Professional Documents

Culture Documents

Container Crane FEA

Uploaded by

Mogan RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Container Crane FEA

Uploaded by

Mogan RajCopyright:

Available Formats

Finite Element Simulation of Crane Boom Structure

in Container Gantry Crane

Insert names of all team members here

Insert your affiliation

Address – Line 1

Address – Line 2

Address – Line 3

1

e-mail: your email address, ph. +phone nos.

ABSTRACT

The rising demand in the maritime transport industry has dictated that container cranes are

increasing in size to cope with larger international traffic and containerised volumes. However

studies and investigations of wind induced collapses of these cranes boom have determined that

the crane’s tie-down system were the primary cause of failure and were found to be lacking in

their mechanical response due to failing at a fraction of the design load. It was therefore proposed

to examine the static loading, wind loading effects on a container crane with varied

environmental operating conditions using state of the art computational fluid dynamics and

compare with traditional conservative means. Analysis of mesh size, mesh type, and turbulence

model selection have been undertaken to independently characterise the accuracy of this analysis

and grid independence obtained.

Keywords: Failure, Static Loading, Wind Loading, Crane, Boom.

1 SKMM 3033 Finite Element Method-Project Report

Introduction

A)Function of Gantry Crane

1.Designed for loading and unloading the container cargo from a container vessel.

2.Capable of lifting some of the heaviest loads , used for tasks such as lifting container from ship

to port.

B)Problem identification

Container gantry crane structure will face some problems such:

-Wind force

-Vibration force (neglect)

-Deflection force (neglect)

C)Intrest of study

1)Front beam of boom

2)Major Forces:

-Maximum static load

-High force of wind load

-Maximum container load

D)Objectives

1)Carry out strength analysis of the boom in normal wind load operating condition.

2)Carry out strength analysis of the boom at extreme wind load operating condition

-typhoon wind condition

-level 5 wind condition

3) Determine the maximum container load that front part of the boom can handle

2 SKMM 3033 Finite Element Method-Project Report

1. Finite Element Model

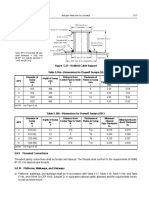

Provide a brief description of the model. Indicate dimensions of the model in the Figure. Label

important features on the figure. Refer to instructions in the OUTLINE OF REPORT (Part C)

Include Item D – Materials description in this section 2.

Figure 1. Geometry of a plate with a central hole

Figure 2. A quarter model of the plate with a central hole

3 SKMM 3033 Finite Element Method-Project Report

Figure 3. Finite element mesh of the model with triangular elements

2. Results and Discussion

Results of finite element simulation are presented and discussed in terms of deformation of the

plate, stress distribution and stress gradient.

2.1 Case 1- d/D = 0.2

Refer to instructions in the OUTLINE OF REPORT for the content of this section.

Figure 4a. Deformation of the quarter-model under tension load

4 SKMM 3033 Finite Element Method-Project Report

Figure 4b. Maximum principal stress distribution in the plate at P = 5 N

4

Distance (mm)

0

0 0.5 1 1.5 2 2.5 3 3.5

von Mises Stress (MPa)

Figure 4c. Variation of von Mises stress along path a-b (see Figure 2)

5 SKMM 3033 Finite Element Method-Project Report

2.2 Case 2- d/D = 0.5

Repeat discussion for this case, with Figure 5a, Figure 5b and Figure 5c, respectively.

(Repeat this section as required)

3. Conclusions

Stress concentration in a plate with central hole under tension has been analyzed using FEM.

Results show that;

The computed stress concentration factor is Kt = 2.9.

(Limit to 3 major conclusions)

4. References

1. (Provide list of references used)

2. (Limit to 5 references)

5. Acknowledgment

This work is part of a course on Finite Element Method conducted at … (This section is optional).

6 SKMM 3033 Finite Element Method-Project Report

You might also like

- Maritime Economics - Costs, Revenue and CashflowDocument45 pagesMaritime Economics - Costs, Revenue and Cashflowlavkesh100% (3)

- Technical Manual: At-Pac RinglockDocument20 pagesTechnical Manual: At-Pac RinglockKen Su100% (1)

- Tem 3413354 0101Document67 pagesTem 3413354 0101Kolawole KehindeNo ratings yet

- CEL Legacy CB200 Installation Manual PDFDocument18 pagesCEL Legacy CB200 Installation Manual PDFMartin LandersNo ratings yet

- ACE Agreement 5 - Homeowner (For Use in Scotland) Model Letter of Appointment For A Specific TaskDocument2 pagesACE Agreement 5 - Homeowner (For Use in Scotland) Model Letter of Appointment For A Specific TaskMelissa GrahamNo ratings yet

- BS-3037-2 Tyres For Crane - TMPDocument10 pagesBS-3037-2 Tyres For Crane - TMPgazali0% (1)

- Din en 14080-2005Document36 pagesDin en 14080-2005Debreteni Florin100% (2)

- A320 Documentation (1 CMP) PDFDocument198 pagesA320 Documentation (1 CMP) PDFRamakrishnan AmbiSubbiah75% (4)

- Yahama Golf Cart G2e Parts ManualDocument50 pagesYahama Golf Cart G2e Parts Manualtl3883100% (1)

- Under Running Single GirderDocument8 pagesUnder Running Single GirderJorge GtzNo ratings yet

- Assembly Guide - HD AgrDocument26 pagesAssembly Guide - HD AgrAlNo ratings yet

- Continental Steel CatalogueDocument175 pagesContinental Steel CatalogueTariq HasanNo ratings yet

- Y-Bc0035 GBDocument4 pagesY-Bc0035 GBYousef AlipourNo ratings yet

- Astm c150 Type 2Document14 pagesAstm c150 Type 2Dae Yeol KimNo ratings yet

- Lifting EquipmentDocument10 pagesLifting EquipmentMohamedNo ratings yet

- TCVN 4244-2005Document179 pagesTCVN 4244-2005Toàn ĐinhNo ratings yet

- Material Hoist Kit Operators Manual PDFDocument27 pagesMaterial Hoist Kit Operators Manual PDFSajeewa LakmalNo ratings yet

- Din 4024Document13 pagesDin 4024Muhammad HassanNo ratings yet

- JDN Monocrane - Manufacturers of Overhead Lifting EquipmentDocument19 pagesJDN Monocrane - Manufacturers of Overhead Lifting EquipmentJDN MonocraneNo ratings yet

- 07 - KeeLine OVERHEAD System Data Sheet ISS06Document19 pages07 - KeeLine OVERHEAD System Data Sheet ISS06Miguel Angel Fonseca AcevedoNo ratings yet

- Slip Form (Our Report)Document16 pagesSlip Form (Our Report)Simran DeepNo ratings yet

- Bending Moment Capacity of PipesDocument13 pagesBending Moment Capacity of Pipess3201696No ratings yet

- 10191Document7 pages10191Ravi KumarNo ratings yet

- 12 - (4th Civil) (R.C. Bridges) Box Girder BridgesDocument15 pages12 - (4th Civil) (R.C. Bridges) Box Girder BridgesAymanengNo ratings yet

- Exactly The Power You Need.: The NC-B SeriesDocument12 pagesExactly The Power You Need.: The NC-B SeriesbalanNo ratings yet

- KDACI New V1 PDFDocument30 pagesKDACI New V1 PDFVasaNo ratings yet

- m571c XL Cat d7g Web Spec SheetDocument2 pagesm571c XL Cat d7g Web Spec SheetRahmat RiskiNo ratings yet

- Aac Spec 377003Document25 pagesAac Spec 377003JakesNo ratings yet

- Technical Information On ISO Shipping Container: IOP Conference Series: Materials Science and EngineeringDocument8 pagesTechnical Information On ISO Shipping Container: IOP Conference Series: Materials Science and EngineeringĐăng ThạnhNo ratings yet

- ASCE 7.10 - Wind Loads PDFDocument60 pagesASCE 7.10 - Wind Loads PDFOsama TamariNo ratings yet

- Precast Wall Lifting AnchorsDocument40 pagesPrecast Wall Lifting AnchorsJacob Chirayil100% (1)

- Pallet Racking GuideDocument33 pagesPallet Racking GuideAnonymous 1gbsuaafddNo ratings yet

- Instability of Slender Concrete Deep BeamDocument12 pagesInstability of Slender Concrete Deep BeamFrederick TanNo ratings yet

- Platipus Anchors - Sheet Pile Tieback Specifications and Submittal Package PDFDocument13 pagesPlatipus Anchors - Sheet Pile Tieback Specifications and Submittal Package PDFDIEGO TUNARROSANo ratings yet

- Kitsen CatalogueDocument20 pagesKitsen CatalogueAbdul MunirNo ratings yet

- 125 128Document4 pages125 128Majdi JerbiNo ratings yet

- Quick Reference Sheet Standard Scaffold Tube in Accordance With BS 5973Document1 pageQuick Reference Sheet Standard Scaffold Tube in Accordance With BS 5973shear_stress8500No ratings yet

- Use of BS 5950Document3 pagesUse of BS 5950Smr Only100% (1)

- Astm F 1642 - 04Document8 pagesAstm F 1642 - 04Francisco GuerraNo ratings yet

- HSL-3 Heavy Duty Sleeve Anchor 4.3.2Document7 pagesHSL-3 Heavy Duty Sleeve Anchor 4.3.2Charlie ChuNo ratings yet

- American Structural ShapesDocument16 pagesAmerican Structural ShapesSYedZYnAleNo ratings yet

- Catalog ChinaDocument61 pagesCatalog Chinaa.muhammadNo ratings yet

- 2 Concept of Limit State DesignDocument3 pages2 Concept of Limit State DesignVinoth KumarNo ratings yet

- Is 3832 2005 PDFDocument18 pagesIs 3832 2005 PDFSachin5586No ratings yet

- Grating Install ClearanceDocument1 pageGrating Install ClearancenalzackNo ratings yet

- FFall Protection GuideDocument16 pagesFFall Protection GuidepguosNo ratings yet

- Webforge HandrailsDocument6 pagesWebforge HandrailsHezron Yopi Hendratama0% (1)

- DIV 15 Mechanical Labor1Document49 pagesDIV 15 Mechanical Labor1Anila SadasivanNo ratings yet

- NCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FacilDocument131 pagesNCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FaciliagpconceNo ratings yet

- Work Area Guards and HandrailsDocument5 pagesWork Area Guards and Handrailswatch_sutNo ratings yet

- Amortecedores de Poliuretano - WampflerDocument6 pagesAmortecedores de Poliuretano - WampflerrererererererererereNo ratings yet

- Sri Fire Protection Equipmets PDFDocument62 pagesSri Fire Protection Equipmets PDFamal_postNo ratings yet

- Container Lifting Lug - Columbus McKinnonDocument4 pagesContainer Lifting Lug - Columbus McKinnonJogi Oscar SinagaNo ratings yet

- En1991.1-Forklift LoadsDocument2 pagesEn1991.1-Forklift LoadsColin TanNo ratings yet

- DNV-OS-H205 Lifting Operations VMO Standard - Part 2-5 - Replaced With DNVGL ST N001Document1 pageDNV-OS-H205 Lifting Operations VMO Standard - Part 2-5 - Replaced With DNVGL ST N001SantanuNo ratings yet

- Scaffolding-Medical Cert.Document13 pagesScaffolding-Medical Cert.qoolshabiNo ratings yet

- Dokumen - Tips - Bsi Standards Publication 2019 12 13 Bs 59752019 A Tracked Changes ComparesDocument21 pagesDokumen - Tips - Bsi Standards Publication 2019 12 13 Bs 59752019 A Tracked Changes ComparesJohnNo ratings yet

- Concrete Topping IFC PDFDocument7 pagesConcrete Topping IFC PDFTEC PlantNo ratings yet

- Mechanics of Composite Materials - Coursework-2022-23-ResitDocument8 pagesMechanics of Composite Materials - Coursework-2022-23-ResitAdham SamanoudyNo ratings yet

- Stress History Generation For Truss Bridges Using Multi-Level ModelsDocument11 pagesStress History Generation For Truss Bridges Using Multi-Level Modelsjoaobarbosa22No ratings yet

- Flange Lateral Bending Stress (F) Under The Wind Pressure: Atorod Azizinamini, Ph.D.,P.EDocument41 pagesFlange Lateral Bending Stress (F) Under The Wind Pressure: Atorod Azizinamini, Ph.D.,P.EalbertoxinaNo ratings yet

- Failure Analysis of Bolted Steel FlangesDocument7 pagesFailure Analysis of Bolted Steel FlangesjcrosaNo ratings yet

- Coursework Brief - Resit - Rev0Document4 pagesCoursework Brief - Resit - Rev0mohammed qasimNo ratings yet

- Reinforced Concrete Continuous Beam Analysis and Design (CSA A23.3-14)Document44 pagesReinforced Concrete Continuous Beam Analysis and Design (CSA A23.3-14)Kriselle Jane Ang-angan GaerlanNo ratings yet

- IC Equipment Downtime Tracker Template 10559Document3 pagesIC Equipment Downtime Tracker Template 10559Mogan RajNo ratings yet

- Qa Learing SkillsDocument10 pagesQa Learing SkillsMarcia PattersonNo ratings yet

- (Page Name Not Set) Audit: Say Goodbye To Paper Checklists!Document3 pages(Page Name Not Set) Audit: Say Goodbye To Paper Checklists!Mogan RajNo ratings yet

- (Page Name Not Set) Audit: Say Goodbye To Paper Checklists!Document3 pages(Page Name Not Set) Audit: Say Goodbye To Paper Checklists!Mogan RajNo ratings yet

- Primary Copper Smelter and Refinery As A Recycling Plant-A System Integrated Approach To Estimate Secondary Raw Material ToleranceDocument11 pagesPrimary Copper Smelter and Refinery As A Recycling Plant-A System Integrated Approach To Estimate Secondary Raw Material ToleranceMogan RajNo ratings yet

- Single-Atom Catalysis Using Pt/Graphene Achieved Through Atomic Layer DepositionDocument10 pagesSingle-Atom Catalysis Using Pt/Graphene Achieved Through Atomic Layer DepositionMogan RajNo ratings yet

- The Proton Exchange Membrane Fuel Cell Should Play A Significant Role in A Hydrogen Economy Since It Enables Convenient and Direct Conversion of Hydrogen Into ElectricityDocument2 pagesThe Proton Exchange Membrane Fuel Cell Should Play A Significant Role in A Hydrogen Economy Since It Enables Convenient and Direct Conversion of Hydrogen Into ElectricityMogan RajNo ratings yet

- Research TankDocument1 pageResearch TankMogan RajNo ratings yet

- OUM GCED 21st Century - TOAZ - INFODocument13 pagesOUM GCED 21st Century - TOAZ - INFOMogan RajNo ratings yet

- SOP For RD TankDocument2 pagesSOP For RD TankMogan RajNo ratings yet

- Qa Learing SkillsDocument10 pagesQa Learing SkillsMarcia PattersonNo ratings yet

- SOP For RD TankDocument2 pagesSOP For RD TankMogan RajNo ratings yet

- OUM GCED 21st Century - 1Document12 pagesOUM GCED 21st Century - 1Mogan RajNo ratings yet

- SOP For RD TankDocument2 pagesSOP For RD TankMogan RajNo ratings yet

- Container Gantry Crane StructureDocument40 pagesContainer Gantry Crane StructureMogan RajNo ratings yet

- Report (Ikie)Document91 pagesReport (Ikie)Mogan RajNo ratings yet

- Scantling ResultDocument2 pagesScantling ResultMogan RajNo ratings yet

- Midship ScantlingDocument1 pageMidship ScantlingMogan RajNo ratings yet

- OLPODocument1 pageOLPOMogan RajNo ratings yet

- Importing A Background ImageDocument6 pagesImporting A Background ImageMogan RajNo ratings yet

- Green Port Marine TransportDocument3 pagesGreen Port Marine TransportMogan RajNo ratings yet

- Ship Design BittuDocument2 pagesShip Design BittuMogan RajNo ratings yet

- Importing A Background ImageDocument6 pagesImporting A Background ImageMogan RajNo ratings yet

- Governing EquationDocument26 pagesGoverning EquationMogan RajNo ratings yet

- Howtologin PDFDocument9 pagesHowtologin PDFMogan RajNo ratings yet

- SKMM3242 Instrumentation: Amplifier Lab ReportDocument15 pagesSKMM3242 Instrumentation: Amplifier Lab ReportMogan RajNo ratings yet

- Chap9 TariffsDocument25 pagesChap9 TariffsMogan RajNo ratings yet

- Man RunDocument30 pagesMan RunMogan RajNo ratings yet

- Annex A - Technical SpecificationsDocument52 pagesAnnex A - Technical SpecificationsNikko MontoyaNo ratings yet

- Upload Photosimages Into Custom Table & Print in Adobe FormDocument14 pagesUpload Photosimages Into Custom Table & Print in Adobe FormEmilSNo ratings yet

- The PA Bible Addn 03 Microphones PDFDocument4 pagesThe PA Bible Addn 03 Microphones PDFjosiasns5257100% (1)

- CAG Report On Antrix-Devas DealDocument76 pagesCAG Report On Antrix-Devas DealCanary Trap100% (1)

- Mooring SystemsDocument6 pagesMooring SystemsVinicius PessottiNo ratings yet

- f77 f55 User ManualDocument36 pagesf77 f55 User ManualGabi GabrielNo ratings yet

- Spirex": Onepiece Spiral Flexible CouplingDocument1 pageSpirex": Onepiece Spiral Flexible CouplingHazim HazimNo ratings yet

- Medium Voltage MZDocument86 pagesMedium Voltage MZsujiNo ratings yet

- Comparison of IEC IP and UL/NEMA TYPE Ratings: ControlsDocument1 pageComparison of IEC IP and UL/NEMA TYPE Ratings: ControlsEdwin LinNo ratings yet

- Polylux WebkatalogDocument96 pagesPolylux WebkatalogNesil Abiera50% (2)

- Blackboard 9.1Document49 pagesBlackboard 9.1ds532No ratings yet

- Standards of MeasurementDocument12 pagesStandards of MeasurementShubham KheraNo ratings yet

- PCMX Data Eng 01Document13 pagesPCMX Data Eng 01spamNo ratings yet

- M2.2.9 Critical Review and Selection of NDT MethodsDocument13 pagesM2.2.9 Critical Review and Selection of NDT MethodsAldy Bagus PratamaNo ratings yet

- Electrical & Civil-1resume PDFDocument2 pagesElectrical & Civil-1resume PDFanjar alamNo ratings yet

- AMICO InstallationManual PDFDocument60 pagesAMICO InstallationManual PDFfernandoNo ratings yet

- Tech. Specs. For 11 KV DP StructureDocument7 pagesTech. Specs. For 11 KV DP StructureSaraswatapalitNo ratings yet

- Quest CCS ProjectDocument10 pagesQuest CCS ProjecttruehemingwayNo ratings yet

- Hepworth Clay DoPs - Full SetDocument54 pagesHepworth Clay DoPs - Full SetAnonymous XYAPaxjbYNo ratings yet

- Transistor IRFP350Document7 pagesTransistor IRFP350MiguelAngelCedanoBurrolaNo ratings yet

- Nupack User Guide 3.2Document44 pagesNupack User Guide 3.2Dicastelgandolfo VchNo ratings yet

- Guinness Case StudyDocument3 pagesGuinness Case StudyMunyaradzi T HotoNo ratings yet

- Odi2-065r16m18s02-Q DS 0-0-0Document3 pagesOdi2-065r16m18s02-Q DS 0-0-0leolima trustitNo ratings yet

- Procesos SCRUMDocument2 pagesProcesos SCRUMRoseNo ratings yet

- ReadmeDocument9 pagesReadmewatzzupNo ratings yet

- NextCloud OnlyOffice PDFDocument89 pagesNextCloud OnlyOffice PDFOmar Gallegos Vazquez100% (1)