Professional Documents

Culture Documents

Concrete Pouring and Form Closure Request

Uploaded by

Jefferson Fontanilla GanadoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Pouring and Form Closure Request

Uploaded by

Jefferson Fontanilla GanadoCopyright:

Available Formats

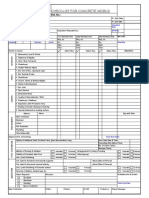

CONCRETE POURING PERMIT

Project:

Location:

Date Requested: CPTR. No.

Structure: Area/ Floor Level: Actual Inspection Date/ Time:

Gridline:

CHECK THAT THE FOLLOWING COMPLY WITH APPROVED SUBMITTALS FOR CONSTRUCTION DRAWINGS AND TECHNICAL SPECIFICATIONS

POURING REQUEST

Subject Area/Structure :

Concrete Strength :

Slump :

Elevation (From Reference Point) :

Date of Scheduled Pouring :

Estimated Volume : Actual Volume :

Time Started : Time Completed :

Number of Sample :

Complied

COMPONENTS Remarks Actions Required

DFC YES NO N/A

A. Formworks

1. Correct Elevation/ Layout

2. Required dimension / thickness satisfied

3. Squareness, Plumbness, Levelness Achieved

4. Adequate and appropriate shoring, braces and supports

5. Approved form-oil applied

a. Water based for Steel forms

b. Resin based for Phenolic Plywood

6. Cleanliness (free from saw dust, concrete laitances,

loose tie wires , debris and alike)

7. Approved construction joint key

B. Rebar

8. "For Construction" Plan, Issued Date:

9. Approved Rebar Cutting List, Ref. No:

10. Passed the Required Tests

11. Free from Scaling, Laitances and other Impurities

12. Concrete spacer minimum concrete covers

a. For Slab (1.0 meter space on center both ways)

b. For Beams ((Bottom/Side Bars, 2 pcs at every

0.80 meter)

13. Correct quantity and spacing

14. Correct splice location/length and development lengths

15. Minimum stirrups/ ties installed above concrete

termination for vertical structures

16. Approved shear bars/ keys at construction joints

C. MEPF Checklist Reference No.

17. Accomplished Electrical

Pre-Concreting Checklist (QC-MEPF-001)

18. Accomplished Plumbing

Sanitary Pre-Concreting Checklist (QC-MEPF-002)

19. Accomplished Fire Protection

Pre-Concreting Checklist (QC-MEPF-003)

20. Approved Penetrations

21. Accomplished Civil Dowels, etc

FORM STRIKING

REMARKS : DFC (Dimensions for Compliance)

INSPECTED BY: CHECKED BY: APPROVED BY:

Contractor's Project Engineer

FORMS CLOSURE REQUEST

Project:

Location:

Date Requested: CPTR. No.

Structure: Area/ Floor Level: Actual Inspection Date/ Time:

Gridline:

CHECK THAT THE FOLLOWING COMPLY WITH APPROVED SUBMITTALS FOR CONSTRUCTION DRAWINGS AND TECHNICAL SPECIFICATIONS

Complied

COMPONENTS Remarks Actions Required

DFC YES NO N/A

REINFORCING STEEL CHECKLIST

1. Bars are not misbent or damaged

2. Bars are free from dirt, loose mill scale, heavy rust, grease or

3. Bar identification are intact and and legible before use

4. After placing reinforcing bars :

5. Approved form-oil applied

a. Bars are free of loose mortar, rust, grease and other

b. Rebar type, size, fabrication, and positioning in accordance with

c. Total Quantity of rebars per schedule

d. Minimum Clearance Distance between bars is equal to nominal

e. For parallel bars in layer or mats the minimum clear distance

f. No. 11 bars and smaller bar are lap sliced. Larger bars are spliced

g. Lap length of splices is according to specifications and drawings.

h. Cover of bars meet or exceeds the minimum requirements.

i. Hook size, length, spacing, degree according to specifications and

j. Reinforcement is adequately supported. Columns, tie beams rest

k. Extra bars, stiffeners and others, according to plans and

l. Field bending or straigthening or rebars is done in accordance

m. Rebent or straightend bars are free of cracks or damage

FORMWORKS

5. Shape, line and grade, dimensions of form- in place

6. Cleaning and oil coating present over whole form area and

7. Tightness of joints and bracings adequate per approved

8. Location of construction/ control/ expansion joints

9. Installation of block-outs and pipes embedment

10. Adequate shoring supports on firm base

11. Vertical and Horizontal Control within tolerances

OPENINGS

12. Door opening according to drawings

13. Window opening according to drawings

14. Lintel Beams

15. Stiffener columns

PENETRATIONS (MEPF)

16. Pipe sleeves spacing, location, type according to drawings

REMARKS : DFC = Dimensions for Compliance

INSPECTED BY: CHECKED BY: APPROVED BY:

You might also like

- Check List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorDocument1 pageCheck List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorBala SubramanianNo ratings yet

- Checklist For Pre ConcretingDocument4 pagesChecklist For Pre ConcretingIfeanyi IwuallaNo ratings yet

- IPS Screed ChecklistDocument2 pagesIPS Screed ChecklistArc FortiusNo ratings yet

- Reinforcement ChecklistDocument1 pageReinforcement ChecklistCSEC Uganda Ltd.100% (2)

- Checklist For VDFDocument1 pageChecklist For VDFGabriel GabeNo ratings yet

- Checklist For ConcretingDocument4 pagesChecklist For ConcretingManish KapadneNo ratings yet

- Concrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17Document1 pageConcrete Pour Card - Checklist For Site Work - Rev. 7. Dtd. 24.08.17mahesh naikNo ratings yet

- Concrete Works ChecklistDocument1 pageConcrete Works Checklistmallikarjuna ketheNo ratings yet

- Checklist For Block Work Lay Out: Project: Client: Consultant: Contractor: Trojan & NPC (J.V.)Document1 pageChecklist For Block Work Lay Out: Project: Client: Consultant: Contractor: Trojan & NPC (J.V.)Mani AppaNo ratings yet

- Project Title:: Checklist For Block WorkDocument2 pagesProject Title:: Checklist For Block Workalfie100% (1)

- Check List For Rebar & FormworkDocument1 pageCheck List For Rebar & FormworkEbrahimAbuZaid0% (1)

- Footing - ChecklistDocument2 pagesFooting - ChecklistbsudhareddyNo ratings yet

- Water Supply ChecklistDocument1 pageWater Supply ChecklistBudoy Smith100% (1)

- Checklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC RequirementsDocument1 pageChecklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC Requirementsmanoj100% (1)

- Check List Shutter RebarDocument3 pagesCheck List Shutter RebarSalama ShurrabNo ratings yet

- Checklist For Column ConcretingDocument2 pagesChecklist For Column ConcretingJuan CTicona80% (5)

- Checklist for CP & Sanitary Accessories InstallationDocument24 pagesChecklist for CP & Sanitary Accessories InstallationparthNo ratings yet

- Concrete Placement Inspection ChecklistDocument4 pagesConcrete Placement Inspection Checklistzelda1022No ratings yet

- Water Proofing ChecklistDocument1 pageWater Proofing ChecklistBudoy SmithNo ratings yet

- Checklist For ShutteringDocument4 pagesChecklist For ShutteringMir Masood Shah0% (1)

- Checklist For Pre-Pour ConcretingDocument1 pageChecklist For Pre-Pour ConcretingDanish mallick100% (1)

- Inspection Test Report (ITR) : Steel Reinforcement ChecklistDocument1 pageInspection Test Report (ITR) : Steel Reinforcement Checklistjay2kay5793No ratings yet

- Inspection Checklist Format - Excavation, Stone Dust Filling & PCCDocument2 pagesInspection Checklist Format - Excavation, Stone Dust Filling & PCCgalfar7100% (2)

- Civil4M Aluminium Sliding Works ChecklistDocument1 pageCivil4M Aluminium Sliding Works ChecklistKishoreNo ratings yet

- Construction Checklist: Excavation, Concrete, BackfillingDocument12 pagesConstruction Checklist: Excavation, Concrete, BackfillingAlvin Badz0% (1)

- Checklist Beam BottomDocument16 pagesChecklist Beam BottomWHITENo ratings yet

- Quality Checklist For Site Works: External & Partition Wall/ RR MasonryDocument1 pageQuality Checklist For Site Works: External & Partition Wall/ RR MasonryBudoy Smith100% (1)

- Checklist For PCCDocument4 pagesChecklist For PCCVishnuhari DevarajNo ratings yet

- Gypsum Ceiling Checklist-R1Document1 pageGypsum Ceiling Checklist-R1KishoreNo ratings yet

- 6-Interior (FalseCeiling) QCDocument1 page6-Interior (FalseCeiling) QCConstruction UpdatePHNo ratings yet

- Checklist For Gypsum Plaster WorksDocument1 pageChecklist For Gypsum Plaster WorksSantosh YadavNo ratings yet

- Paver Blocks FixingDocument1 pagePaver Blocks FixingBharathraj RajNo ratings yet

- Checklist For Granite/Marble Works: Project: Doc. No.: Client: Project LocationDocument4 pagesChecklist For Granite/Marble Works: Project: Doc. No.: Client: Project LocationBeni N SoloNo ratings yet

- Checklist Door, Window, S&P, Plinth ProtectionDocument7 pagesChecklist Door, Window, S&P, Plinth Protectionsoumya0% (1)

- Checklist For ShutteringDocument2 pagesChecklist For ShutteringPravin Bote50% (2)

- Checklist - PCCDocument2 pagesChecklist - PCCajit karandikar100% (2)

- Pour CardDocument1 pagePour CardJohn DoeNo ratings yet

- Checklist For Tiling Wall Dadoing FlooringDocument4 pagesChecklist For Tiling Wall Dadoing FlooringickoNo ratings yet

- Drainage Works (Brickwall)Document1 pageDrainage Works (Brickwall)Siti Rohani IsdrisNo ratings yet

- Internalgypsumplaster 161202112115 PDFDocument2 pagesInternalgypsumplaster 161202112115 PDFReIngenieria S.R.L.No ratings yet

- Concrete Preplacement ChecklistDocument5 pagesConcrete Preplacement ChecklistAr Hitesh ParmarNo ratings yet

- Check List Handover Rev.0Document1 pageCheck List Handover Rev.0Ali Mari BalochNo ratings yet

- 02 Checklist For Interlocking Precast Concrete Pavers and Kerbstones PDFDocument1 page02 Checklist For Interlocking Precast Concrete Pavers and Kerbstones PDFDipin Nediyaparambath100% (3)

- Quality Control - Works Inspection: Glazed DoorsDocument1 pageQuality Control - Works Inspection: Glazed DoorsParasNo ratings yet

- Check List For CONCRETE Blinding WorksDocument1 pageCheck List For CONCRETE Blinding WorksYash SharmaNo ratings yet

- Checklist-Structural Concrete Pre PouringDocument1 pageChecklist-Structural Concrete Pre Pouringajit karandikar100% (1)

- Check List For Floor Screed WorksDocument1 pageCheck List For Floor Screed WorksYash SharmaNo ratings yet

- CHECKLIST FOR CONCRETING PROJECTSDocument13 pagesCHECKLIST FOR CONCRETING PROJECTSMin Khant AungNo ratings yet

- Ceiling Works Inspection ChecklistDocument1 pageCeiling Works Inspection ChecklistSiti Rohani Isdris100% (1)

- Checklist For SolingDocument2 pagesChecklist For SolingPradeep MalhotraNo ratings yet

- Check List For BlockworkDocument2 pagesCheck List For BlockworkVipin Kumar ParasharNo ratings yet

- Installation of Granite CounterDocument1 pageInstallation of Granite CounterBharathraj RajNo ratings yet

- Concrete Post-Pour Inspection ReportDocument1 pageConcrete Post-Pour Inspection ReportKamal FitriNo ratings yet

- Waterproofing Inside Kitchen & ToiletDocument1 pageWaterproofing Inside Kitchen & ToiletShyamontika Choudhury ChakrabartiNo ratings yet

- Dasarathi Naik and Engineers PVT - Ltd. Check List For ReinforcementDocument1 pageDasarathi Naik and Engineers PVT - Ltd. Check List For ReinforcementTusarranjan BhuyanNo ratings yet

- Check List For Excavation: Company NameDocument4 pagesCheck List For Excavation: Company NameVipin Kumar ParasharNo ratings yet

- 02 Pre Concreting Inspection RequestDocument2 pages02 Pre Concreting Inspection RequestAlmira raiza BustamanteNo ratings yet

- 5 CQM Manual Appendix IRC SP 47 1998 (Page 46to79)Document29 pages5 CQM Manual Appendix IRC SP 47 1998 (Page 46to79)Rupesh KumarNo ratings yet

- IR&PC - ConcreteDocument5 pagesIR&PC - ConcreteSukumarNo ratings yet

- Storm Water Drainage ChecklistDocument2 pagesStorm Water Drainage ChecklistShubhadeep MannaNo ratings yet

- Name of PlannersDocument1 pageName of PlannersJefferson Fontanilla GanadoNo ratings yet

- 2016 Revised IRR Clean Format and Annexes 26 August 2016 PDFDocument149 pages2016 Revised IRR Clean Format and Annexes 26 August 2016 PDFRyan JD LimNo ratings yet

- Planners Planning Theory and PrinciplesDocument16 pagesPlanners Planning Theory and PrinciplesJefferson Fontanilla GanadoNo ratings yet

- Product Standards in Our Everyday LifeDocument45 pagesProduct Standards in Our Everyday LifeJefferson Fontanilla GanadoNo ratings yet

- CIP 16 - Measuring Concrete Flexural StrengthDocument2 pagesCIP 16 - Measuring Concrete Flexural StrengthMrcoke SeieNo ratings yet

- Concrete Cover For ReinforcementDocument7 pagesConcrete Cover For ReinforcementJefferson Fontanilla GanadoNo ratings yet

- Series 10 (Class 100) Used For Water Distribution Main System and Socket TypeDocument3 pagesSeries 10 (Class 100) Used For Water Distribution Main System and Socket TypeJefferson Fontanilla GanadoNo ratings yet

- CV301 Lab 4 Flexural Strength of Concrete 09-08-20Document5 pagesCV301 Lab 4 Flexural Strength of Concrete 09-08-20Muhammad Ali HafeezNo ratings yet

- Specification and Grading For RSBDocument1 pageSpecification and Grading For RSBJefferson Fontanilla GanadoNo ratings yet

- Sample Notice To ProceedDocument2 pagesSample Notice To ProceedJefferson Fontanilla GanadoNo ratings yet

- WSDOT FOP for Making Concrete CylindersDocument10 pagesWSDOT FOP for Making Concrete CylindersJefferson Fontanilla GanadoNo ratings yet

- Procedure For Bldg. Permit RegularDocument2 pagesProcedure For Bldg. Permit RegularJefferson Fontanilla GanadoNo ratings yet

- GAM RatingDocument6 pagesGAM RatingJefferson Fontanilla GanadoNo ratings yet

- Fishermen'S Village: Term Item AmountDocument2 pagesFishermen'S Village: Term Item AmountJefferson Fontanilla GanadoNo ratings yet

- 1987 ConstitutionDocument49 pages1987 ConstitutionAerwin AbesamisNo ratings yet

- RA 9507 Loan Restructuring Condonation of Socialized HousingDocument7 pagesRA 9507 Loan Restructuring Condonation of Socialized HousingJefferson Fontanilla GanadoNo ratings yet

- Basic Principles of Urban DesignDocument1 pageBasic Principles of Urban DesignJefferson Fontanilla GanadoNo ratings yet

- ECOLOGICAL PROFILE OutlineDocument2 pagesECOLOGICAL PROFILE OutlineJefferson Fontanilla GanadoNo ratings yet

- PHL Ra 7586 NIPAS ACTDocument36 pagesPHL Ra 7586 NIPAS ACTDexter John Gomez JomocNo ratings yet

- RevisedIRR RA9184Document299 pagesRevisedIRR RA9184Francis Jr CastroNo ratings yet

- Q A On Local Housing Laws Programs and Organizations PDFDocument54 pagesQ A On Local Housing Laws Programs and Organizations PDFJefferson Fontanilla GanadoNo ratings yet

- RevisedIRR RA9184Document299 pagesRevisedIRR RA9184Francis Jr CastroNo ratings yet

- Commercial Printing: How To Speak The Language: Accordion Fold BinderyDocument8 pagesCommercial Printing: How To Speak The Language: Accordion Fold BinderyJefferson Fontanilla GanadoNo ratings yet

- Methods of TestingsDocument9 pagesMethods of TestingsJefferson Fontanilla GanadoNo ratings yet

- Schedule of Minimum Test Requirements PDFDocument6 pagesSchedule of Minimum Test Requirements PDFJefferson Fontanilla GanadoNo ratings yet

- Father's Love LetterDocument6 pagesFather's Love LetterJefferson Fontanilla GanadoNo ratings yet

- Curtain Wall Systems GuideDocument37 pagesCurtain Wall Systems GuideMarc Gregory Queral Olanio80% (5)

- Date-070209 SR - No. Description Unit Rate A Rcc. WorkDocument6 pagesDate-070209 SR - No. Description Unit Rate A Rcc. WorkNiroshan Naguleswaran0% (1)

- QTs EcoSeriesDocument22 pagesQTs EcoSeriesasrihamidNo ratings yet

- Gothic ArchitectureDocument95 pagesGothic ArchitectureJean Angelove SantosNo ratings yet

- Proposal Structure AnalysisDocument3 pagesProposal Structure AnalysisVincent TeoNo ratings yet

- 5.2a Bridge Construction MethodsDocument211 pages5.2a Bridge Construction MethodsJulrey Angelo SedenoNo ratings yet

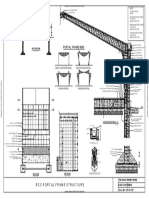

- 1701 and 1707 RCC Portal FrameDocument1 page1701 and 1707 RCC Portal Frame1707 Bhitale SiddharthNo ratings yet

- S1, S2 - S3 - S4 - MergedDocument4 pagesS1, S2 - S3 - S4 - Mergedselvakumar sNo ratings yet

- 2 Straight Line Diag.Document1 page2 Straight Line Diag.Nix GabrielNo ratings yet

- Mies van der Rohe Architectural ReportDocument34 pagesMies van der Rohe Architectural ReportAshish Hooda100% (1)

- Uma Material Schedule LatestDocument37 pagesUma Material Schedule LatestEmmanuel OtienoNo ratings yet

- Previous Papers PPSC Assistant Architect Competitive Exam Code 6350Document15 pagesPrevious Papers PPSC Assistant Architect Competitive Exam Code 6350Sukhdeep Singh58% (12)

- Wall Load Chase Down ExampleDocument2 pagesWall Load Chase Down ExampleBunkun15No ratings yet

- Detail Termination WaterproofingDocument14 pagesDetail Termination WaterproofingbaspiskoposNo ratings yet

- Front Elevation: Ceiling LineDocument1 pageFront Elevation: Ceiling LineMJian VergaraNo ratings yet

- Design of Seismic Force On BuildingDocument12 pagesDesign of Seismic Force On BuildingAjay DalviNo ratings yet

- Reid Furniture Store: Monthly TransactionsDocument15 pagesReid Furniture Store: Monthly TransactionsMintNo ratings yet

- Section X1-X1 Section X2-X2: Compacted Murram Base Compacted Murram Base Compacted Murram BaseDocument1 pageSection X1-X1 Section X2-X2: Compacted Murram Base Compacted Murram Base Compacted Murram BaseLubangakene BrianNo ratings yet

- Product Portfolio Systems and Solutions Guide: Wall Panels / Roof Panels / AccessoriesDocument42 pagesProduct Portfolio Systems and Solutions Guide: Wall Panels / Roof Panels / AccessoriesSuresh BabuNo ratings yet

- Visvesvaraya Technological University: "Shuttering and Scaffolding"Document27 pagesVisvesvaraya Technological University: "Shuttering and Scaffolding"Prem ChandraNo ratings yet

- Walter GropiusDocument25 pagesWalter GropiusSowmi MaheNo ratings yet

- Sample EstimateDocument58 pagesSample EstimateMark Kenneth P. OntejoNo ratings yet

- Coursed Rubble Stone Masonry in SuperstructureDocument4 pagesCoursed Rubble Stone Masonry in SuperstructureDeenNo ratings yet

- Perspective View: Majic Oven (Renovation)Document1 pagePerspective View: Majic Oven (Renovation)Joan GalangNo ratings yet

- Feroshah KotlaDocument7 pagesFeroshah KotlaHuzaifa J AhmedabadwalaNo ratings yet

- 9 SUPERSTUDIO Superprojects Objects, Monuments, CitiesDocument25 pages9 SUPERSTUDIO Superprojects Objects, Monuments, CitiesSabina IuliaNo ratings yet

- Quantity Take Off - NoneDocument375 pagesQuantity Take Off - NoneAnanya N BNo ratings yet

- Goldberg Copy3Document11 pagesGoldberg Copy3kundan_bokNo ratings yet

- Mep Material Submittals LogDocument1 pageMep Material Submittals LogSanthosh KumarNo ratings yet

- Answers-Construction Technology 1 House ConstructionDocument18 pagesAnswers-Construction Technology 1 House Constructionengsniper21No ratings yet