ±0.25(0.01") unless otherwise noted.

3. The specifications, characteristics and technical data described in the datasheet are subject to change without prior notice.

4. The device has a single mounting surface. The device must be mounted according to the specifications.

SPEC NO: DSAJ4024 REV NO: V.10B DATE: AUG/10/2014 PAGE: 1 OF 6

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.Liu ERP: 1201007945

Handling Precautions

Compare to epoxy encapsulant that is hard and brittle, silicone is softer and flexible. Although its characteristic

significantly reduces thermal stress, it is more susceptible to damage by external mechanical force.

As a result, special handling precautions need to be observed during assembly using silicone encapsulated

LED products. Failure to comply might lead to damage and premature failure of the LED.

1. Handle the component along the side surfaces by using forceps or appropriate tools.

2. Do not directly touch or handle the silicone lens surface. It may damage the internal circuitry.

3. Do not stack together assembled PCBs containing exposed LEDs. Impact may scratch the silicone lens or

damage the internal circuitry.

4.1. The inner diameter of the SMD pickup nozzle should not exceed the size of the LED to prevent air leaks.

4.2. A pliable material is suggested for the nozzle tip to avoid scratching or damaging the LED surface during pickup.

4.3. The dimensions of the component must be accurately programmed in the pick-and-place machine to insure precise pickup

and avoid damage during production.

5. As silicone encapsulation is permeable to gases, some corrosive substances such as H2S might corrode silver plating of

leadframe. Special care should be taken if an LED with silicone encapsulation is to be used near such substances.

SPEC NO: DSAJ4024 REV NO: V.10B DATE: AUG/10/2014 PAGE: 2 OF 6

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.Liu ERP: 1201007945

Selection Guide

Iv (cd) [2] Φv (lm) [2]* Viewing

Part No. Dice Lens Type @ 150mA @ 150mA Angle [1]

Min. Typ. Min. Typ. 2 θ 1/2

AA3535SEL1Z1S Hyper Orange (AlGaInP) Water Clear 2.7 3.6 8.6 11 120 °

Notes:

1. θ1/2 is the angle from optical centerline where the luminous intensity is 1/2 of the optical peak value.

2. Luminous intensity/ luminous Flux: +/-15%.*LEDs are binned according to their luminous flux.

3.Luminous intensity flux value is traceable to the CIE127-2007 compliant national standards.

Absolute Maximum Ratings at TA=25°C

Parameter Symbol Value Unit

Power Dissipation PD 510 mW

Junction Temperature [1] TJ 130 °C

Operating Temperature Top -40 To +85 °C

Storage Temperature Tstg -40 To +85 °C

DC Forward Current [1] IF 150 mA

Reverse Voltage VR 5 V

Peak Forward Current [2] IFM 270 mA

Thermal Resistance [1]

Rth j-a 240 °C/W

(Junction/ambient)

Thermal Resistance [1]

Rth j-S 100 °C/W

(Junction/solder point)

Electrostatic Discharge Threshold (HBM) 8000 V

Notes:

1.Results from mounting on PC board FR4(pad size ≥ 70mm 2 ), mounted on pc board-metal core PCB is recommend

for lowest thermal Resistance.

2.1/10 Duty Cycle, 0.1ms Pulse Width.

Electrical / Optical Characteristics at TA=25°C

Parameter Symbol Value Unit

Wavelength at peak emission IF=150mA [Typ.] λ peak 630 nm

Dominant Wavelength IF=150mA [Typ.] λ dom [1] 618 nm

Spectral Line Half-width IF=150mA [Typ.] Δλ 20 nm

Forward Voltage IF=150mA [Min.] 2.4

Forward Voltage IF=150mA [Typ.] VF [2] 2.9 V

Forward Voltage IF=150mA [Max.] 3.4

Allowable Reverse Current [Max.] IR 85 mA

Temperature coefficient of λ peak

TC λ peak 0.11 nm/ ° C

IF=150mA, -10 ° C≤ T≤100 ° C [Typ.]

Temperature coefficient of λ dom

TC λ dom 0.09 nm/ ° C

IF=150mA, -10 ° C≤ T≤100 ° C [Typ.]

Temperature coefficient of VF

TCV -3.6 mV/ ° C

IF=150mA, -10 ° C≤ T≤100 ° C [Typ.]

Notes:

1.Wavelength: +/-1nm.

2. Forward Voltage: +/-0.1V.

3.Wavelength value is traceable to the CIE127-2007 compliant national standards.

SPEC NO: DSAJ4024 REV NO: V.10B DATE: AUG/10/2014 PAGE: 3 OF 6

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.Liu ERP: 1201007945

Hyper Orange AA3535SEL1Z1S

SPEC NO: DSAJ4024 REV NO: V.10B DATE: AUG/10/2014 PAGE: 4 OF 6

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.Liu ERP: 1201007945

AA3535SEL1Z1S

Reflow soldering is recommended and the soldering profile is shown below.

Other soldering methods are not recommended as they might cause damage to the product.

Reel Dimension

Tape Specifications

(Units : mm)

SPEC NO: DSAJ4024 REV NO: V.10B DATE: AUG/10/2014 PAGE: 5 OF 6

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.Liu ERP: 1201007945

PACKING & LABEL SPECIFICATIONS AA3535SEL1Z1S

Terms and conditions for the usage of this document

1.The information included in this document reflects representative usage scenarios and is intended

for technical reference only.

2.The part number, type, and specifications mentioned in this document are subject to future change

and improvement without notice. Before production usage customer should refer to the latest

datasheet for the updated specifications.

3.When using the products referenced in this document, please make sure the product is being

operated within the environmental and electrical limits specified in the datasheet. If customer usage

exceeds the specified limits, Kingbright will not be responsible for any subsequent issues.

4.The information in this document applies to typical usage in consumer electronics applications.

If customer's application has special reliability requirements or have life-threatening liabilities,

such as automotive or medical usage, please consult with Kingbright representative for further

assistance.

5.The contents and information of this document may not be reproduced or re-transmitted without

permission by Kingbright.

6.All design applications should refer to Kingbright application notes available at

http://www.KingbrightUSA.com/ApplicationNotes

SPEC NO: DSAJ4024 REV NO: V.10B DATE: AUG/10/2014 PAGE: 6 OF 6

APPROVED: WYNEC CHECKED: Allen Liu DRAWN: Y.Liu ERP: 1201007945

You might also like

- Data Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesDocument2 pagesData Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesEtbn SnoaNo ratings yet

- Xpower: Preliminary Spec Part Number: Aad1-9090Sy9Zc/2-S Super Bright YellowDocument4 pagesXpower: Preliminary Spec Part Number: Aad1-9090Sy9Zc/2-S Super Bright YellowarturjatNo ratings yet

- Subminiature Solid State Lamp: AttentionDocument5 pagesSubminiature Solid State Lamp: Attentionn tanevarNo ratings yet

- 1W High Power LED PDFDocument14 pages1W High Power LED PDFdyaza_1No ratings yet

- Technical Data Sheet Power LED @150ma Current: 34-03UYC/S599Document8 pagesTechnical Data Sheet Power LED @150ma Current: 34-03UYC/S599Jeannot MpianaNo ratings yet

- Kingbright: T-1 3/4 (5Mm) Full Color Led LampDocument8 pagesKingbright: T-1 3/4 (5Mm) Full Color Led LampAbhijit GhoshNo ratings yet

- Apfa3010Lseezgkqbkc: 3.0 X 1.0 MM Right Angle SMD Chip LED LampDocument4 pagesApfa3010Lseezgkqbkc: 3.0 X 1.0 MM Right Angle SMD Chip LED LampHemantkumarNo ratings yet

- T-1 3/4 (5mm) SOLID STATE LAMPDocument6 pagesT-1 3/4 (5mm) SOLID STATE LAMPGiuseppe ZuffelatoNo ratings yet

- Vbhw1149jte 100 TRDocument26 pagesVbhw1149jte 100 TRdenysenkovovan84No ratings yet

- Technical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290StuxnetNo ratings yet

- 3535 White 1W SMD - Specification - R3 - 20160129Document20 pages3535 White 1W SMD - Specification - R3 - 20160129Anonymous G1iPoNOKNo ratings yet

- T-1 3/4 (5mm) SOLID STATE LAMPDocument6 pagesT-1 3/4 (5mm) SOLID STATE LAMPAnkit SrivastavaNo ratings yet

- Luckylight: 0805 Package Blue Chip LED Technical Data SheetDocument9 pagesLuckylight: 0805 Package Blue Chip LED Technical Data SheetWaltencirNo ratings yet

- Everlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDocument4 pagesEverlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDhuck DhNo ratings yet

- Is Now Part ofDocument8 pagesIs Now Part ofGabrielConsentidoNo ratings yet

- 10W High Power LED: Features: Package DimensionsDocument4 pages10W High Power LED: Features: Package DimensionsilieoniciucNo ratings yet

- LED Chip LGDocument18 pagesLED Chip LGMinh Khuê Nguyễn ThịNo ratings yet

- Uvtop260 FW To39 LEDDocument5 pagesUvtop260 FW To39 LEDslowmosquitoNo ratings yet

- Data Sheet: para Light Electronics Co., LTDDocument14 pagesData Sheet: para Light Electronics Co., LTDmuaadhNo ratings yet

- 3528 SMD Chip LED - Red: FeaturesDocument5 pages3528 SMD Chip LED - Red: FeaturesdogeballNo ratings yet

- BN44 00852a L48MSF FdyDocument53 pagesBN44 00852a L48MSF FdyRaimundo SantanaNo ratings yet

- Uvled 385 nv3bDocument5 pagesUvled 385 nv3b林益祥No ratings yet

- Kingbright: 2X5Mm Rectangular Led LampDocument6 pagesKingbright: 2X5Mm Rectangular Led LampGorea GrigNo ratings yet

- Technical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290StuxnetNo ratings yet

- LED - EVERLIGHT - 67-21S-Y2C-D8595B7L32128Z6-2T - V1 (Novo PLCC2835-60mA-Amarelo)Document10 pagesLED - EVERLIGHT - 67-21S-Y2C-D8595B7L32128Z6-2T - V1 (Novo PLCC2835-60mA-Amarelo)Carlos H. GojleviciusNo ratings yet

- 200-1788 Yellow PDFDocument4 pages200-1788 Yellow PDFAdriana CostaNo ratings yet

- 1N4148WS (T4)Document4 pages1N4148WS (T4)DuanReisNo ratings yet

- ET-3528-C 1W White Datasheet: PLCC SeriesDocument11 pagesET-3528-C 1W White Datasheet: PLCC SeriesconganthonNo ratings yet

- TLP731 Datasheet en 20170518Document10 pagesTLP731 Datasheet en 20170518Lucas HenriqueNo ratings yet

- SMD Led Product Data Sheet: Ltst-C170KgktDocument12 pagesSMD Led Product Data Sheet: Ltst-C170KgktHemantkumarNo ratings yet

- STTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeDocument15 pagesSTTH1R02: 200 V - 1.5 A Ultrafast Recovery DiodeAlex Nicole SanchezNo ratings yet

- STTH1R02 200V 1.5A U-FastDocument15 pagesSTTH1R02 200V 1.5A U-Fastrara221122raraNo ratings yet

- Apgf0606Seekcgkxc-Tt: 0.65 X 0.65 X 0.2 MM Bi-Color Surface Mount LEDDocument4 pagesApgf0606Seekcgkxc-Tt: 0.65 X 0.65 X 0.2 MM Bi-Color Surface Mount LEDCarlos ParapeNo ratings yet

- Led 5mm Verde PDFDocument4 pagesLed 5mm Verde PDFCarlos Muñoz HernándezNo ratings yet

- Is Now Part ofDocument7 pagesIs Now Part offrancescoNo ratings yet

- HB CLS6B FKWDocument11 pagesHB CLS6B FKWkrishNo ratings yet

- AERD N2xB DS101Document9 pagesAERD N2xB DS101William Medina GómezNo ratings yet

- Display - ELD-511SURWB-S530-A3Document5 pagesDisplay - ELD-511SURWB-S530-A3guibsgvNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysDocument6 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysStuxnetNo ratings yet

- WP7113SYTKTNR254: T-1 3/4 (5mm) Tape and Reel LED LampDocument5 pagesWP7113SYTKTNR254: T-1 3/4 (5mm) Tape and Reel LED LampEnzo SánchezNo ratings yet

- 10.92mm (0.43INCH) SINGLE DIGIT NUMERIC DisplayDocument4 pages10.92mm (0.43INCH) SINGLE DIGIT NUMERIC DisplayoscarNo ratings yet

- 2 SIC9231SE EN Rev1.0Document6 pages2 SIC9231SE EN Rev1.0Vishal dtuNo ratings yet

- Xpower: Preliminary Spec Part Number: Aad1-9090Qb10Zc-SDocument4 pagesXpower: Preliminary Spec Part Number: Aad1-9090Qb10Zc-SJuan David OrtizNo ratings yet

- Lites06889-1 0Document5 pagesLites06889-1 0edward blancoNo ratings yet

- Preliminary Spec: 10Mm (0.4inch) Dual Digit Numeric DisplayDocument4 pagesPreliminary Spec: 10Mm (0.4inch) Dual Digit Numeric DisplaycepimasterodroNo ratings yet

- APG1005CGC-T: 1.0 X 0.5 X 0.2 MM (0402) SMD Chip LED LampDocument4 pagesAPG1005CGC-T: 1.0 X 0.5 X 0.2 MM (0402) SMD Chip LED LampAbel GaunaNo ratings yet

- TLP731, TLP732: Office Machine Household Use Equipment Solid State Relay Switching Power SupplyDocument9 pagesTLP731, TLP732: Office Machine Household Use Equipment Solid State Relay Switching Power SupplysNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysStuxnetNo ratings yet

- Cinta Led SMD 5060 Interior RGB 30 Led M 12v 96w M 1m PDFDocument3 pagesCinta Led SMD 5060 Interior RGB 30 Led M 12v 96w M 1m PDFJacob MelladoNo ratings yet

- Everlight Electronics Co., LTD.: 5mm PhototransistorDocument7 pagesEverlight Electronics Co., LTD.: 5mm PhototransistorFrancisco Javier González HernándezNo ratings yet

- LS SF67 (8) 1usd24Document7 pagesLS SF67 (8) 1usd24Nexor PocztaNo ratings yet

- P-Series 0.5W White SPMWHT366EA3: Middle Power LED PLCC SeriesDocument19 pagesP-Series 0.5W White SPMWHT366EA3: Middle Power LED PLCC SeriesRivera FernandoNo ratings yet

- Datasheet Bd9422efvDocument28 pagesDatasheet Bd9422efvj0rge avendañoNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysStuxnetNo ratings yet

- KingbrightDocument5 pagesKingbrightEazhil PreethiNo ratings yet

- Dnmc6000e2e3 SM V01Document82 pagesDnmc6000e2e3 SM V01Erick Alexander JimenezNo ratings yet

- Display 7 Segmentos 7mm Da03-11srwaDocument4 pagesDisplay 7 Segmentos 7mm Da03-11srwaDJ_CROWNNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.39" Single Digit DisplaysStuxnetNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- MC34063A, MC33063A, NCV33063A 1.5 A, Step Up/Down/ Inverting Switching RegulatorsDocument14 pagesMC34063A, MC33063A, NCV33063A 1.5 A, Step Up/Down/ Inverting Switching RegulatorsVũ TưởngNo ratings yet

- ULN2803-SMD: Array Darlington 5A 50V TTL SMDocument12 pagesULN2803-SMD: Array Darlington 5A 50V TTL SMAbel GaunaNo ratings yet

- 4 Pin Dip Phototransistor Photocoupler EL817 Series: FeaturesDocument13 pages4 Pin Dip Phototransistor Photocoupler EL817 Series: FeaturesDavid Santiago Daza QuirogaNo ratings yet

- Ds ft232rDocument40 pagesDs ft232rapi-432313169No ratings yet

- Ap3031 PDFDocument17 pagesAp3031 PDFAbel GaunaNo ratings yet

- S-8261 Series: Battery Protection Ic For 1-Cell PackDocument33 pagesS-8261 Series: Battery Protection Ic For 1-Cell PackAbel GaunaNo ratings yet

- AP3031Document30 pagesAP3031Abel GaunaNo ratings yet

- MAX232x Dual EIA-232 Drivers/Receivers: 1 Features 3 DescriptionDocument27 pagesMAX232x Dual EIA-232 Drivers/Receivers: 1 Features 3 DescriptionLuisNo ratings yet

- Mbra340t3 DDocument5 pagesMbra340t3 DAbel GaunaNo ratings yet

- BAS16 Series: 1. Product ProfileDocument21 pagesBAS16 Series: 1. Product ProfileAbel GaunaNo ratings yet

- STTH 102Document12 pagesSTTH 102Abel GaunaNo ratings yet

- Sk34 Schottky Rectifier: ApplicationsDocument5 pagesSk34 Schottky Rectifier: ApplicationsAbel GaunaNo ratings yet

- MMBT3906: 40V PNP Small Signal Transistor in Sot23Document7 pagesMMBT3906: 40V PNP Small Signal Transistor in Sot23Abel GaunaNo ratings yet

- SMD High Voltage Transistor (NPN)Document6 pagesSMD High Voltage Transistor (NPN)Abel GaunaNo ratings yet

- VLMW11..: Vishay SemiconductorsDocument8 pagesVLMW11..: Vishay SemiconductorsAbel GaunaNo ratings yet

- VLMW11..: Vishay SemiconductorsDocument8 pagesVLMW11..: Vishay SemiconductorsAbel GaunaNo ratings yet

- BC847BS PDFDocument12 pagesBC847BS PDFAbel GaunaNo ratings yet

- APG1005CGC-T: 1.0 X 0.5 X 0.2 MM (0402) SMD Chip LED LampDocument4 pagesAPG1005CGC-T: 1.0 X 0.5 X 0.2 MM (0402) SMD Chip LED LampAbel GaunaNo ratings yet

- Ao3401 PDFDocument5 pagesAo3401 PDFWalter FabianNo ratings yet

- S1A, S1B, S1D, S1G, S1J, S1K, S1M: Vishay General SemiconductorDocument4 pagesS1A, S1B, S1D, S1G, S1J, S1K, S1M: Vishay General SemiconductorAbel GaunaNo ratings yet

- Preliminary Spec: 3.2mmx1.6mm SMD CHIP LED LAMPDocument6 pagesPreliminary Spec: 3.2mmx1.6mm SMD CHIP LED LAMPAbel GaunaNo ratings yet

- VLMW11..: Vishay SemiconductorsDocument8 pagesVLMW11..: Vishay SemiconductorsAbel GaunaNo ratings yet

- 3.5X3.5 MM SMD Chip Led Lamp: AttentionDocument6 pages3.5X3.5 MM SMD Chip Led Lamp: AttentionAbel GaunaNo ratings yet

- BC847 SerDocument3 pagesBC847 SerAbel GaunaNo ratings yet

- BC847 Series: 1 Product ProfileDocument18 pagesBC847 Series: 1 Product ProfileAbel GaunaNo ratings yet

- Preliminary Spec: 3.2mmx1.6mm SMD CHIP LED LAMPDocument6 pagesPreliminary Spec: 3.2mmx1.6mm SMD CHIP LED LAMPAbel GaunaNo ratings yet

- BC847 Series: 1 Product ProfileDocument18 pagesBC847 Series: 1 Product ProfileAbel GaunaNo ratings yet

- C 1815Document2 pagesC 1815Abel GaunaNo ratings yet

- LTV 8X7 Series Lite OnDocument18 pagesLTV 8X7 Series Lite OnStick BohorquezNo ratings yet

- Newsela Teacher Review - Common Sense EducationDocument1 pageNewsela Teacher Review - Common Sense EducationJessicaNo ratings yet

- EvolutionCombatMedic 2022Document17 pagesEvolutionCombatMedic 2022smith.kevin1420344100% (1)

- 377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1Document7 pages377 Situational Expression Advanced Level Test Quiz Online Exercise With Answers 1zdravkamajkicNo ratings yet

- You're reading a free preview. Pages 4 to 68 are not shown in this preview. Leer la versión completa You're Reading a Free Preview Page 4 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 5 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 6 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 7 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 8 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 9 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 10 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 11 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 12 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 13 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 14 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 15 is notDocument9 pagesYou're reading a free preview. Pages 4 to 68 are not shown in this preview. Leer la versión completa You're Reading a Free Preview Page 4 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 5 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 6 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 7 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 8 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 9 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 10 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 11 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 12 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 13 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 14 is not shown in this preview. DESCARGA You're Reading a Free Preview Page 15 is notFernando ToretoNo ratings yet

- Hatayoga 1Document11 pagesHatayoga 1SACHIDANANDA SNo ratings yet

- Jar Doc 06 Jjarus Sora Executive SummaryDocument3 pagesJar Doc 06 Jjarus Sora Executive Summaryprasenjitdey786No ratings yet

- Math ExamDocument21 pagesMath ExamedgemarkNo ratings yet

- LMSTC Questionnaire EFFECTIVENESS IN THE IMPLEMENTATION OF LUCENA MANPOWER SKILLS TRAINING CENTER BASIS FOR PROGRAM ENHANCEMENTDocument3 pagesLMSTC Questionnaire EFFECTIVENESS IN THE IMPLEMENTATION OF LUCENA MANPOWER SKILLS TRAINING CENTER BASIS FOR PROGRAM ENHANCEMENTCriselda Cabangon DavidNo ratings yet

- Historical Perspective of OBDocument67 pagesHistorical Perspective of OBabdiweli mohamedNo ratings yet

- Marine-Derived Biomaterials For Tissue Engineering ApplicationsDocument553 pagesMarine-Derived Biomaterials For Tissue Engineering ApplicationsDobby ElfoNo ratings yet

- Pds Hempel's Maestro Water Borne Primer 28830 En-GbDocument2 pagesPds Hempel's Maestro Water Borne Primer 28830 En-GbKalaiyazhagan ElangeeranNo ratings yet

- Sidomuncul20190313064235169 1 PDFDocument298 pagesSidomuncul20190313064235169 1 PDFDian AnnisaNo ratings yet

- Programming MillDocument81 pagesProgramming MillEddy ZalieNo ratings yet

- 50 Law-Firms Details by Vaibhav SharmaDocument17 pages50 Law-Firms Details by Vaibhav SharmaApoorva NandiniNo ratings yet

- (QII-L2) Decorate and Present Pastry ProductsDocument30 pages(QII-L2) Decorate and Present Pastry ProductsLD 07100% (1)

- Coefficient of Restitution - Center of MassDocument3 pagesCoefficient of Restitution - Center of MassMannyCesNo ratings yet

- Technical DescriptionDocument2 pagesTechnical Descriptioncocis_alexandru04995No ratings yet

- Carte EnglezaDocument112 pagesCarte EnglezageorgianapopaNo ratings yet

- How To Make An Effective PowerPoint PresentationDocument12 pagesHow To Make An Effective PowerPoint PresentationZach Hansen100% (1)

- HC+ Shoring System ScaffoldDocument31 pagesHC+ Shoring System ScaffoldShafiqNo ratings yet

- Reviewer in EntrepreneurshipDocument6 pagesReviewer in EntrepreneurshipRachelle Anne SaldeNo ratings yet

- Distance SortDocument6 pagesDistance SortAI Coordinator - CSC JournalsNo ratings yet

- Context in TranslationDocument23 pagesContext in TranslationRaluca FloreaNo ratings yet

- Team 6 - Journal Article - FinalDocument8 pagesTeam 6 - Journal Article - FinalAngela Christine DensingNo ratings yet

- Under Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisDocument13 pagesUnder Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisMahmud RahmanNo ratings yet

- TABEL Sifat Uap Jenuh Tabel Suhu Dan TekananDocument8 pagesTABEL Sifat Uap Jenuh Tabel Suhu Dan Tekanan21-002 Alditua sinabaribaNo ratings yet

- Rate If Iodine and PropanoneDocument3 pagesRate If Iodine and Propanoneshareef1No ratings yet

- TRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateDocument4 pagesTRAVEL POLICY CARLO URRIZA OLIVAR Standard Insurance Co. Inc - Travel Protect - Print CertificateCarlo OlivarNo ratings yet

- Necromunda CatalogDocument35 pagesNecromunda Catalogzafnequin8494100% (1)

- 0409 Book About Minoru Yamasaki, ReviewDocument4 pages0409 Book About Minoru Yamasaki, RevieweviannNo ratings yet