Professional Documents

Culture Documents

Fixed Times (After Loading) : Segment Seconds Minutes Hours

Uploaded by

Angeline ChiongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fixed Times (After Loading) : Segment Seconds Minutes Hours

Uploaded by

Angeline ChiongCopyright:

Available Formats

CHIONG, ANGELINE D.

EM 156 – Probset 2

2014-16900 Gabriel Pamintuan Jr., PhD

Given:

• Production drifts: 24.4m

• Production x-cuts: 12.2m

• Drift size: 4.2m x 4.1m

• Ore passes: 200m apart

• Caving rate: 0.30m/day

General Assumptions:

• Tramming distance is

minimized by assigning

draw points 1-8 to Ore

Pass 1 and draw points

9-16 to Ore Pass 2.

• Maximum tramming

distance = 100m

• Maximum truck speed =

10kph (up to 2nd gear)

• Available operating time

= 350min/shift for 3

shifts/day

• Loaded bucket maximum

capacity = 10 DMT

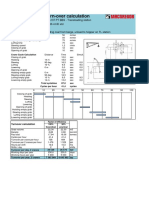

Time Motion Studies of Sandvik LH410-14

SEGMENT Seconds Minutes Hours

Fixed Times (After loading)

Back-out of draw point 0 0 0

Bucket to carry position 7.500 0.125 0.002

Maneuver 2.424 0.040 0.001

Travel to Dumping Point

Hauling 19.2 0.320 0.005

Fixed Times (Dumping Point)

Maneuver into dumping point 5.667 0.094 0.002

Lift bucket to dump 7.500 0.125 0.002

Dumping 2.200 0.037 0.001

Lower Bucket 4.000 0.067 0.001

Maneuver out of dumping point 5.667 0.094 0.002

Travel to Draw Point

Empty return 19.2 0.320 0.005

Fixed Times (Loading)

Maneuver into draw point 2.424 0 0

Lower bucket to digging position 4.000 0.067 0.001

Dig 7.500 0.125 0.002

TOTAL CYCLE TIME 87.281 1.455 0.024

CHIONG, ANGELINE D. EM 156 – Probset 2

2014-16900 Gabriel Pamintuan Jr., PhD

Other assumptions:

• 1st gear – driving speed for maneuvering

• 2nd gear – driving speed in production drifts

• No need to back out of draw point since the LHD will not enter the crosscuts anymore. Only

the buckets will maneuver towards the crosscuts.

• In maneuvering after loading, the turning angle of 42.5 degrees, and the average of the inner

and outer turning radius of 3.635m was used.

• In traveling to and from the dumping point, the average distance from drawpoint to ore passes

of 51.2m was used.

• Maneuvering in and out of the dumping point are done at 8.5m from the ore pass.

• Digging time is the same as the lifting of bucket.

Driving

kph mps

Speeds

1st gear 5.4 1.5

2nd gear 9.6 2.7

Draw Draw Distance to/from OP

Distance to/from OP (m)

point point (m)

1 8.5 9 93.9

2 20.7 10 81.7

3 32.9 11 69.5

4 45.1 12 57.3

5 57.3 13 45.1

6 69.5 14 32.9

7 81.7 15 20.7

8 93.9 16 8.5

AVERAGE 51.2

1. Production Capacity per LHD per day

𝑇𝑜𝑡𝑎𝑙 𝑎𝑣𝑎𝑖𝑙𝑎𝑏𝑙𝑒 𝑡𝑖𝑚𝑒 𝑡𝑜 ℎ𝑎𝑢𝑙 𝑝𝑒𝑟 𝑑𝑎𝑦 × 𝐵𝑢𝑐𝑘𝑒𝑡 𝑐𝑎𝑝𝑎𝑐𝑖𝑡𝑦

𝑃𝑟𝑜𝑑𝑢𝑐𝑡𝑖𝑜𝑛 𝑐𝑎𝑝𝑎𝑐𝑖𝑡𝑦 =

𝑇𝑜𝑡𝑎𝑙 𝑐𝑦𝑐𝑙𝑒 𝑡𝑖𝑚𝑒

𝑚𝑖𝑛 ℎ𝑟 𝑠ℎ𝑖𝑓𝑡𝑠 1ℎ𝑟

(50 ×7 ×3 )× × 10 𝐷𝑀𝑇

ℎ𝑟 𝑠ℎ𝑖𝑓𝑡 𝑑𝑎𝑦 60 𝑚𝑖𝑛

=

0.024 ℎ𝑟

= 𝟕𝟐𝟏𝟖. 𝟏𝟎𝟓 𝑫𝑴𝑻 𝒑𝒆𝒓 𝑳𝑯𝑫 𝒑𝒆𝒓 𝒅𝒂𝒚

2. Number of units required based on tonnage requirement

𝑇𝑜𝑛𝑛𝑎𝑔𝑒 𝑟𝑒𝑞𝑢𝑖𝑟𝑒𝑚𝑒𝑛𝑡

𝑁𝑜. 𝑜𝑓 𝑢𝑛𝑖𝑡𝑠 =

𝑃𝑟𝑜𝑑𝑢𝑐𝑡𝑖𝑜𝑛 𝑐𝑎𝑝𝑎𝑐𝑖𝑡𝑦

25,000 𝐷𝑀𝑇/𝑑𝑎𝑦

=

7218.105 𝐷𝑀𝑇/𝐿𝐻𝐷/𝑑𝑎𝑦

= 𝟑. 𝟒𝟔𝟒 ≈ 𝟒 𝒖𝒏𝒊𝒕𝒔 𝒐𝒇 𝑳𝑯𝑫

3. Cost of hauling per ton

𝑁𝑜. 𝑜𝑓 𝑢𝑛𝑖𝑡𝑠 × 𝑃𝑜𝑤𝑒𝑟 𝑜𝑢𝑡𝑝𝑢𝑡 × 𝑂𝑝𝑒𝑟𝑎𝑡𝑖𝑛𝑔 𝑡𝑖𝑚𝑒 × 𝐸𝑙𝑒𝑐𝑡𝑟𝑖𝑐𝑖𝑡𝑦 𝑟𝑎𝑡𝑒

𝐶𝑜𝑠𝑡 𝑝𝑒𝑟 𝑡𝑜𝑛 =

𝑇𝑜𝑛𝑛𝑎𝑔𝑒 𝑝𝑒𝑟 𝑑𝑎𝑦

ℎ𝑜𝑢𝑟𝑠 𝑃ℎ𝑝

4 𝑢𝑛𝑖𝑡𝑠 × 220 𝑘𝑊 × 17.5 × 5.84

𝑑𝑎𝑦 𝑘𝑊ℎ

=

25,000 𝐷𝑀𝑇/𝑑𝑎𝑦

= 𝑷𝒉𝒑 𝟑. 𝟓𝟗𝟕 𝒑𝒆𝒓 𝑫𝑴𝑻

You might also like

- Slide TSP308 TSP 308 005 Metoda Dan Peralatan KonstruksiDocument29 pagesSlide TSP308 TSP 308 005 Metoda Dan Peralatan KonstruksiMOHD SALMANNo ratings yet

- Arvin Nicole C. Alvarez 2012-00754 Bs em Problem Set 2Document2 pagesArvin Nicole C. Alvarez 2012-00754 Bs em Problem Set 2Arvin AlvarezNo ratings yet

- 608 P2 Lec02 DozerDocument83 pages608 P2 Lec02 DozerMohammad RaeisiNo ratings yet

- Cycletime HaulerDocument2 pagesCycletime HaulerAzmi MaulanaNo ratings yet

- Lecture 7 ProductivityDocument49 pagesLecture 7 Productivitywawan aries sandiNo ratings yet

- Nozzle Thrust and Efficiency MeasurementDocument12 pagesNozzle Thrust and Efficiency MeasurementDhruvNagpalNo ratings yet

- Basic Drilling CalculationsDocument56 pagesBasic Drilling CalculationsArvindNo ratings yet

- CBR Lab ReportDocument11 pagesCBR Lab ReportFazrul Amin50% (2)

- Chapter 2 Slide BDocument104 pagesChapter 2 Slide Bgidey67% (3)

- Lifting Capacity:2.93ton X 2.5mDocument3 pagesLifting Capacity:2.93ton X 2.5m이현기No ratings yet

- Divertion Timur Edit BuyaDocument10 pagesDivertion Timur Edit BuyaImam GozaliNo ratings yet

- Khwopa College of Engineering: Tribhuvan UniversityDocument9 pagesKhwopa College of Engineering: Tribhuvan UniversitySudip ShresthaNo ratings yet

- KEP Presentation NCJWDocument28 pagesKEP Presentation NCJWfilu786No ratings yet

- Relative Viscosity: Department of Mechanical EngineeringDocument6 pagesRelative Viscosity: Department of Mechanical EngineeringJenalyn FloresNo ratings yet

- Basic Drilling Calculations - FullDocument56 pagesBasic Drilling Calculations - FullMohamed Kamal100% (1)

- CBR Test 1Document6 pagesCBR Test 1Prabhav DeujaNo ratings yet

- English Instruction For ZYC200B-B1Document33 pagesEnglish Instruction For ZYC200B-B1sokimjamesNo ratings yet

- Q Q X X E X E: Produkt'y DozerDocument25 pagesQ Q X X E X E: Produkt'y DozerRicco GantengNo ratings yet

- CBR ExperimentDocument9 pagesCBR ExperimentAniket JainNo ratings yet

- Fleet Capacity Estimator v2Document41 pagesFleet Capacity Estimator v2Emmanuel InkoomNo ratings yet

- Air Quality DesignDocument15 pagesAir Quality DesignShermal FernandoNo ratings yet

- Bored PilingDocument7 pagesBored PilingEng Ly HengNo ratings yet

- Determination of CBR Value ObjectivesDocument7 pagesDetermination of CBR Value ObjectivesSaurav ShresthaNo ratings yet

- Phase Ii (Detailed Engineering Works) : I. Canal LocationDocument5 pagesPhase Ii (Detailed Engineering Works) : I. Canal LocationJescel AraracapNo ratings yet

- ZAT1200V753Technical Specifications 20231116Document142 pagesZAT1200V753Technical Specifications 20231116云逸No ratings yet

- Hangcha Self Propelled Electric Scissor Lifts - Aerial Work PlatformDocument2 pagesHangcha Self Propelled Electric Scissor Lifts - Aerial Work PlatformTommy SmithNo ratings yet

- Sandvik LH307 (TORO 6) (6 - 7t)Document2 pagesSandvik LH307 (TORO 6) (6 - 7t)Дмитрий АсташонокNo ratings yet

- Technical Specifications: Zoomlion Zlj5420Jqz55D Truck CraneDocument21 pagesTechnical Specifications: Zoomlion Zlj5420Jqz55D Truck CraneYulianto JoeNo ratings yet

- Rating Curve at Weir AxisDocument2 pagesRating Curve at Weir AxisbakrichodNo ratings yet

- Cyclone Design - Stairmand MethodDocument4 pagesCyclone Design - Stairmand MethodFaizan AhmedNo ratings yet

- Cement Process Engineering Vade-Mecum: 4. MillingDocument21 pagesCement Process Engineering Vade-Mecum: 4. Millinganwar saeedNo ratings yet

- Design of Outlets - JaboriDocument7 pagesDesign of Outlets - JaboriHaji Ahmad BhattiNo ratings yet

- P e W C: Project Job NoDocument1 pageP e W C: Project Job NoAnonymous 0x2pwMCWgjNo ratings yet

- Lifting PlanDocument19 pagesLifting PlanCoco Rhomo100% (3)

- DeWeese CVASP 2017Document84 pagesDeWeese CVASP 2017bobbyNo ratings yet

- BA16CERT2 Specication SheetDocument2 pagesBA16CERT2 Specication SheetAtila AmayaNo ratings yet

- نسخة من 1252639293TONMILESDocument6 pagesنسخة من 1252639293TONMILESAbdul Hameed OmarNo ratings yet

- Sand Control Lecture#2 - 13-05-2023Document16 pagesSand Control Lecture#2 - 13-05-2023Mohammed OmranNo ratings yet

- Consolidation (Part 2) Lecture 2Document36 pagesConsolidation (Part 2) Lecture 2Jawad AhmadNo ratings yet

- Submitted by Submitted To: Lab Report-03 Determination of Soil Intake Characteristics Using Cylinder InfiltrometerDocument4 pagesSubmitted by Submitted To: Lab Report-03 Determination of Soil Intake Characteristics Using Cylinder InfiltrometerMd. Murshedul Islam 173-47-091No ratings yet

- The Underground Experts: Key Specifications Components and OptionsDocument2 pagesThe Underground Experts: Key Specifications Components and Optionsjorge aliaga articaNo ratings yet

- 330D Texr0431 PDFDocument12 pages330D Texr0431 PDFsuwarjitechnicNo ratings yet

- Annex I-1 Process Technical and Production Capacity-Rev01Document29 pagesAnnex I-1 Process Technical and Production Capacity-Rev01jackhuguesNo ratings yet

- Q-DAT - August - 2010 - Version NW Region ST - Croix County Morning (Illustration)Document12 pagesQ-DAT - August - 2010 - Version NW Region ST - Croix County Morning (Illustration)Kocic GradnjaNo ratings yet

- TennisDocument14 pagesTennisElma MosticNo ratings yet

- ZT20J/ZT26J: Telescopic Boom LiftsDocument2 pagesZT20J/ZT26J: Telescopic Boom Liftskarthik bhatNo ratings yet

- Flow Process Chart: Chart No.:-1 Sheet No.: - 1Document4 pagesFlow Process Chart: Chart No.:-1 Sheet No.: - 1Wankhede SwapnilNo ratings yet

- Flow Process Chart: Chart No.:-1 Sheet No.: - 1Document4 pagesFlow Process Chart: Chart No.:-1 Sheet No.: - 1Wankhede SwapnilNo ratings yet

- Paterson Nut Ts 2009Document35 pagesPaterson Nut Ts 2009HI HINo ratings yet

- Page 55Document1 pagePage 55GANESH KUMARNo ratings yet

- S2632E/2646E/3246E: Slab Scissor LiftsDocument1 pageS2632E/2646E/3246E: Slab Scissor LiftsbejoythomasNo ratings yet

- Submitted by Submitted To: Lab Report-03 Determination of Soil Intake Characteristics Using Cylinder InfiltrometerDocument5 pagesSubmitted by Submitted To: Lab Report-03 Determination of Soil Intake Characteristics Using Cylinder InfiltrometerMd. Murshedul Islam 173-47-091No ratings yet

- Perhitungan Kebutuhan Unit Dan EOCDocument21 pagesPerhitungan Kebutuhan Unit Dan EOCHanna Rizanti KartinaNo ratings yet

- Experiment No-5 AD2Document15 pagesExperiment No-5 AD2bad guyNo ratings yet

- Infiltration Ponds: Pond WT Equiv Pond Size Aspect Silt/bio CorrDocument1 pageInfiltration Ponds: Pond WT Equiv Pond Size Aspect Silt/bio CorrJoseph Babu PNo ratings yet

- Turnover and Load Cycle - Transloading Station 2xK3030 + SULDocument1 pageTurnover and Load Cycle - Transloading Station 2xK3030 + SULafandybaharuddinNo ratings yet

- Daily Operations Report (DOR)Document3 pagesDaily Operations Report (DOR)Dheeraj KapoorNo ratings yet

- Experiment # 01Document8 pagesExperiment # 01qamarNo ratings yet

- Casing Design - ENI CompanyDocument87 pagesCasing Design - ENI CompanyLeon ZidaneNo ratings yet

- Ioi Group - Capric Acid 98%Document7 pagesIoi Group - Capric Acid 98%Wong MjNo ratings yet

- Javascript NotesDocument5 pagesJavascript NotesRajashekar PrasadNo ratings yet

- Bofa Turkish Banks-Back On The RadarDocument15 pagesBofa Turkish Banks-Back On The RadarexperhtmNo ratings yet

- Chanakya: For The Indian Television Series Based On His Life, SeeDocument11 pagesChanakya: For The Indian Television Series Based On His Life, SeeTrinadh CrazyguyNo ratings yet

- Bai Tap Av 12 Thi Diem Unit TwoDocument7 pagesBai Tap Av 12 Thi Diem Unit TwonguyenngocquynhchiNo ratings yet

- B2B Marketing: Chapter-8Document23 pagesB2B Marketing: Chapter-8Saurabh JainNo ratings yet

- Hot Rolled Coils Plates & SheetsDocument40 pagesHot Rolled Coils Plates & Sheetssreekanth6959646No ratings yet

- Indian Traditional Musical InstrumentsDocument3 pagesIndian Traditional Musical InstrumentsPiriya94No ratings yet

- Reservoir Bag Physics J PhilipDocument44 pagesReservoir Bag Physics J PhilipJashim JumliNo ratings yet

- Exploded Views and Parts List: 6-1 Indoor UnitDocument11 pagesExploded Views and Parts List: 6-1 Indoor UnitandreiionNo ratings yet

- Haymne Uka@yahoo - Co.ukDocument1 pageHaymne Uka@yahoo - Co.ukhaymne ukaNo ratings yet

- Ezpdf Reader 1 9 8 1Document1 pageEzpdf Reader 1 9 8 1AnthonyNo ratings yet

- Geopolitica y Medio Ambiente - Tarea 4 - Evaluacion FinalDocument7 pagesGeopolitica y Medio Ambiente - Tarea 4 - Evaluacion FinalKATERINENo ratings yet

- Capital Structure and Leverage: Multiple Choice: ConceptualDocument53 pagesCapital Structure and Leverage: Multiple Choice: ConceptualArya StarkNo ratings yet

- Lit 30Document2 pagesLit 30ReemAlashhab81No ratings yet

- Bahan Ajar Application LetterDocument14 pagesBahan Ajar Application LetterNevada Setya BudiNo ratings yet

- 8. Nguyễn Tất Thành- Kon TumDocument17 pages8. Nguyễn Tất Thành- Kon TumK60 TRẦN MINH QUANGNo ratings yet

- Cad32gd - Contactor ManualDocument28 pagesCad32gd - Contactor Manualhassan karimiNo ratings yet

- Chapter 5 - Amino acids and Proteins: Trần Thị Minh ĐứcDocument59 pagesChapter 5 - Amino acids and Proteins: Trần Thị Minh ĐứcNguyễn SunNo ratings yet

- Balinghasay V CastilloDocument1 pageBalinghasay V CastilloMirella100% (3)

- Brachiocephalic Artery: AnteriorDocument37 pagesBrachiocephalic Artery: AnteriorFarah FarahNo ratings yet

- 506 Koch-Glitsch PDFDocument11 pages506 Koch-Glitsch PDFNoman Abu-FarhaNo ratings yet

- Development of A Small Solar Thermal PowDocument10 pagesDevelopment of A Small Solar Thermal Powעקיבא אסNo ratings yet

- Catalogo HydronixDocument68 pagesCatalogo HydronixNANCHO77No ratings yet

- AYUSH Warli Art 100628Document10 pagesAYUSH Warli Art 100628adivasi yuva shakti0% (1)

- Cs205-E S3dec18 KtuwebDocument2 pagesCs205-E S3dec18 KtuwebVighnesh MuralyNo ratings yet

- The Function and Importance of TransitionsDocument4 pagesThe Function and Importance of TransitionsMarc Jalen ReladorNo ratings yet

- NIFT GAT Sample Test Paper 1Document13 pagesNIFT GAT Sample Test Paper 1goelNo ratings yet

- A Short History of Denim: (C) Lynn Downey, Levi Strauss & Co. HistorianDocument11 pagesA Short History of Denim: (C) Lynn Downey, Levi Strauss & Co. HistorianBoier Sesh PataNo ratings yet

- Sco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Document4 pagesSco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Udaya PrathimaNo ratings yet