Professional Documents

Culture Documents

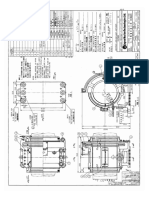

SKF-coupling OK 270 HB

Uploaded by

Mischa CHO0 ratings0% found this document useful (0 votes)

108 views6 pagesSKF-coupling OK 270 HB

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSKF-coupling OK 270 HB

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

108 views6 pagesSKF-coupling OK 270 HB

Uploaded by

Mischa CHOSKF-coupling OK 270 HB

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

Date 1980-04-01 180-490.

INSTRUCTIONS FOR MOUNTING AND DISMOUNTING

of shaft coupling OK __270 _HB used on the

olld/hollow shafting in__ Hull No 402

THE PRINCIPLE OF THE COUPLING

The OK-HB coupling consists basically of two sleeves of high quality steel, a thin inner sleeve and a thick

‘outer sleeve, The outer surface of the inner sleeve is slightly tapered and the bore of the outer sleeve has a

corresponding taper. The inner sleeve bore is somewhat larger than the diameter of the shafts, so that the sleeve

can be passed over them with ease. The outer sleeve is then driven up the tapered inner sleeve using the hy-

draulic unit incorporated in the coupling; this action compresses the inner sleeve onto both shafts. To allow

this drive-up, the friction of the matching tapered surfaces is first overcome by injecting oil at high pressure

between them, where it forms a load-carrying film separating the two components. When the outer sleeve has

reached its correct position, the injection pressure is released and the oil drains off, restoring normal friction

between the sleeves.

Dismounting the coupling is equally simple. Oil is injected between the coupling sleeves to overcome the

friction. As a result of the taper, the compressive force has an axial component which causes the outer sleeve

to slide down the taper, forcing the oil out of the hydraulic unit. By controlling the flow of this oil, the sleeve

can be prevented from sliding too quickly.

You might also like

- JMT Intermediate Shaft BearingDocument1 pageJMT Intermediate Shaft BearingMischa CHONo ratings yet

- CP Propeller Equipment OverviewDocument27 pagesCP Propeller Equipment OverviewFuchsbauNo ratings yet

- CAT Marine Products PDFDocument2 pagesCAT Marine Products PDFMischa CHONo ratings yet

- 3054 & 3056 Marine Generator Sets - Operation and Maintenance ManualDocument140 pages3054 & 3056 Marine Generator Sets - Operation and Maintenance ManualMischa CHO75% (4)

- Spec Sheet - Cat 3176C PropulsionDocument2 pagesSpec Sheet - Cat 3176C PropulsionMischa CHONo ratings yet

- 瓦锡兰样册brochure Marine Solutions 2016Document224 pages瓦锡兰样册brochure Marine Solutions 2016Mischa CHONo ratings yet

- SR4 Generator and Control Panels - Operation and Maintenance Manual PDFDocument64 pagesSR4 Generator and Control Panels - Operation and Maintenance Manual PDFMischa CHO94% (16)

- Engine Specs and Operating DataDocument91 pagesEngine Specs and Operating DataMischa CHO100% (1)

- Tools and Shop Products GuideDocument405 pagesTools and Shop Products GuideAnonymous 340A7vnwV1100% (1)

- VULKAN RATO-S CouplingDocument33 pagesVULKAN RATO-S CouplingMischa CHO100% (1)

- CAT-MaK Engineer Handbook - General Part PDFDocument193 pagesCAT-MaK Engineer Handbook - General Part PDFMischa CHO100% (1)

- III-2 Rolls-Royce Boegschroef Timca Manual + Scedules T9255-56 Rev A PDFDocument117 pagesIII-2 Rolls-Royce Boegschroef Timca Manual + Scedules T9255-56 Rev A PDFMischa CHO100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)